Thanks! I think that’s another reason why I’ve been holding off on modifications for now. There are quite a few things I could probably do on the cheap right now, but none of them support my future plans. What I should have learned in my Teenage years with this car, is it doesn’t make sense to spend money twice, just because you cheeped out the first time.

BUILD THREAD Street/Strip Cutlass Build: Race it, break it, fix it, repeat.

- Thread starter Kwik_Cutty88

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I've been busy!

I caved and ordered some things. I've been wanting to do EFI on this car for a while now. As usual, the snowball effect happened.

I want EFI, I need an EFI suitable fuel system, and wanted one with an in-tank pump. Since I'm converting to an electric pump, I wanted a more robust electrical system, and a shutoff switch to kill the pump if needed.

So I ordered a Taylor trunk mount battery kit, and a jegs shutoff kit. I opted for 1/0AWG type SGX battery cable, which is what some OEM's use. It is fluid and abrasion resistant. Of course I got some DEI heat sleeving and P clamps to route it clean.

I ordered an Aeromotive Stealth fuel tank with a 340LPH pump, although its on backorder 🙁

And the part I'm most excited about, Holley Terminator X-Max Stealth EFI. Unfortunately, also on backorder. The X-Max has transmission control capability so I can swap a 4L80E later on.

While I'm waiting for my tank and EFI, I made a bracket to mount the battery box in the trunk. I figured it would be easier to bolt into the car.

Just a quick mockup with some scraps I had laying around for proof of concept.

I ended up cutting off the hook for the spare tire. This car will never have a spare mounted here again.

A quick mockup shot with the rough location of the battery shutoff switch.

Starting to bend and cut the real material now. The black straps are some old bracket I had in the garage, I don't remember what its from, but it was nice 1/8" thick material. The strap on the left side of the photo is just 1.5"x1/8" thick strap from the hardware store. You can see where I cut the seam sealer on the right side of the trunk. I originally had the brackets a little longer, but ended up shortening them up. 4 bolts hold this bracket in the car.

Adding in the cross bars and starting to burn it in. I know, my welds are BAD. This is my first welding project.

Here's a couple shots of the bracket out of the car. Not pictured, I decided to weld in some triangular gussets on the two upright brackets. It stiffened up the whole thing a little bit.

Here it is all painted, with the battery tray bolted to it. I'm not 100% sure what I'm going to do with the carpet yet, but this looks pretty nice. I forgot to get a photo, but I cut out the sheet metal and welded a small patch in to cover up the holes left by the spot welds on the spare tire mount.

Was this a little more complex than just bolting the battery straight down into the spare tire well? Maybe, but I wanted to use a battery box so I could avoid the NHRA rear firewall requirement. Sure I could have cut the spare tire well and welded a delete plate in, but I wanted to keep the battery box accessible, but out of the way and maintain as much trunk space as possible.

I caved and ordered some things. I've been wanting to do EFI on this car for a while now. As usual, the snowball effect happened.

I want EFI, I need an EFI suitable fuel system, and wanted one with an in-tank pump. Since I'm converting to an electric pump, I wanted a more robust electrical system, and a shutoff switch to kill the pump if needed.

So I ordered a Taylor trunk mount battery kit, and a jegs shutoff kit. I opted for 1/0AWG type SGX battery cable, which is what some OEM's use. It is fluid and abrasion resistant. Of course I got some DEI heat sleeving and P clamps to route it clean.

I ordered an Aeromotive Stealth fuel tank with a 340LPH pump, although its on backorder 🙁

And the part I'm most excited about, Holley Terminator X-Max Stealth EFI. Unfortunately, also on backorder. The X-Max has transmission control capability so I can swap a 4L80E later on.

While I'm waiting for my tank and EFI, I made a bracket to mount the battery box in the trunk. I figured it would be easier to bolt into the car.

Just a quick mockup with some scraps I had laying around for proof of concept.

I ended up cutting off the hook for the spare tire. This car will never have a spare mounted here again.

A quick mockup shot with the rough location of the battery shutoff switch.

Starting to bend and cut the real material now. The black straps are some old bracket I had in the garage, I don't remember what its from, but it was nice 1/8" thick material. The strap on the left side of the photo is just 1.5"x1/8" thick strap from the hardware store. You can see where I cut the seam sealer on the right side of the trunk. I originally had the brackets a little longer, but ended up shortening them up. 4 bolts hold this bracket in the car.

Adding in the cross bars and starting to burn it in. I know, my welds are BAD. This is my first welding project.

Here's a couple shots of the bracket out of the car. Not pictured, I decided to weld in some triangular gussets on the two upright brackets. It stiffened up the whole thing a little bit.

Here it is all painted, with the battery tray bolted to it. I'm not 100% sure what I'm going to do with the carpet yet, but this looks pretty nice. I forgot to get a photo, but I cut out the sheet metal and welded a small patch in to cover up the holes left by the spot welds on the spare tire mount.

Was this a little more complex than just bolting the battery straight down into the spare tire well? Maybe, but I wanted to use a battery box so I could avoid the NHRA rear firewall requirement. Sure I could have cut the spare tire well and welded a delete plate in, but I wanted to keep the battery box accessible, but out of the way and maintain as much trunk space as possible.

Very nice!!

Which Terminator part number did you order? You can use most any of them and swap injector plugs if needed. I just bought a Term X (no trans control) and had it in 5 days, but others are mission impossible to get.

You can use about any of the Term X Max setups and swap stuff very easily. I have a 24X setup for truck injectors that I swapped to a 58x motor with EV1 injector plugs.

What are you running for intake, injectors and TB (or planning to run)? I like the battery box giddyup - nice work!!

Which Terminator part number did you order? You can use most any of them and swap injector plugs if needed. I just bought a Term X (no trans control) and had it in 5 days, but others are mission impossible to get.

You can use about any of the Term X Max setups and swap stuff very easily. I have a 24X setup for truck injectors that I swapped to a 58x motor with EV1 injector plugs.

What are you running for intake, injectors and TB (or planning to run)? I like the battery box giddyup - nice work!!

I ordered 550-1012. Which is going on my carb’ed small block. Part of the reason I ordered this one was to be able to swap engine harnesses and put it on an LS later on.Very nice!!

Which Terminator part number did you order? You can use most any of them and swap injector plugs if needed. I just bought a Term X (no trans control) and had it in 5 days, but others are mission impossible to get.

You can use about any of the Term X Max setups and swap stuff very easily. I have a 24X setup for truck injectors that I swapped to a 58x motor with EV1 injector plugs.

What are you running for intake, injectors and TB (or planning to run)? I like the battery box giddyup - nice work!!

EDIT: I forgot to add, I’ll be controlling the timing by swapping to a GM Small Cap Distributor

Just skimmed the manual. So this will run coil packs and can trigger off from a cam and crank sensor as needed as well.

Very neat. And it appears it will work as a blow through setup as well if you wanted to.

Very neat. And it appears it will work as a blow through setup as well if you wanted to.

Will also support nitrous 🙂Just skimmed the manual. So this will run coil packs and can trigger off from a cam and crank sensor as needed as well.

Very neat. And it appears it will work as a blow through setup as well if you wanted to.

I really liked how feature packed it was compared to the sniper or terminator tbi.

Yes and no. 4 extra inputs and outputs seems like a lot of them until you need more lol.

I can't speak of the TB setup (plenty of extra $$), but to run a multiport setup and 4l60/80/85, there is nothing cheaper. And it's extremely user friendly. There are a couple of things about it that could and should be better, but as a hole it's a great deal. There is one thing in particular that makes it crazy good - you can run multiple outputs from a single output. For example, I have launch timing retard, boost building when on the transbrake, two step and boost control all initiated by one input. Getting a new harness and wideband sensor is the deal maker. No one else is close to the same quality and functionality for the price.

On the other hand, I cannot use the dome control/boost setup unless it's initiated by the transbrake release - kinda silly. My son has an MS3X that does all of the same outputs and each is on a seperate button, but if I flip a switch while driving I can go to boost control by rpm, TPS or just full on with full feedback control. All the of the safety settings are the same .

No matter about that - you'll be happy as hell with the Holley. Lose the dizzy ad go with junkyard coil packs. 5 times the spark for little to no money. And yes, nitrous is a breeze with the Term X.

I can't speak of the TB setup (plenty of extra $$), but to run a multiport setup and 4l60/80/85, there is nothing cheaper. And it's extremely user friendly. There are a couple of things about it that could and should be better, but as a hole it's a great deal. There is one thing in particular that makes it crazy good - you can run multiple outputs from a single output. For example, I have launch timing retard, boost building when on the transbrake, two step and boost control all initiated by one input. Getting a new harness and wideband sensor is the deal maker. No one else is close to the same quality and functionality for the price.

On the other hand, I cannot use the dome control/boost setup unless it's initiated by the transbrake release - kinda silly. My son has an MS3X that does all of the same outputs and each is on a seperate button, but if I flip a switch while driving I can go to boost control by rpm, TPS or just full on with full feedback control. All the of the safety settings are the same .

No matter about that - you'll be happy as hell with the Holley. Lose the dizzy ad go with junkyard coil packs. 5 times the spark for little to no money. And yes, nitrous is a breeze with the Term X.

The new CAN BUS box they just came out with that add's some extra I/O's looks neat also.Yes and no. 4 extra inputs and outputs seems like a lot of them until you need more lol.

I can't speak of the TB setup (plenty of extra $$), but to run a multiport setup and 4l60/80/85, there is nothing cheaper. And it's extremely user friendly. There are a couple of things about it that could and should be better, but as a hole it's a great deal. There is one thing in particular that makes it crazy good - you can run multiple outputs from a single output. For example, I have launch timing retard, boost building when on the transbrake, two step and boost control all initiated by one input. Getting a new harness and wideband sensor is the deal maker. No one else is close to the same quality and functionality for the price.

On the other hand, I cannot use the dome control/boost setup unless it's initiated by the transbrake release - kinda silly. My son has an MS3X that does all of the same outputs and each is on a seperate button, but if I flip a switch while driving I can go to boost control by rpm, TPS or just full on with full feedback control. All the of the safety settings are the same .

No matter about that - you'll be happy as hell with the Holley. Lose the dizzy ad go with junkyard coil packs. 5 times the spark for little to no money. And yes, nitrous is a breeze with the Term X.

My fuel injection FINALLY showed up after 5 months. The throttle body looks really cool. But unfortunately its a paper weight until my fuel tank from Aeromotive comes in (going on nearly 7 months now!) I did order the fuel pressure regulator already, and started planning out my lines. I'll order everything soon.

Anyway, I decided that I'd be able to complete the trunk mount battery and engine harness re-wiring. Here are some photos. I think it came out pretty clean. I ended up having to buy a 4 pole switch so I can shut the alternator "off" as well, you can't do that with a 2 pole switch and 3 wire alternator.

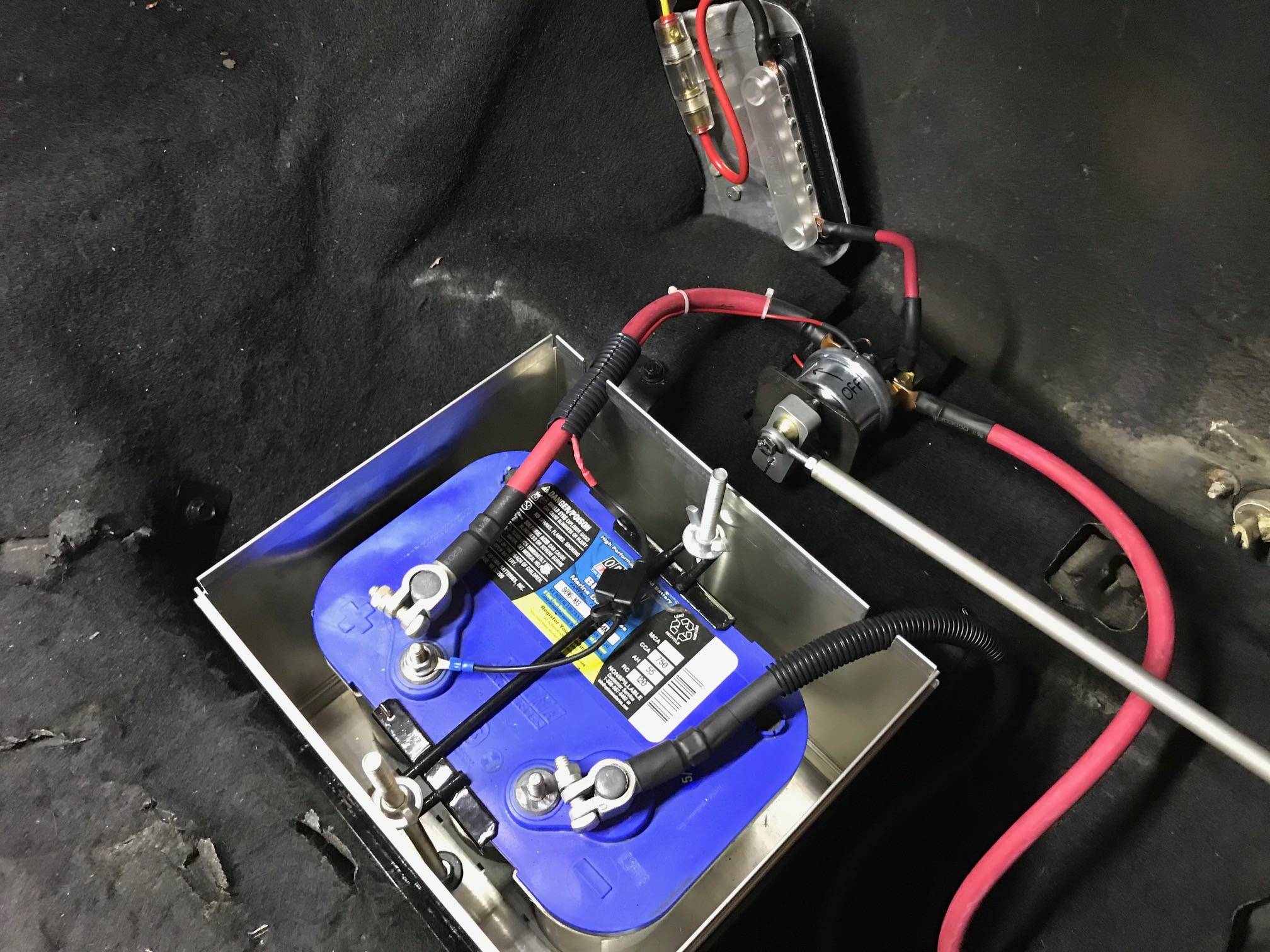

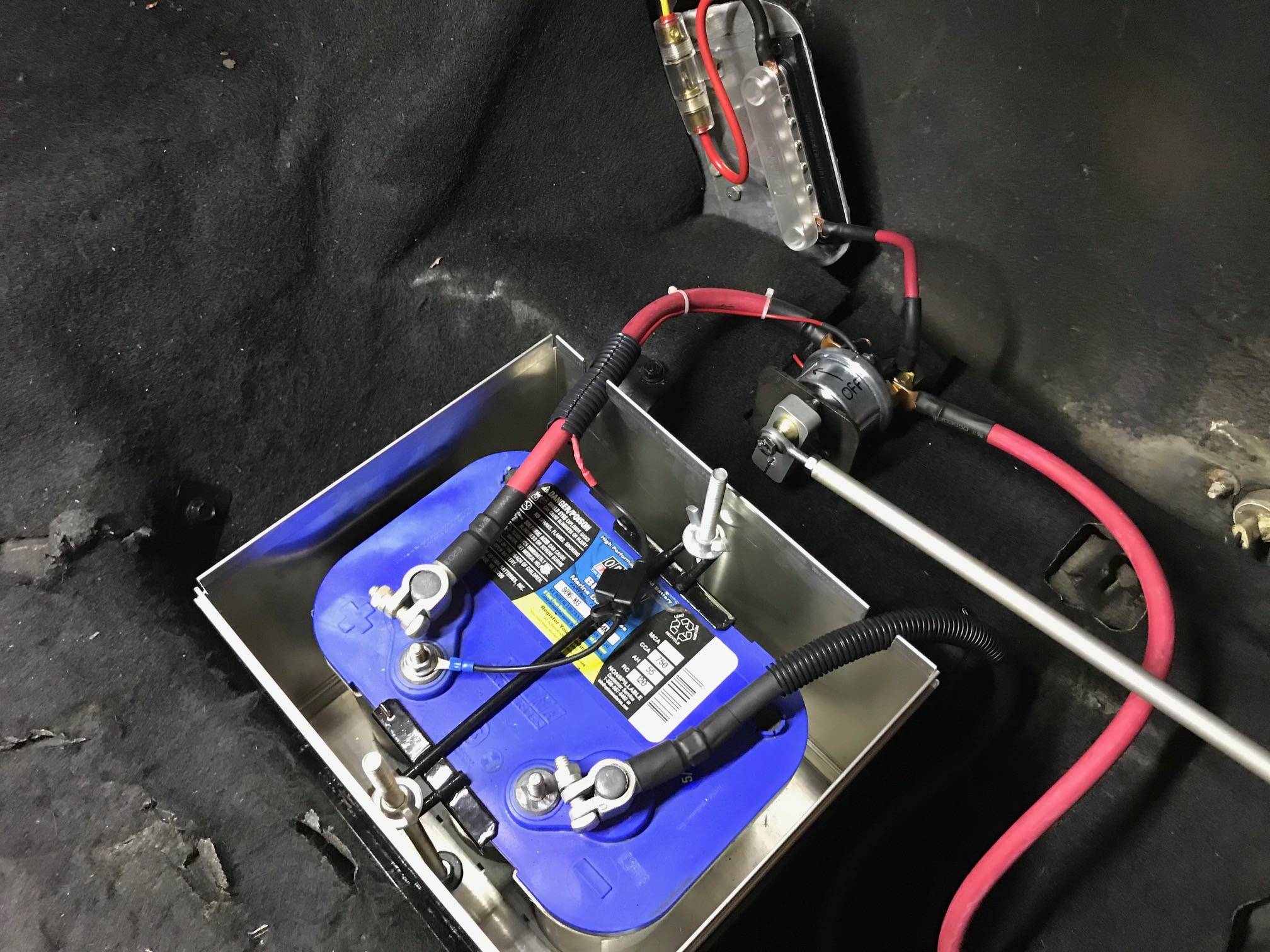

The battery box is tucked up nicely in the old spare tire well. The shutoff switch is welded directly to the body. Super sturdy. Everything is out of the way, there is still plenty of trunk space, just what I was going for. The battery cable termination came out nice as well. All 1/0AWG type SGX battery cable. Everything is wrapped in split loom front to back, and where the cables run near the engine is in DEI heat sleeve.

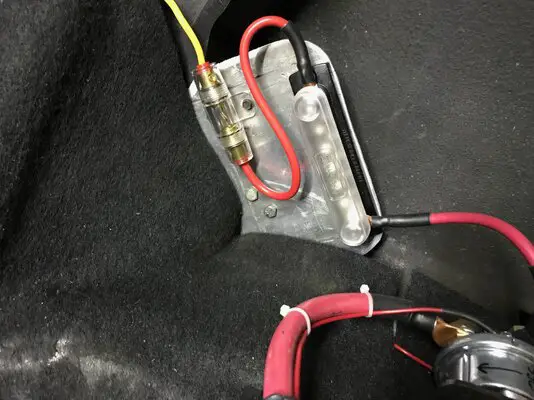

Inside the battery box is pretty clean, there is one fuse holder to fuse the "hot" wire to the alternator plug. You can see the panel I made to hold a small distribution block and the amplifier fuse holder.

I used waterproof grommets to pass the cables into the car.

The engine bay cleaned up nicely. There is one relay mounted on the firewall (you can't see it from here) to power the choke. Hopefully that'll be gone soon. I moved my vacuum tank to under the car just in front of the drivers side tire

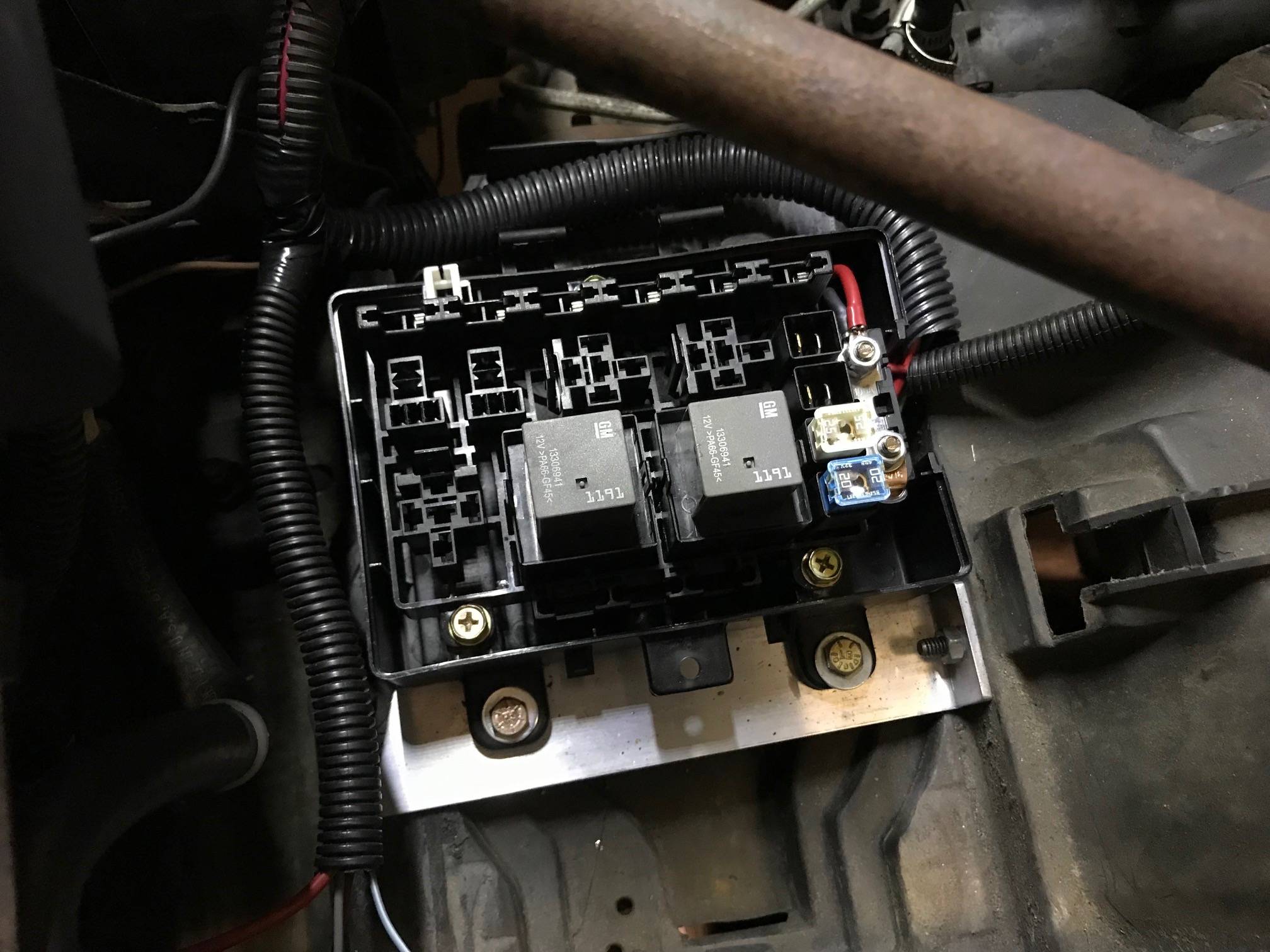

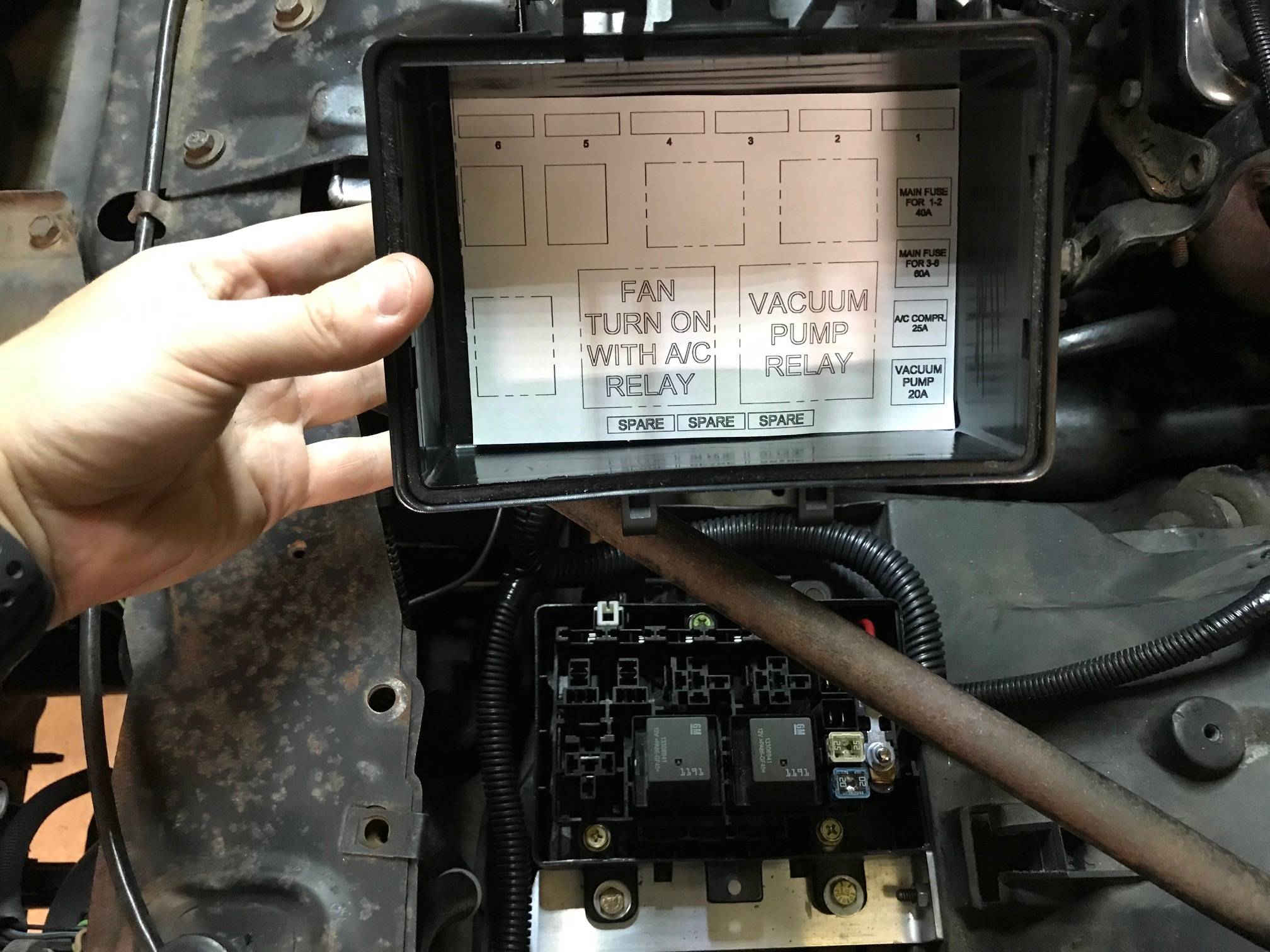

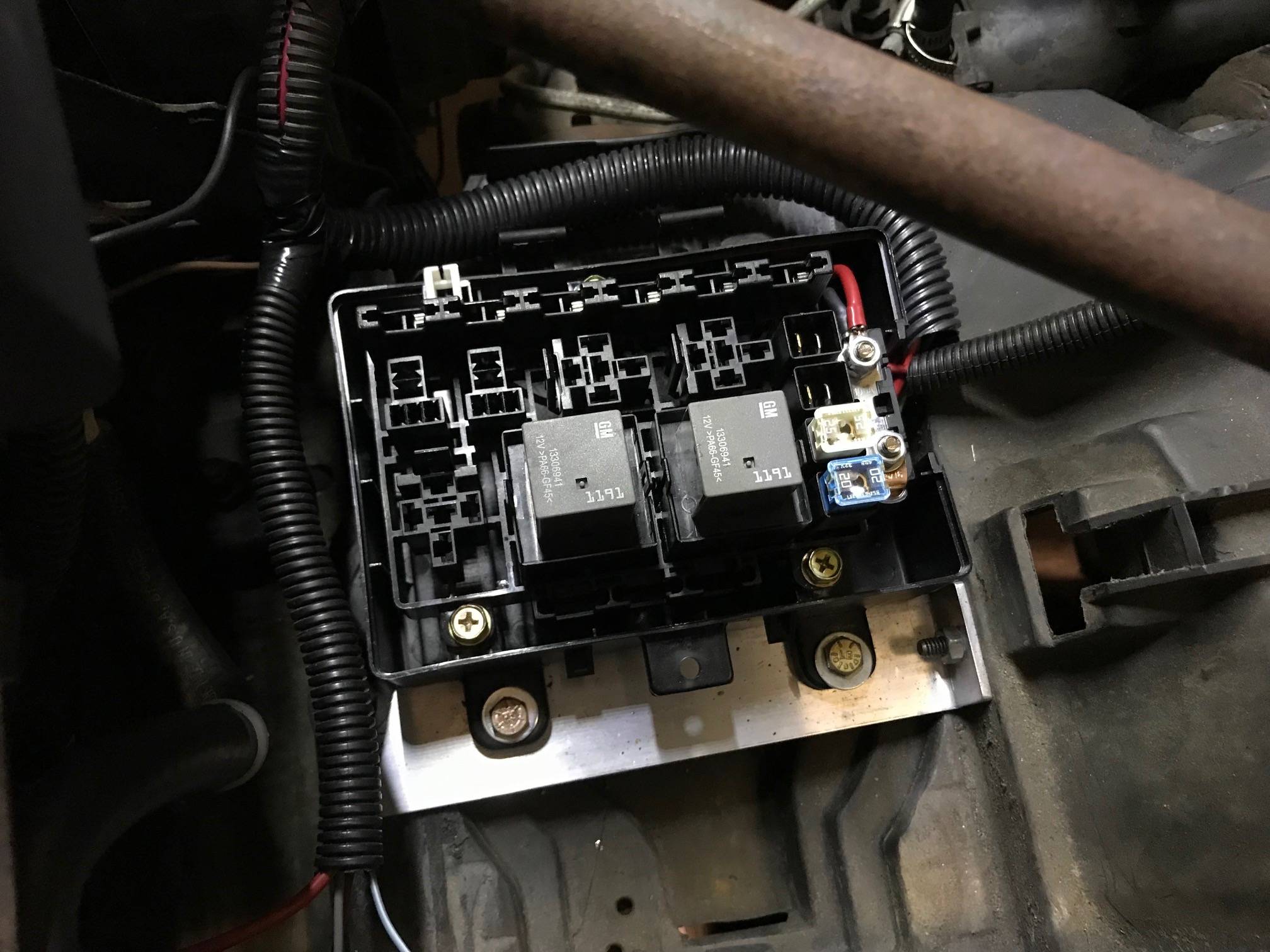

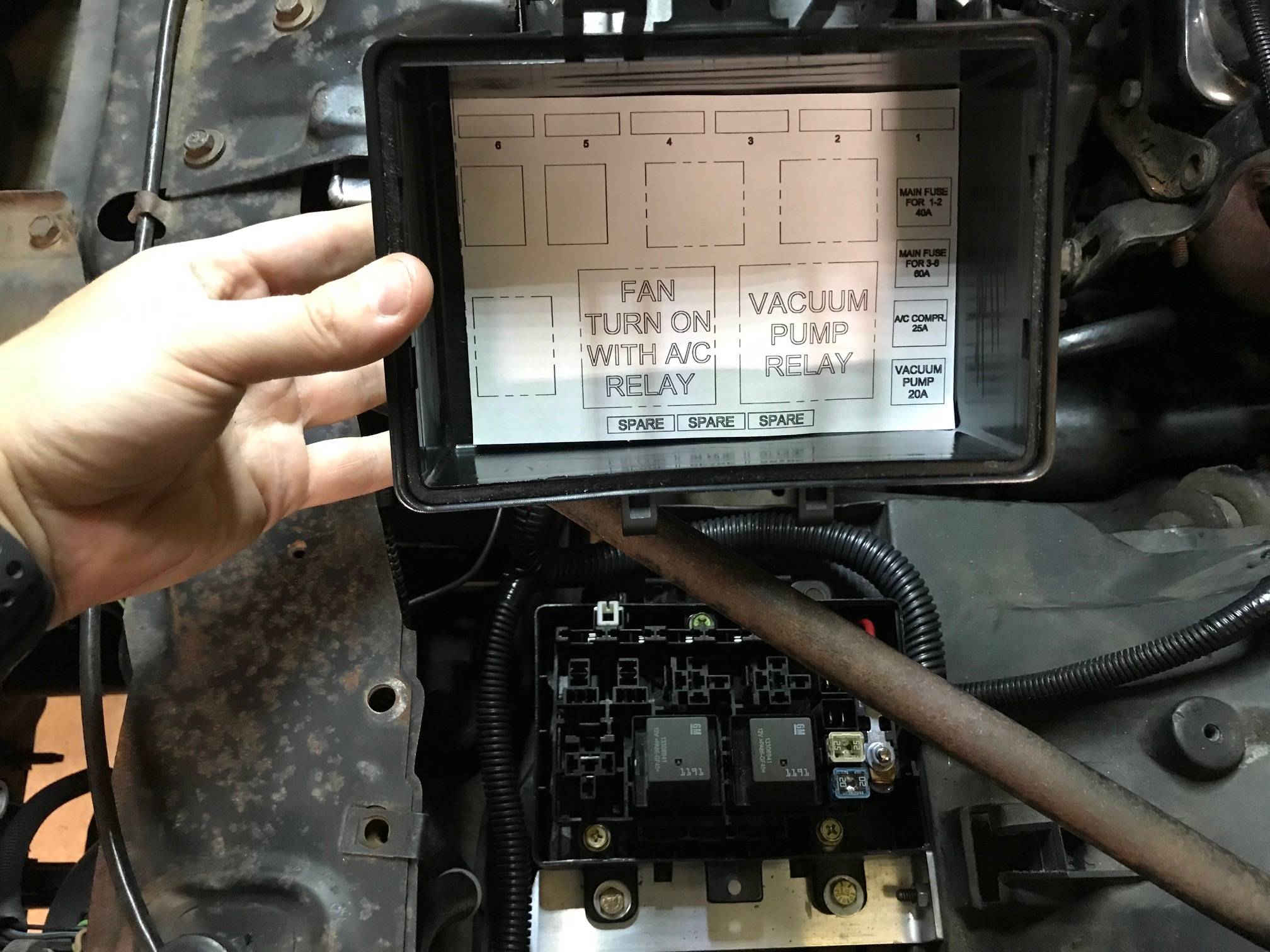

This cheap amazon fuse box worked out really well. Mounted where the battery used to be.

I drew up a diagram in fusion 360 just to keep track of things. I'll revise it as I add components. The pull handle came out nice also. In this photo it is in the "ON" position, so it does not stick out far at all. That sticker is actually a magnet, so I can take it off when not at the track.

And a little bonus. I found a deal I could not pass up on two of these NX bottles with upgraded valves. My recent plan was nitrous anyway, but these will sit around while I get the car up and running on EFI. I plan to design the fuel system around adding the nitrous later on.

Anyway, I decided that I'd be able to complete the trunk mount battery and engine harness re-wiring. Here are some photos. I think it came out pretty clean. I ended up having to buy a 4 pole switch so I can shut the alternator "off" as well, you can't do that with a 2 pole switch and 3 wire alternator.

The battery box is tucked up nicely in the old spare tire well. The shutoff switch is welded directly to the body. Super sturdy. Everything is out of the way, there is still plenty of trunk space, just what I was going for. The battery cable termination came out nice as well. All 1/0AWG type SGX battery cable. Everything is wrapped in split loom front to back, and where the cables run near the engine is in DEI heat sleeve.

Inside the battery box is pretty clean, there is one fuse holder to fuse the "hot" wire to the alternator plug. You can see the panel I made to hold a small distribution block and the amplifier fuse holder.

I used waterproof grommets to pass the cables into the car.

The engine bay cleaned up nicely. There is one relay mounted on the firewall (you can't see it from here) to power the choke. Hopefully that'll be gone soon. I moved my vacuum tank to under the car just in front of the drivers side tire

This cheap amazon fuse box worked out really well. Mounted where the battery used to be.

I drew up a diagram in fusion 360 just to keep track of things. I'll revise it as I add components. The pull handle came out nice also. In this photo it is in the "ON" position, so it does not stick out far at all. That sticker is actually a magnet, so I can take it off when not at the track.

And a little bonus. I found a deal I could not pass up on two of these NX bottles with upgraded valves. My recent plan was nitrous anyway, but these will sit around while I get the car up and running on EFI. I plan to design the fuel system around adding the nitrous later on.

Attachments

My fuel injection is installed and complete! I've only driven it around 20-30 miles, but I'm already impressed.

I'll work from back to front with the photos here. Here's a quick shot of the aeromotive tank. Nice piece, not sure if it was worth the 7 month wait. That's a 340LPH pump in there, -6AN feed/return. One thing that frustrated me: see that black aeromotive aluminum piece there to the right of the top hat? That is the sender, and it hits the floor brace on the trunk pan. We had to cut that out in order to get the tank to fit right. I feel like if these are advertised as a direct fit, I shouldn't have to do that. I opted to use the factory 3/8" feed hardline as the return, and I ran a new 3/8" aluminum hard line as the feed. I wanted the lines tucked up and out of the way, and the way the frame rails are on these cars are, I felt it was a lot easier to fit two 3/8" hardlines rather that 2 -6 lines that are like 5/8" OD. I used 3/8" to -6 hardline adapters.

The fuel filter is mounted just in front of the passenger rear tire. I ended up having this plastic bracket laying around from something. Some sort of fuel filter bracket, but it worked really nice. You can see the hardline adapters better here. I think they are rated to like 250PSI, and they don't leak.

Just another quick shot of the fuel line routing. The new hard line pretty much follows the old one. I cut out the original 1/4" return line to make room here. The factory double clips were cut and p clamps added to hold the new line. Where the wiring harness passes near the headers, I used velcro heat wrap. This kind is the summit brand, not terrible quality, should do the job.

Another "I had this laying around" that worked so well. This 90 degree grommet. The engine harness passes right through the factory hole in the firewall, and sealed up nice. Again, velcro heat wrap just in case.

Now the throttle body itself. Nothing really to see here. I used a trick flow throttle bracket. Its designed to work with traditional throttle linkages that have the big hole in them, so we had to get creative to attach that little arm to the throttle linkage. When the bolt is tightened, everything still moves freely. The pedal feels better than it did with the carburetor. You'll notice the GM "Small Cap" HEI-required so the Terminator X can also control timing. I opted for a cheap $40 MSD coil. All tied into the CD ignition box that I had before. Its not the tidiest engine bay, but its functional.

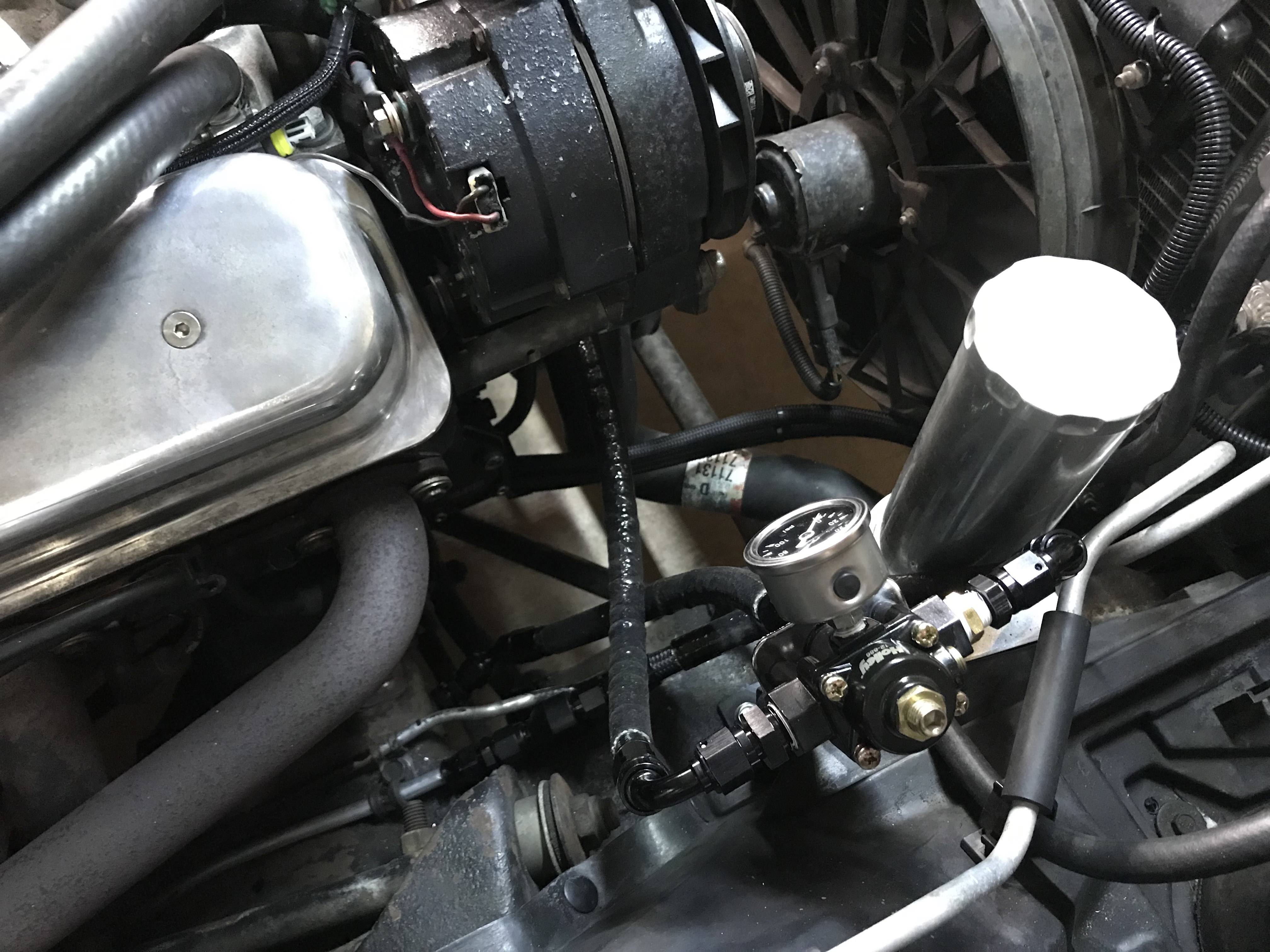

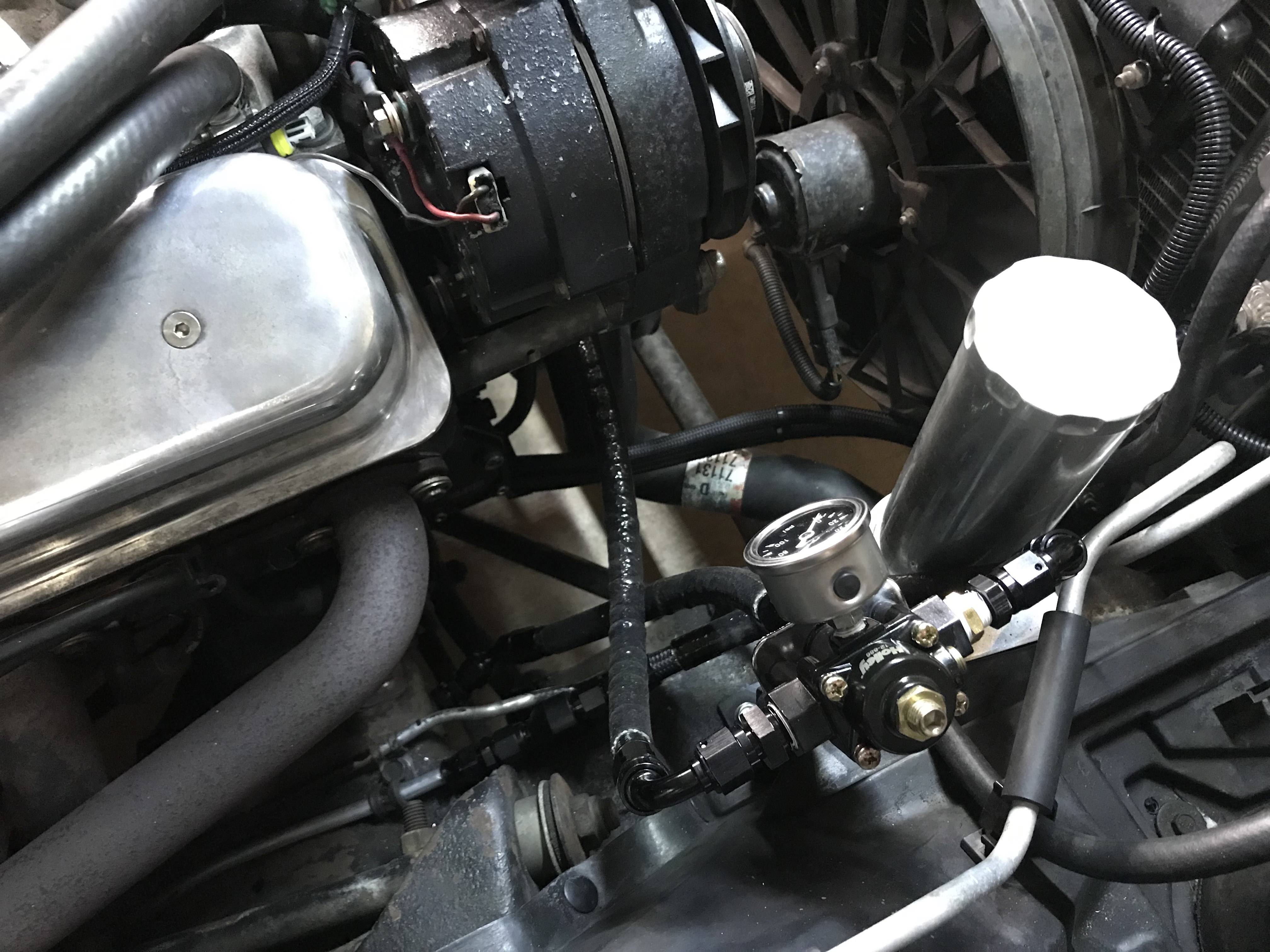

We bent up this bracket to mount the fuel pressure regulator. I probably could have just mounted it to the inner fender, but something about that bothered me. Its nice and away from the header here. You'll notice all the AN lines up front are covered with heat sleeving. Ignore the brass fitting. I did what I had to do to get it fired up, the AN fitting will be here soon.

I still plan to add Nitrous later, so I wanted to T-off the main fuel system for a nitrous regulator later on. I found this -6AN T and capped off one side of it for now. That worked well. All the AN lines up front are pretty short and manageable.

The computer I mounted in the kick panel like factory. I had to do some trimming to the cover, but you would not know it is there.

I plan to do a full Holley digital dash later on (the price tag hurts) but I wanted to mount the hand held discreetly. Its just velcroed to the cluster so I can pop it off to get the SD card out. I like the positioning there.

I'll work from back to front with the photos here. Here's a quick shot of the aeromotive tank. Nice piece, not sure if it was worth the 7 month wait. That's a 340LPH pump in there, -6AN feed/return. One thing that frustrated me: see that black aeromotive aluminum piece there to the right of the top hat? That is the sender, and it hits the floor brace on the trunk pan. We had to cut that out in order to get the tank to fit right. I feel like if these are advertised as a direct fit, I shouldn't have to do that. I opted to use the factory 3/8" feed hardline as the return, and I ran a new 3/8" aluminum hard line as the feed. I wanted the lines tucked up and out of the way, and the way the frame rails are on these cars are, I felt it was a lot easier to fit two 3/8" hardlines rather that 2 -6 lines that are like 5/8" OD. I used 3/8" to -6 hardline adapters.

The fuel filter is mounted just in front of the passenger rear tire. I ended up having this plastic bracket laying around from something. Some sort of fuel filter bracket, but it worked really nice. You can see the hardline adapters better here. I think they are rated to like 250PSI, and they don't leak.

Just another quick shot of the fuel line routing. The new hard line pretty much follows the old one. I cut out the original 1/4" return line to make room here. The factory double clips were cut and p clamps added to hold the new line. Where the wiring harness passes near the headers, I used velcro heat wrap. This kind is the summit brand, not terrible quality, should do the job.

Another "I had this laying around" that worked so well. This 90 degree grommet. The engine harness passes right through the factory hole in the firewall, and sealed up nice. Again, velcro heat wrap just in case.

Now the throttle body itself. Nothing really to see here. I used a trick flow throttle bracket. Its designed to work with traditional throttle linkages that have the big hole in them, so we had to get creative to attach that little arm to the throttle linkage. When the bolt is tightened, everything still moves freely. The pedal feels better than it did with the carburetor. You'll notice the GM "Small Cap" HEI-required so the Terminator X can also control timing. I opted for a cheap $40 MSD coil. All tied into the CD ignition box that I had before. Its not the tidiest engine bay, but its functional.

We bent up this bracket to mount the fuel pressure regulator. I probably could have just mounted it to the inner fender, but something about that bothered me. Its nice and away from the header here. You'll notice all the AN lines up front are covered with heat sleeving. Ignore the brass fitting. I did what I had to do to get it fired up, the AN fitting will be here soon.

I still plan to add Nitrous later, so I wanted to T-off the main fuel system for a nitrous regulator later on. I found this -6AN T and capped off one side of it for now. That worked well. All the AN lines up front are pretty short and manageable.

The computer I mounted in the kick panel like factory. I had to do some trimming to the cover, but you would not know it is there.

I plan to do a full Holley digital dash later on (the price tag hurts) but I wanted to mount the hand held discreetly. Its just velcroed to the cluster so I can pop it off to get the SD card out. I like the positioning there.

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 465

- Replies

- 0

- Views

- 530

- Replies

- 5

- Views

- 878

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.