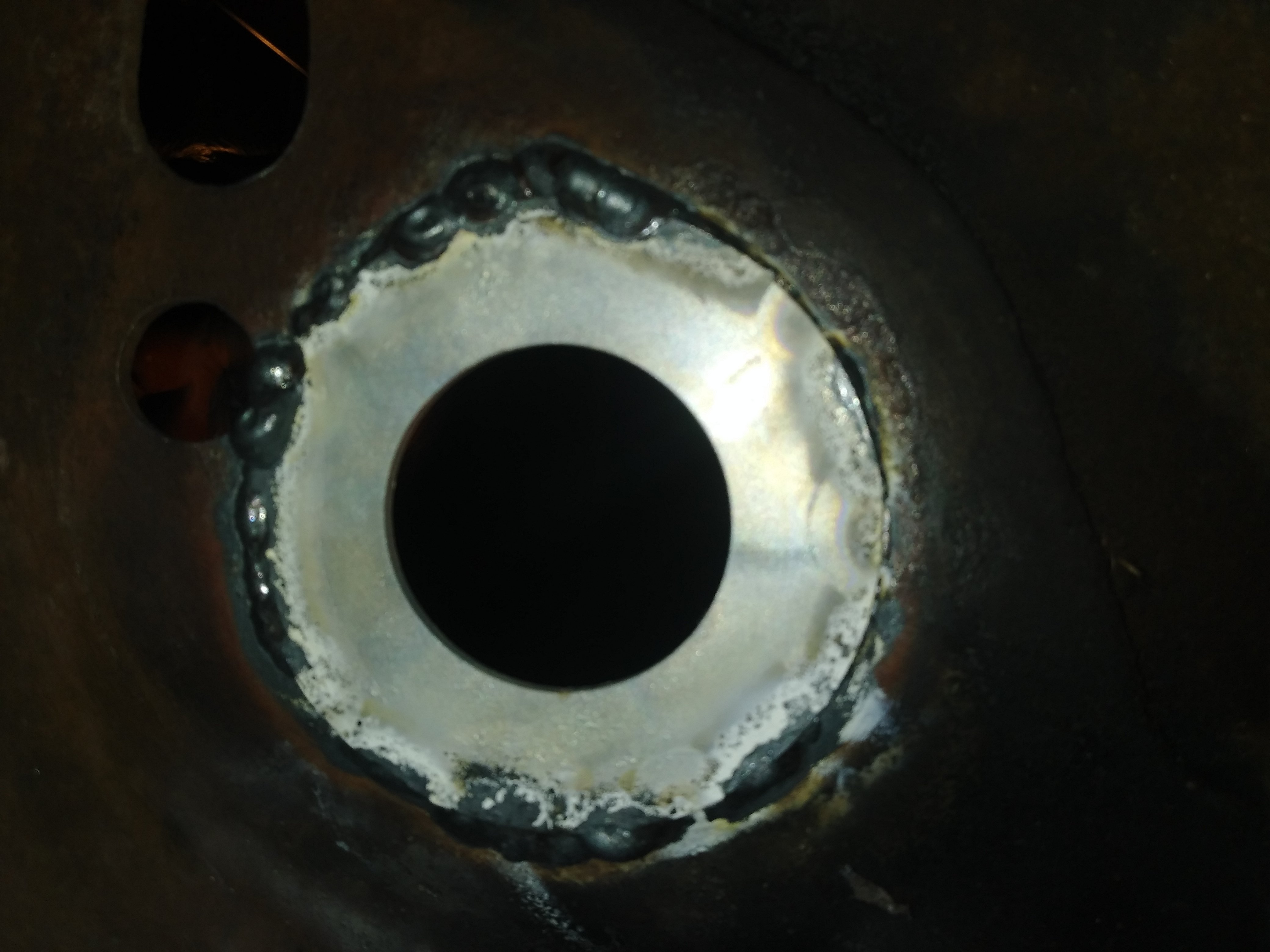

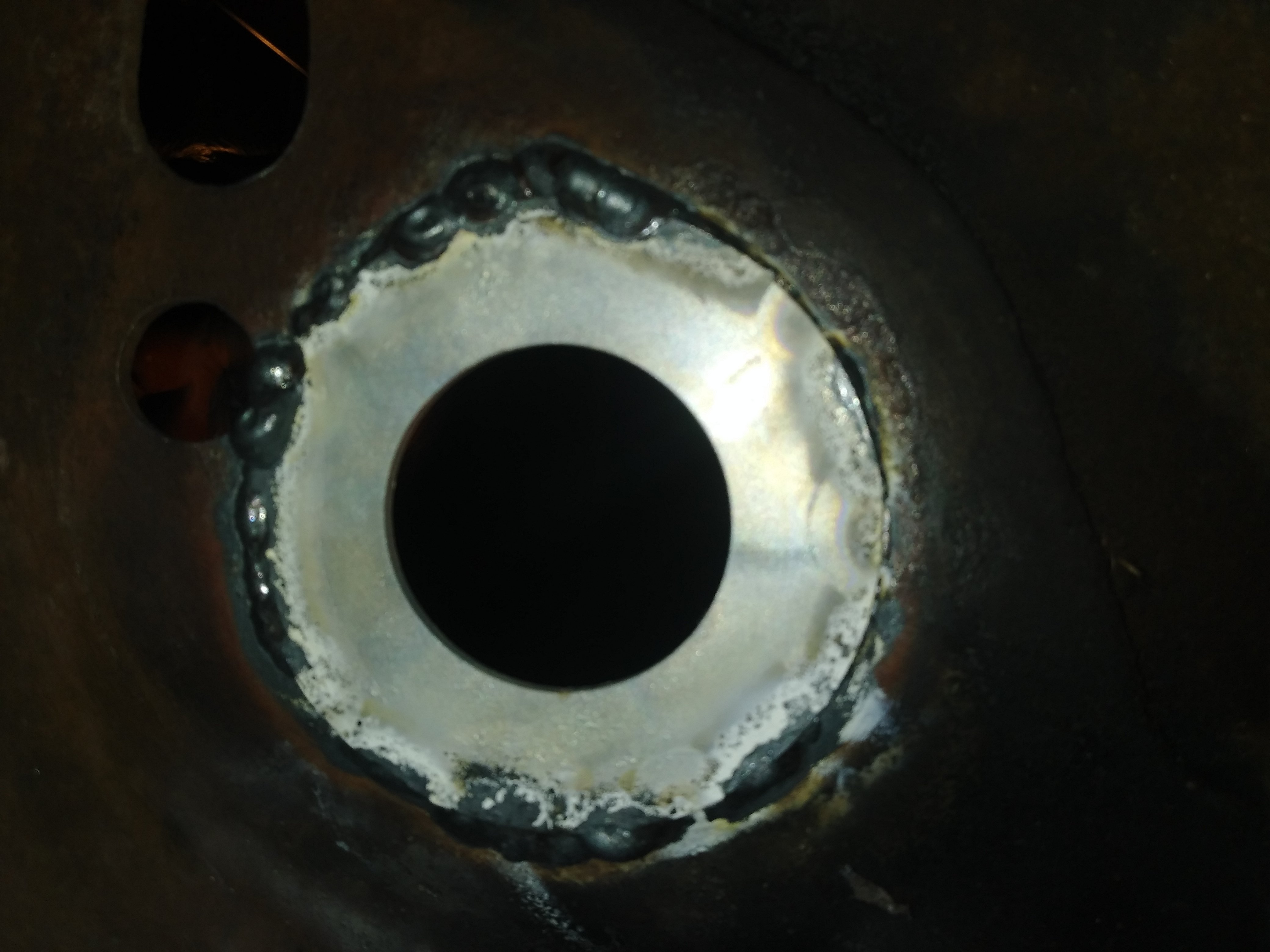

Well you know when you wanna try something but everything you've read says not to try it. Well I tried it lol. It didn't work out so well. Im talking about fixing my body mount holes on the frame. I have .025 wire in the machine. I didn't wanna switch it to .035(lazy) so I tried to burn it in with 025 on my 110 mig. And penetration is lacking unfortunately. So i have to grind it down and redo.

I think im gonna get a roll of flux core to burn in the frame since that's what i read you need. Shortcuts and bein lazy never work for me, yet ill still try. Why? IDK.

I also got the back seat patched up. I butted the patch at the bottom and lapped it on top. It turned out pretty good. Here it is cut out and halfway fit.

Welded in.

Driver side

I also got the trunk completely welded in. I had 1 small patch to make.

Question to the body guys. What should I use to cover the welds in the wheelhouse and trunk? Kitty/tiger hair? All metal filler? Ill ground it down mostly flat. I just wanted to make it look a little better and be as resistant to water as possible. Thanks

I think im gonna get a roll of flux core to burn in the frame since that's what i read you need. Shortcuts and bein lazy never work for me, yet ill still try. Why? IDK.

I also got the back seat patched up. I butted the patch at the bottom and lapped it on top. It turned out pretty good. Here it is cut out and halfway fit.

Welded in.

Driver side

I also got the trunk completely welded in. I had 1 small patch to make.

Question to the body guys. What should I use to cover the welds in the wheelhouse and trunk? Kitty/tiger hair? All metal filler? Ill ground it down mostly flat. I just wanted to make it look a little better and be as resistant to water as possible. Thanks