Interior looks great, Donovan, very clean. Are you running a TH700R4 or TH200R4?

BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Interior looks great, Donovan, very clean. Are you running a TH700R4 or TH200R4?

Thanks Mike.

It’s an OZ code 200r4 from an ‘85 442. Rebuilt with a new D5 torque converter and a TransGo stage II shift kit.

I got the 4 spd shifter from fellow member Anubis. It took a bit more effort to find the proper 4 spd console top plate, but I eventually got it from one of the members here too.

That 442 also donated its cross member and driveshaft to the cause as well.

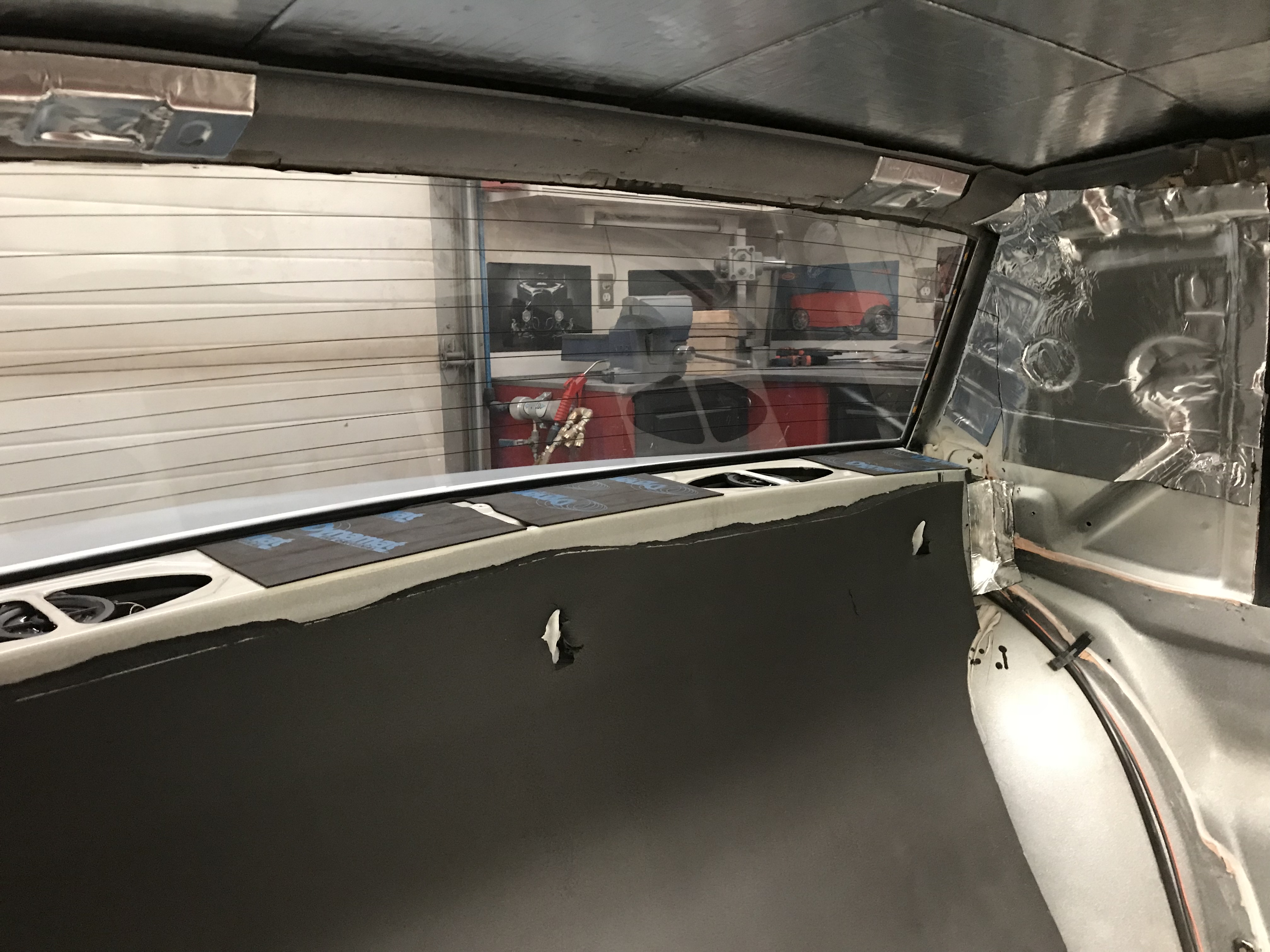

Did a thing today with some stuff.

Now I need to get some more stuff to finish the thing.

😁

D.

Now I need to get some more stuff to finish the thing.

😁

D.

You're just a guy, doing a thing.

Did you knock on the roof panel after the install? It sounds like wood.

Looking good.

Looking good.

You're just a guy, doing a thing.

Indeed I am Jared. With some stuff.

Mustn’t forget the stuff.

😅

Did you knock on the roof panel after the install? It sounds like wood.

Looking good.

I sure did Mike, it deadened it down pretty good.

I picked that stuff up over a year ago now to firm up the roof after I had to do such drastic surgery to it. I’ve noticed driving around without the AstroRoof in it I sometimes get a wicked harmonic vibration at the leading edge of the opening, likely from the lack of support.

I think this should help with that in the meantime and keep things tight and quiet when the AstroRoof finally goes back in it.

A little more progress...nice!

Yep, a little more everyday Kevin!

As long as I keep moving forward I don’t mind. It’s when everything backfires and sets me 3 steps back constantly that I get frustrated.

Tomorrow I’m going to try water testing all the glass again to see if things are sealed up for good this time. If that goes well, the reinstallation of the rear interior won’t be far behind.

🤞🏻

Well, it’s been a pretty busy and productive couple of days on the car since the last update.

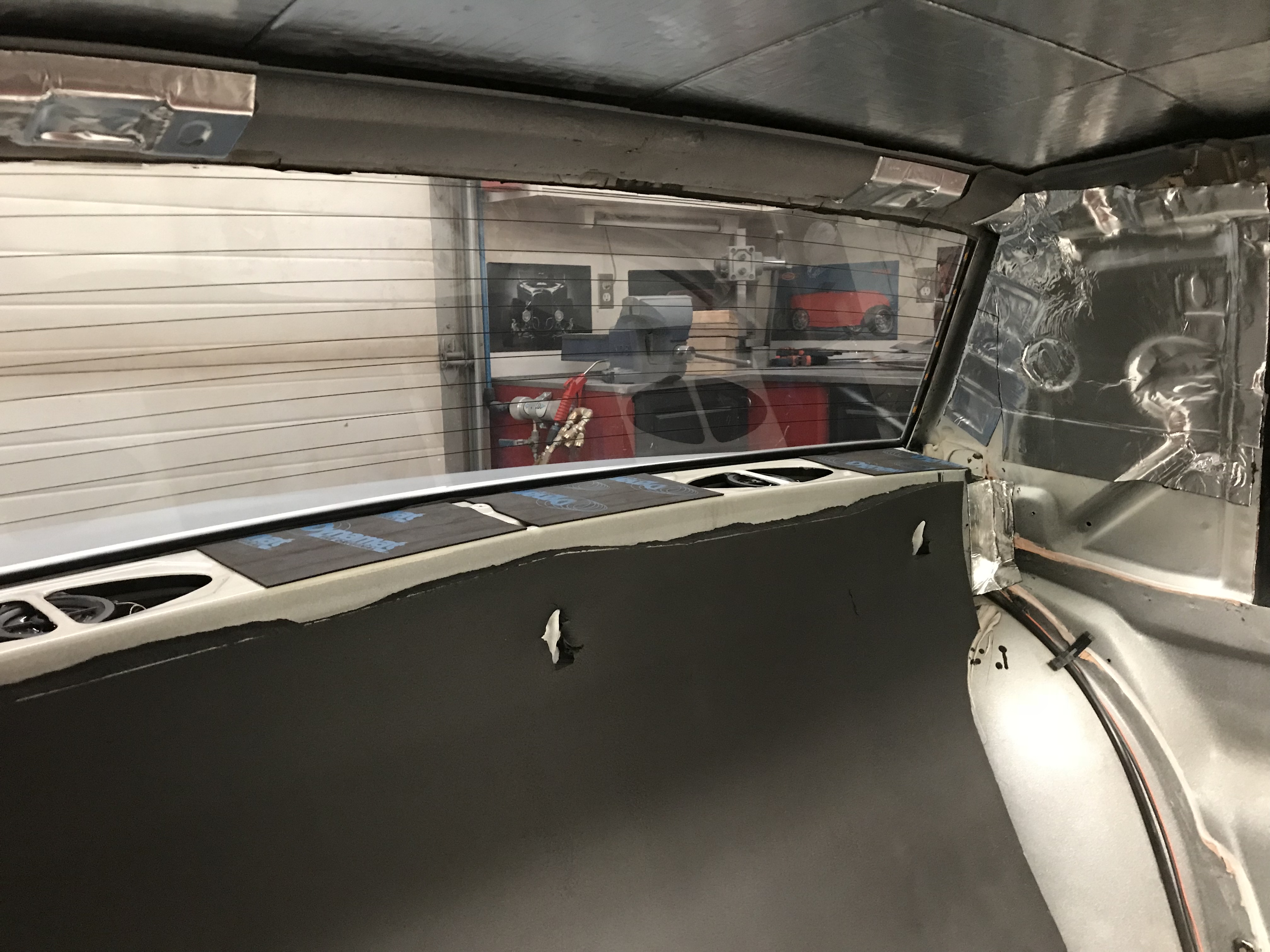

After using up the last of the sound deadener on the roof and sail panels, the following day I headed out and picked up another package to finish off the rear part of the interior. While I was there, I priced out the foil tape made by the same manufacturer for sealing up the seams in the deadener. The speed shop wanted $40 for a 1 1/2” x 30’ roll of it!

Now I may be slightly crazy, but I ain’t stupid. I politely declined and put it back on the shelf. Instead, afterwards I headed to the local hardware supply and picked up 2 rolls of nearly the same thing for less than half the price.

Sealing up the seams is really an unnecessary step, but it’s not hard to do and it really finishes off the job nicely in my opinion. Likewise, covering 100% of the surface area with the sound deadener isn’t necessary either, but hey, that’s what I bought it for, so I figured I might as well use it all up.

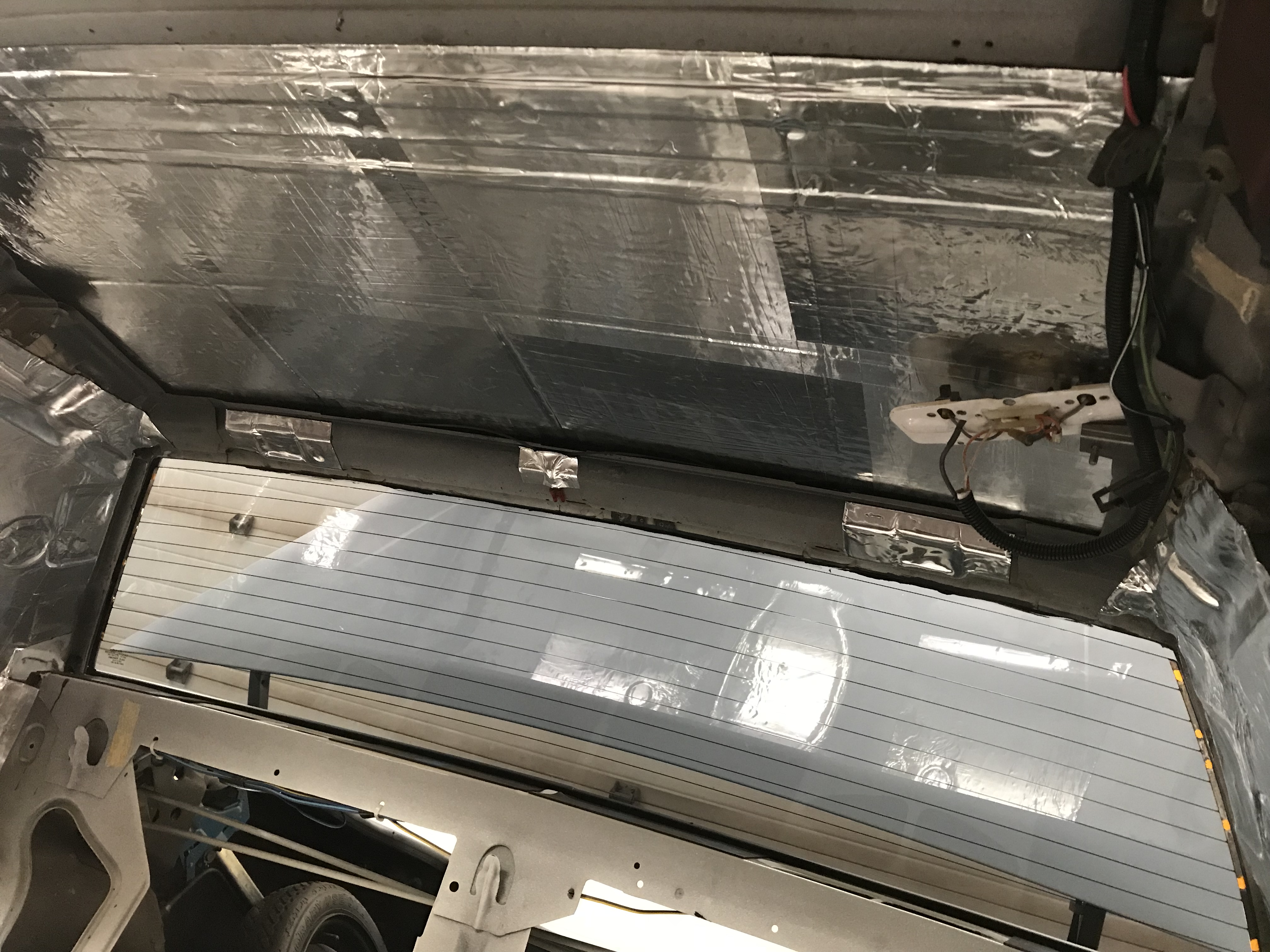

Several hours and an evening later, I had the rest of the sail panels covered along with all around the seatbelt boxes. I also did the front of the rear wheelwells, inside the backseat wells, over the transmission hump and covered over the holes in the roof structure above the door glass.

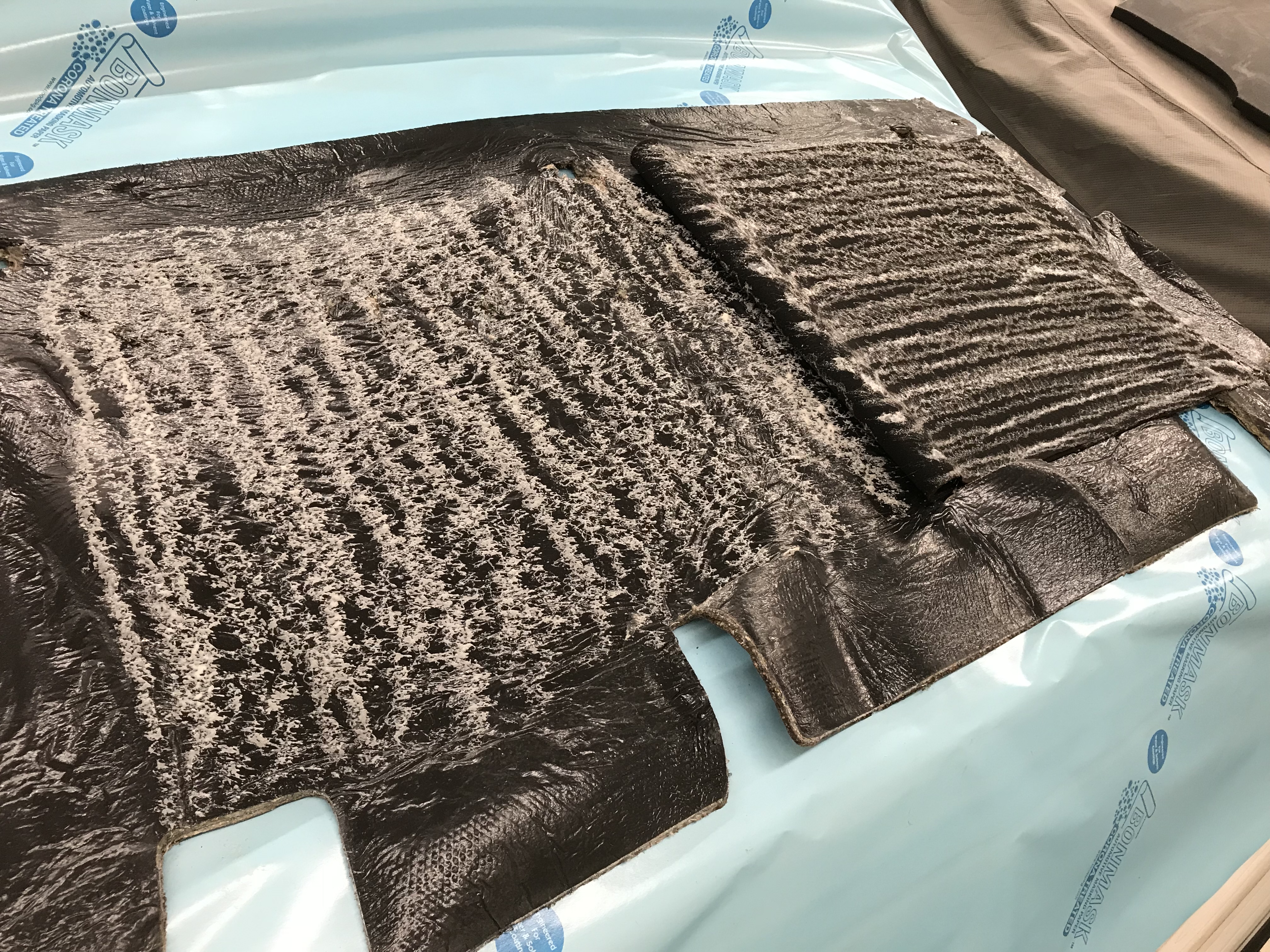

Here’s the finished product, nearly 20 square feet of sound deadener here, and all the seams taped up:

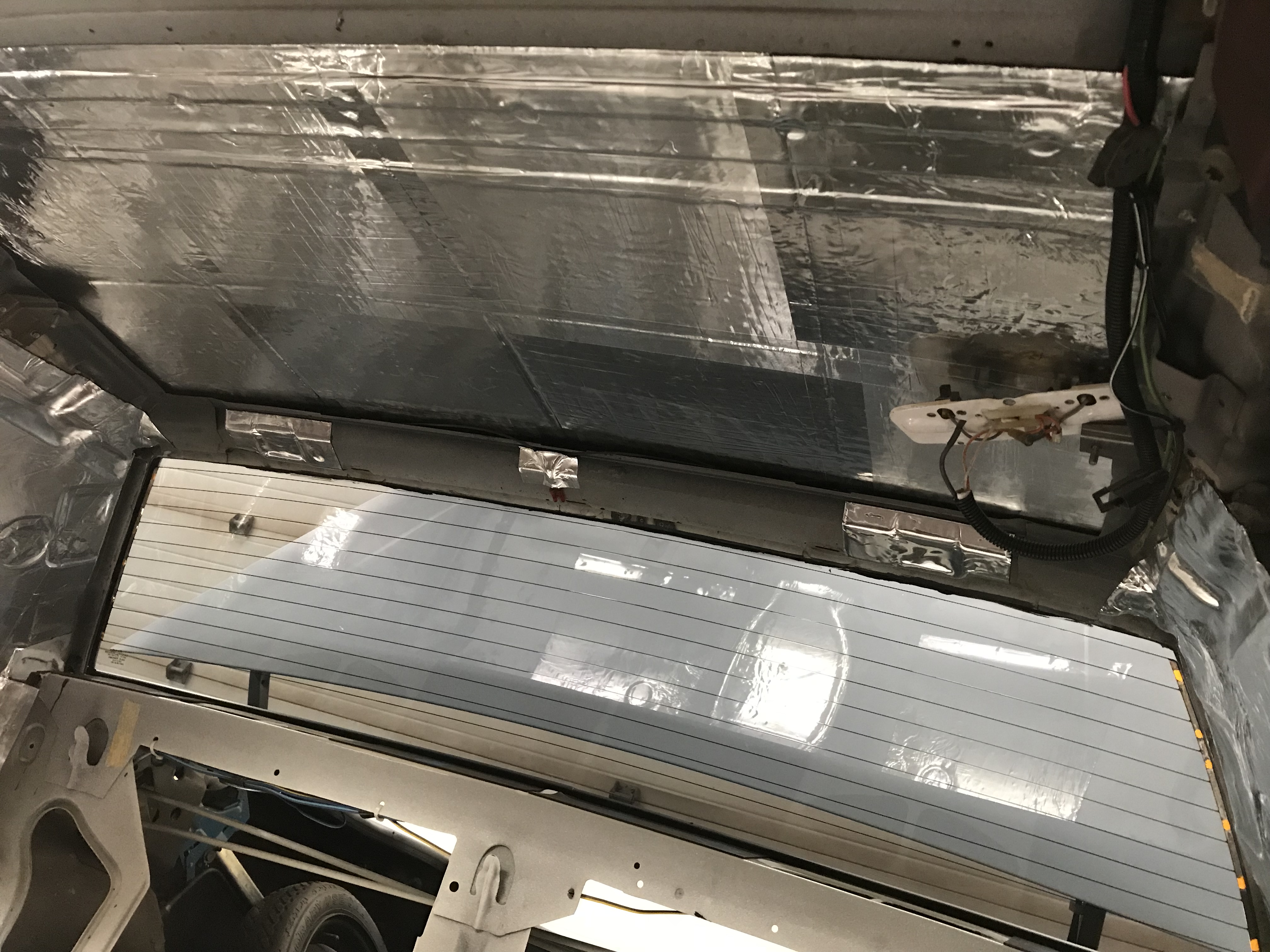

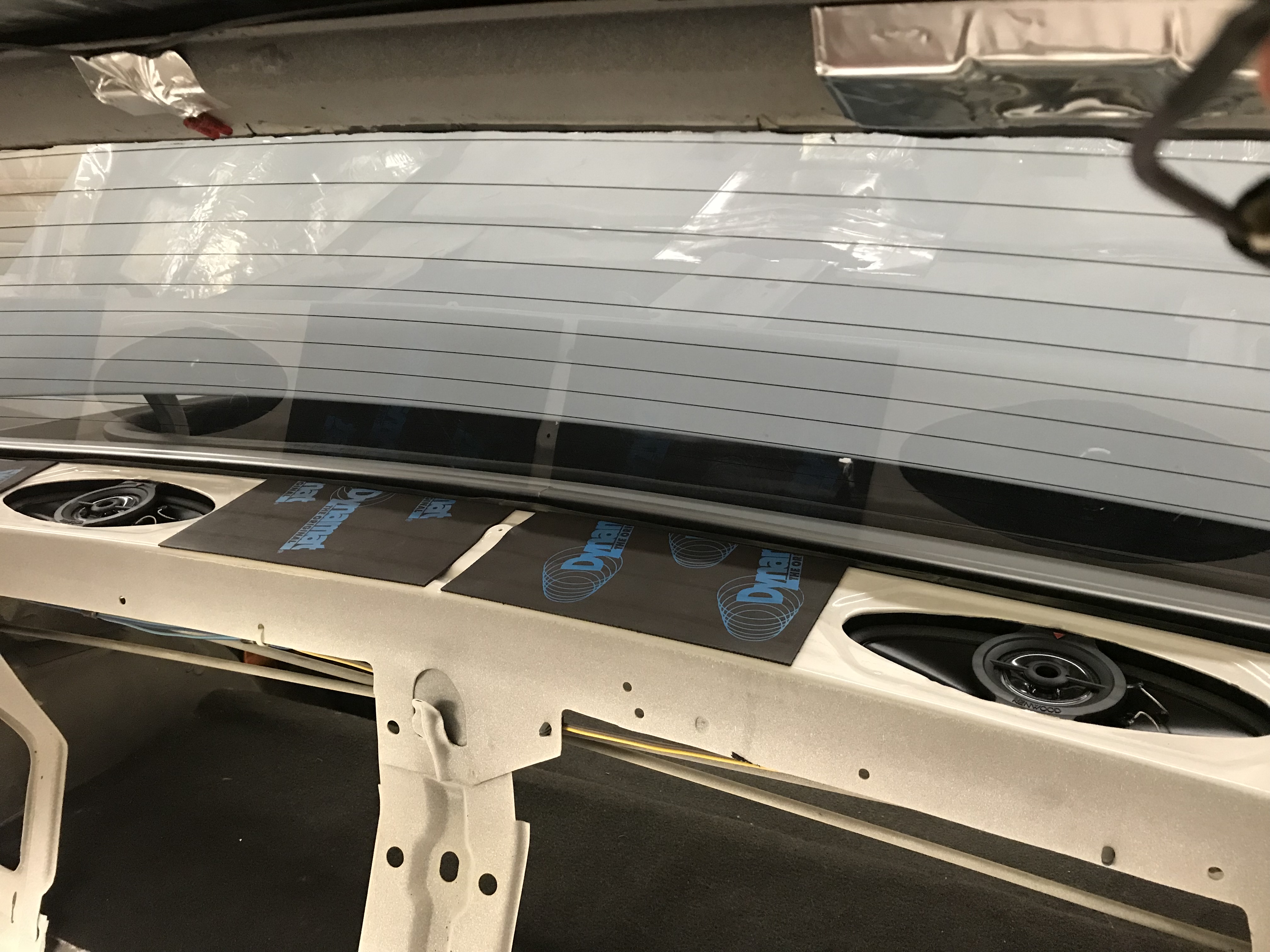

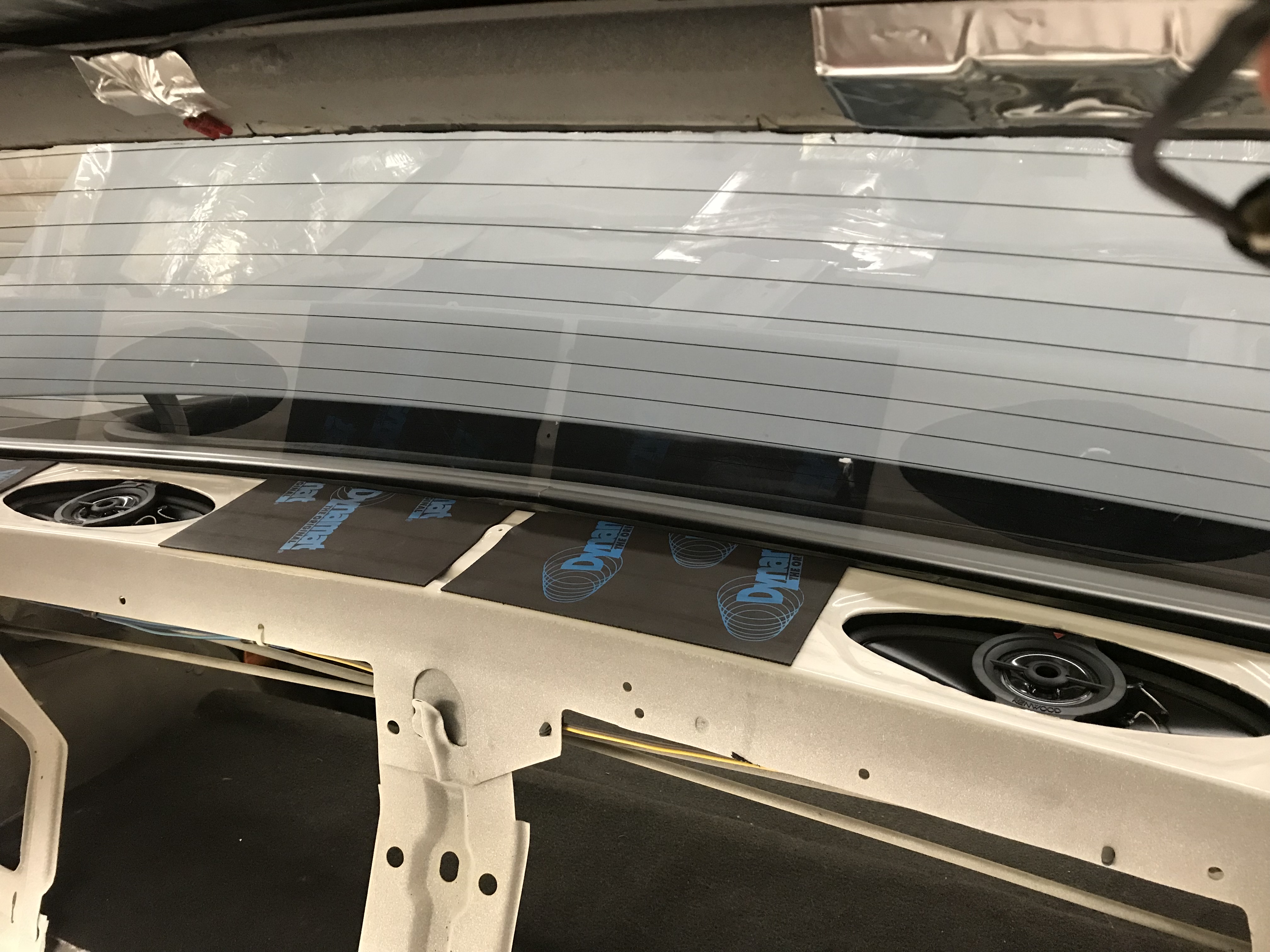

I had mentioned earlier that the center supports in the rear speaker openings were interfering slightly with the integral tweeters, so next it was time to address that.

After removing the speakers and setting them aside, I used my air powered body saw to carefully cut the supports out then I dressed up the edges.

Before:

After:

With that done, I wanted to get the car somewhat put back together to be able to attend the weekly Friday night cruise at a local burger joint. I reinstalled the factory sound deadening mat that hangs behind the seat back, along with the package tray cover and the seat cushions.

Being that this was the first drive with the rear now all sound deadened and sealed up, I can tell you the difference before and after was astonishing. Gone now were all the squeaks, rattles and road noise. The new speakers now sounded simply amazing too, considering they’re only powered by a factory stereo! Also gone was the weird and obnoxious harmonic roof vibration I would get under certain speeds and wind conditions.

Overall, I’m extremely impressed and happy with the difference installing the sound deadening made. I’d do it again in a heartbeat, and plan on adding it to the insides of the doors too when the time comes.

In other news, enough time had finally passed to where I could water test the glass in the car again. Not much good news here however. While the quarter windows were now sealed up, the front windshield and back window still leaked a bit. Not as bad as previously, but still some nonetheless.

As the old saying goes, “if you want something done right, ya gotta do it yourself”. And so it was.

Thankfully the glass guy gave me a partial tube of urethane for any persistent problem areas after I had taken it to them to get fixed. Using this little bit he gave me, I applied some in the areas that appeared to still be leaking, and that he had missed. I’m 99% confident now that I’ve got everything sealed up, but I’ll be watching inside like a hawk the next time I wash the car.

Ok, now onto yesterday and today’s happenings.

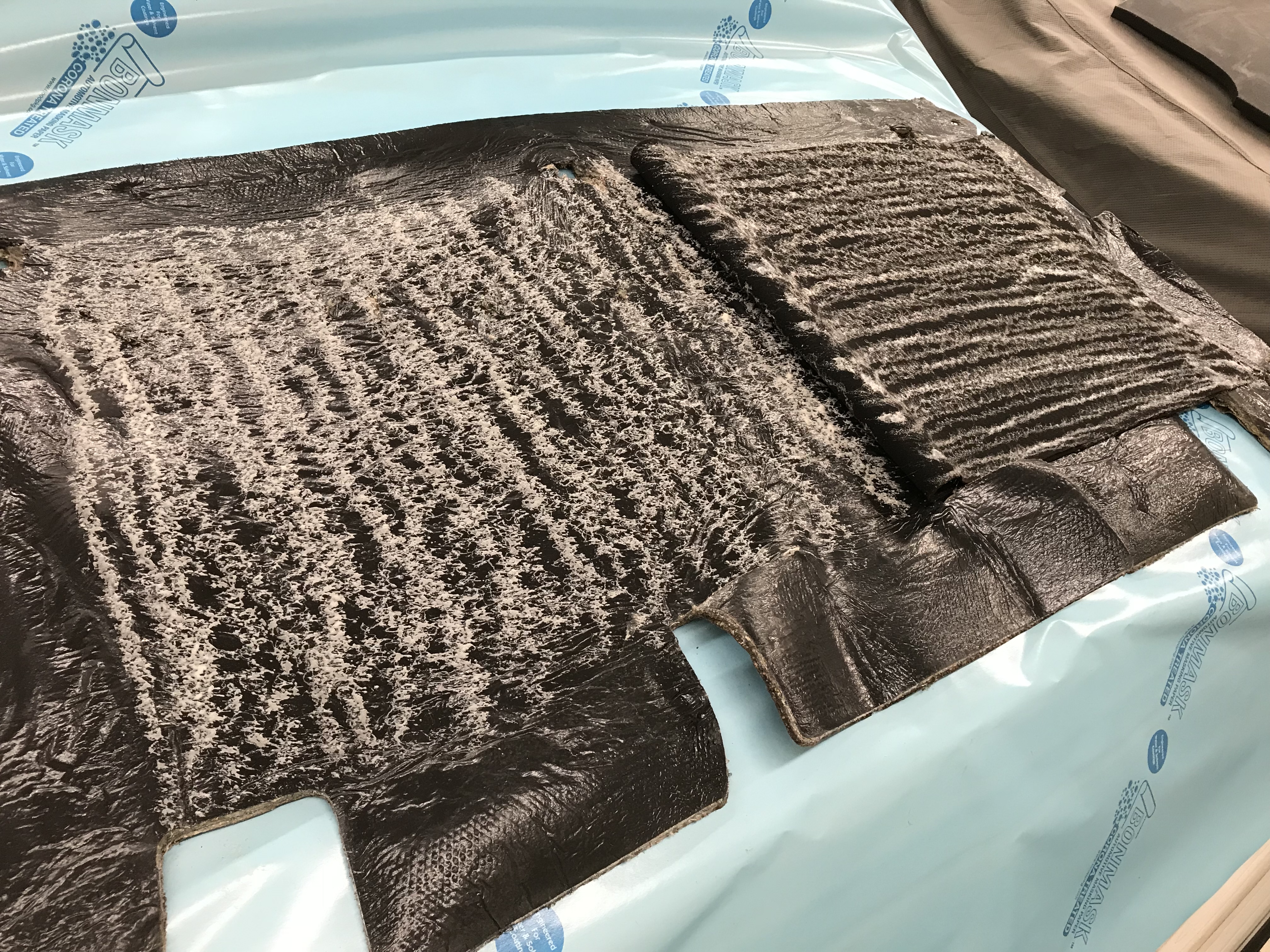

Yesterday, I was on a bit of a mission to find a solution to something that’s bothered me since I got the inside of the trunk finished. The factory sound deadening mat that hangs behind the seat back I mentioned earlier also provides a finished look from inside the trunk. Problem is, it’s made of a thin flimsy plastic foil type stuff similar to a garbage bag but much thinner.

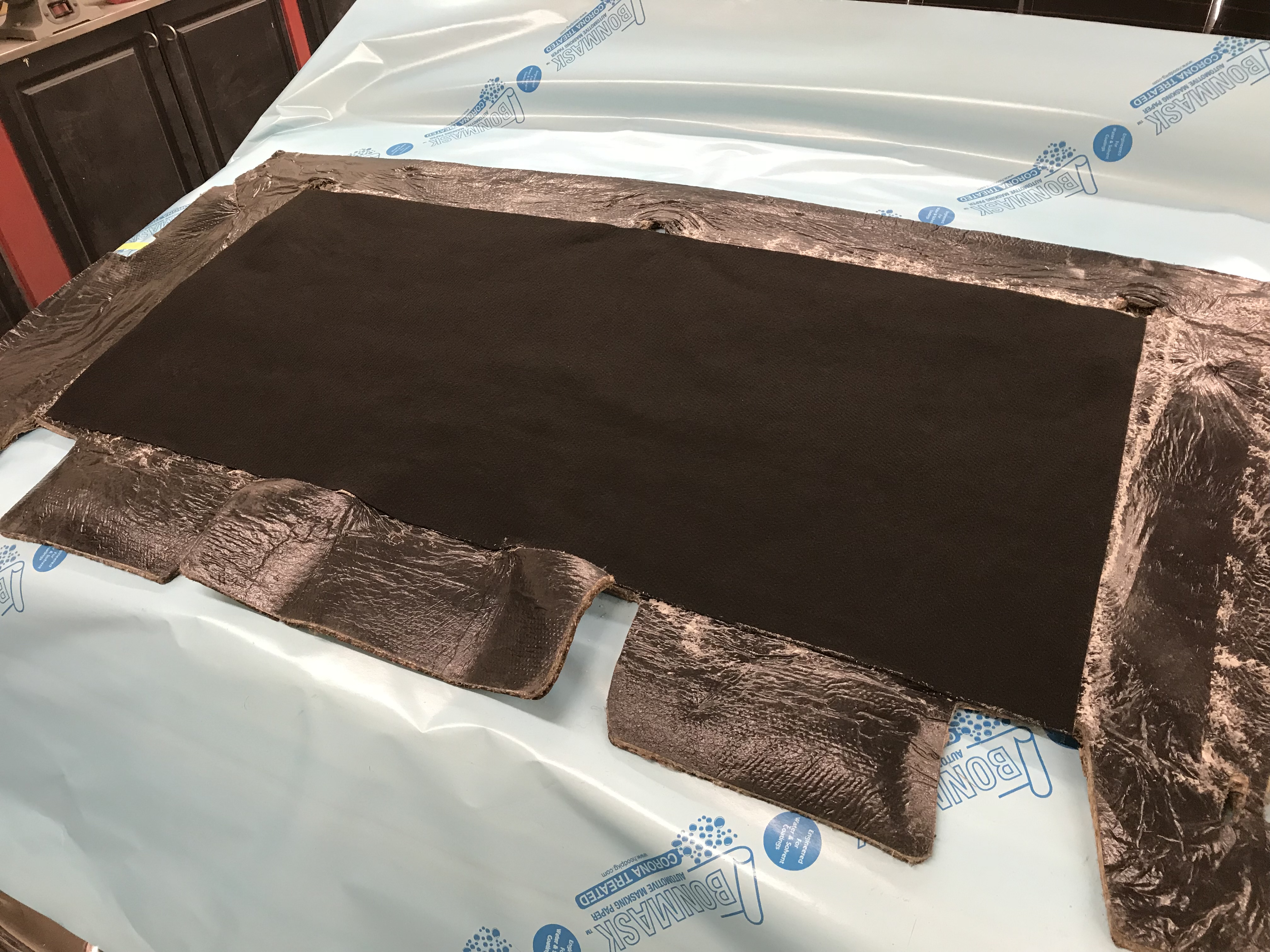

Over the years and due to people carelessly throwing stuff in the trunk, this plastic foil had gotten torn in several places and looked terrible. Here’s what I’m talking about:

After much thought, I decided upon what might be the best solution. I located some fabric at a local store that matched the stock trunk mat near identically. I picked up a meter and a half of it ( a little over 5 1/2 feet for you Imperial guys) for less than 8 bucks. I already had some high strength spray adhesive at home, so I was all set to begin.

This is the spray adhesive I was going to use:

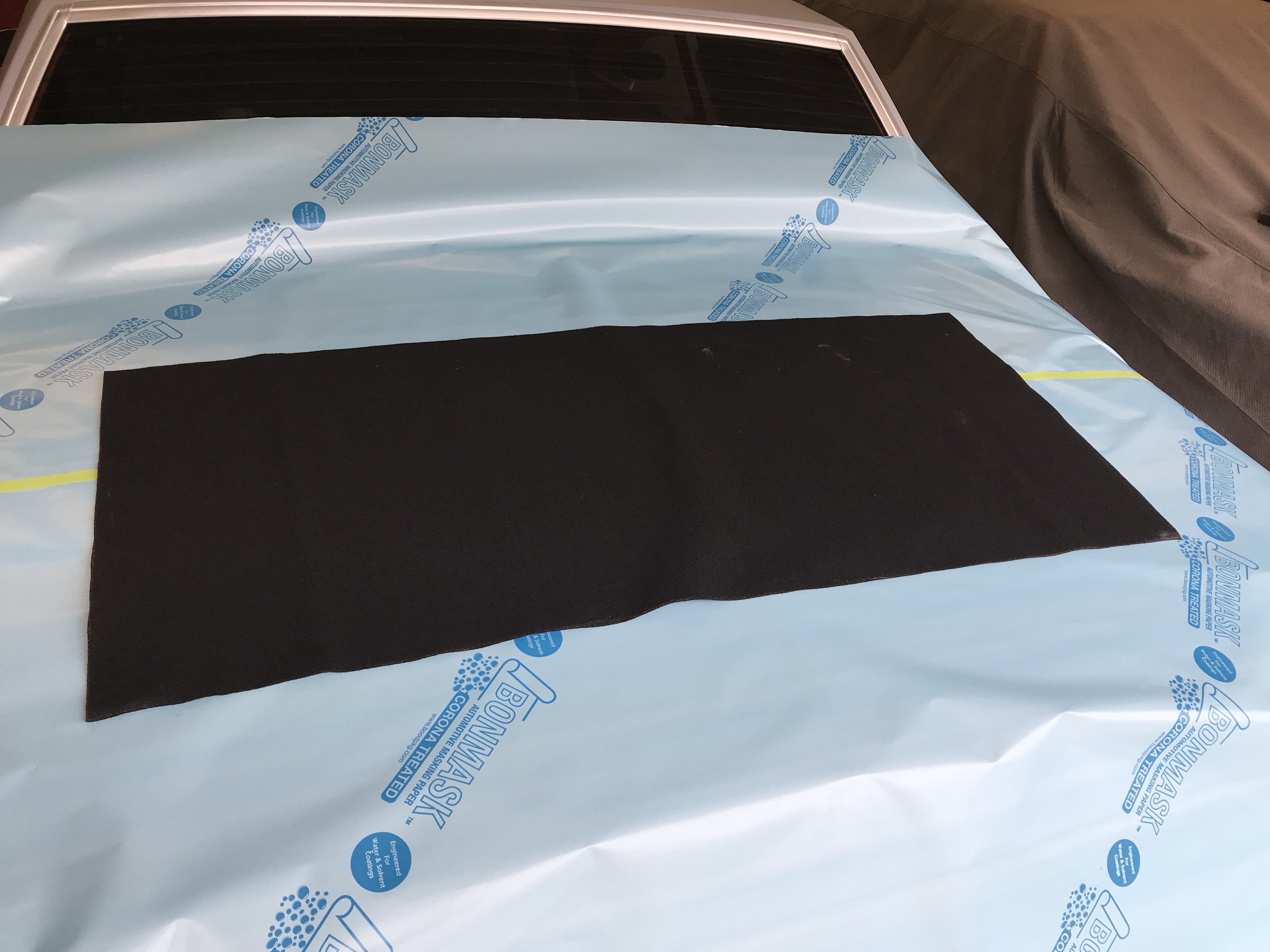

First, I masked off the outside of the trunk lid to give myself a large, flat clean area to work on. Then I laid out the new fabric:

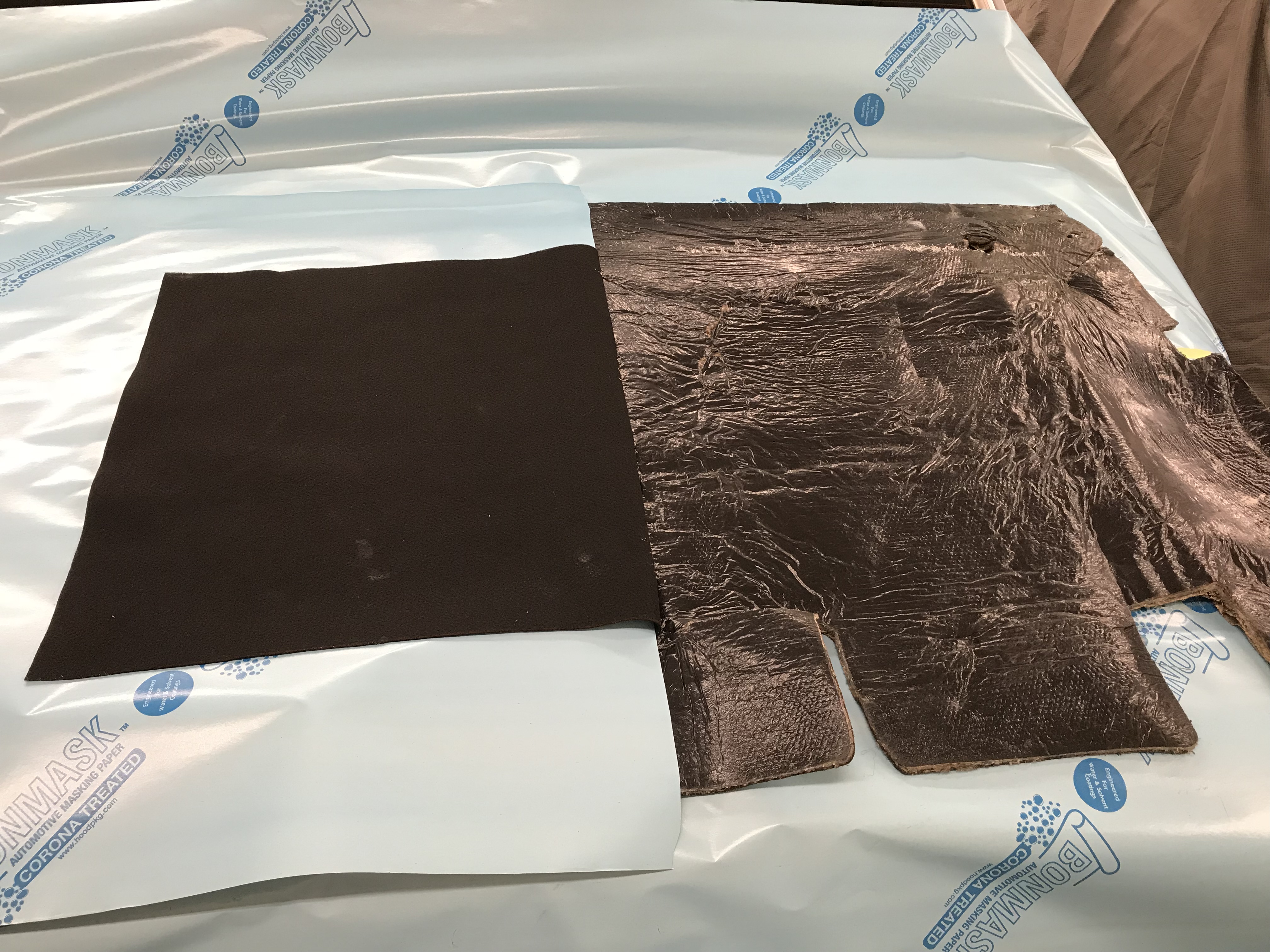

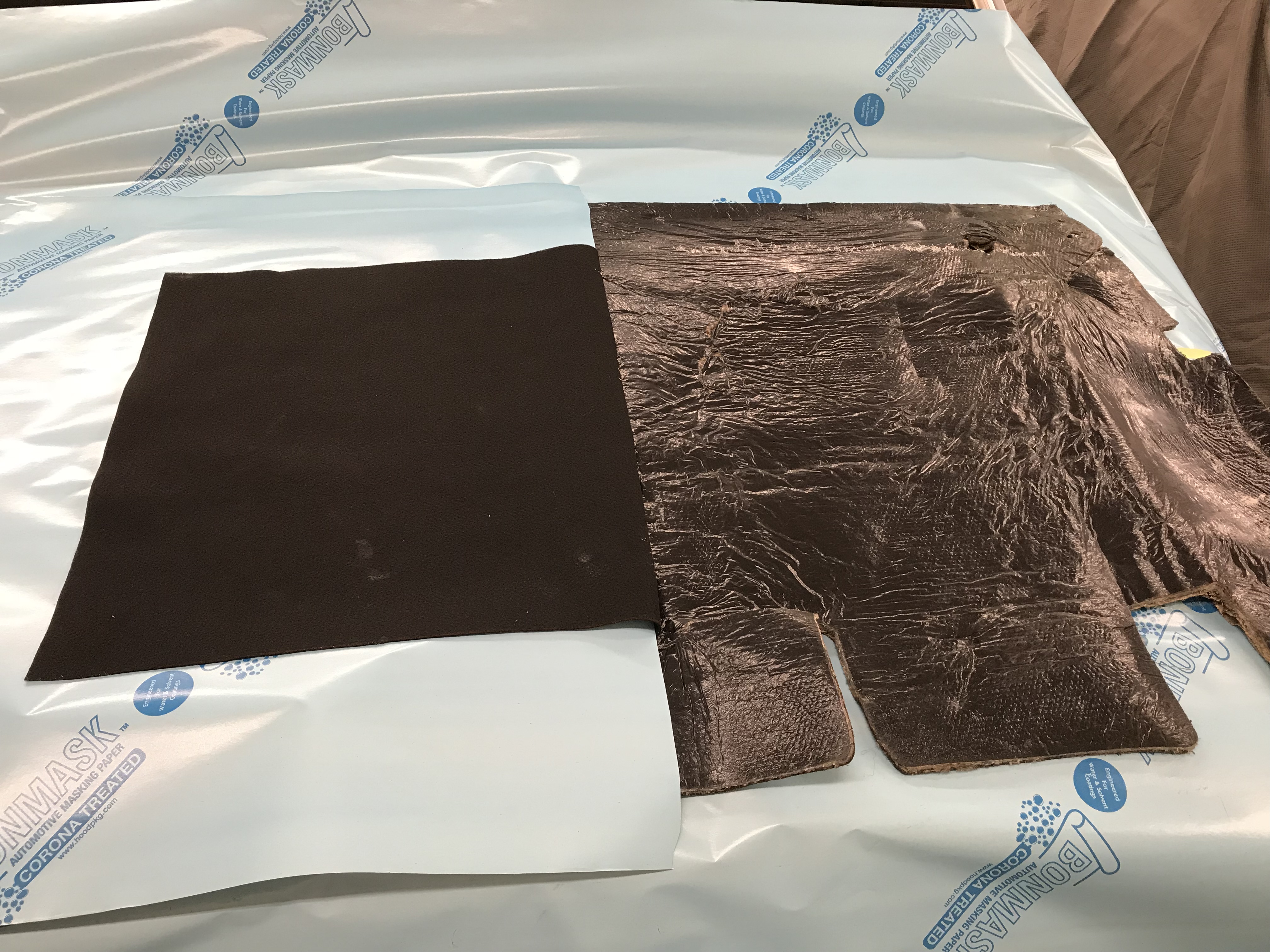

After removing the sound deadening mat from the car, I laid it over the fabric and made some reference marks on the fabric to get it cut down to size:

Once I had my marks made, I removed the mat and marked out the cut lines with a grease pencil:

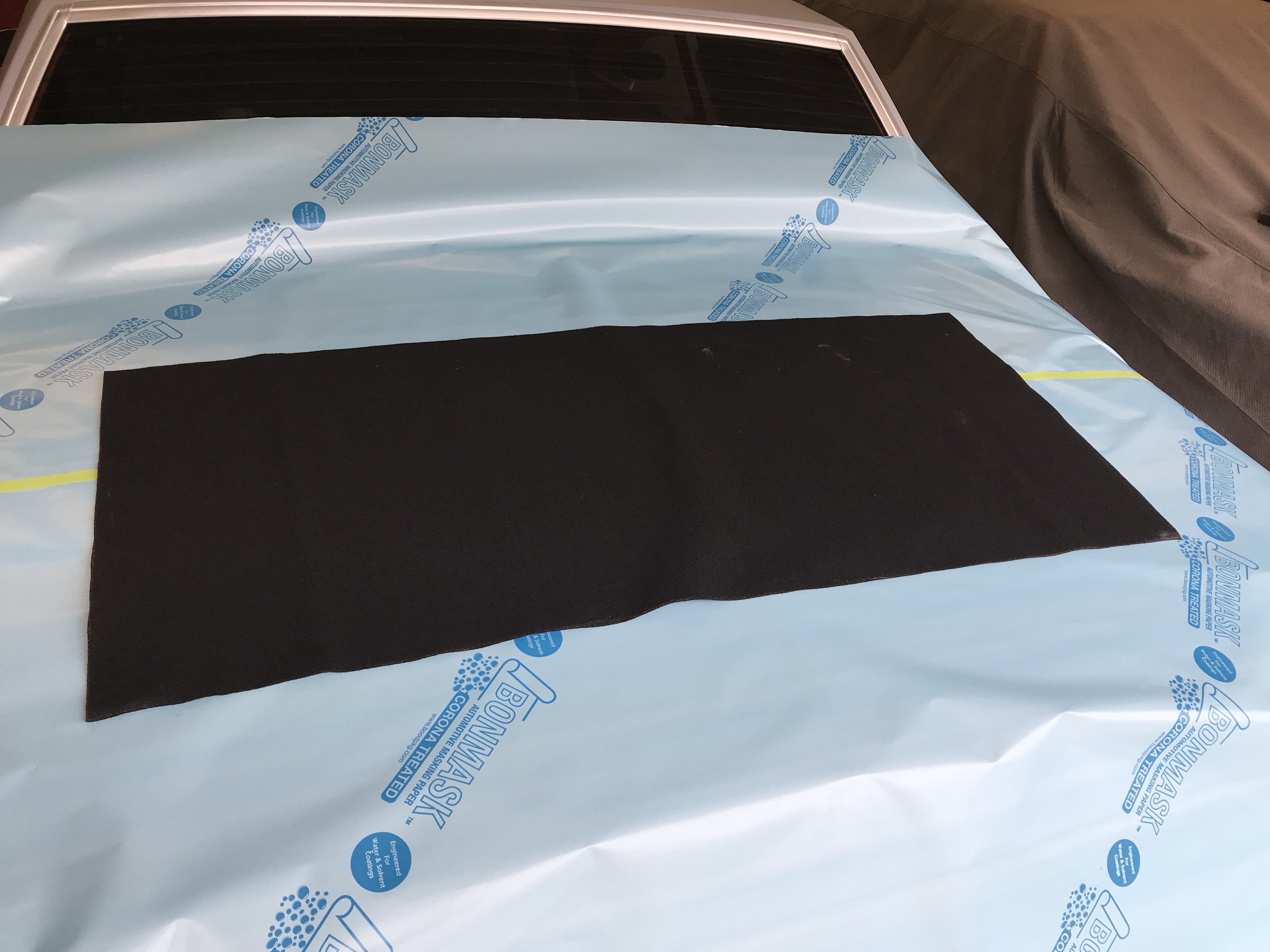

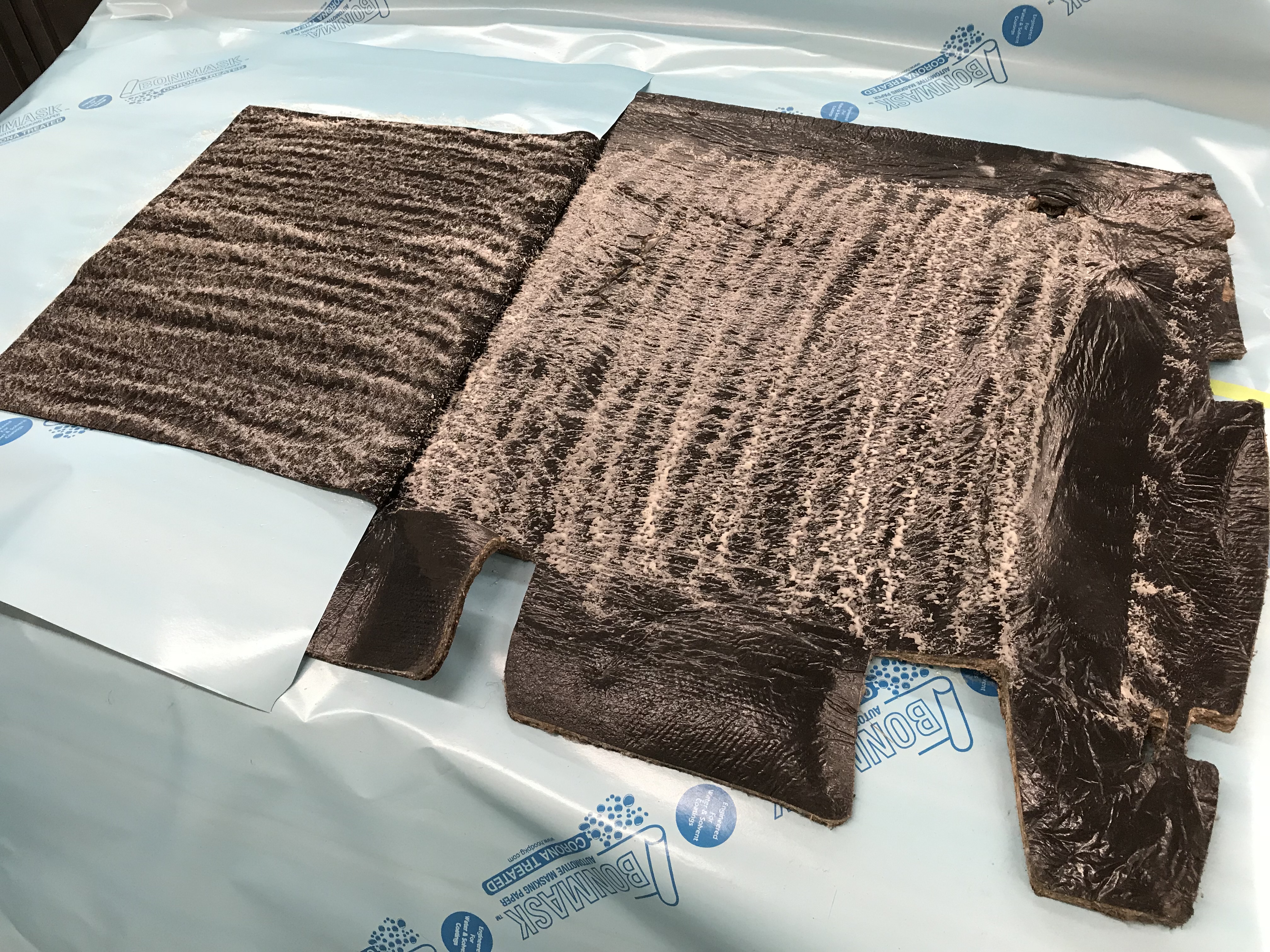

Next was to make the cuts. Here’s the final size it’s going to be:

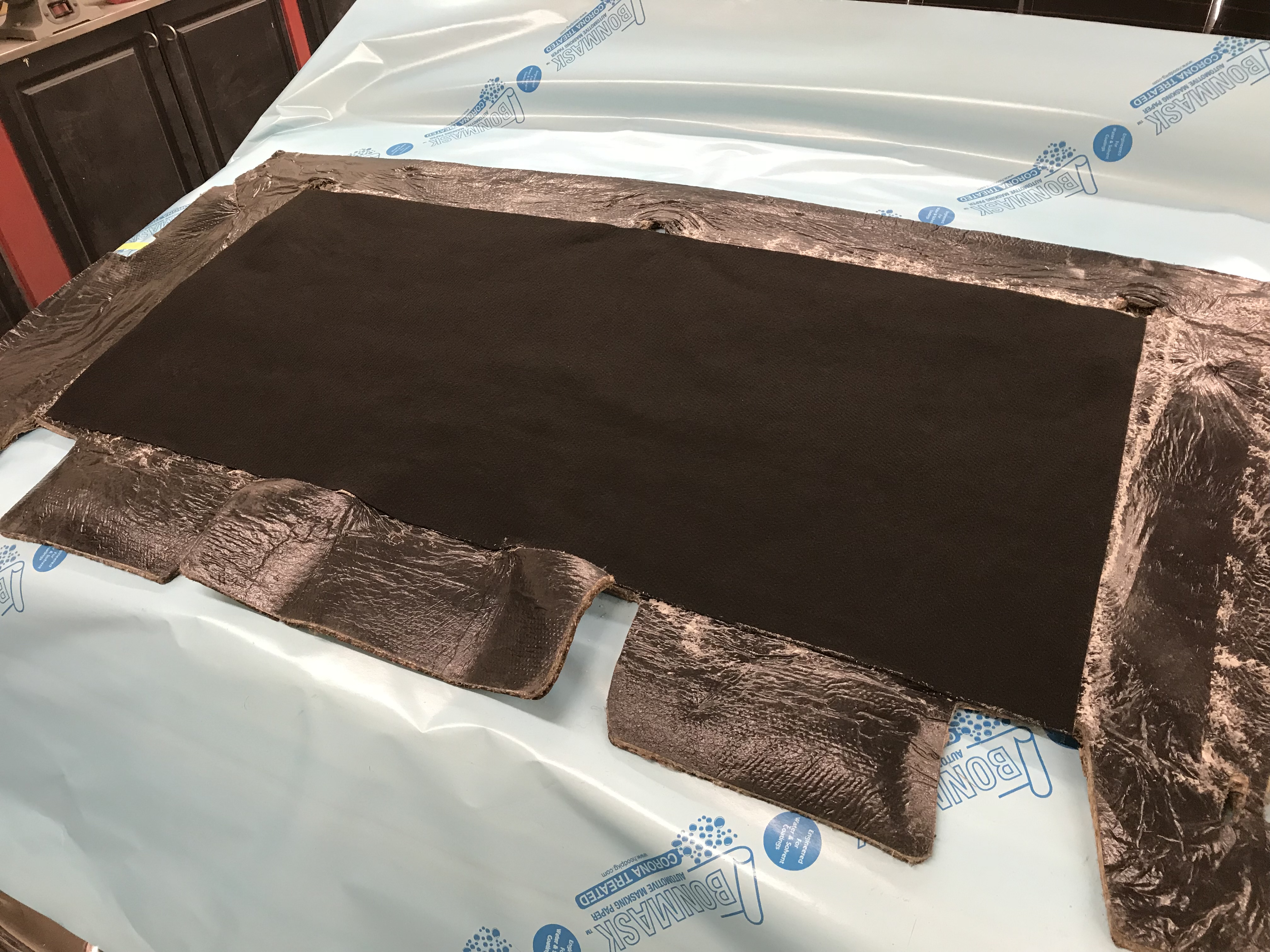

Now it was time to move the fabric off to the side temporarily and lay down the mat:

After cleaning the mat and carefully centering the fabric on it where it needed to be...

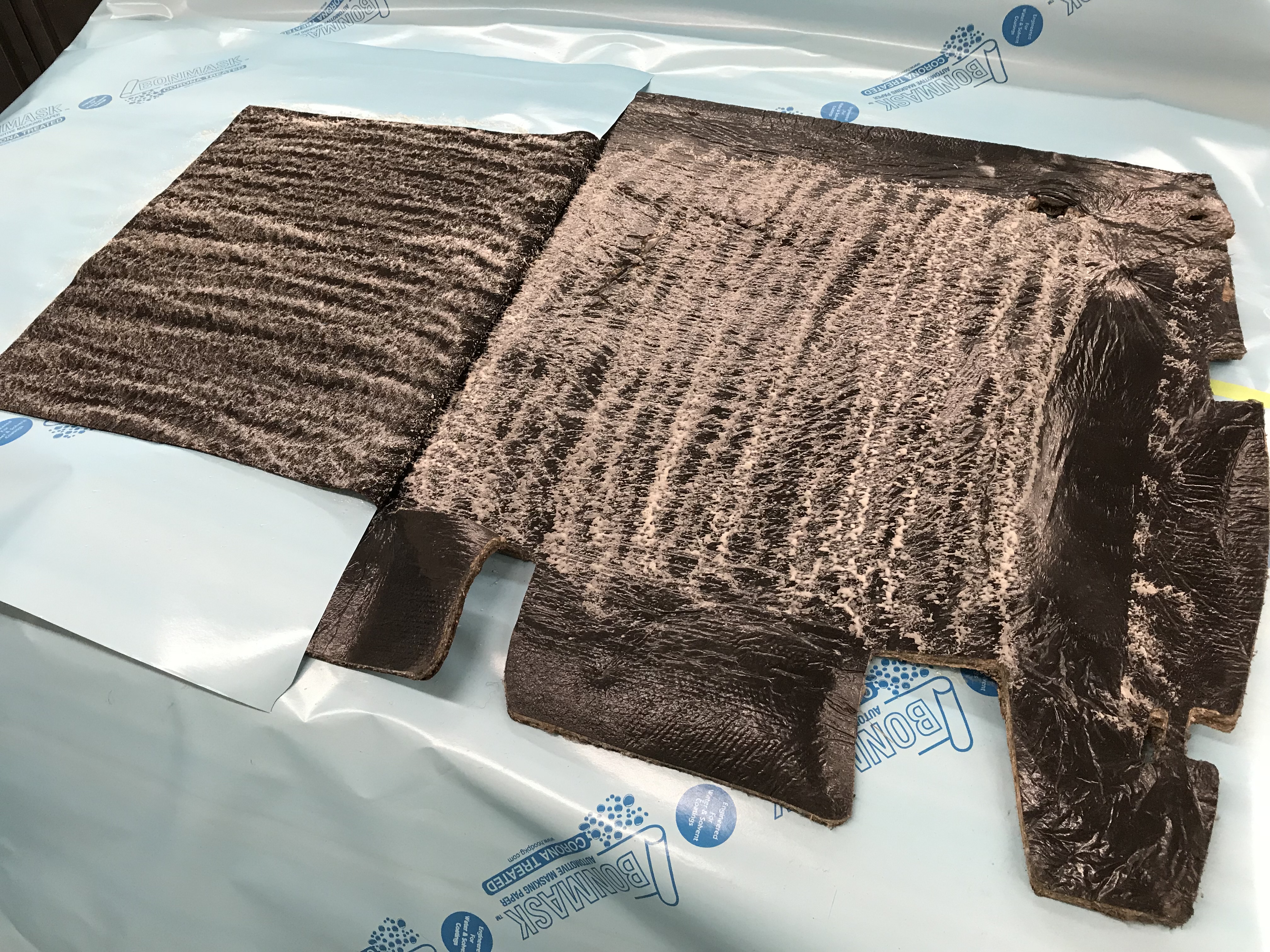

...I folded one side of the fabric over on itself and applied the spray glue. In accordance with the glue instructions to achieve to strongest possible bond, I applied the glue on each side in opposite directions to each other:

Once that was done, I carefully folded the glued side over, attached it to the mat, and smoothed it out. Next I laid a large piece of masking paper over the finished glued section and folded the other half over:

The same “opposite direction gluing” procedure was done on the other half:

Again, I repeated the process and adhered the second half to the mat. After it had some time to cure, this is how it looked:

Pretty simple. Now time for installation! Here’s the finished product, it matches the stock trunk mat almost perfectly. Much better than the old unsightly ripped view before, and all for less than 8 bucks and a couple hours of my time.

😁

I think that’s more than enough for now, thanks for checking in on the progress now that there’s finally some worthy of relaying!

Till the next update guys,

D.

After using up the last of the sound deadener on the roof and sail panels, the following day I headed out and picked up another package to finish off the rear part of the interior. While I was there, I priced out the foil tape made by the same manufacturer for sealing up the seams in the deadener. The speed shop wanted $40 for a 1 1/2” x 30’ roll of it!

Now I may be slightly crazy, but I ain’t stupid. I politely declined and put it back on the shelf. Instead, afterwards I headed to the local hardware supply and picked up 2 rolls of nearly the same thing for less than half the price.

Sealing up the seams is really an unnecessary step, but it’s not hard to do and it really finishes off the job nicely in my opinion. Likewise, covering 100% of the surface area with the sound deadener isn’t necessary either, but hey, that’s what I bought it for, so I figured I might as well use it all up.

Several hours and an evening later, I had the rest of the sail panels covered along with all around the seatbelt boxes. I also did the front of the rear wheelwells, inside the backseat wells, over the transmission hump and covered over the holes in the roof structure above the door glass.

Here’s the finished product, nearly 20 square feet of sound deadener here, and all the seams taped up:

I had mentioned earlier that the center supports in the rear speaker openings were interfering slightly with the integral tweeters, so next it was time to address that.

After removing the speakers and setting them aside, I used my air powered body saw to carefully cut the supports out then I dressed up the edges.

Before:

After:

With that done, I wanted to get the car somewhat put back together to be able to attend the weekly Friday night cruise at a local burger joint. I reinstalled the factory sound deadening mat that hangs behind the seat back, along with the package tray cover and the seat cushions.

Being that this was the first drive with the rear now all sound deadened and sealed up, I can tell you the difference before and after was astonishing. Gone now were all the squeaks, rattles and road noise. The new speakers now sounded simply amazing too, considering they’re only powered by a factory stereo! Also gone was the weird and obnoxious harmonic roof vibration I would get under certain speeds and wind conditions.

Overall, I’m extremely impressed and happy with the difference installing the sound deadening made. I’d do it again in a heartbeat, and plan on adding it to the insides of the doors too when the time comes.

In other news, enough time had finally passed to where I could water test the glass in the car again. Not much good news here however. While the quarter windows were now sealed up, the front windshield and back window still leaked a bit. Not as bad as previously, but still some nonetheless.

As the old saying goes, “if you want something done right, ya gotta do it yourself”. And so it was.

Thankfully the glass guy gave me a partial tube of urethane for any persistent problem areas after I had taken it to them to get fixed. Using this little bit he gave me, I applied some in the areas that appeared to still be leaking, and that he had missed. I’m 99% confident now that I’ve got everything sealed up, but I’ll be watching inside like a hawk the next time I wash the car.

Ok, now onto yesterday and today’s happenings.

Yesterday, I was on a bit of a mission to find a solution to something that’s bothered me since I got the inside of the trunk finished. The factory sound deadening mat that hangs behind the seat back I mentioned earlier also provides a finished look from inside the trunk. Problem is, it’s made of a thin flimsy plastic foil type stuff similar to a garbage bag but much thinner.

Over the years and due to people carelessly throwing stuff in the trunk, this plastic foil had gotten torn in several places and looked terrible. Here’s what I’m talking about:

After much thought, I decided upon what might be the best solution. I located some fabric at a local store that matched the stock trunk mat near identically. I picked up a meter and a half of it ( a little over 5 1/2 feet for you Imperial guys) for less than 8 bucks. I already had some high strength spray adhesive at home, so I was all set to begin.

This is the spray adhesive I was going to use:

First, I masked off the outside of the trunk lid to give myself a large, flat clean area to work on. Then I laid out the new fabric:

After removing the sound deadening mat from the car, I laid it over the fabric and made some reference marks on the fabric to get it cut down to size:

Once I had my marks made, I removed the mat and marked out the cut lines with a grease pencil:

Next was to make the cuts. Here’s the final size it’s going to be:

Now it was time to move the fabric off to the side temporarily and lay down the mat:

After cleaning the mat and carefully centering the fabric on it where it needed to be...

...I folded one side of the fabric over on itself and applied the spray glue. In accordance with the glue instructions to achieve to strongest possible bond, I applied the glue on each side in opposite directions to each other:

Once that was done, I carefully folded the glued side over, attached it to the mat, and smoothed it out. Next I laid a large piece of masking paper over the finished glued section and folded the other half over:

The same “opposite direction gluing” procedure was done on the other half:

Again, I repeated the process and adhered the second half to the mat. After it had some time to cure, this is how it looked:

Pretty simple. Now time for installation! Here’s the finished product, it matches the stock trunk mat almost perfectly. Much better than the old unsightly ripped view before, and all for less than 8 bucks and a couple hours of my time.

😁

I think that’s more than enough for now, thanks for checking in on the progress now that there’s finally some worthy of relaying!

Till the next update guys,

D.

Similar threads

- Replies

- 10

- Views

- 423

- Replies

- 310

- Views

- 16K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.