I've probably been putting this off since things didn't go exactly as planned, but it's time that I finally gave a detailed account of how my car got back on the road after dying in the driveway a couple Sundays ago. So gather 'round, ye with time to kill, and I shall tell you a tale. A tale of a Cutlass and her camshaft: second draft.

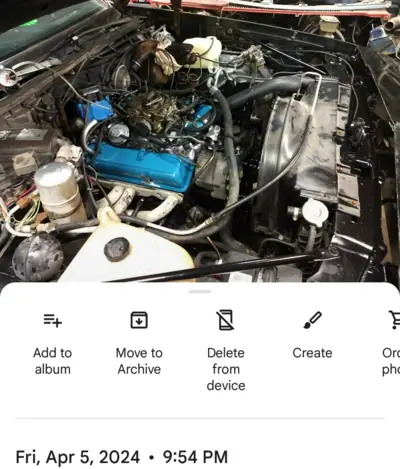

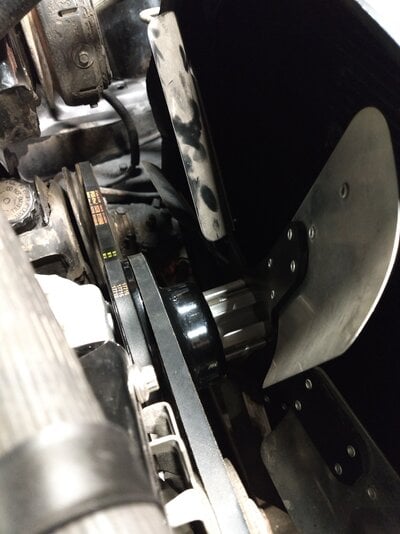

After pushing Gina into the secure confines of the metal outbuilding I once again elevated her to sit atop her throne of four 6 ton jack stands and left a jack supporting the differential. Naturally, I disconnected the battery but at this time left the fuel lines and oil filter in place, as well as the manifolds and rear exhaust pipe. Of course I removed the center Y pipe section, and aside from limited access due to ALL of the stock items being present things came off of this car relatively easily. Some fasteners required substantial cleaning before a tool could relieve them of their duty, and all but one released its grip without fail. We lost a thermostat housing bolt in the skirmish- some just can't let go. That basically got us to here which you've already seen since I previously posted a picture of the lifter valley and the contents, but it was rather blurry so here's a better view.

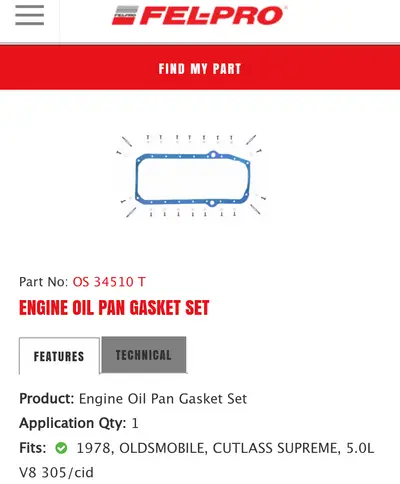

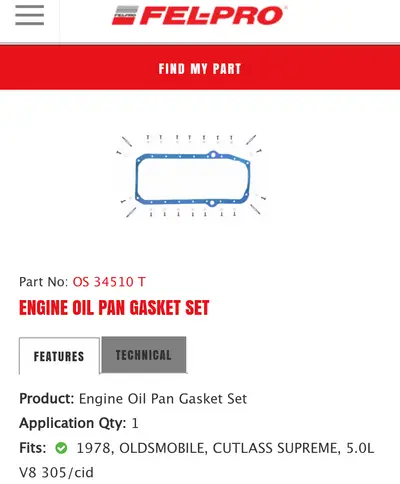

I wanted to get the oil pan completely out so I could clean the area well, paint the pan, and get new gaskets in without adding a bunch of grit and grime to my oil. I also planned to utilize a FelPro one-piece reusable pan gasket (34510T) because they're SO much easier to install- whether in the car or on a stand. These babies are gold at $42 and Amazon currently has a few on sale for $25- act now.

To get the engine high enough required unbolting it from the frame, loosening the trans mount, and lifting with a transmission jack under the engine oil pan. I then set up 2 small jack stands with a 2x4 laid across them, added a t-shirt on top, and lowered the transmission pan onto it. I had to mess with this a little to get the required height but it worked out in the end and I was able to slither between things while the engine remained elevated. While not the best way it's not the worst: I've seen people place a board across the fenders and support the engine with long bolts protruding from the heads. It's much better if you can support the engine from above with a cherry picker or chain fall hoist.

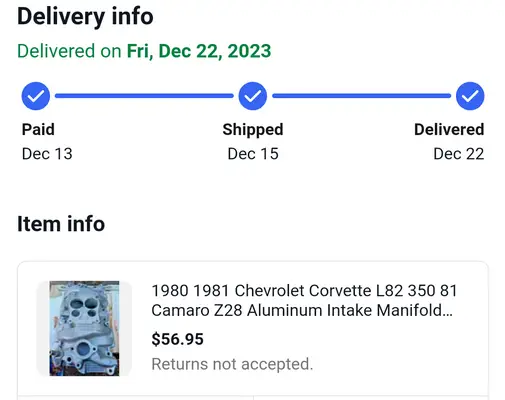

I took this opportunity to paint the valve covers which had been soaking in heavy duty oven cleaner containing sodium hydroxide in hopes of dissolving the old paint a little bit. Today's brake cleaner helps to strip it too but not as well as the old brake cleaner used to. The idea was that I'd accomplish twice as much work while I waited on solvents and paint to do their "thing", so I also gave my old EGR valve a two-tone paint job since a new one (EGR1024) is $73 and to my knowledge the old one is good. While the fumes were flowing I opted to coat another intake manifold in VHT "Aluminum" as I didn't like the factory black finish and someone had already done a poor job of painting it silver once before anyway. My attempts at removing all the old paint weren't quite successful but it covered up well and I think the end result verges on pretty. Here's what I bought, you'll see the results later.

While the VHT was already shook up I also painted a starter that I'd previously shot in white to keep temps down. I had no intention of attaining show quality results but simply needed to cover the white. This is a 6416S model, which I've mentioned in another thread about GM factory "performance" starters. The proper long bolts with the correct stepped knurling are also on display in the upper left corner (12338064).

https://gbodyforum.com/threads/factory-starter-upgrade.89016/#post-956132

With wet paint sparkling under the setting sun I resumed my place in the garage with the giant speakers and proceeded to remove the oil pan and timing cover so they could also get cleaned. Words cannot describe how incredibly filthy these things were and I used multiple Scotch Brite pads, oven cleaner, brake cleaner, Gator Wipes, and about 6 pair of latex gloves getting them clean after scraping them. I tried to remain productive in other areas any time the parts were soaking or paint was drying.

With the mounts undone you know damn good & well that I intend to upgrade to polyurethane: I bought a pair of Energy Suspension inserts (31116R, $36 ea.) to go inside some brand new Duralast clamshells (2292, $12 ea.) so they'd be clean and ready to go in at a moment's notice. I may end up powder coating new engine side brackets once I figure out the small differences between the multiple car versions (334970, 140278, 3993371, 3993372- last two are a matched set L/R) but could just as easily clean and paint the old ones. I've learned that it's very nice to have complete sets of spares on hand if you can though. Drilling and reassembly of the mounts was accomplished while the solvents worked their magic on the pan and timing cover.

After setting those on the trunk I painted the pan, timing cover, t-stat housing, all bolts, and everything else I could think of that I planned to put back on. Now it was time to scrape the 1" thick gunk from the block and k-member as well as vacuum out the valley and every orifice the tip of the Shop Vac hose would fit into. Finally, things were starting to look good and organized again! Following that I removed the lifters with a pick and some Icon brand pliers which are quite nice, and relieved the header panel of a support bracket to make room for camshaft removal. The A/C condenser was gingerly swung out of the way, the cam was carefully removed, and I squeezed out the contents of 6 cans of brake cleaner while scrubbing every part of the engine that I could. This included hitting the lifter bores with Scotch Brite followed by lint free rags to ensure that things moved freely in the future. Eventually, my fingertips told me the engine was clean enough and I moved on to other things like stealing more parts from Karma, the El Camino.

Cue Paul Harvey again...

After pushing Gina into the secure confines of the metal outbuilding I once again elevated her to sit atop her throne of four 6 ton jack stands and left a jack supporting the differential. Naturally, I disconnected the battery but at this time left the fuel lines and oil filter in place, as well as the manifolds and rear exhaust pipe. Of course I removed the center Y pipe section, and aside from limited access due to ALL of the stock items being present things came off of this car relatively easily. Some fasteners required substantial cleaning before a tool could relieve them of their duty, and all but one released its grip without fail. We lost a thermostat housing bolt in the skirmish- some just can't let go. That basically got us to here which you've already seen since I previously posted a picture of the lifter valley and the contents, but it was rather blurry so here's a better view.

I wanted to get the oil pan completely out so I could clean the area well, paint the pan, and get new gaskets in without adding a bunch of grit and grime to my oil. I also planned to utilize a FelPro one-piece reusable pan gasket (34510T) because they're SO much easier to install- whether in the car or on a stand. These babies are gold at $42 and Amazon currently has a few on sale for $25- act now.

To get the engine high enough required unbolting it from the frame, loosening the trans mount, and lifting with a transmission jack under the engine oil pan. I then set up 2 small jack stands with a 2x4 laid across them, added a t-shirt on top, and lowered the transmission pan onto it. I had to mess with this a little to get the required height but it worked out in the end and I was able to slither between things while the engine remained elevated. While not the best way it's not the worst: I've seen people place a board across the fenders and support the engine with long bolts protruding from the heads. It's much better if you can support the engine from above with a cherry picker or chain fall hoist.

I took this opportunity to paint the valve covers which had been soaking in heavy duty oven cleaner containing sodium hydroxide in hopes of dissolving the old paint a little bit. Today's brake cleaner helps to strip it too but not as well as the old brake cleaner used to. The idea was that I'd accomplish twice as much work while I waited on solvents and paint to do their "thing", so I also gave my old EGR valve a two-tone paint job since a new one (EGR1024) is $73 and to my knowledge the old one is good. While the fumes were flowing I opted to coat another intake manifold in VHT "Aluminum" as I didn't like the factory black finish and someone had already done a poor job of painting it silver once before anyway. My attempts at removing all the old paint weren't quite successful but it covered up well and I think the end result verges on pretty. Here's what I bought, you'll see the results later.

While the VHT was already shook up I also painted a starter that I'd previously shot in white to keep temps down. I had no intention of attaining show quality results but simply needed to cover the white. This is a 6416S model, which I've mentioned in another thread about GM factory "performance" starters. The proper long bolts with the correct stepped knurling are also on display in the upper left corner (12338064).

https://gbodyforum.com/threads/factory-starter-upgrade.89016/#post-956132

With wet paint sparkling under the setting sun I resumed my place in the garage with the giant speakers and proceeded to remove the oil pan and timing cover so they could also get cleaned. Words cannot describe how incredibly filthy these things were and I used multiple Scotch Brite pads, oven cleaner, brake cleaner, Gator Wipes, and about 6 pair of latex gloves getting them clean after scraping them. I tried to remain productive in other areas any time the parts were soaking or paint was drying.

With the mounts undone you know damn good & well that I intend to upgrade to polyurethane: I bought a pair of Energy Suspension inserts (31116R, $36 ea.) to go inside some brand new Duralast clamshells (2292, $12 ea.) so they'd be clean and ready to go in at a moment's notice. I may end up powder coating new engine side brackets once I figure out the small differences between the multiple car versions (334970, 140278, 3993371, 3993372- last two are a matched set L/R) but could just as easily clean and paint the old ones. I've learned that it's very nice to have complete sets of spares on hand if you can though. Drilling and reassembly of the mounts was accomplished while the solvents worked their magic on the pan and timing cover.

After setting those on the trunk I painted the pan, timing cover, t-stat housing, all bolts, and everything else I could think of that I planned to put back on. Now it was time to scrape the 1" thick gunk from the block and k-member as well as vacuum out the valley and every orifice the tip of the Shop Vac hose would fit into. Finally, things were starting to look good and organized again! Following that I removed the lifters with a pick and some Icon brand pliers which are quite nice, and relieved the header panel of a support bracket to make room for camshaft removal. The A/C condenser was gingerly swung out of the way, the cam was carefully removed, and I squeezed out the contents of 6 cans of brake cleaner while scrubbing every part of the engine that I could. This included hitting the lifter bores with Scotch Brite followed by lint free rags to ensure that things moved freely in the future. Eventually, my fingertips told me the engine was clean enough and I moved on to other things like stealing more parts from Karma, the El Camino.

Cue Paul Harvey again...

Last edited: