So not a whole lot to report on this week’s progress, just more of the 3 step program you’ve all now undoubtedly seen me do several times before.

Paint, primer, seam sealer and general crud removal, rust converting the deep pits and inaccessible areas, then sanding the converter and fresh epoxy.

Unfortunately I’m at the stage where the work to be done is just slow and time consuming. It sucks, but it is what it is. Just gotta keep plugging away at it.

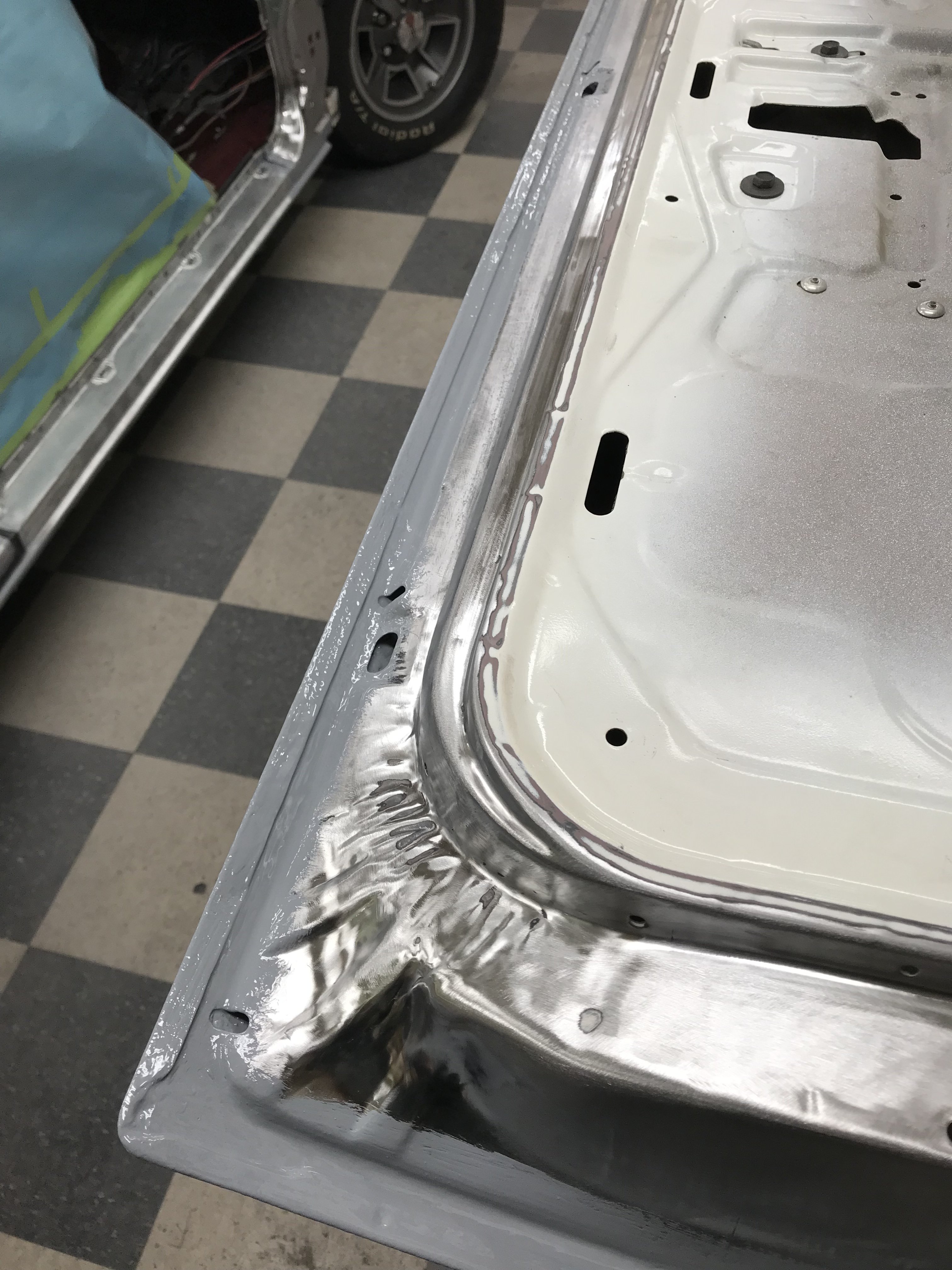

This week’s surgical patient’s were the front of the rocker, the side of the cowl, and the seam all around the door edge.

Side of the cowl before. Note the undercoating and primer overspray, along with the old cracked seam sealer:

UGLY!!!

Here’s an interesting tidbit for those of you that are unfamiliar with factory AstroRoof cars, the stub end you see sticking out here is a rubber hose. It’s a drain tube that runs up inside the “A” pillar, and is hooked into the outer AstroRoof pan up top. There’s a matching one on the driver’s side:

Any water that makes its way past the outer weatherstrip seal ends up in the outer pan and drains out through these tubes.

You won’t find these or even their holes in a conventional hardtop coupe!

Moving along, this was the front section of the rocker before:

And now, after several nights of stripping, sanding, grinding and treating the rusty areas. A fresh coat of epoxy was applied tonight in the spots to be resealed:

MUCH better!!!

This is the area that had all that old crappy dried out and cracked seam sealer, looks MUCH better now. Thankfully, I didn’t find much more than just surface rust underneath:

The rest of the work was done on the inside of the door, more epoxy in the seam areas all around the edges:

That’s all for now gents, I’ll let the epoxy set up a couple days then get it scuffed up and feather edged in preparation for new seam sealer.

Till then, thanks all!

D.