If you would of stayed Olds V8, you could have used a 76 or older bellhousing. Olds used the dual pattern because of the Ford Toploader 3 spd used as the heavy duty option starting in 66 I believe and kept the holes there even after Muncie made their own heavy duty 3 spd in 71. I would assume the starter position would be an issue on the Buick. A member on here bolted those V6 trans to an Olds 350 with the dual pattern bellhousing, just the input shaft needed shortening. With an adapter you should not need to shorten the input. That trans is rated at 310 ft/lbs, the most of any T-5.

BUICK The Final Objective (Mission Accomplished, 7/23)

- Thread starter 307 Regal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Did some shopping around on hydraulic throw out bearings. Yikes. Prices have gone up over the last few years. I'm assuming I'll have to make a spacer to compensate for the depth added by my adapter plate. I also read up on some old threads that I've had bookmarked. Apparently Bonnewagon had luck using a BOP bell with a regular Firebird clutch fork (which are the same parts that I have) so I'm tempted to look into going with mechanical linkages. My engine block has the hole for a Z bar, but I need to make sure that my headers are not in the way. Just testing the waters here.

Are you mating this trans with the olds 307? I mated a T5 in my Caballero to a 307 SBC using my original bellhousing and z bar. My T5 was pulled from a '92 S10 pu and was originally a hydraulic clutch. I am running long tube Headman headers.Did some shopping around on hydraulic throw out bearings. Yikes. Prices have gone up over the last few years. I'm assuming I'll have to make a spacer to compensate for the depth added by my adapter plate. I also read up on some old threads that I've had bookmarked. Apparently Bonnewagon had luck using a BOP bell with a regular Firebird clutch fork (which are the same parts that I have) so I'm tempted to look into going with mechanical linkages. My engine block has the hole for a Z bar, but I need to make sure that my headers are not in the way. Just testing the waters here.

Are you mating this trans with the olds 307? I mated a T5 in my Caballero to a 307 SBC using my original bellhousing and z bar. My T5 was pulled from a '92 S10 pu and was originally a hydraulic clutch. I am running long tube Headman headers.

I'm mating it to a Buick 350. I took a look at my headers tonight and the rear primary tube immediately moves away from the z bar location, so clearance should be okay I assume.

I've been moving into an apartment so working on the car has been hard, but it's on my mind every day!

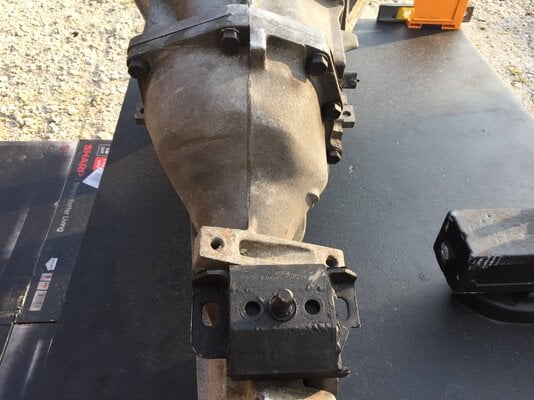

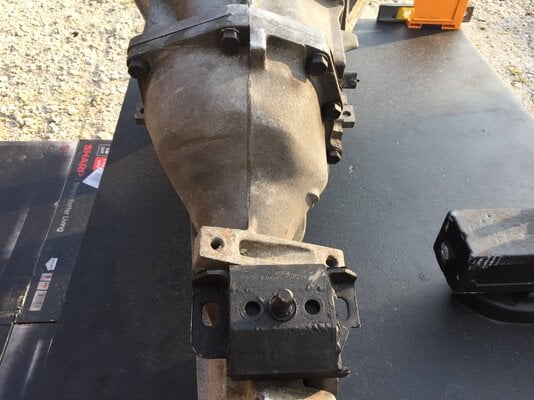

I was at least able to get the bellhousing mated to the transmission. The four mounting holes had to be opened up just a hair with a 1/2" drill bit in order for the HotRodWorks adapter plate's hardware to go through. No worries there since those aren't being used to center the unit in the bell. That's the front bearing retainer's job.

Also I filed off and sanded down (with emery cloth) the lumps of metal built up on the input shaft. It looks good. Unfortunately I may have taken a hair too much off as there is a slight wiggle when I but the new pilot bushing on. (I don't know. This is my first time.) I'm hoping that the bushing will constrict just slightly when it is pressed into the crankshaft. I may upload video of the bushing on the input shaft just to get opinions.

I was at least able to get the bellhousing mated to the transmission. The four mounting holes had to be opened up just a hair with a 1/2" drill bit in order for the HotRodWorks adapter plate's hardware to go through. No worries there since those aren't being used to center the unit in the bell. That's the front bearing retainer's job.

Also I filed off and sanded down (with emery cloth) the lumps of metal built up on the input shaft. It looks good. Unfortunately I may have taken a hair too much off as there is a slight wiggle when I but the new pilot bushing on. (I don't know. This is my first time.) I'm hoping that the bushing will constrict just slightly when it is pressed into the crankshaft. I may upload video of the bushing on the input shaft just to get opinions.

Just an update again. The COVID situation is has gotten a bit more pressing in my area and more precautions are being taken. For me this means less visits to where my Regal and T5 are.

I'm still thinking about it constantly, and I just wish I had a place to work on the thing properly. As in take the trans (or engine with it) out and be able to start at least mocking things up and seeing how much room I have, where things need to be, etc.

After much deliberation and a voting thread here, I'm leaning toward an internal slave cylinder. Though I still wish I could make an external unit work. Dunno if I'd have the room with the wrong bell and fork though! [shrug]

I do think that I've found a solution for the 18 degree tilt on the trans mount. I found a thread on mgexp.com about cutting it flat and making angled shims. This should be a good solution that will keep the mount from hanging down too low. I know some guys have either made wedges to cancel out the angle (but add height to the mount) or welded the mount tab on at an angle, but I like this new idea instead.

www.mgexp.com

www.mgexp.com

I'm still thinking about it constantly, and I just wish I had a place to work on the thing properly. As in take the trans (or engine with it) out and be able to start at least mocking things up and seeing how much room I have, where things need to be, etc.

After much deliberation and a voting thread here, I'm leaning toward an internal slave cylinder. Though I still wish I could make an external unit work. Dunno if I'd have the room with the wrong bell and fork though! [shrug]

I do think that I've found a solution for the 18 degree tilt on the trans mount. I found a thread on mgexp.com about cutting it flat and making angled shims. This should be a good solution that will keep the mount from hanging down too low. I know some guys have either made wedges to cancel out the angle (but add height to the mount) or welded the mount tab on at an angle, but I like this new idea instead.

Using a Camaro T5 without the 17* tilt : MG Engine Swaps Forum : The MG Experience

As I've observed in a few other threads, if people are fabbing shimmed mounts for their Camaro T5s, they're going about things the difficult way! Looking at the mounting boss on the tailstock, you can see it's an angled boss protruding from a flat surface. It's actually hollow, so you can see wha

My point is that if you have stock height ball joints, you're good. Taller lowers put you in bump steer correction mode...

Can't you get extended tie rod ends to help match it up?

It never occurred to my OCD mind to just use the angled bolt holes and stack washers under there. I had elaborate ideas about machining the thing flat then putting a band over the top of the tailhousing and using that as a clamp for the T-mount. Naother alternative might be to weld up the bolt holes, then drill and retap upright.Just an update again. The COVID situation is has gotten a bit more pressing in my area and more precautions are being taken. For me this means less visits to where my Regal and T5 are.

I'm still thinking about it constantly, and I just wish I had a place to work on the thing properly. As in take the trans (or engine with it) out and be able to start at least mocking things up and seeing how much room I have, where things need to be, etc.

After much deliberation and a voting thread here, I'm leaning toward an internal slave cylinder. Though I still wish I could make an external unit work. Dunno if I'd have the room with the wrong bell and fork though! [shrug]

I do think that I've found a solution for the 18 degree tilt on the trans mount. I found a thread on mgexp.com about cutting it flat and making angled shims. This should be a good solution that will keep the mount from hanging down too low. I know some guys have either made wedges to cancel out the angle (but add height to the mount) or welded the mount tab on at an angle, but I like this new idea instead.

Using a Camaro T5 without the 17* tilt : MG Engine Swaps Forum : The MG Experience

As I've observed in a few other threads, if people are fabbing shimmed mounts for their Camaro T5s, they're going about things the difficult way! Looking at the mounting boss on the tailstock, you can see it's an angled boss protruding from a flat surface. It's actually hollow, so you can see whawww.mgexp.com

Looks like the thread hasn’t been locked for inactivity! ha

Well, I finally ordered a master rebuild for my T5, and a cluster gear support plate to help things hold up. Since the T5 is a ‘94 from a Camaro, I needed to adapt the speedometer to mechanical. I ordered a speedometer “bullet” (driven gear housing) from Amazon which came with a locking tab and 4 or 5 driven gears. It’s a universal kit for many older gearboxes. It fits, but the locking tab is too short for this conversion. It should be easy to make a longer one.

I almost went ahead and flattened the 17 degree mount like in the link I shared, but I had a new concern with it. Would there even be enough aluminum left on the passenger side??

Looking like a “no.”

I don’t want to weld on the crossmember mounting tab at an angle, so this leaves me with either fabricating a 17 degree wedge, or locating a discontinued McLeod 8653 universal bellhousing. I like one of those options much better, but know the other would be easier.

Well, I finally ordered a master rebuild for my T5, and a cluster gear support plate to help things hold up. Since the T5 is a ‘94 from a Camaro, I needed to adapt the speedometer to mechanical. I ordered a speedometer “bullet” (driven gear housing) from Amazon which came with a locking tab and 4 or 5 driven gears. It’s a universal kit for many older gearboxes. It fits, but the locking tab is too short for this conversion. It should be easy to make a longer one.

I almost went ahead and flattened the 17 degree mount like in the link I shared, but I had a new concern with it. Would there even be enough aluminum left on the passenger side??

Looking like a “no.”

I don’t want to weld on the crossmember mounting tab at an angle, so this leaves me with either fabricating a 17 degree wedge, or locating a discontinued McLeod 8653 universal bellhousing. I like one of those options much better, but know the other would be easier.

I'm voting for modifying the crossmember. It's very easy to test fit a T5 because it's so light. Just need to leave the clutch out. That also makes it easy to confirm proper amount of pilot bearing engagement.

And good to see you're still at it!

And good to see you're still at it!

- Status

- Not open for further replies.

Similar threads

- Replies

- 14

- Views

- 649

- Replies

- 14

- Views

- 840

- Replies

- 7

- Views

- 356

- Replies

- 50

- Views

- 2K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.