I better do an update here before I get too far ahead.

Before I got sidetracked with the hood and mirror painting project, I had started in on the driver’s side fender and that’s where I’m back to.

I had welded up the trim holes at the bottom front and back...

...so it was time to continue with that little endeavour. The inside edge of the wheelwell was a mess, chipped paint and holes for the fender trim that came off, but also from the “old man” mud flaps that were on it when I got it. Naturally all the Phillips head screws holding the mud flaps on were rusted in and heads stripped out, so at the time I just ground the heads off and left the rest of the screws in, saying to myself “I’ll get to that someday”.

Well, someday is here.

Welding a small bead on the end of the headless fasteners, I was able to get my small vise grips on the bead and simply twist them out. Worked like a hot damn.

I continued this method until all 5 were out...

...then stripped the entire inner edge with the 3M Clean and Strip wheel. It does a great job for stuff like this.

Once all the old paint and crud were gone, I proceeded to weld up all the holes:

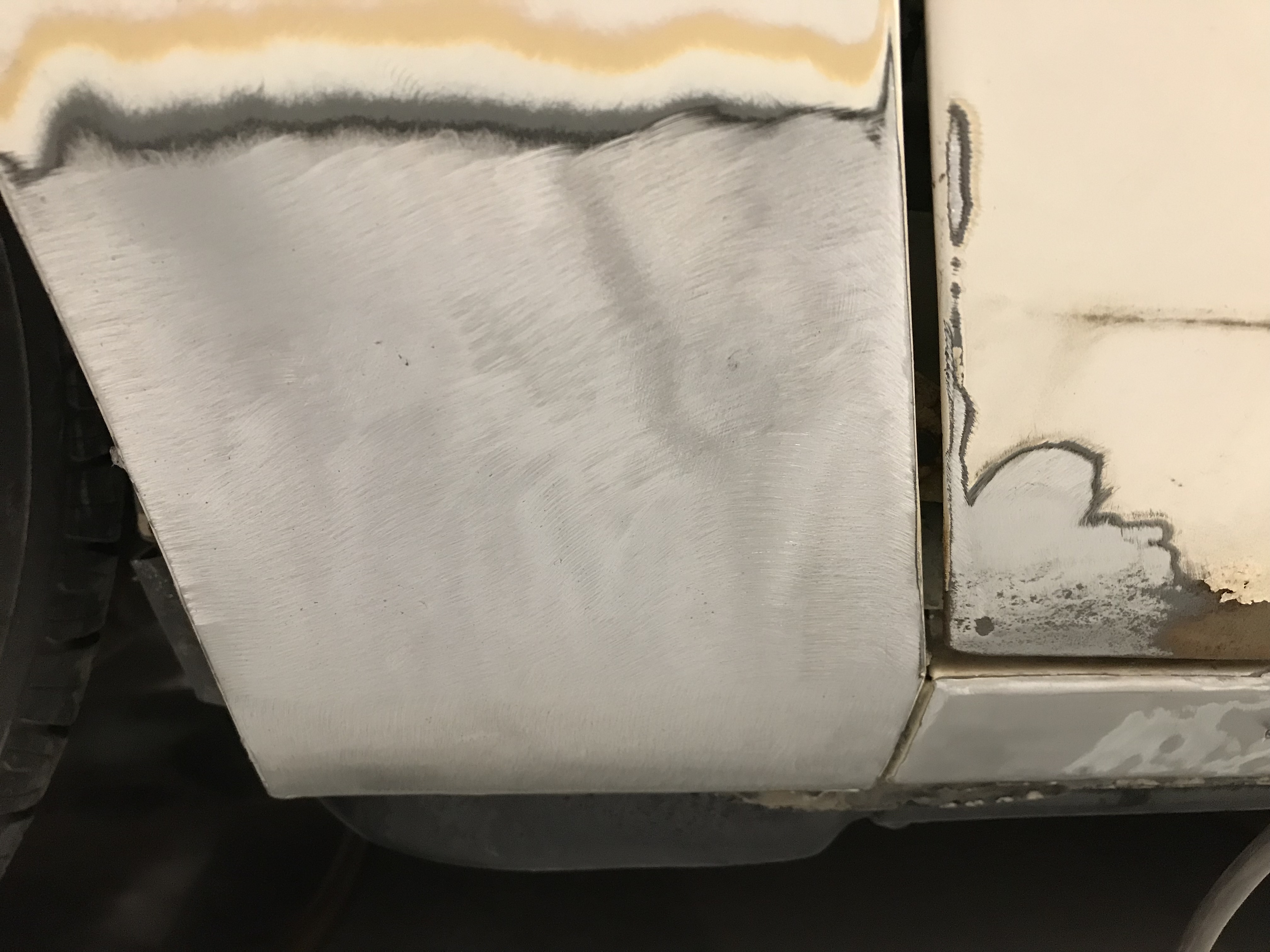

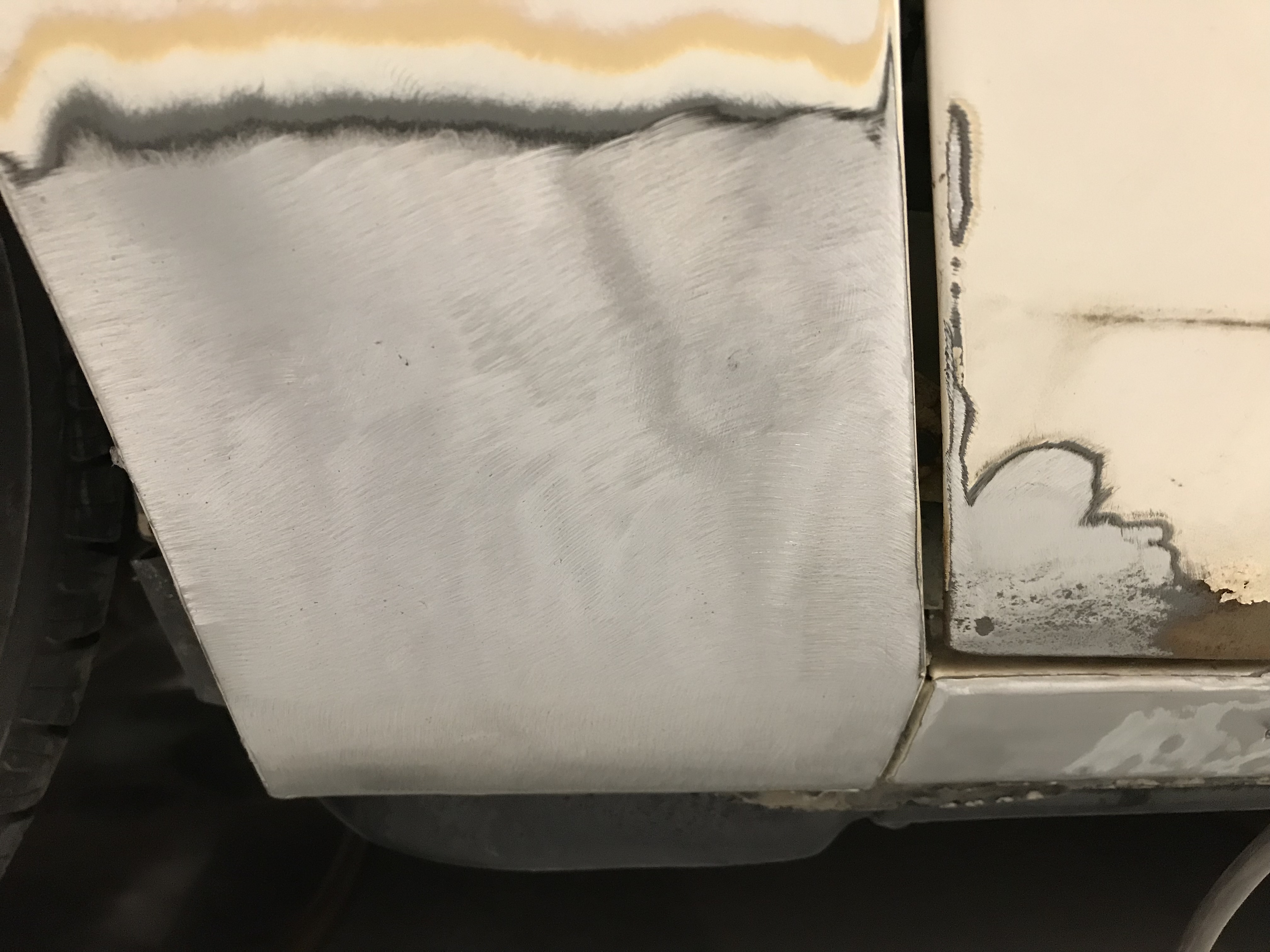

Once that nonsense was done and outta the way, I spent another evening stripping the rest of the fender. Better already.

Time for a preliminary skim of filler on the larger areas.

Laying on your back sanding filler upside down sucks!

What I’m gonna skim over briefly here next

has already been covered, oddly enough, almost one year ago to the day. It entails what goes into the creation of the marker light patch, and for those interested or just want a refresher, it can be found here:

gbodyforum.com

gbodyforum.com

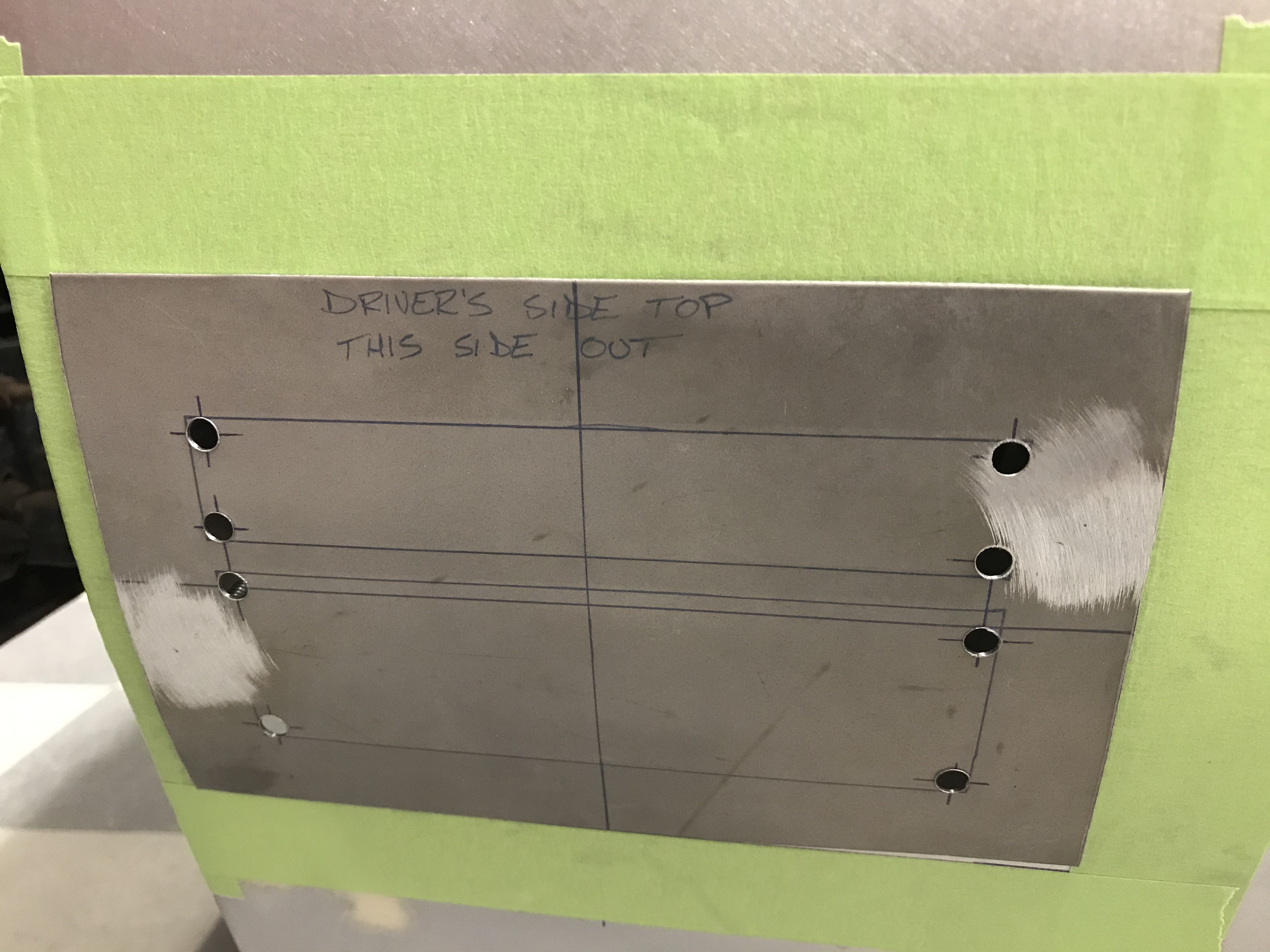

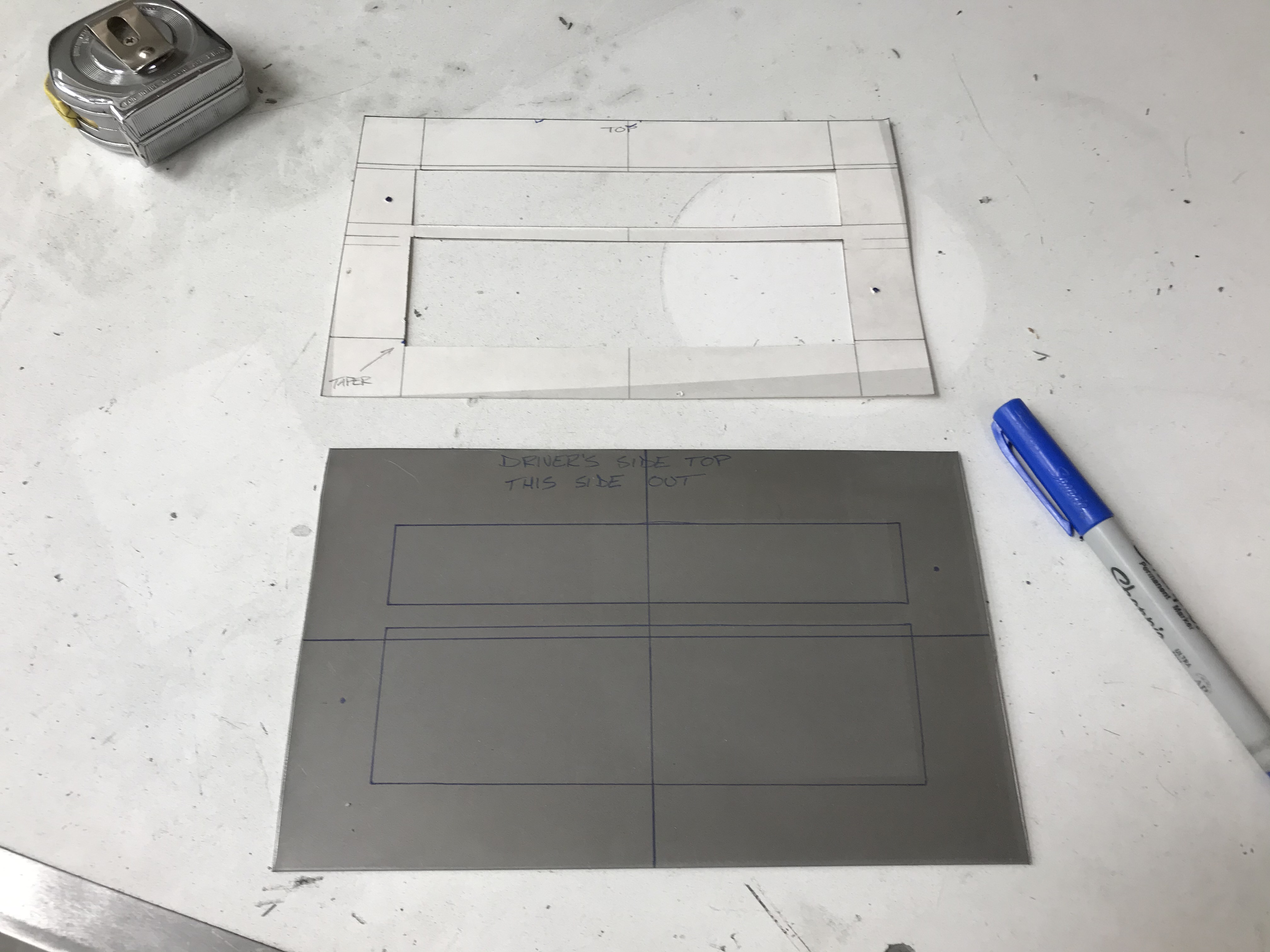

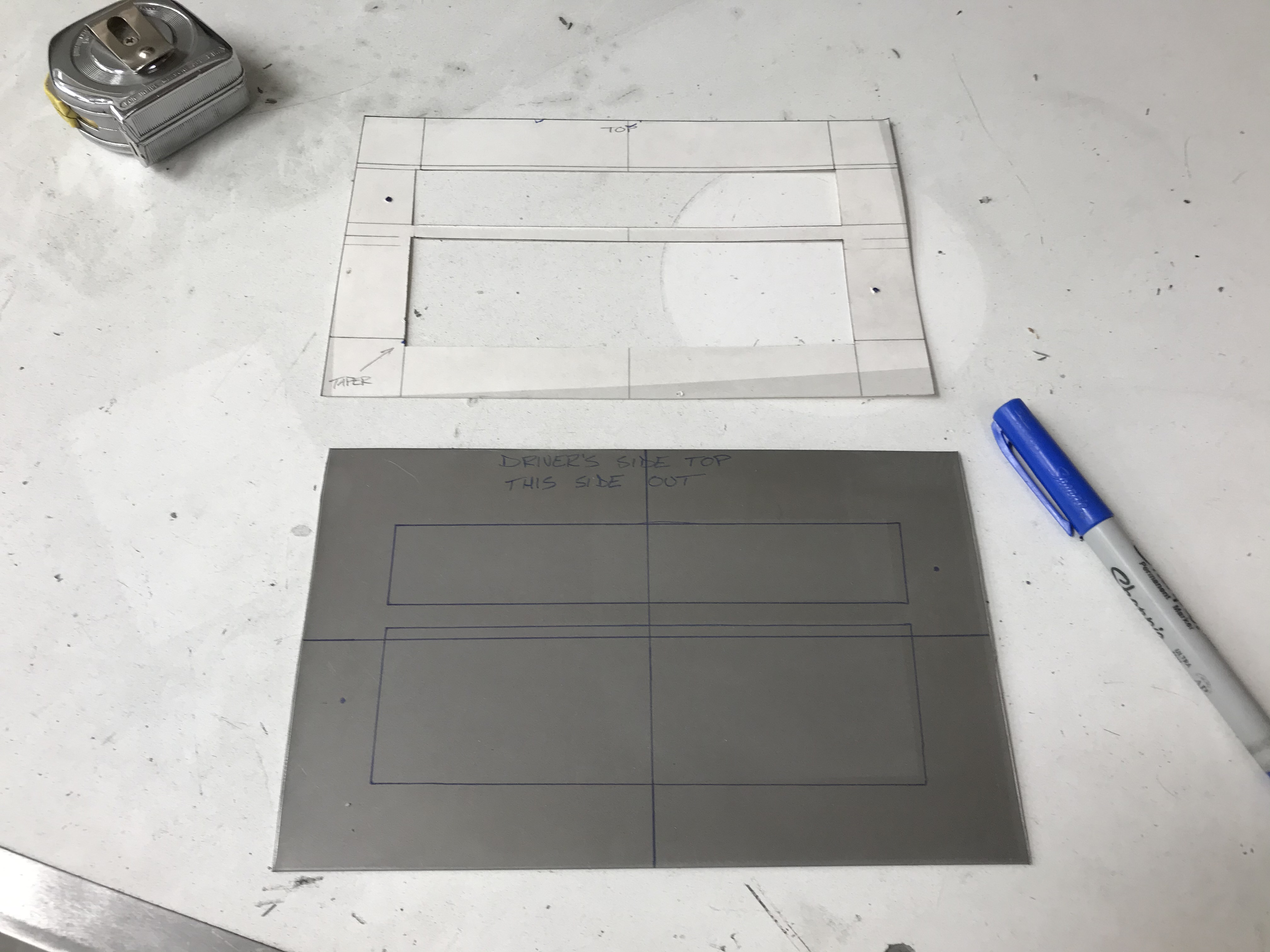

Thankfully I made the mirror image drivers side rough patch last year when I was making the passenger’s side one. So that’s what I started with.

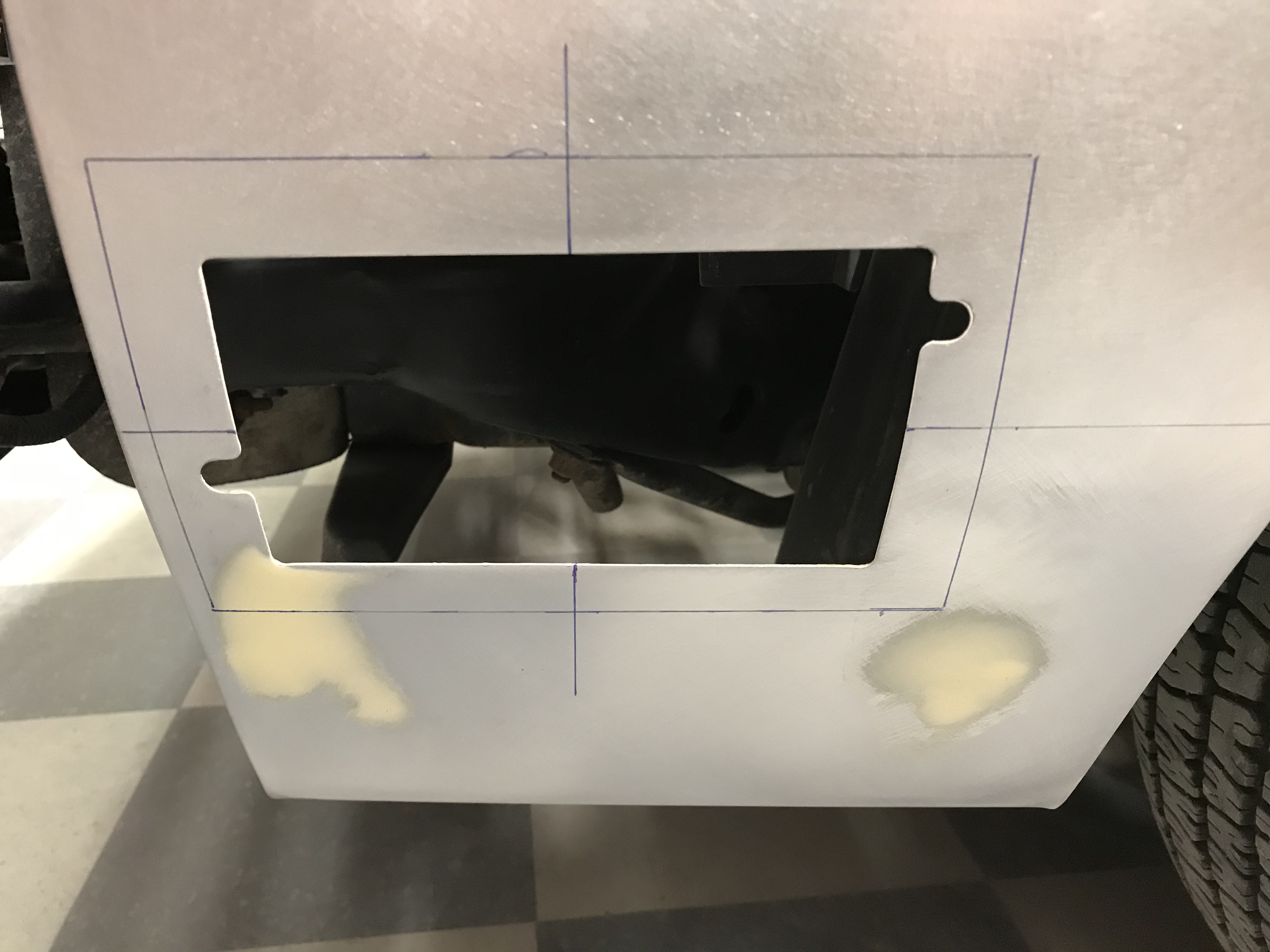

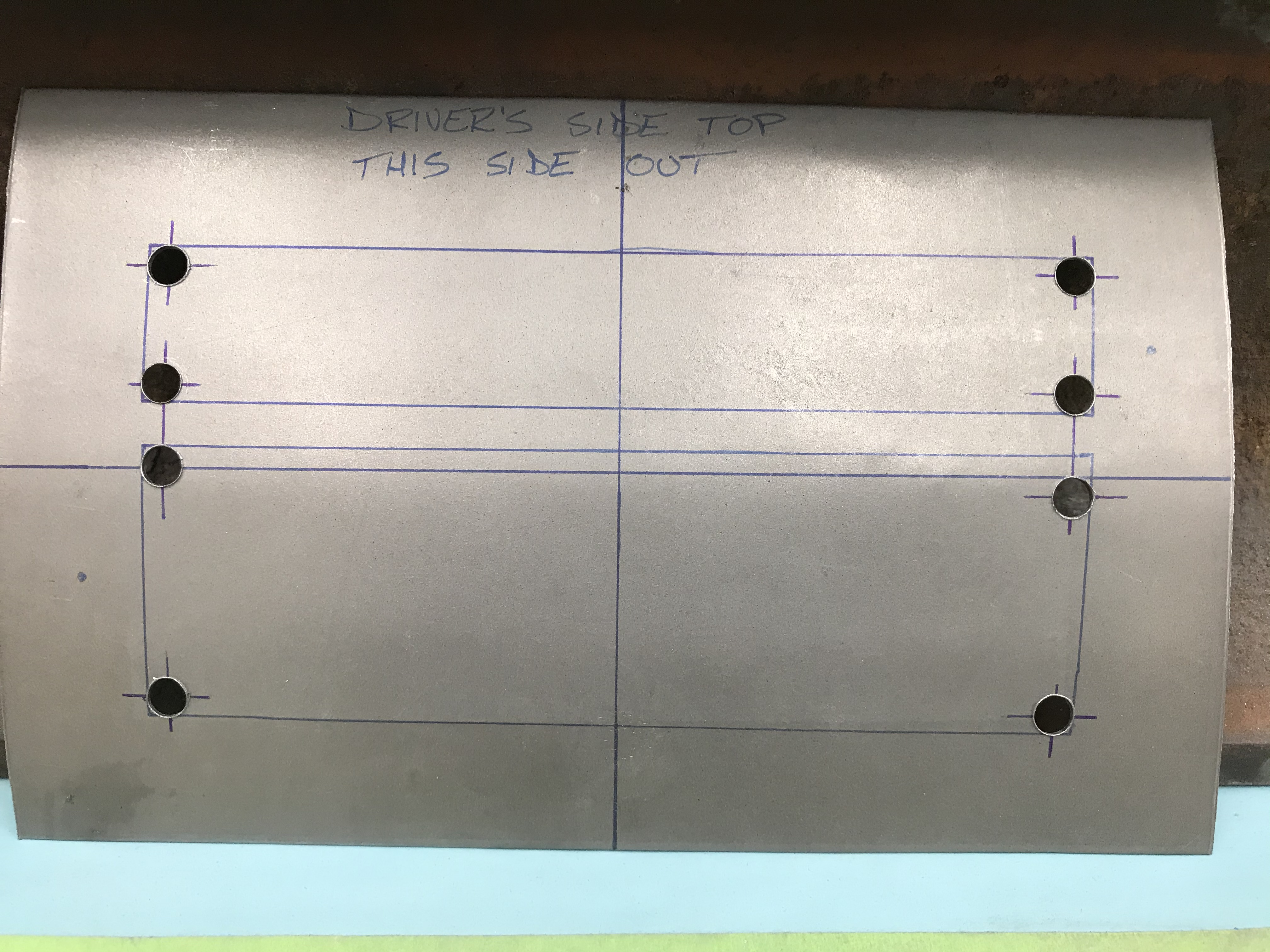

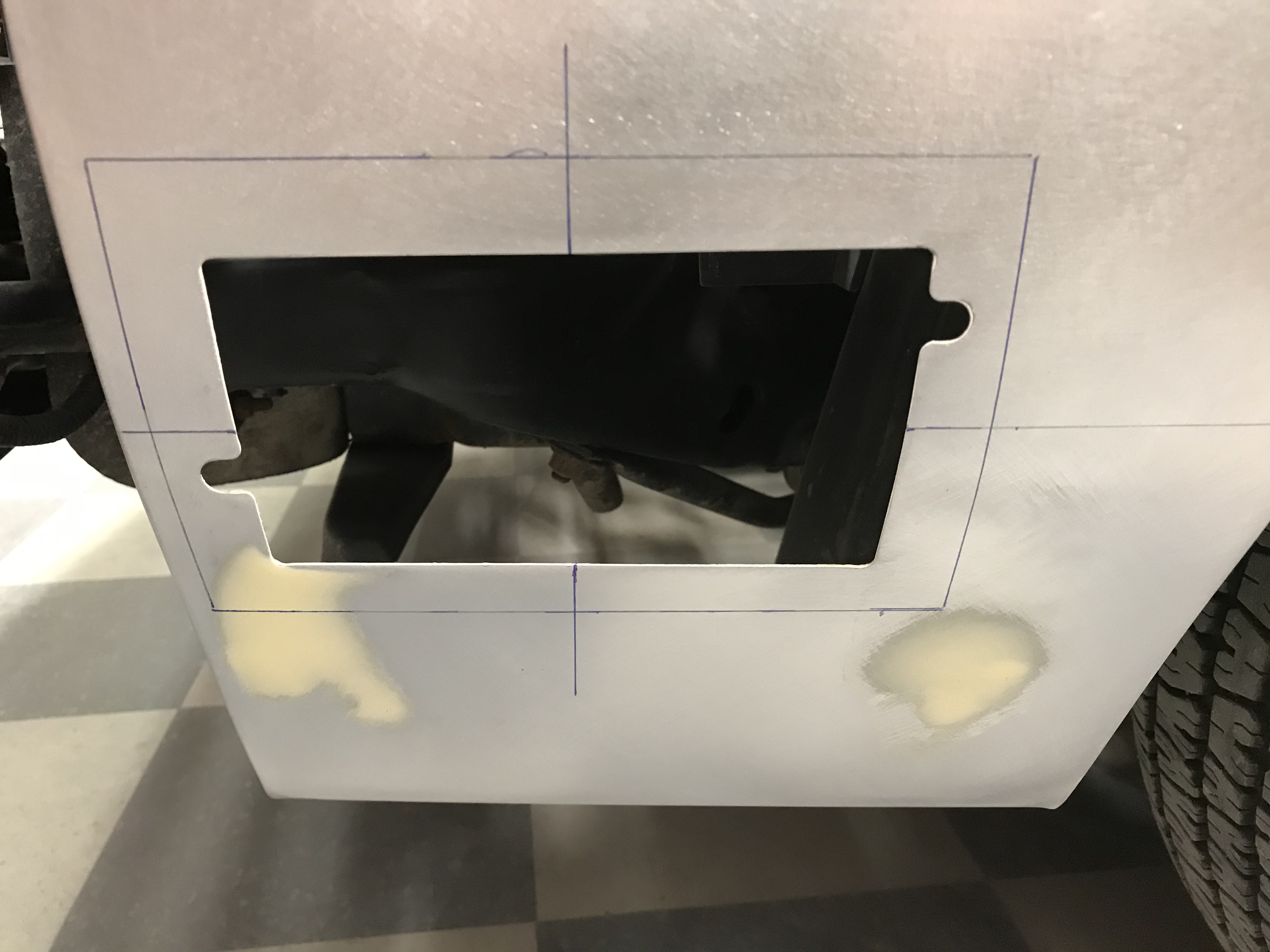

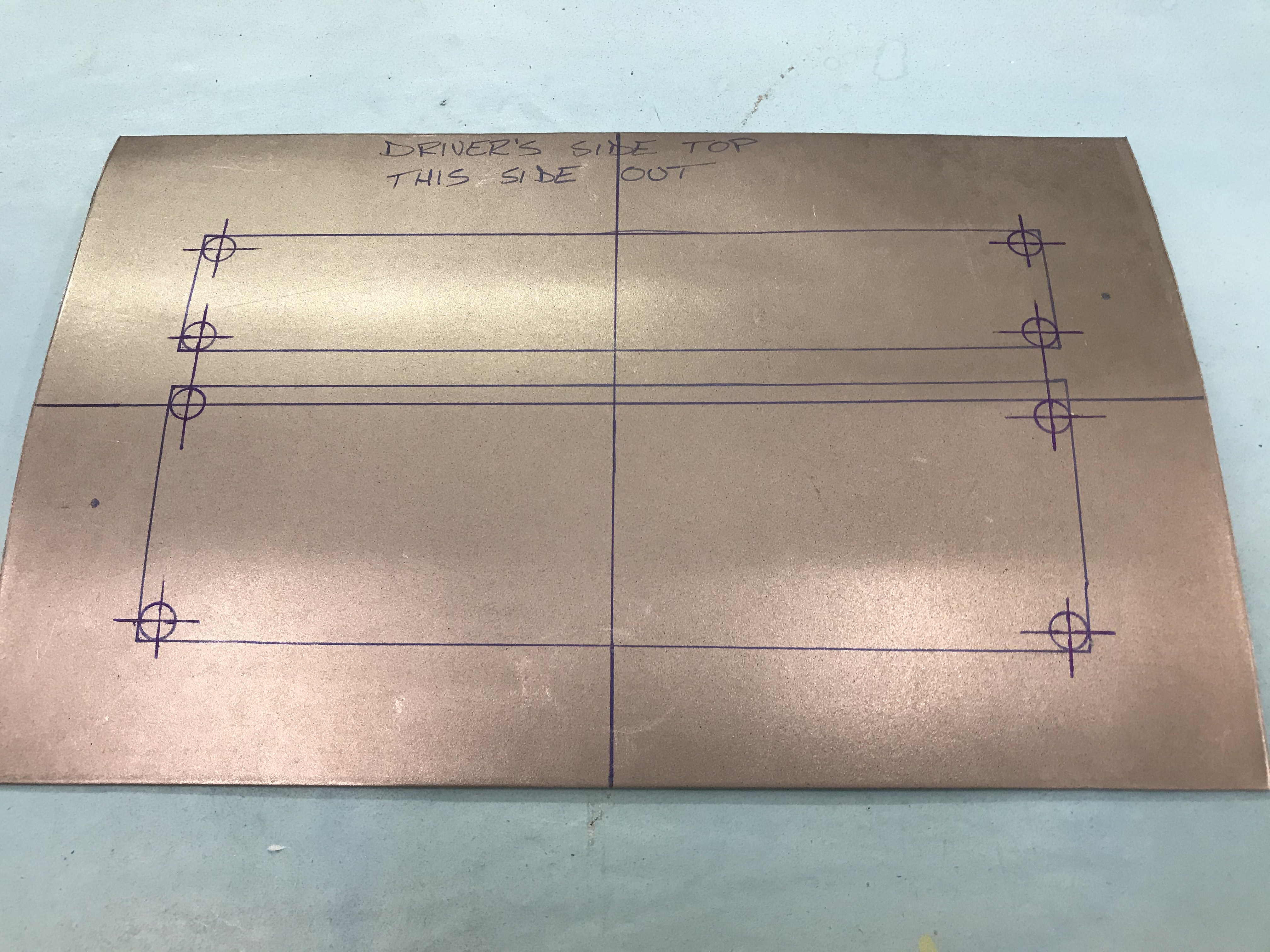

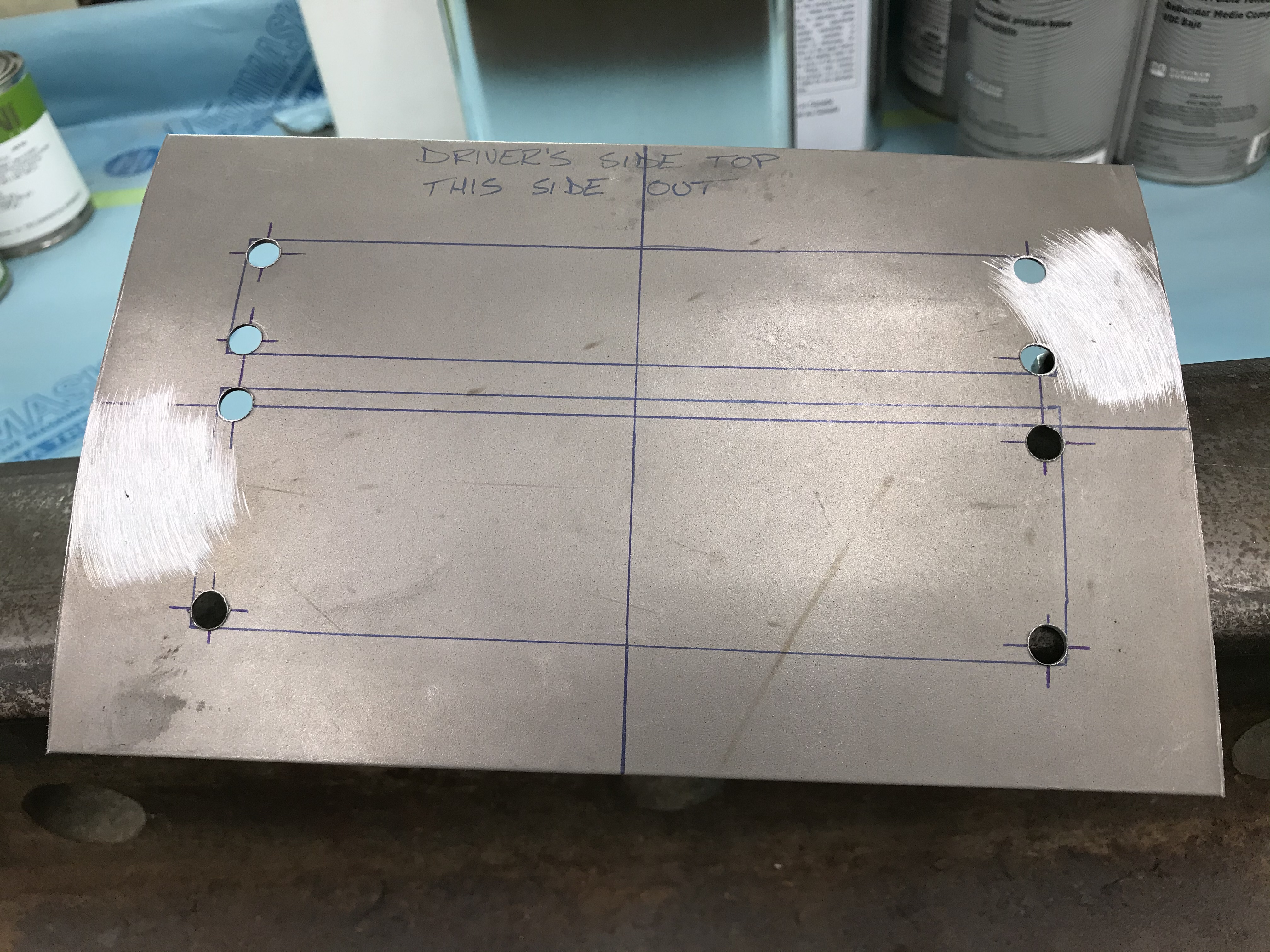

Laid out my centerline reference marks first and traced around the patch after shaping it to the curvature of the fender...

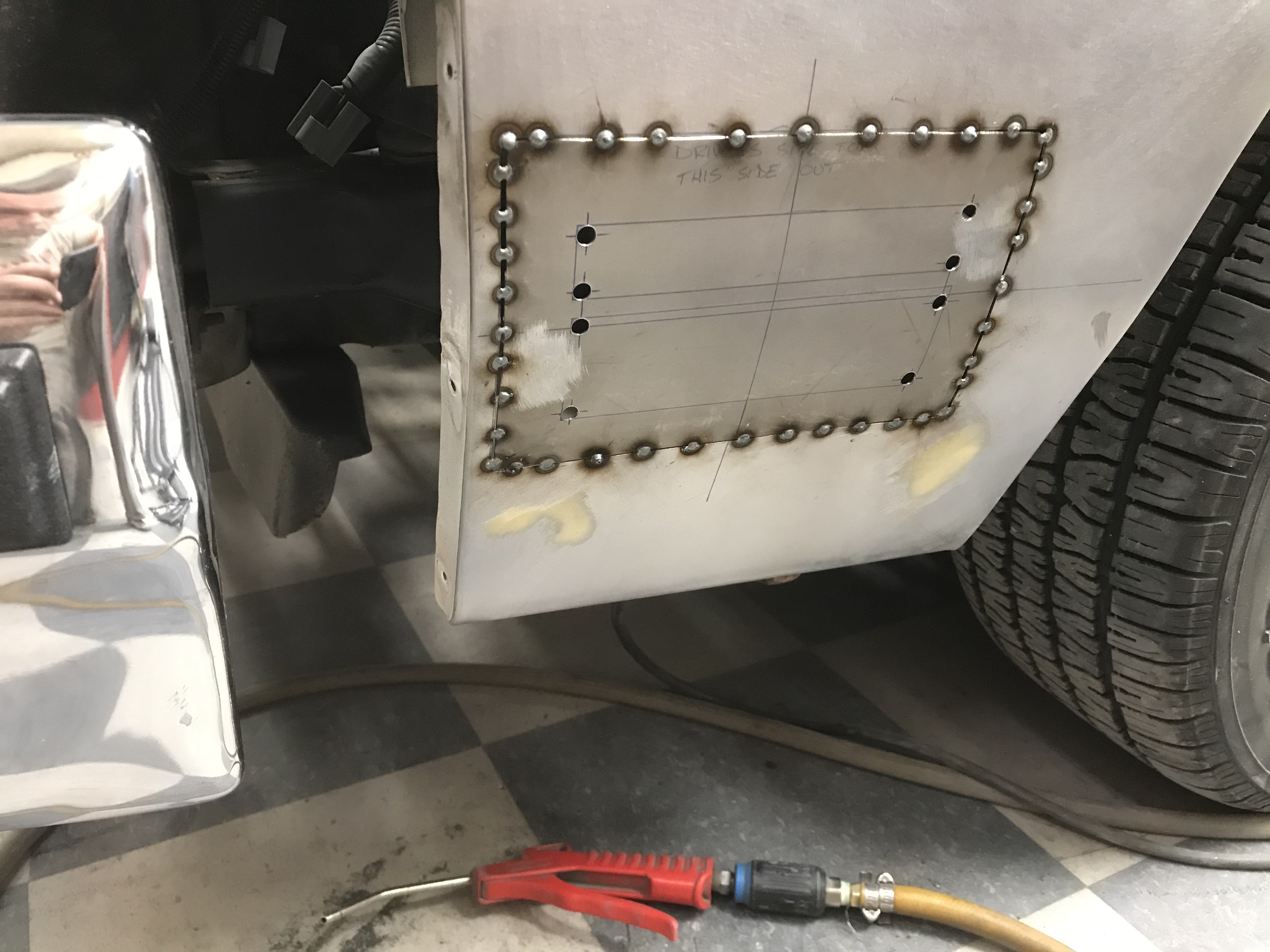

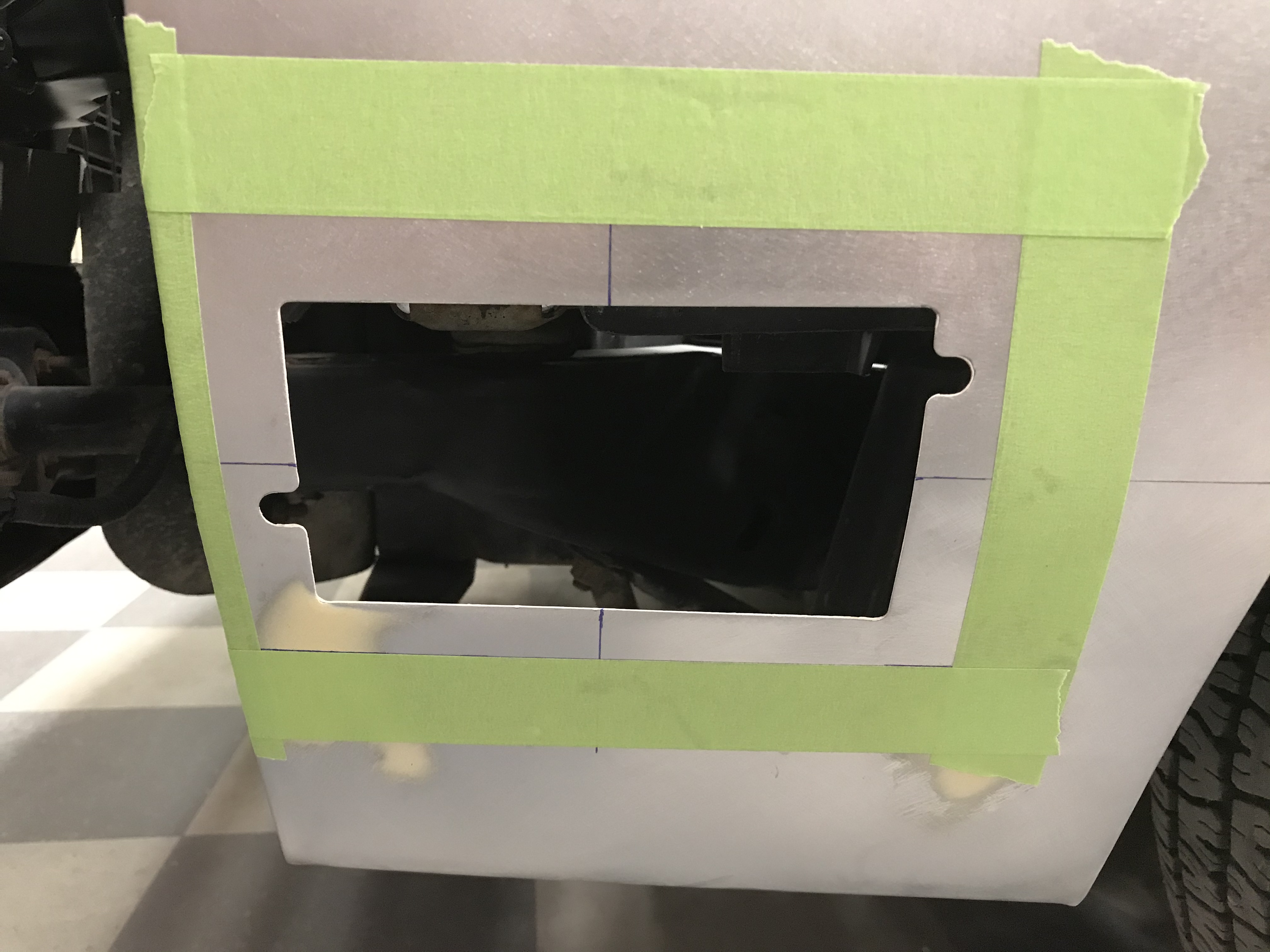

...then mocked up the patch in place. You can see the additional time spent here making sure it fits nicely is well worth it:

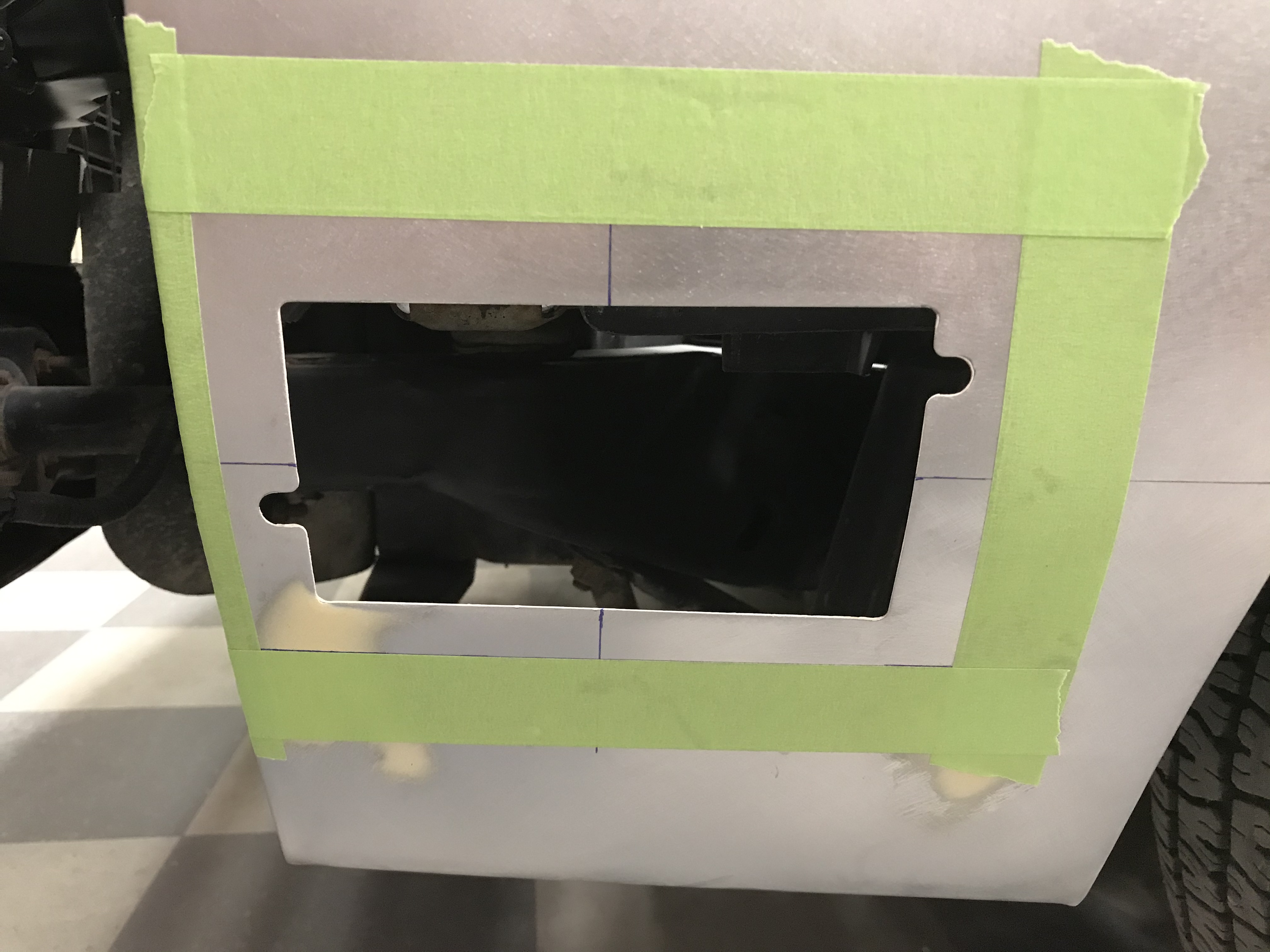

Laid out some masking tape along the traced edges to provide a hi-vis cut line next.

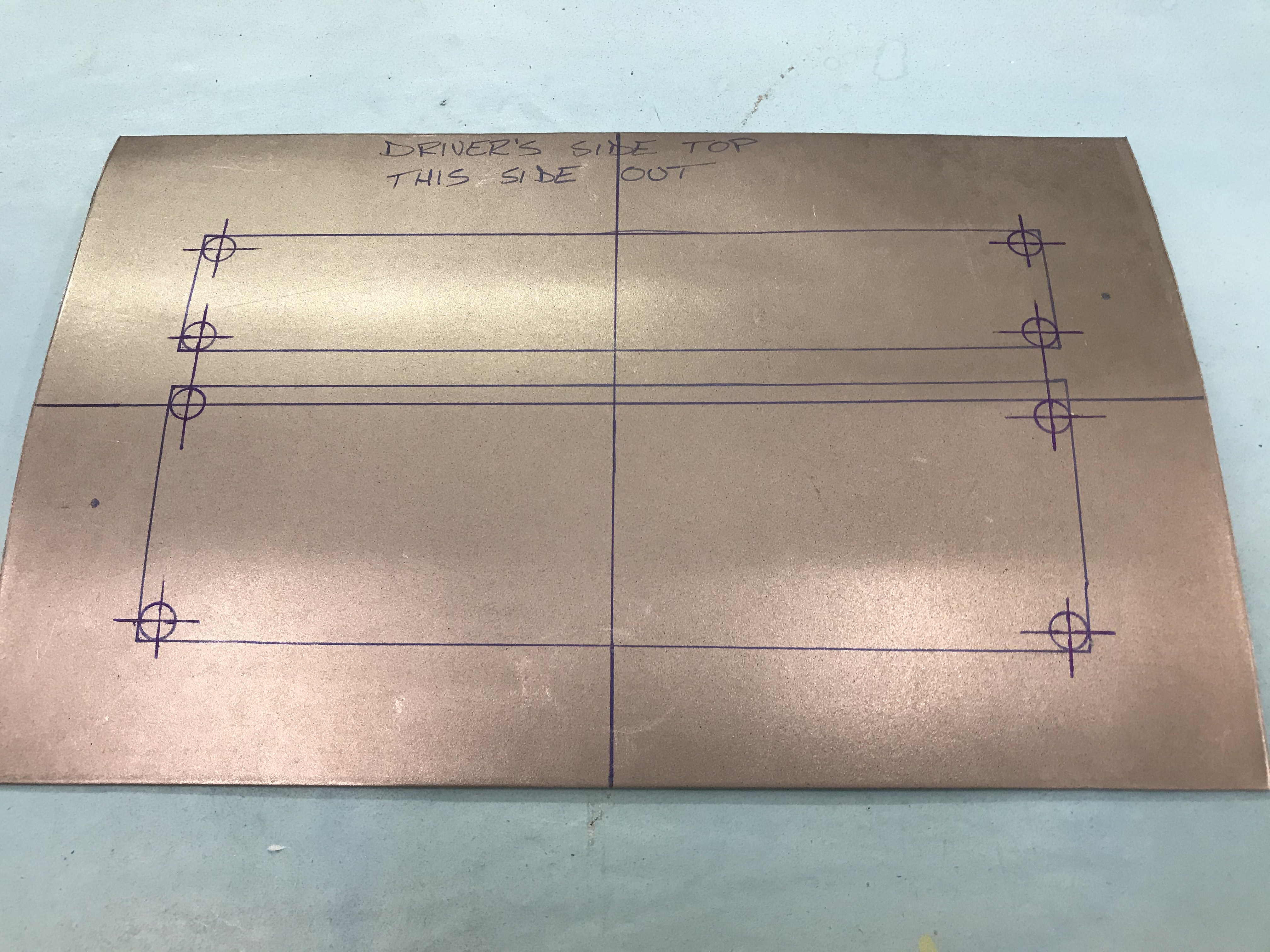

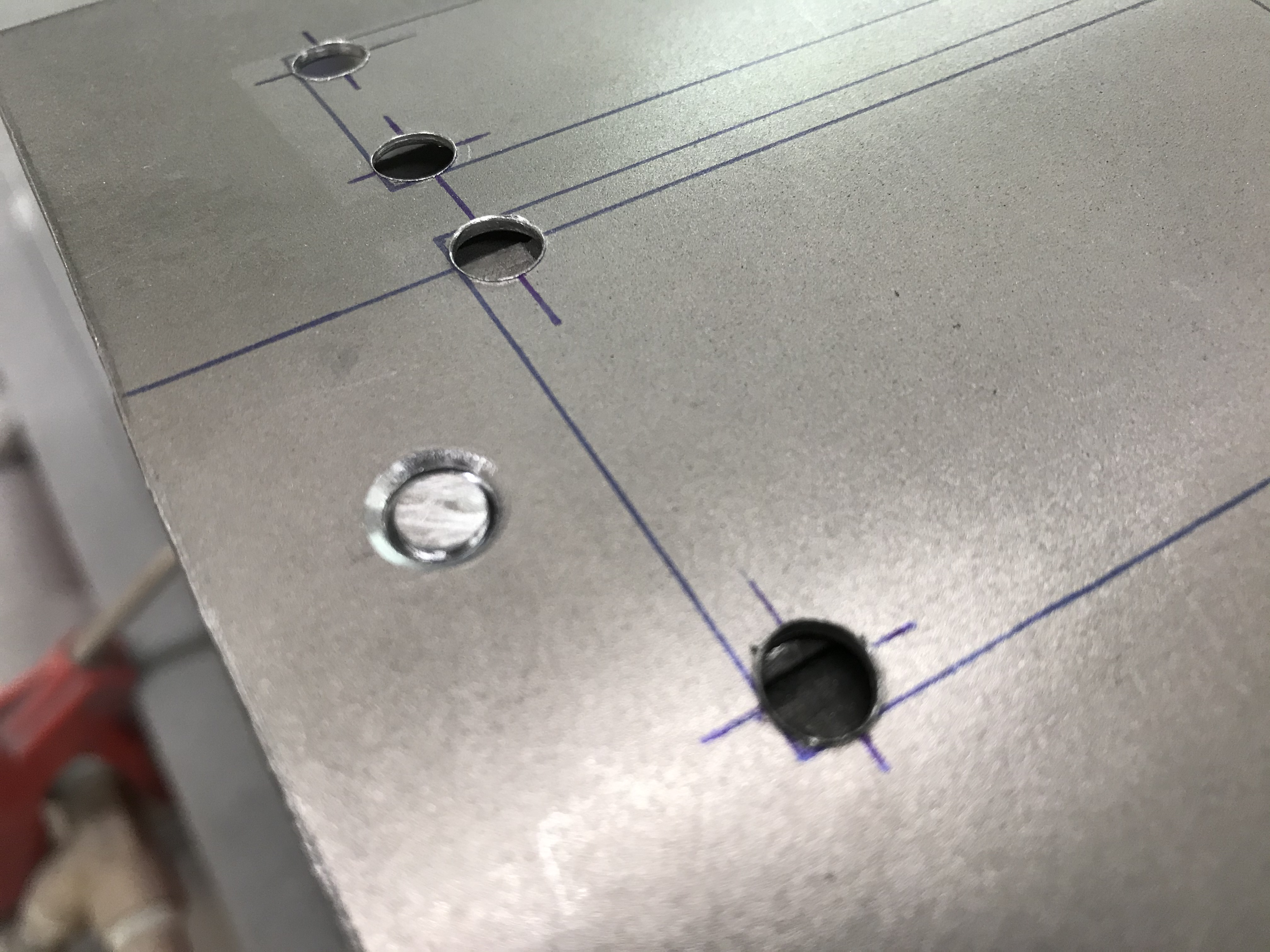

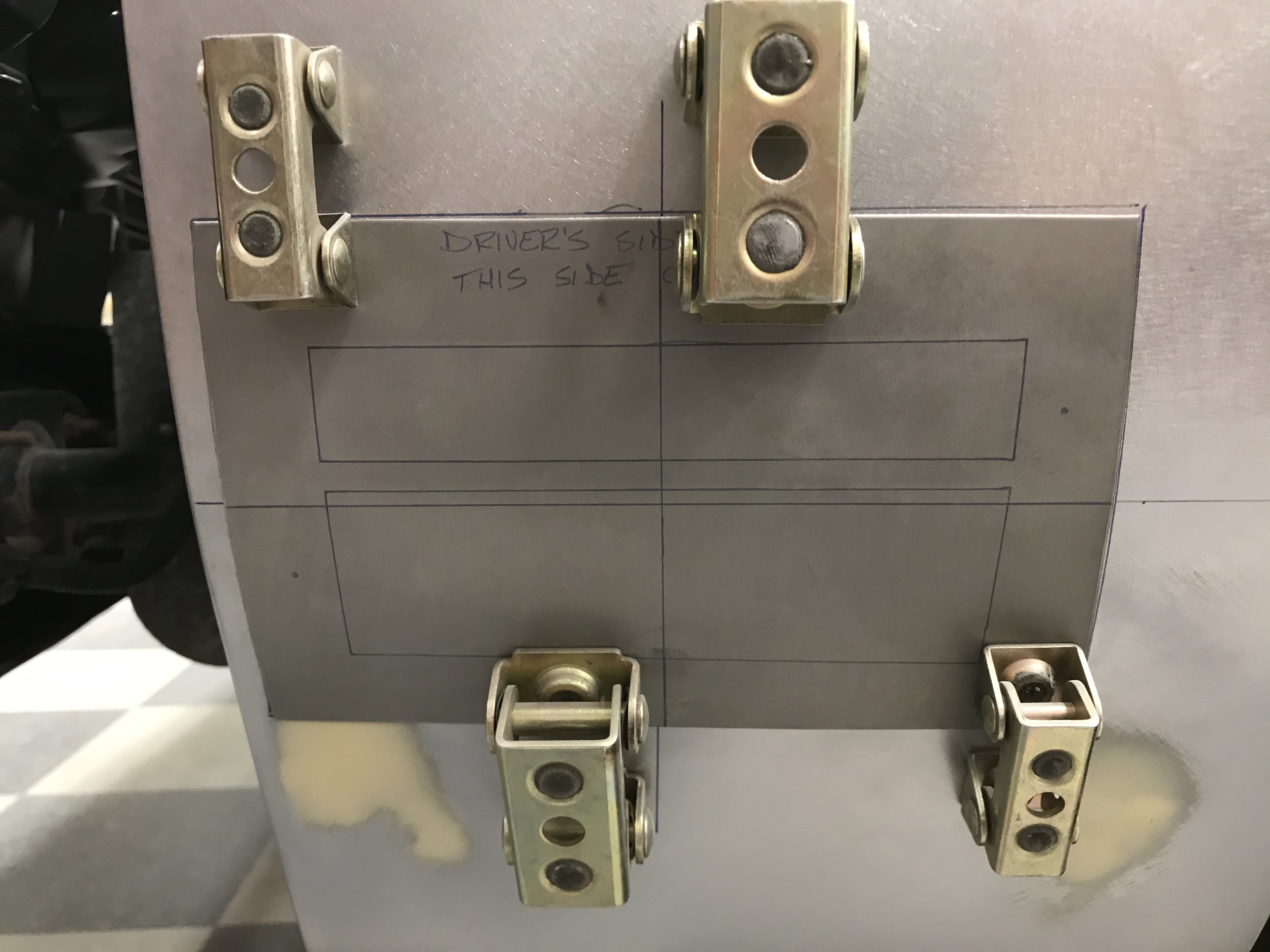

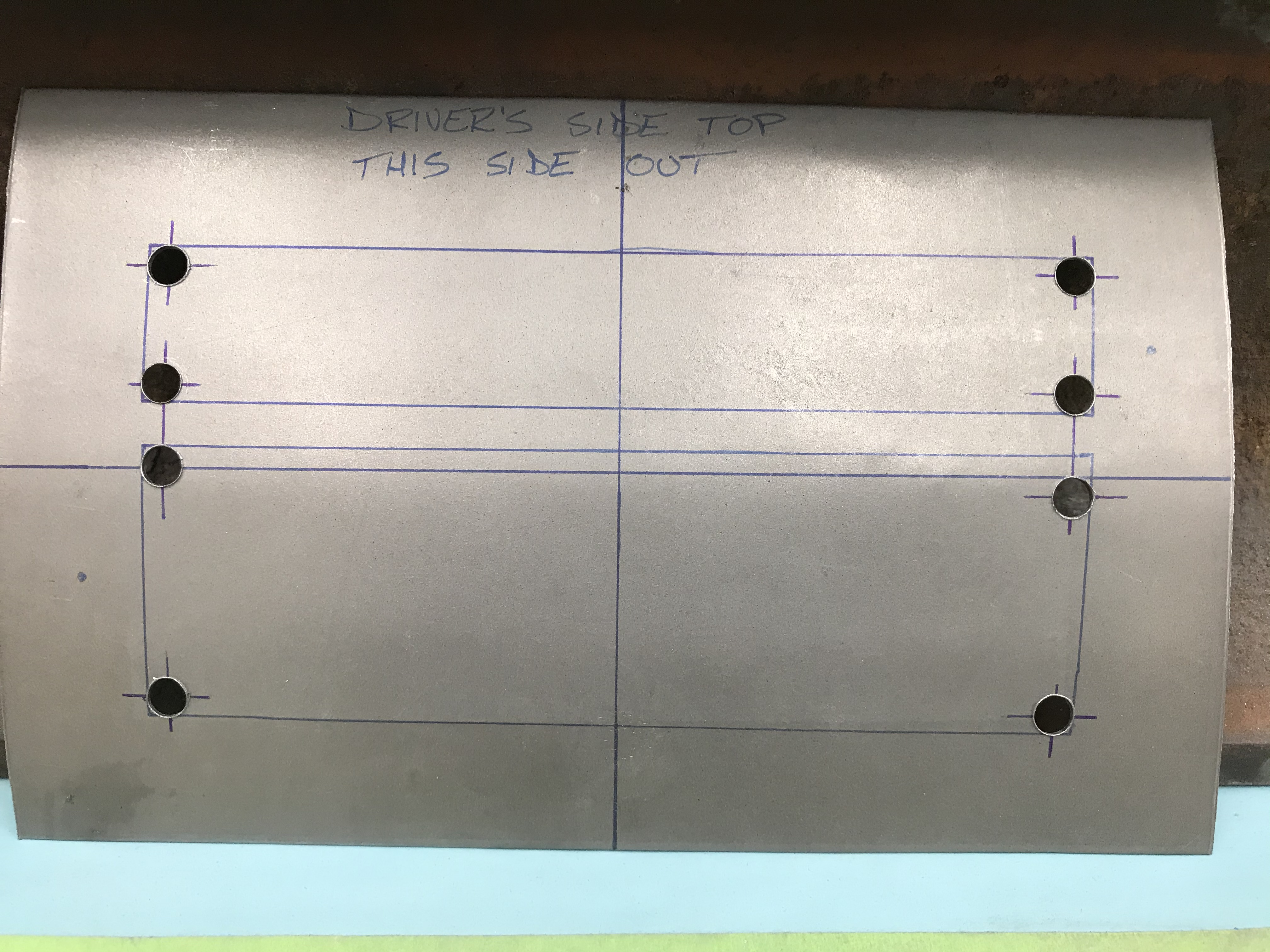

Time to finish preparing the patch for fitting. Marked out some 1/4” holes in the corners to match the radius of the lights...

...then drilled them out:

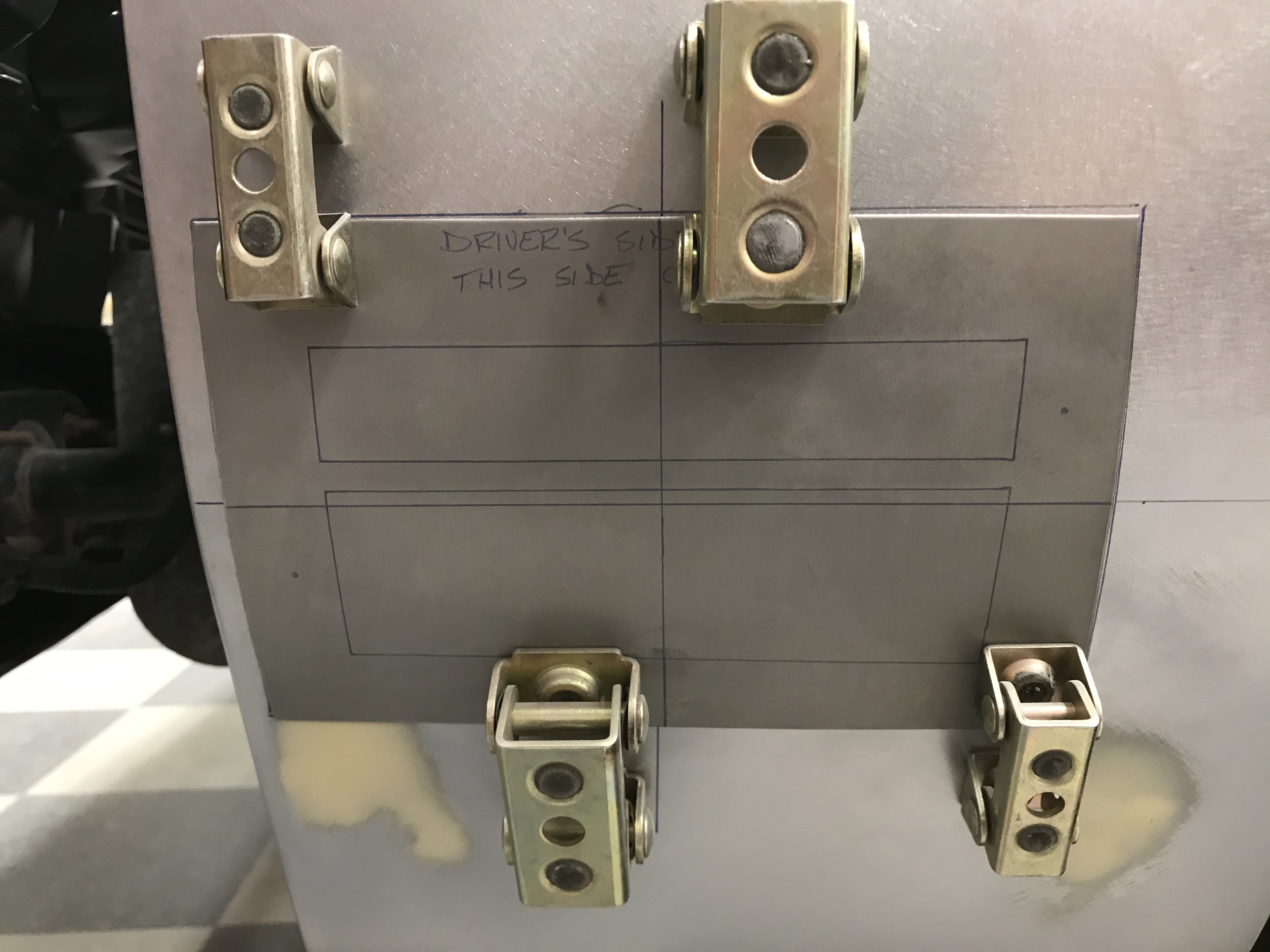

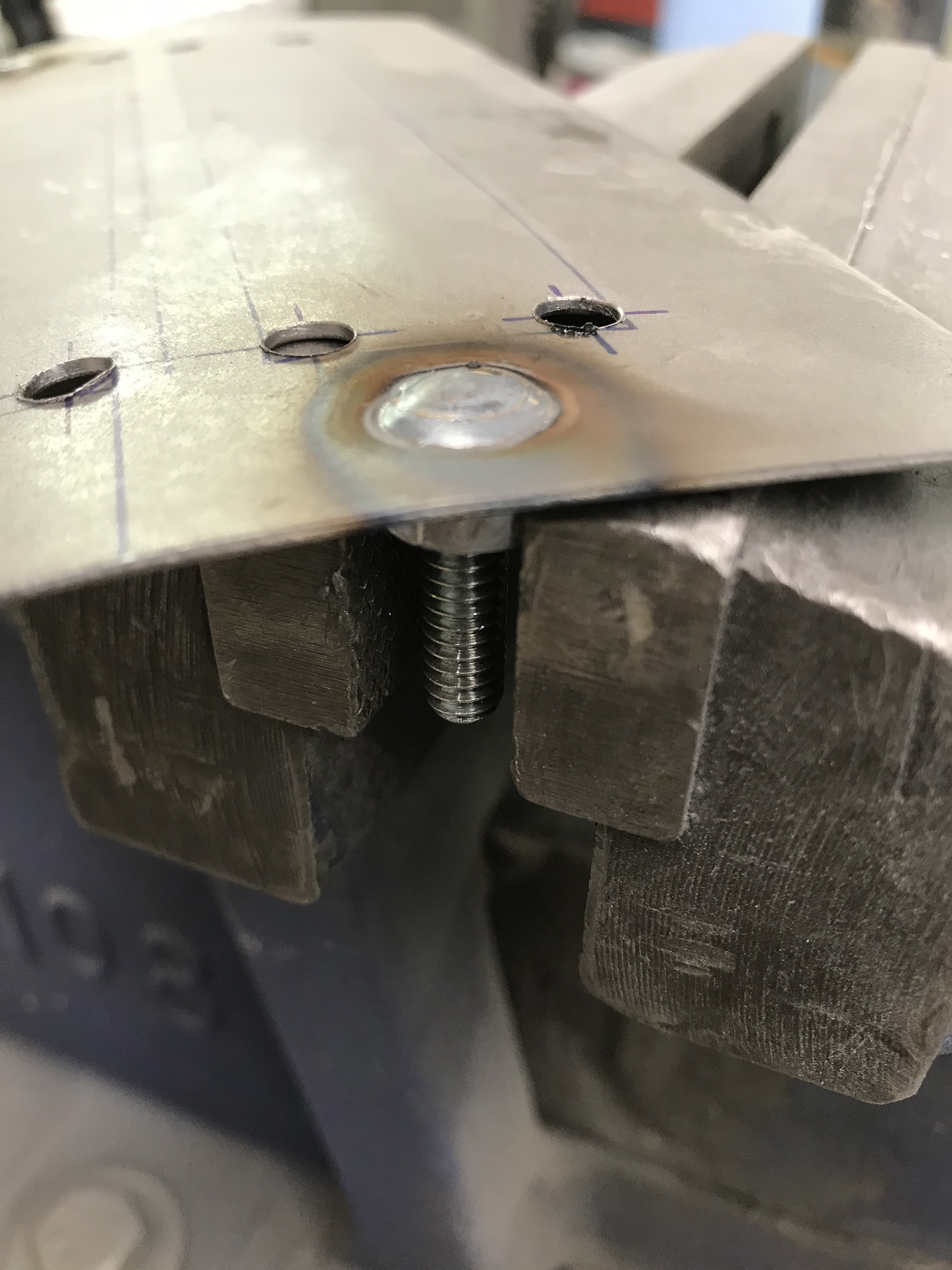

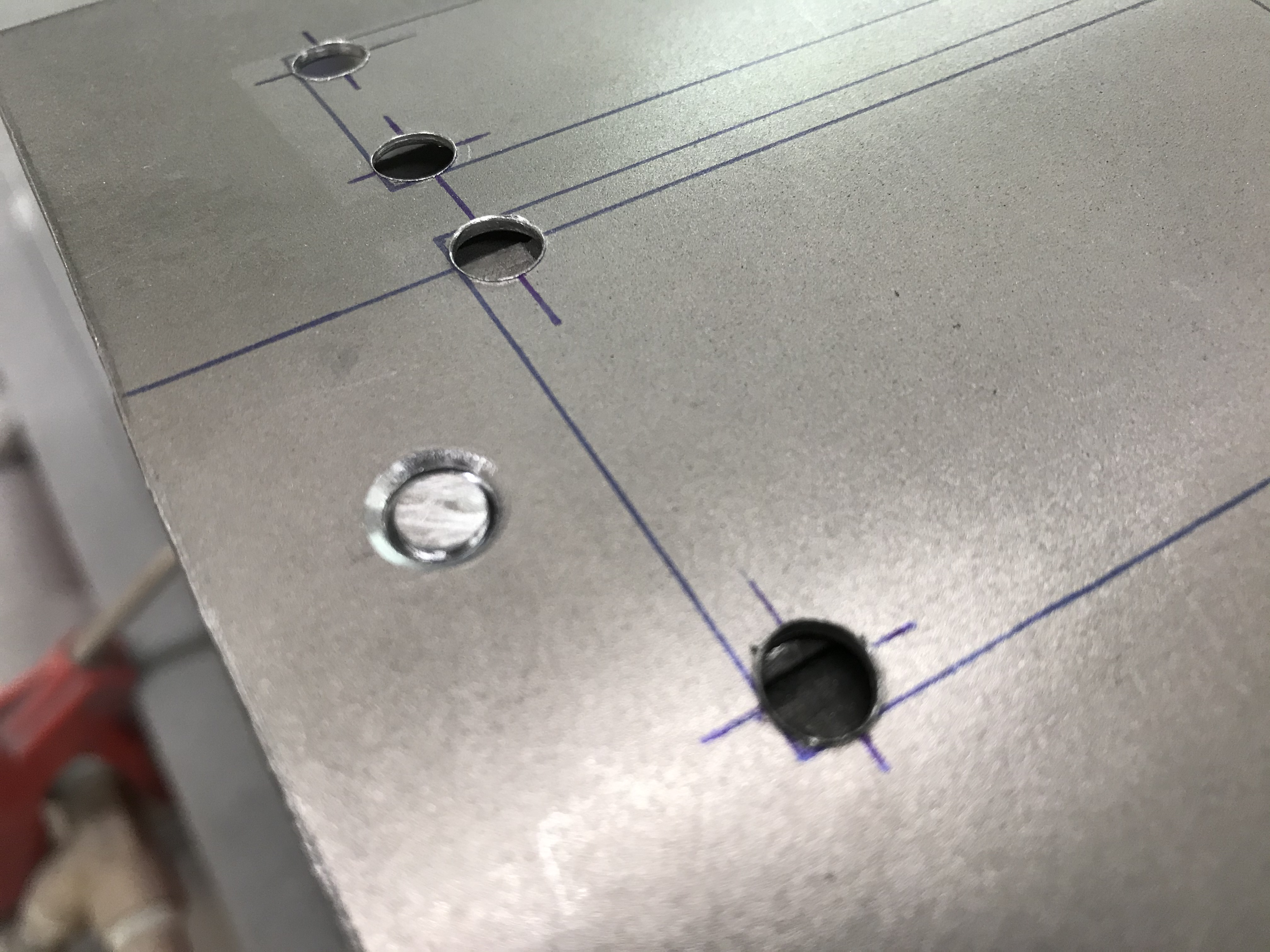

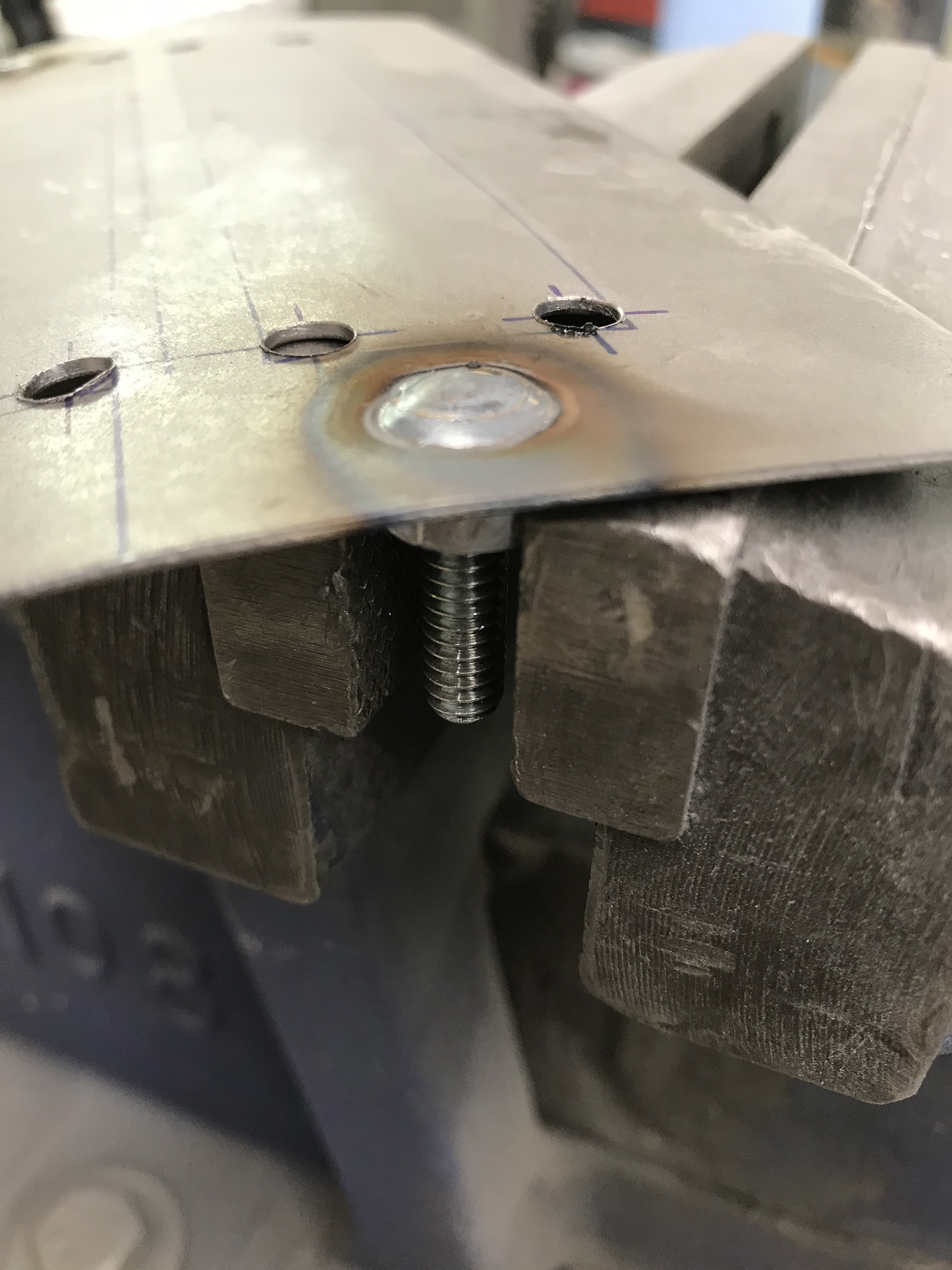

Mustn’t forget the studs to mount the light, so the locations were center punched, drilled out, and slightly countersunk. I’ve already cut the head off one the 1/4”x1” long bolts that I’m using as studs, you can see it underneath the hole just before welding:

Welded...

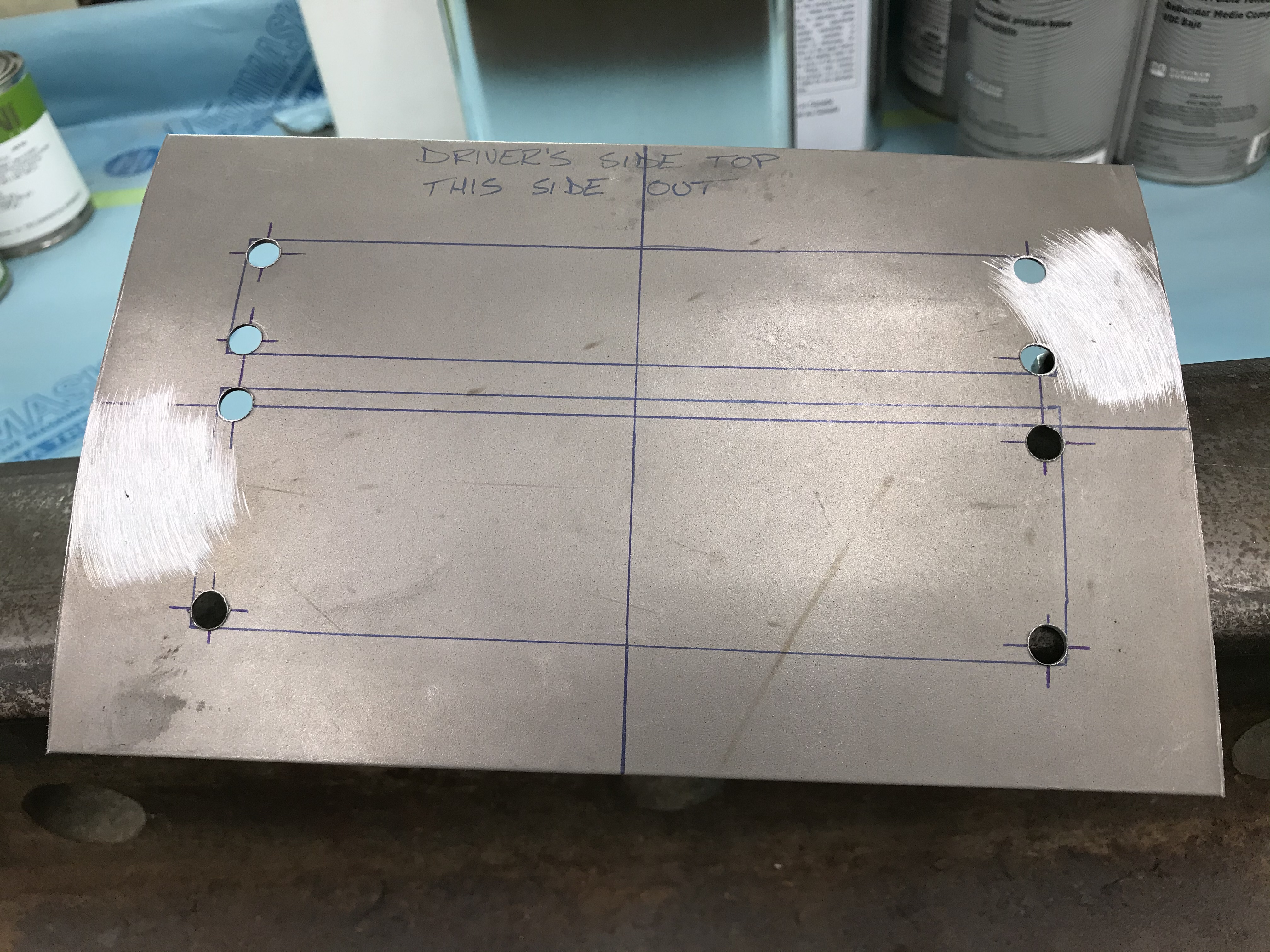

...and ground flush:

Continued >>>

Before I got sidetracked with the hood and mirror painting project, I had started in on the driver’s side fender and that’s where I’m back to.

I had welded up the trim holes at the bottom front and back...

...so it was time to continue with that little endeavour. The inside edge of the wheelwell was a mess, chipped paint and holes for the fender trim that came off, but also from the “old man” mud flaps that were on it when I got it. Naturally all the Phillips head screws holding the mud flaps on were rusted in and heads stripped out, so at the time I just ground the heads off and left the rest of the screws in, saying to myself “I’ll get to that someday”.

Well, someday is here.

Welding a small bead on the end of the headless fasteners, I was able to get my small vise grips on the bead and simply twist them out. Worked like a hot damn.

I continued this method until all 5 were out...

...then stripped the entire inner edge with the 3M Clean and Strip wheel. It does a great job for stuff like this.

Once all the old paint and crud were gone, I proceeded to weld up all the holes:

Once that nonsense was done and outta the way, I spent another evening stripping the rest of the fender. Better already.

Time for a preliminary skim of filler on the larger areas.

Laying on your back sanding filler upside down sucks!

What I’m gonna skim over briefly here next

has already been covered, oddly enough, almost one year ago to the day. It entails what goes into the creation of the marker light patch, and for those interested or just want a refresher, it can be found here:

BUILD THREAD - Project Olds Cool (Recognition!!)

Well THAT got outta hand in a hurry.... I think maybe I had too much coffee tonight! Explanation and update to follow tomorrow as soon as I get a chance. Stay tuned... D.

gbodyforum.com

gbodyforum.com

Thankfully I made the mirror image drivers side rough patch last year when I was making the passenger’s side one. So that’s what I started with.

Laid out my centerline reference marks first and traced around the patch after shaping it to the curvature of the fender...

...then mocked up the patch in place. You can see the additional time spent here making sure it fits nicely is well worth it:

Laid out some masking tape along the traced edges to provide a hi-vis cut line next.

Time to finish preparing the patch for fitting. Marked out some 1/4” holes in the corners to match the radius of the lights...

...then drilled them out:

Mustn’t forget the studs to mount the light, so the locations were center punched, drilled out, and slightly countersunk. I’ve already cut the head off one the 1/4”x1” long bolts that I’m using as studs, you can see it underneath the hole just before welding:

Welded...

...and ground flush:

Continued >>>

Last edited: