“Strike while the iron is hot” they say.

Whoever the hell “they” are, but ok.

So to that end I’m still rolling right along on this passenger fender, putting in a couple of hours each night.

With the antenna hole welded up, I gave the area a couple skims of filler and putty, then blocked them out nice and flat and smooth.

Finished with 120 grit, as per my usual:

I mentioned earlier that there was some damage to the lower rear from a previous owner. This is the area in question, it’s a bit tough to see due to it being white, but you can still kinda see some of it:

Earlier when I had the engine and inner fenderwell out to remove the antenna, I had taken one of my heavy flat dollies to the area and tried to gently coax out as much of the dent as I could. It was more or less successful, I got it to look better than it was at least. It spider webbed the paint a little bit, but at the time it was good enough for me to live with until I could fix it properly. Now is that time.

Moving forward, it was time to start removing trim so I could weld up the holes that wouldn’t be needed. I removed the large chrome trim pieces from the bottom of the fender, these won’t be going back on. I will keep the long thin chrome trim that covers the rocker panels, but that’s it. The larger pieces are just too big and gawdy for my liking, plus they’re perfect rust breeding grounds.

While I was at it and giving the entire panel a close going over, I found another crease I had not even realized was there. Again, it’s tough to see in the pic but it’s just above my fingernail. Great, yet another thing to fix:

With that done, it was time to strip the rest of the lower rear part of the fender down to bare metal. 80 grit on the DA and about an hour later accomplished this.

I also stripped the inner wheelwell flange, it was heavily rock chipped and had several holes in it from the wheelwell trim and the mud flaps that were on it when I got it.

Hole-y!!!

Time for the metal glue gun. I got the holes in the outer skin closed up, along with all the ones in the inner flange. The hole you see still left there needs to remain, it’s for mounting the front of the chrome rocker panel trim:

Now to address that damage. The deepest part of the dent oddly enough, was right next to the wheel opening. I marked off the area that needed working with a Sharpie, then broke out the stud gun and welded on a series of porcupine quills:

I coaxed out the area with the slide hammer on the studs, working my way from the deepest damage out to the shallowest. This actually required a second smaller row of studs to be added next to the first:

After a feel with my hand, I found a small bulge above and to the left. I gently worked it out with my body hammer, you can see the marks it left:

If anyone is going to attempt a repair like this, the thing to keep in mind is you’re not trying to “hammer” the bulge down. If you use a slapping motion with the hammer, you can persuade the metal to move from its highest point to its lowest, allowing you to even everything out. I’ve done this many times before in the past, and it’s very effective.

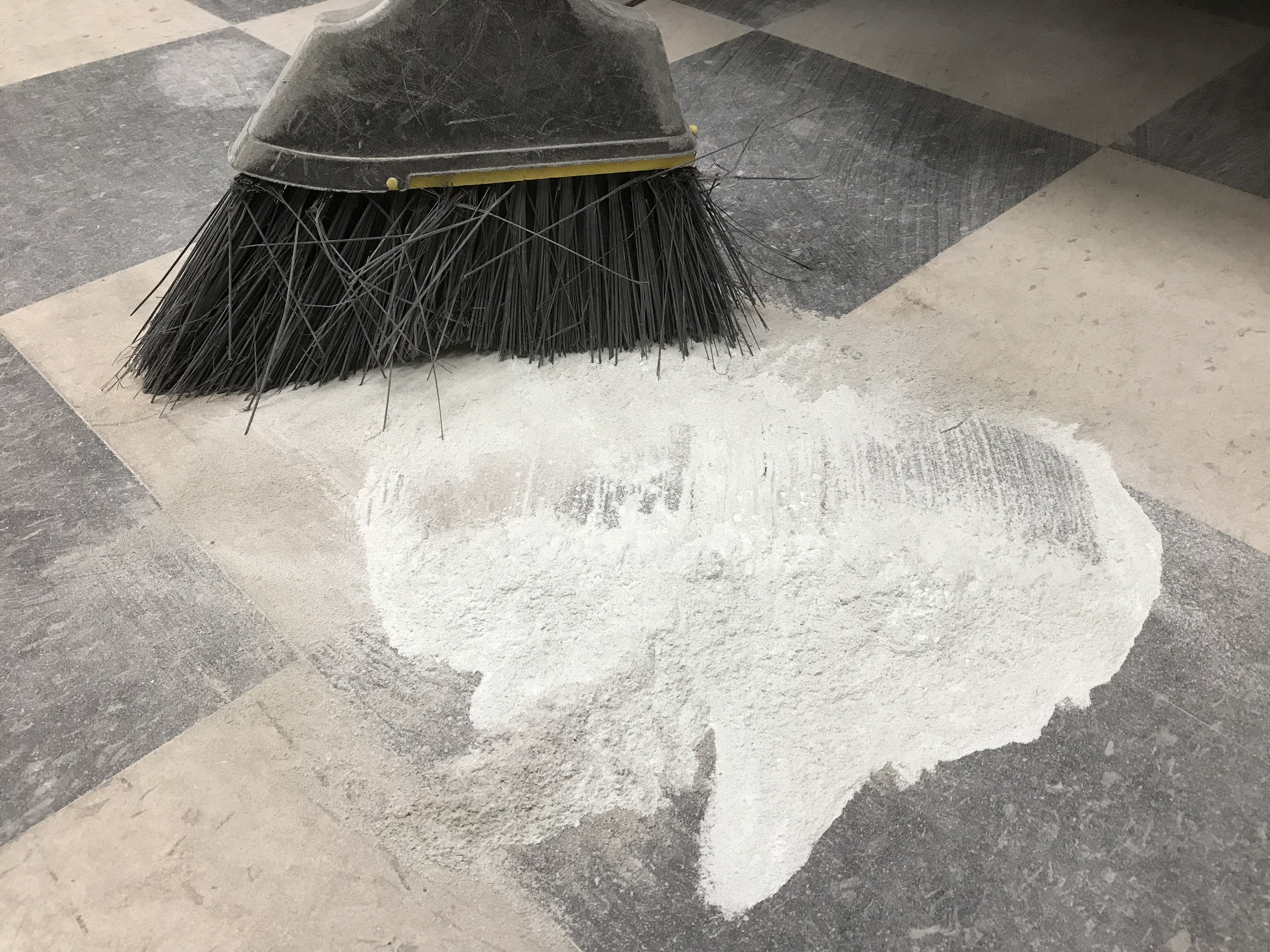

Once I was satisfied that the area was pulled back out and adequately repaired, the studs were removed and the repaired spot ground with 36 grit on the air angle grinder. A few light passes with a finer 40 grit disc got the entire lower part ready for a skim of filler:

That’s it for now guys, I’ll be getting back on it bright and early tomorrow morning (likely today for most of you that are reading this). There’s lots more than need to be done on it yet!

Thanks for following along.

D.