Well I got about 90 mins this morning to work on the car. The block and all the parts are painted. I even got a chance to bake the smaller parts at 160 deg for a couple hours at work Friday night and then applied the engine enamel clearcoat which I hope will help with the intake and valve covers staying clean for longer.

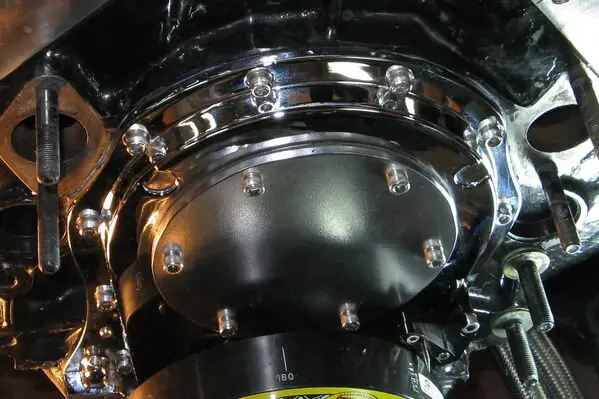

New cam went in without a hitch in a couple minutes. The rest of the time was spent trying to get the darn cam button clearance sorted out. I started with button appx 5/16" too long by installing the cam gear with button and trying to install the timing cover overtop with a couple bolts until it was even all around and measuring the gap. I don't have a lathe and the drill press is at work ( and my micrometer too ! ). Finally I figured to put timing gear in the vice with wood blocks. I cut a circle out of 1/4" plywood and drilled a hole in the centre. The plywood was then placed on the gearface with the cam button popped up in the hole I drilled. This way I could file the cam button straight and smooth as the plywood would keep it both level and square. Once close I stuck some plumbing putty on the backside of the timing cover and kept filing it down until I got it to where there was almost perfect ( where it would push out 99% of all the plumbers putty showing the timing cover underneath ) It took quite a few tries to get it all dialed in. From what I have read the gasket thickness will make up the 0.05 -0.10 clearance I need.

The lifters are now taking an oil bath with the pushrods and I hope to get those in tomorrow night. I am going to enjoy the rest of the day off and head out fishing for a couple hours ! I figure with an hour here and hour there I should have this running by next weekend. The cam button was the only thing that I was unfamiliar with so now that's over and I can make some progress 🙂

New cam went in without a hitch in a couple minutes. The rest of the time was spent trying to get the darn cam button clearance sorted out. I started with button appx 5/16" too long by installing the cam gear with button and trying to install the timing cover overtop with a couple bolts until it was even all around and measuring the gap. I don't have a lathe and the drill press is at work ( and my micrometer too ! ). Finally I figured to put timing gear in the vice with wood blocks. I cut a circle out of 1/4" plywood and drilled a hole in the centre. The plywood was then placed on the gearface with the cam button popped up in the hole I drilled. This way I could file the cam button straight and smooth as the plywood would keep it both level and square. Once close I stuck some plumbing putty on the backside of the timing cover and kept filing it down until I got it to where there was almost perfect ( where it would push out 99% of all the plumbers putty showing the timing cover underneath ) It took quite a few tries to get it all dialed in. From what I have read the gasket thickness will make up the 0.05 -0.10 clearance I need.

The lifters are now taking an oil bath with the pushrods and I hope to get those in tomorrow night. I am going to enjoy the rest of the day off and head out fishing for a couple hours ! I figure with an hour here and hour there I should have this running by next weekend. The cam button was the only thing that I was unfamiliar with so now that's over and I can make some progress 🙂

2 toolboxes and 3 cabinets at home + 1 toolbox and 2 cabinets at work and its in none of them. For now I timed it with the vacuum guage for the highest reading and smoothest idle with an easy re-start without touching the previous carb setting.

2 toolboxes and 3 cabinets at home + 1 toolbox and 2 cabinets at work and its in none of them. For now I timed it with the vacuum guage for the highest reading and smoothest idle with an easy re-start without touching the previous carb setting.