Donovan can you please explain what type of white epoxy you brushed and why ? Thanks again for your help and advice.

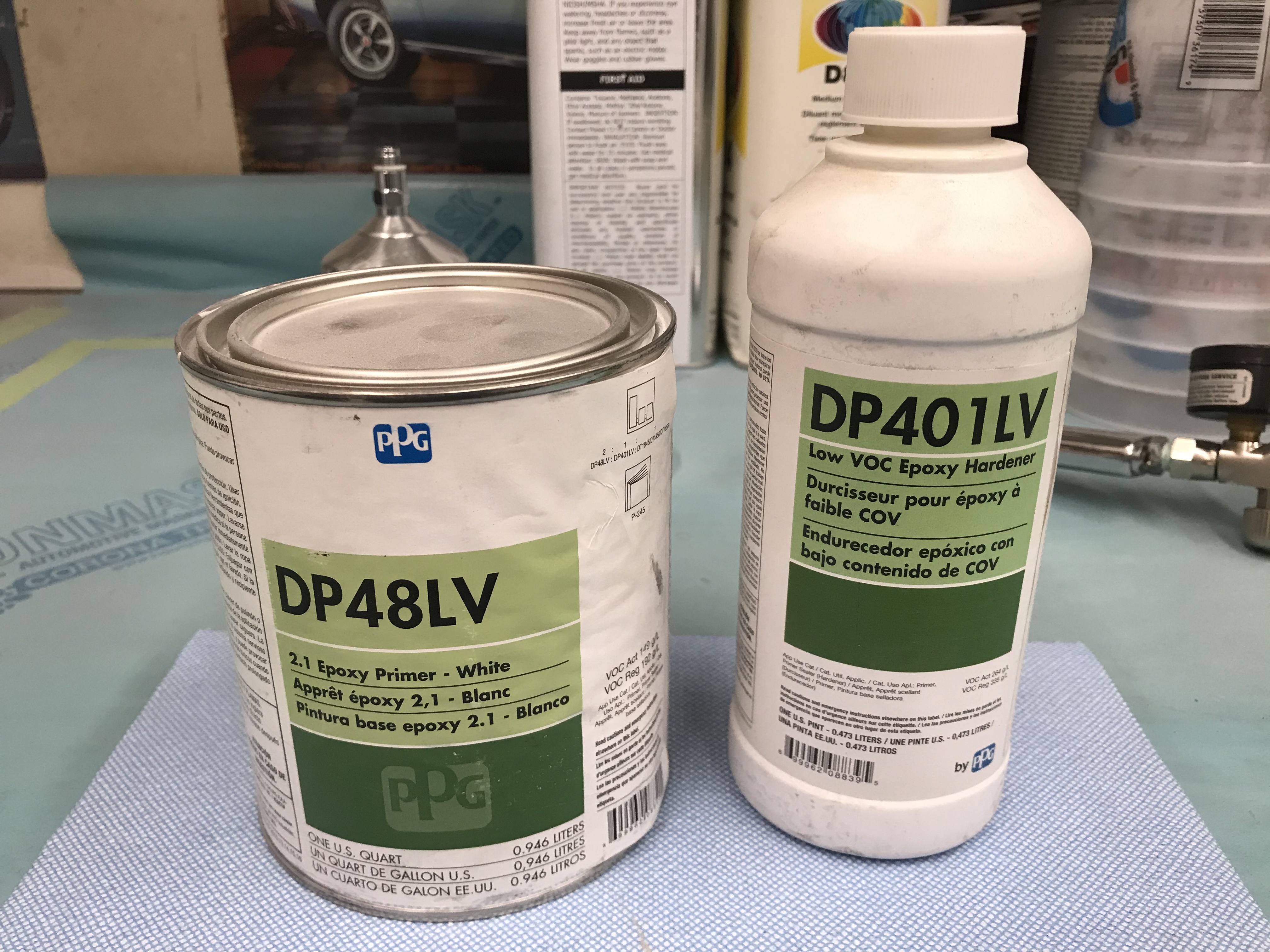

Tony, the epoxy I use is PPG’s DP48LV.

The color is inconsequential for the most part, it’s available in white, grey, and possibly black. Plus they can be mixed to achieve varying shades of grey. The last quart of epoxy I got was grey, but the last time I needed to restock I decided to get white, simply because it would require less actual paint to achieve “hiding” (complete coverage where the underlying color isn’t visible). Because, well, at least 50% of what I’m painting over the epoxy is white.

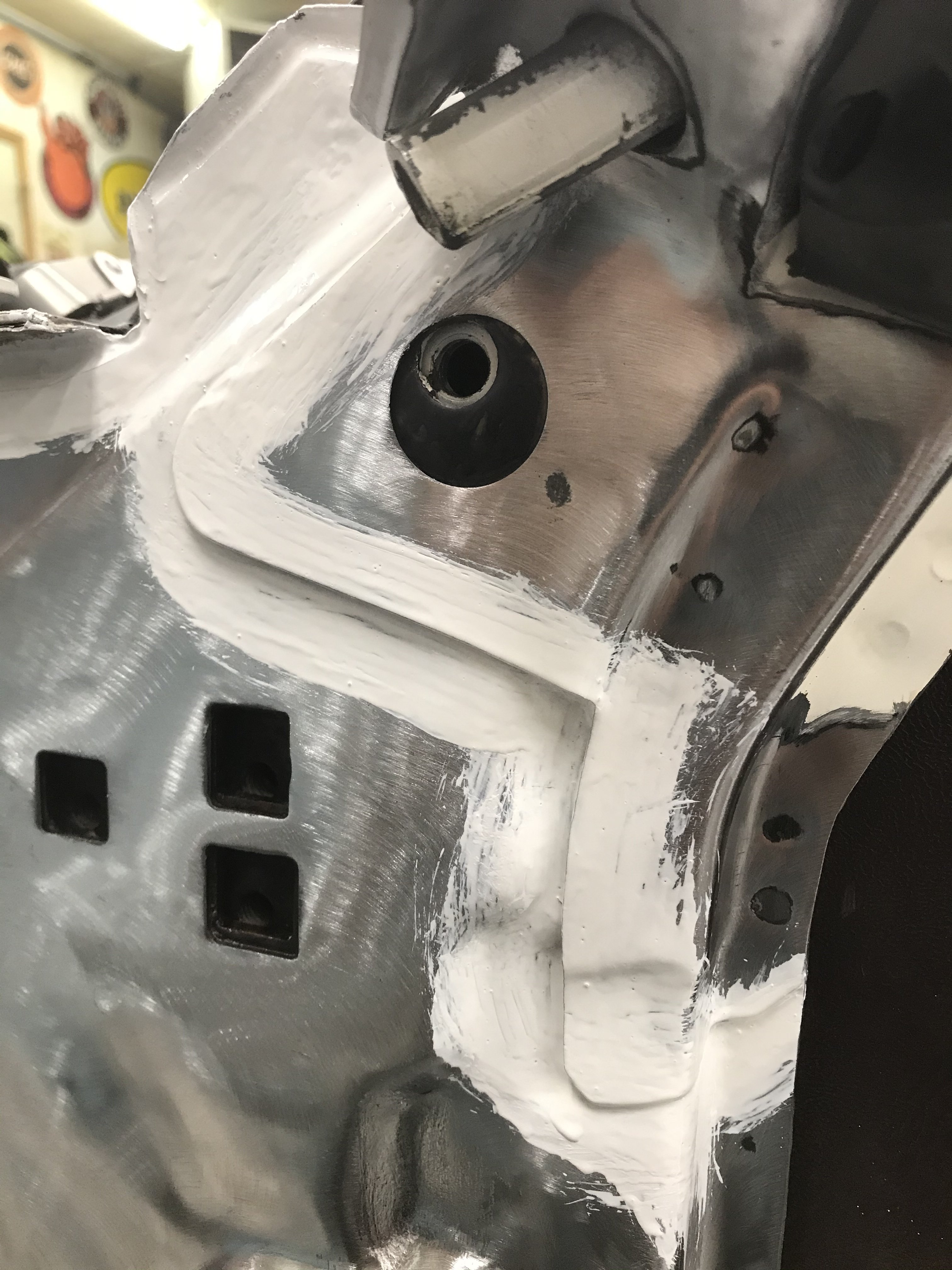

As far as why I apply it before seam sealer, the answer is simple: I’m not a fan of, nor do I believe, that seam sealer should be laid over bare metal. I’m pretty sure GM did it that way on our cars, and look at the number of problems there are with rust coming through from underneath. Take a close look at this picture, and you’ll see it’s a prime example:

By applying epoxy to the areas where the seam sealer will be applied ahead of time, I’m ensured that the metal is protected, and that the seam sealer won’t be going on over bare metal.

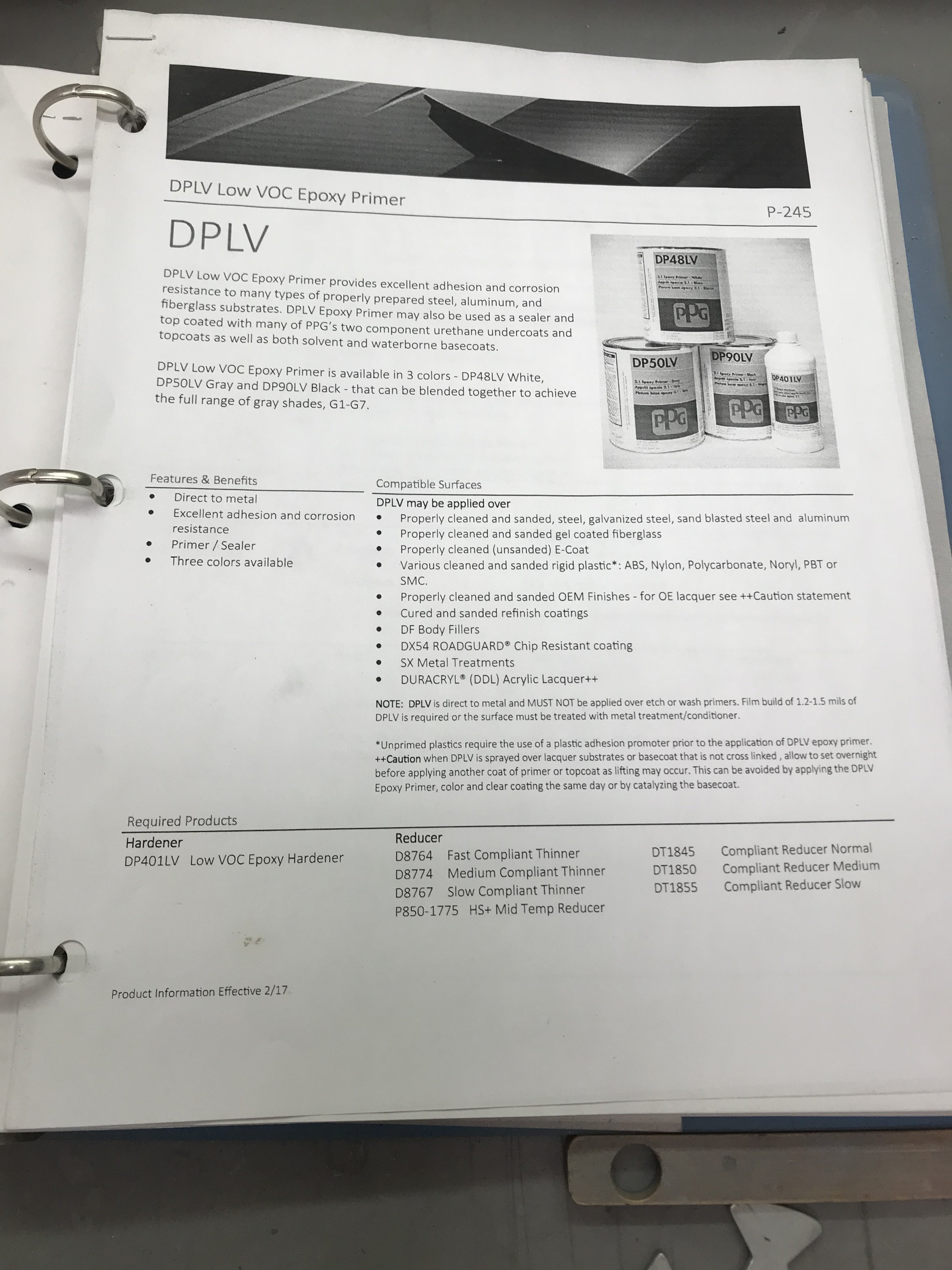

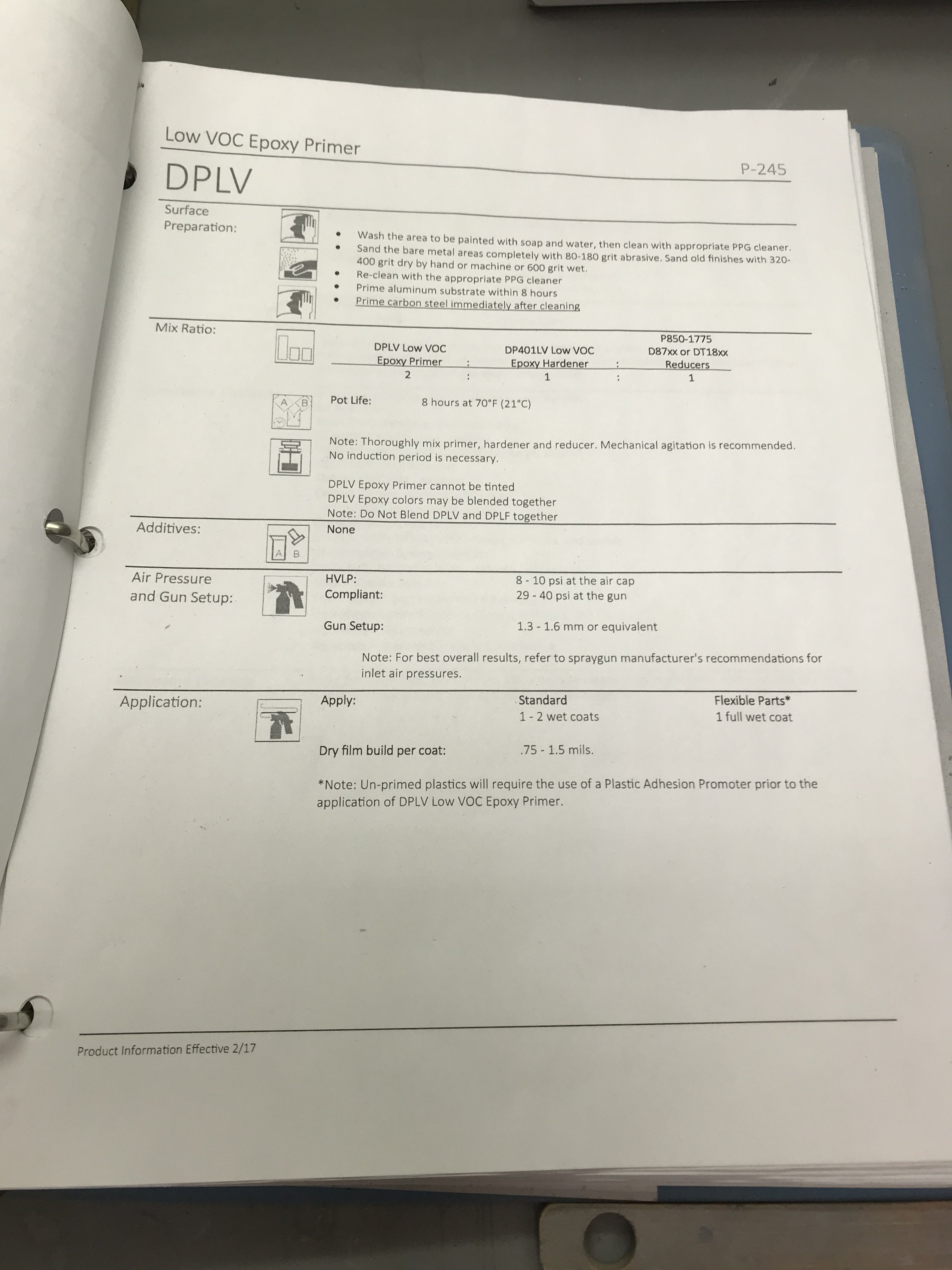

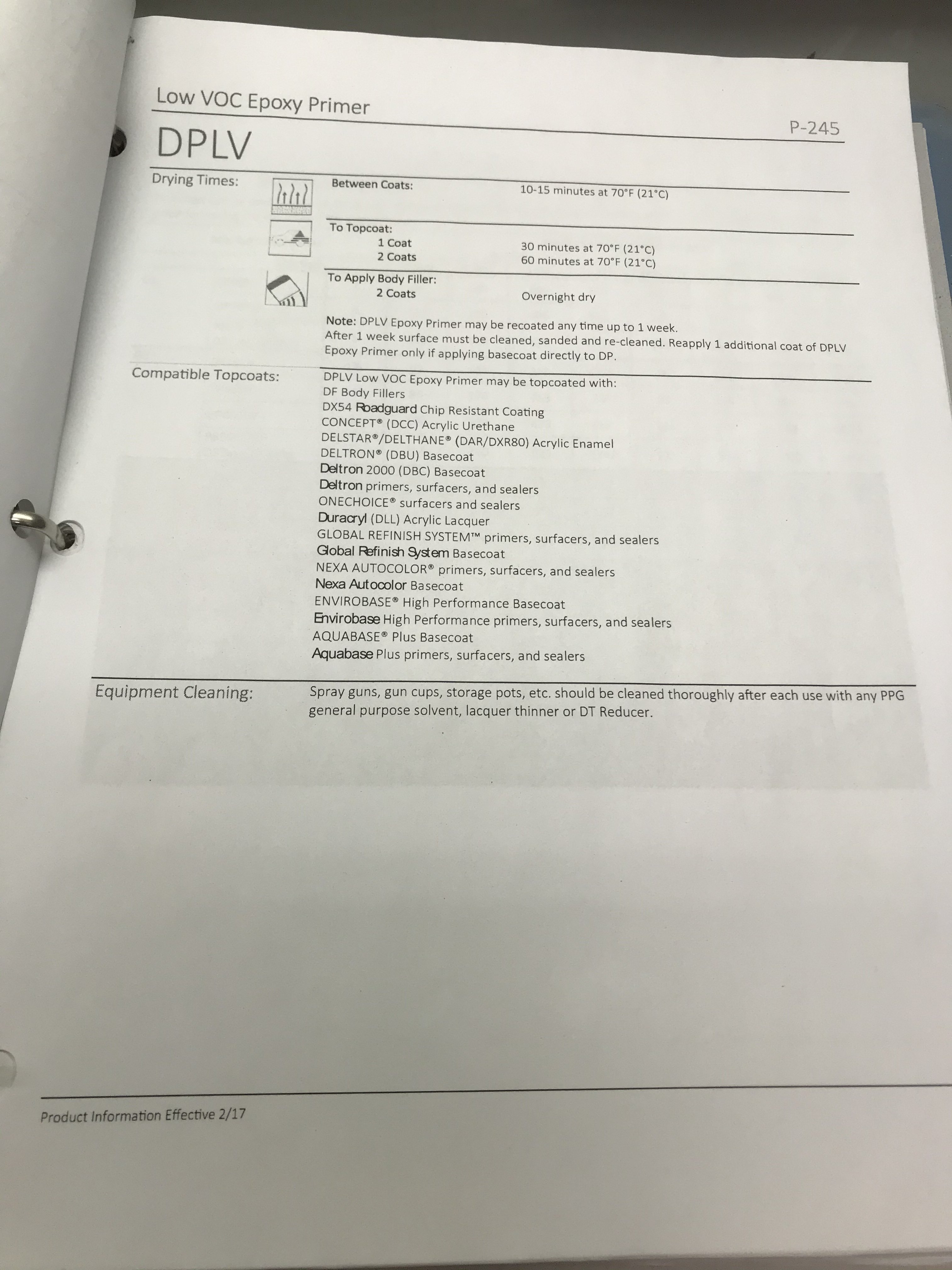

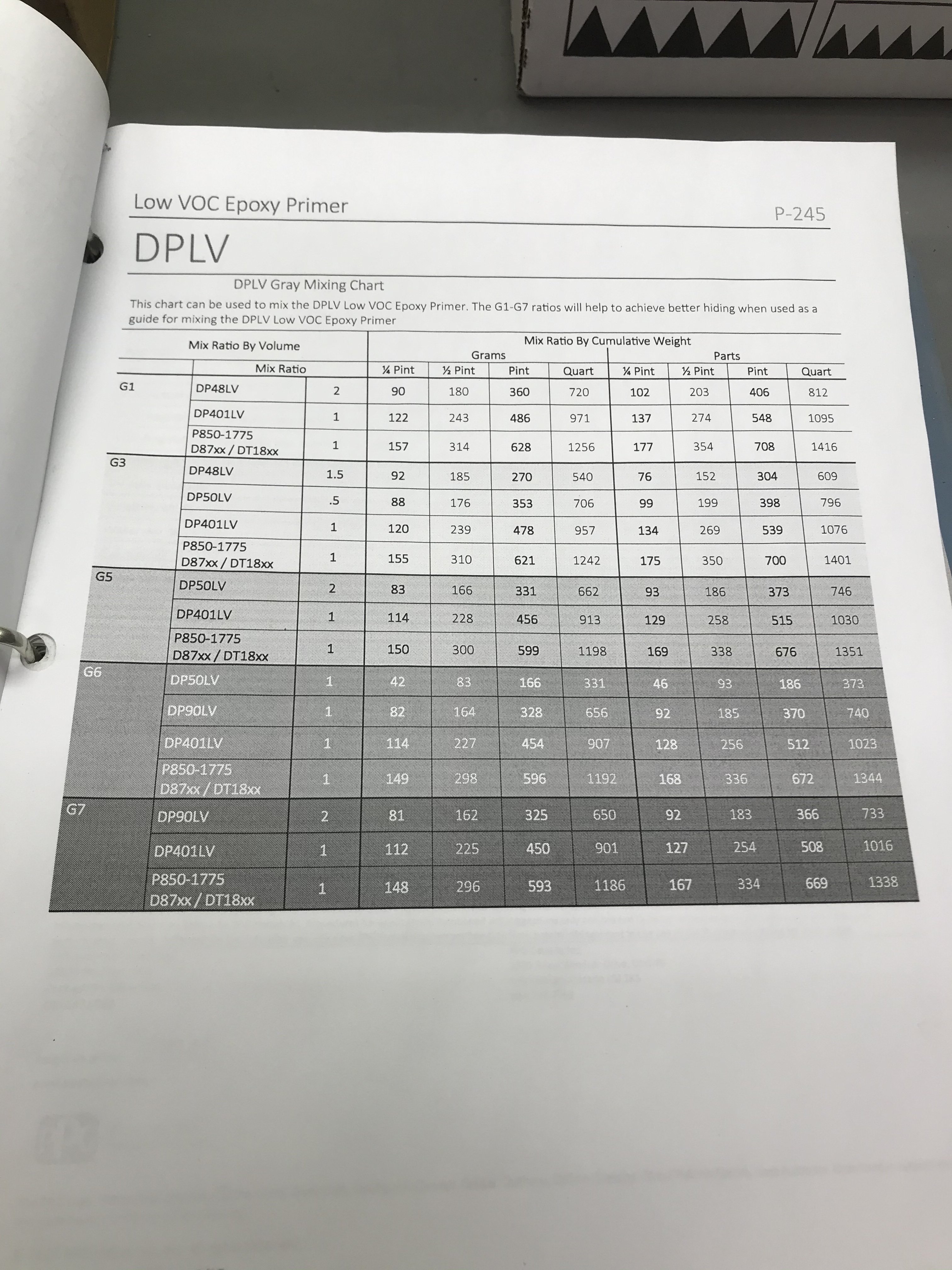

Also shown here for general information, are some pictures of what’s called a “P-Sheet”, it’s available for every professional refinishing product, and is the bible for everything related to it. Number of coats, compatibility’s, flash times, dry times, prep, you name it.

This is the P-sheet for the epoxy I’m using:

Hope this helps answer your questions.

D.