Hey bud, thanks allot for the input.... Have you contributed a thing to this thread or just here to talk trash?

So you want me to show you how misguided and ignorant you are being?

Okay, here we go...

Let's start with your potential spring selection being based upon their lowering height versus measured rate.

Dismissing control arms due to their lack of powdercoating options.

Based upon what I see here you are arbitrarily cobbling together critical suspension pieces (control arms, spindle heights, and ball joint length) based upon a skewed qualitative analysis of size. Moar is moar better. Moar longerer. Moar thickerer. Moar rederer.

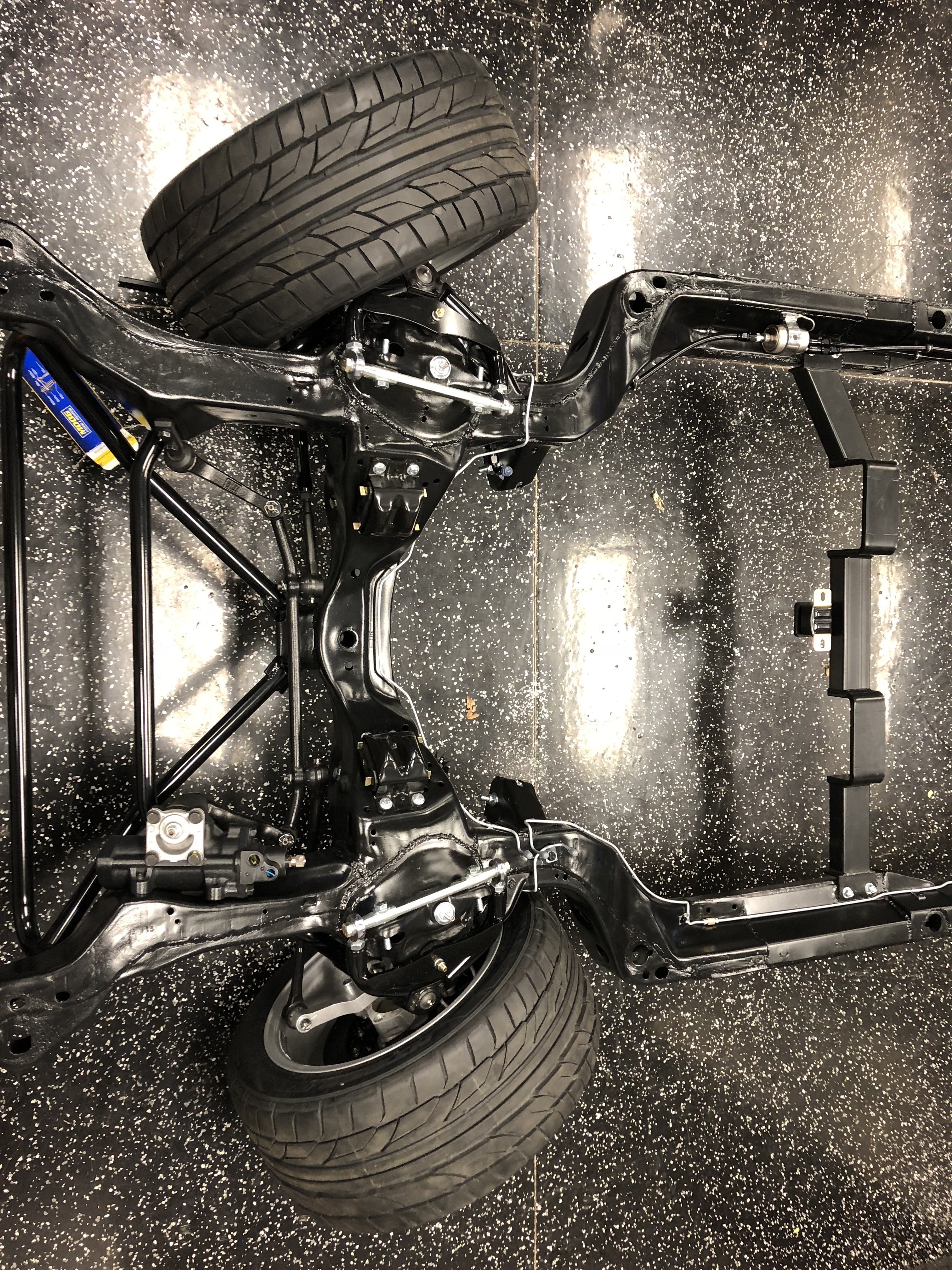

If you aren't going to take the opportunity to allow an engineered kit to be utilized and just buy things at random you are going to end up mismatched parts that fight each other and upset the driving/suspension characteristics.

With that in mind: What is the current (or expected) F/R and corner balance with the drivetrain set in place, and you in the driver's seat? Have you allowed for appropriate weight transfer during acceleration and dive both on and off camber? How much camber gain/loss are you going to require to accommodate both scenarios during performance driving? What is your experience with understeer and snap oversteer? Because even the best G-body still exhibits these characteristics at the most inopportune time. Are you running a big bar/small spring, small bar/big spring, or big bar/big spring combo? This is going to impact your shock rebound and compression requirements along with the weight considerations I mentioned at the beginning (not even touching on reciprocating, sprung and unsprung masses). This will also translate into the amount of detectable bumpsteer you have. Tire and wheel combination (width, weight, sidewall height, etc) can have a nasty influence on control - nothing better than being in an off camber corner, understeering while braking, with the wheels tram-lining in a rut. Biggerer is not always betterer.

Funny how it has come full circle - almost like it needs to work together in synergy, eh?

Tire compound and contact patch will ultimately make or break a well designed combination. Or mask a shitty one.

Ironically you could be better off welding the suspension solid with the car set as low as possible and run some large sidewall tires - and use those to tune the suspension (by basically making a 3200lb go kart) - as opposed to slapping some stuff together based upon assumption and conjecture or because it comes in red.

Your best bet is to start off near stock and test the car in a racing setting. Get to the car's and your limits (believe me you are way more limited than the car) and adjust one thing at a time - readapt - and make another logic based incremental change. And keep asking yourself: What is the car doing that it shouldn't? Is it a mechanical limitation or a personal one? Can or should I change to suit it - or does the car require an engineered solution? Or am I at a point of diminishing returns because this is still a G-body?