Hey guys

It hasn’t really been all that long since the last update, but things have been a’happenin’ around here at a much better pace lately.

Lots of pics in this one, my apologies in advance if it’s slow to load...

In one of my last updates I mentioned that my good friend and cohort in all things automotive related, Mike, had decided to reinstate garage time on our two projects. Since things have changed a bit in the two years since we last worked on the cars together, “garage nights” which used to happen on Friday nights, have now changed to Sunday afternoon/evenings, so I guess I gotta get used to calling it just “garage time” now instead.

But I digress.

We’ve done sessions on each car already, and when it was Olds Cool’s turn we accomplished quite a bit. Mostly on stuff that I needed an extra set of hands for. We started out by doing a little hammer and dolly work on a few areas, most notably the driver’s quarter/rocker panel area in front of the tire, and on the passenger’s side rear quarter panel where I had welded in the marker light patch. Both areas needed a little work, but access to each area made it a little too tough to get to by myself.

The driver’s side front patch smoothed out nicely without much effort, but the passenger’s side marker light patch was a different story. The more we worked the panel and levelled things out, the more we seemed to accumulate a pretty gnarly lump near the bottom corner of the patch.

Try as we may, it would not go away.

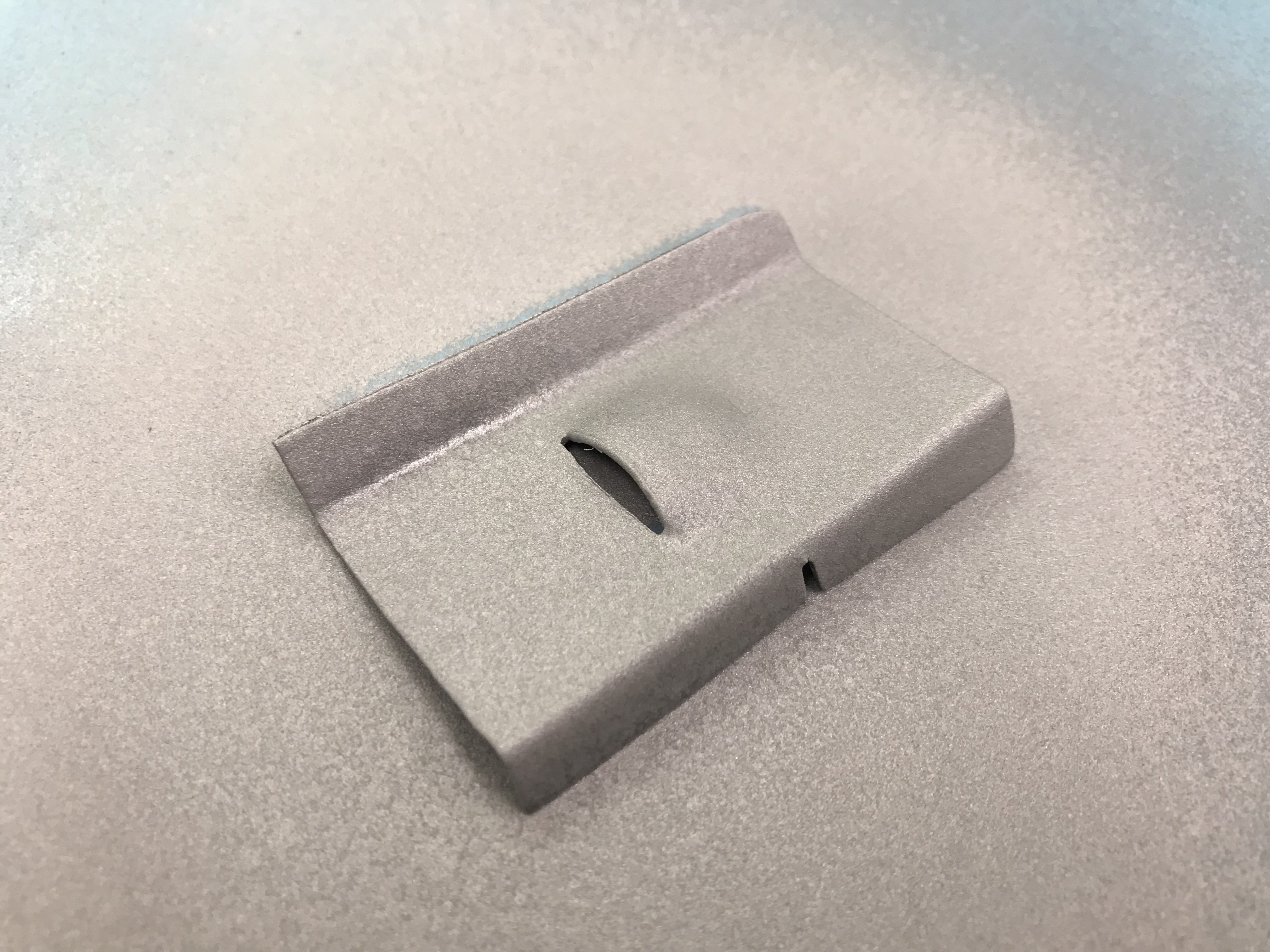

So desperate times call for desperate measures, and we had to break out the torch and do a couple shrinks to get things to pull back into alignment. Here’s a pic of the nastiness once we were done...

Thankfully the shrinks did the trick and we were able to move on.

The next item on my agenda was to finally fix the mess I had going on back on the driver’s side quarter panel, this time on the rear edge of the wheel opening. Someone in the car’s previous life had managed to damage the area pretty badly and while I had tried to repair it as best I could while still driving it, I knew it needed much more attention than I could devote to it at the time.

Here’s the area in question, with the paint stripped off. You can see my obvious (and poor) attempt at trying to get it pulled back into shape:

Knowing that being able to successfully repair this area (especially with the tricky reverse reveal around the opening) with what was existing would be nearly impossible, I reached out to LAX-Rated for a patch panel for the affected area. Thankfully he was able to help out, and sent me a nice rust free piece to use:

Thanks José, much appreciated man!

When I took delivery of the patch several weeks ago, I immediately cut out all the unneeded stuff from the backside and stripped the paint from the front.

Now that I finally had a nice piece to use on this area, Mike and I wasted no time on paring it down to size and cutting the damaged crap out:

Initially, the curvature of the patch along the inner flange didn’t jive well with what was on the car, but after tweaking it just a bit with the shrinking jaws in my shrinker/stretcher, it lined up beautifully.

Working slowly and methodically, we got the new piece fit nicely and tacked it in.

I spent the next few nights continuing to fully weld it in, as well as spent considerable time cleaning up and straightening out the pinch weld below. Here’s the completed repair and areas:

I can honestly say, after three years of looking at this nasty spot, I was more than happy to finally have it properly fixed and crossed off the list!

Moving back over to the passenger’s side quarter, I wanted to repeat the pinch weld cleanup and straightening...

...but with one minor little speed bump. I had a spot where the cancer bit a little too deep.

So out came the cutting tools, and away it went.

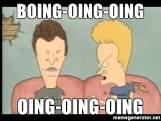

Tonight after welding up the fender trim holes and repairing the bottom lower corner of the wheelwell flange, I fabricated a little patch for the rusted area. I made sure to duplicate the proper size and shape of the drain hole, and then clamped it up for a test fit:

Satisfied that it would work alright, I removed it and prepped the two areas as I always do...

...then started tacking and welding it in.

This is where I’m currently at, it’s obviously not done yet, but it’s getting pretty close.

If you can’t tell already, my big push is to get the last of the metal work done on the back end of the car before Sunday. When Mike shows up Sunday afternoon, I want the two of us to be able to dive straight into the filler work again at long last. Barring any unforeseen issues, I think I’m on track for this at this point.

🙂

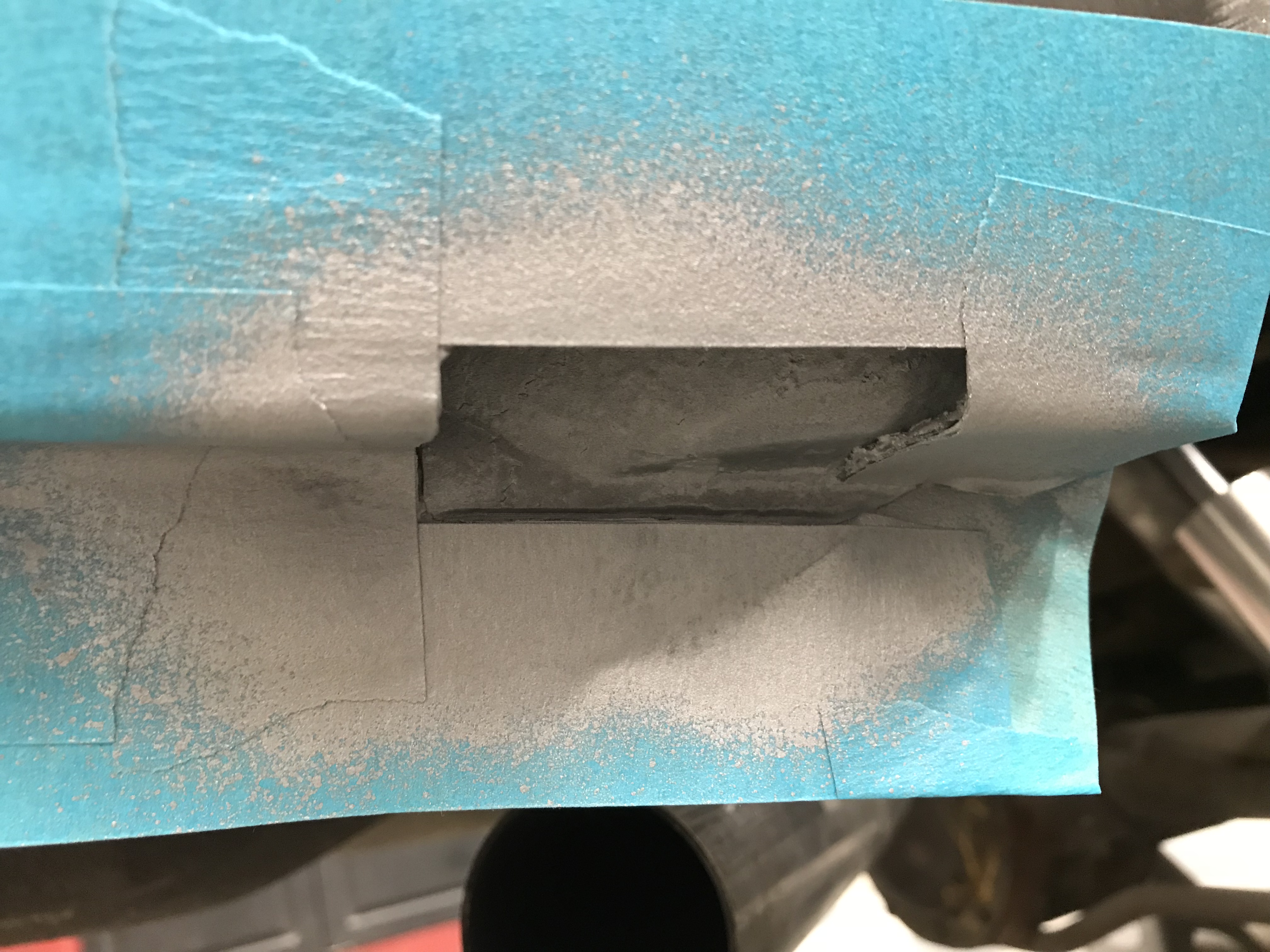

In other news, a package arrived today from Timo, he came through big time for me in locating and shipping a set of increasingly rare clips for the filler panel between the back window and trunk lid. These are the correct ones that are needed for use on non-vinyl roof, hardtop cars.

Thanks Tim!!!

That’s all I’ve got for now guys, stay tuned, hopefully by Sunday we can start rocking on the filler work on the quarter panels!

Primer on the back half of the car may not be in the too far distant future...

D.