The thread isn't locked yet? Excellent!

SOOOoooooOoo I went to a swap meet today and found something important! A driveshaft! I haven't accomplished much other than research lately, but it was important information. As documented on this forum and others, a stock G body with a 7.5" rear should have a driveshaft length of 52.5". According to posts about 700R4 swaps into said cars, the driveshaft needs to be shortened 3". The T5 transmission which I am using shares this requirement with the 700R4, as documented most relevantly here:

https://www.garage-scene.com/t5-into-ag-body/ Their similar dimensions can be verified on sites like thirdgen.org

So the common consensus is that the driveshaft should be 49.5" long. Well that's all well and good but my BOP-to-Ford-pattern-T5 adapter plate is .5" thick. So for me: 49" length is ideal.

And what did I find in the second to last row of the swap meet? A '69 Z28 driveshaft measuring 49.25" long! That's about perfect! It will need a yoke though, and I will probably rebuild it and have it balanced. There is a small chip on the lip which holds the sort of snap ring retainer for the rear u-joint on one side, but it seems minor.

I've been looking at the SickSpeedMonte clutch pedal brackets, and I'm getting close to buying a kit from him. I'm thinking about going with the F-body master cylinder version in hopes of taking advantage of parts availability in the future. After that, I would just need to figure out which internal slave cylinder to use.

I'm getting more ideas on how to solve the Camaro/Firebird T5 tilt. I've seen a clever idea from the MG community.

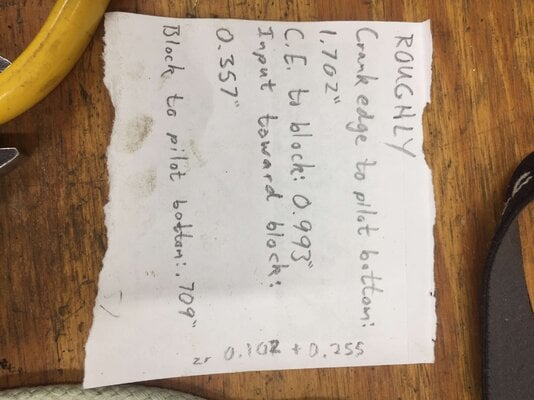

Apparently, instead of a wedge, what's pictured here is a Z-shaped bracket. The top plate is welded on to the vertical plate at an angle. Once you weld the bottom plate on, you've eliminated the angle entirely. The MG crossmember looks to be ahead of the trans mount pad. If I did the math correctly on mine, adapter plate included, my 200-4R crossmember pad should be about 4.44" behind the T5 mount pad. So maybe if I can make my own Z-type bracket, and extend the bottom plate enough, I might be able to leave my transmission crossmember as-is. We'll see.

Side note: the company which makes that MG bracket appears to be D&D Fabrications INC, out of Almont Michigan. Seems like a neat company. Dunno how much business they do. Here's their web address:

http://aluminumv8.com/