Looks good D you'll be seam sealing and shooting epoxy in no time

BUILD THREAD “The Juggernaut”

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I’ve been off on a week’s holidays this week, so I’ve been keeping myself busy in The Skunkworks while the nonstop rain continues to fall.

Yesterday I made a run to the dump to dispose of some old fluorescent tubes now that the shop has been upgraded to all LED replacements. While I was at it, it was time to get rid of all the old scrap sheetmetal that has been accumulating as I’ve been cutting and fabricating. It was quite a bit!

On the car, I’ve been logging in some serious time, and putting in work behind the welding helmet and grinders.

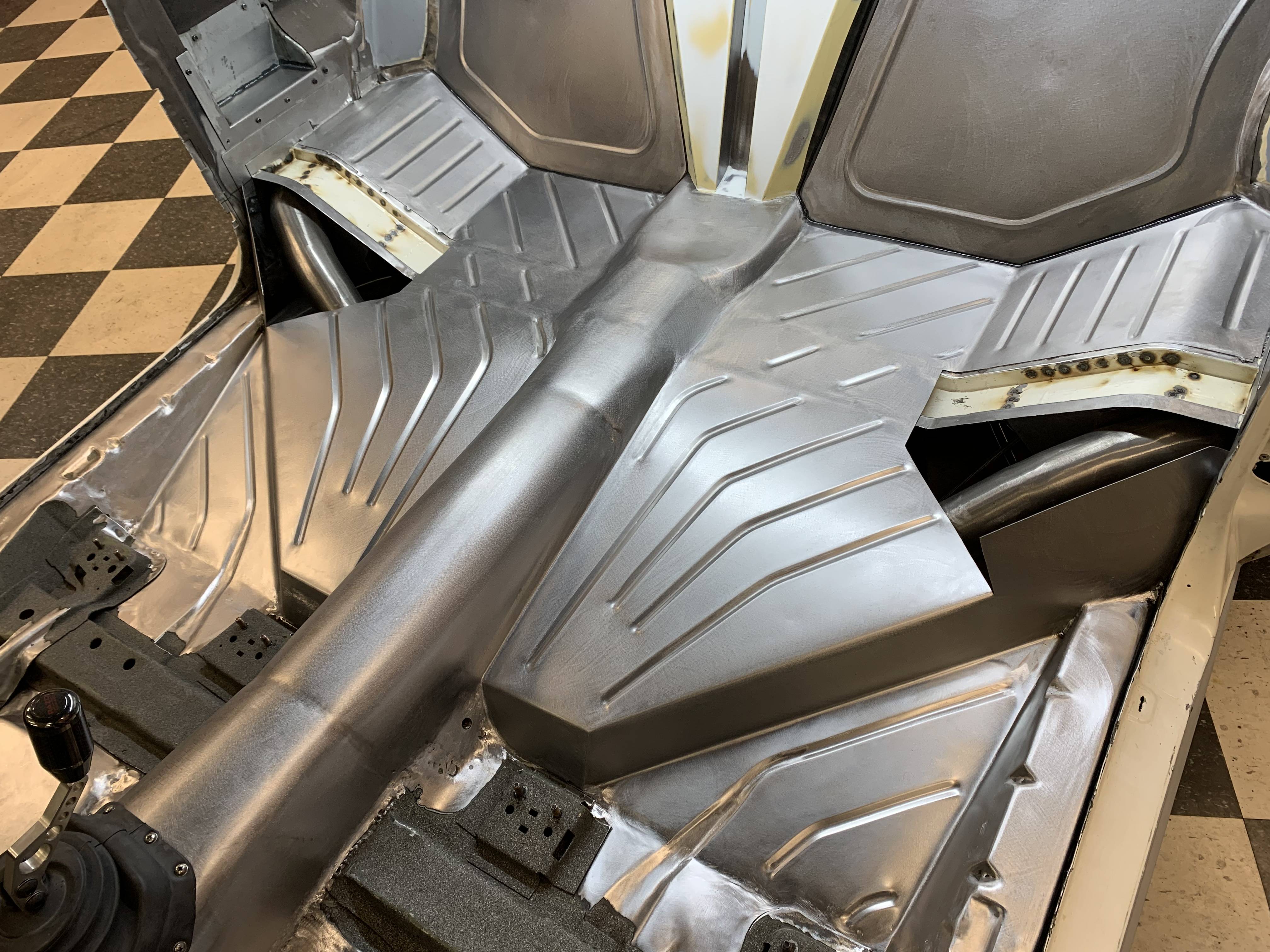

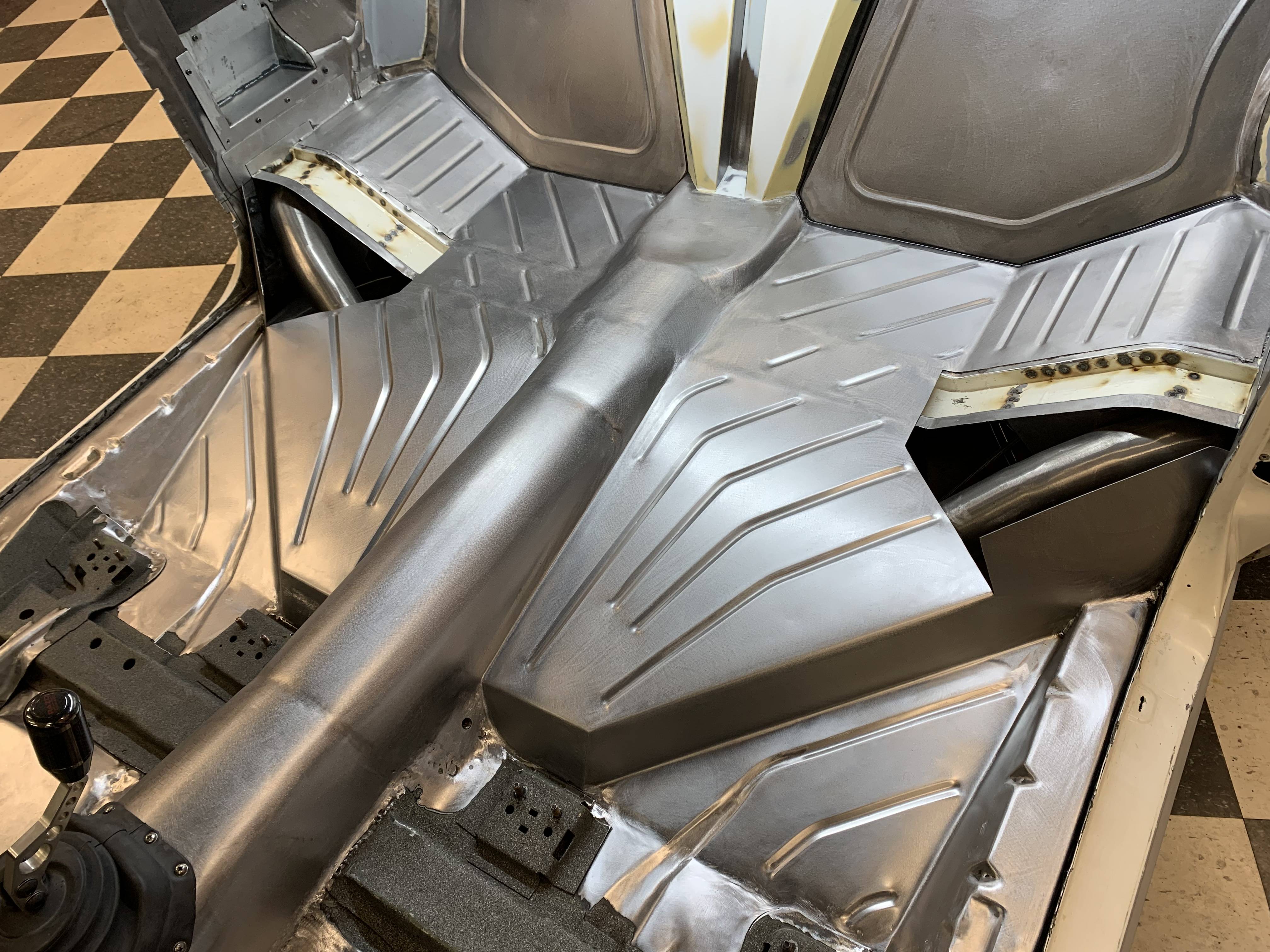

Hot off the welding torch (the metal is probably still warm) I JUST finished the large section of the driver’s side floor pan.

Here it is finally, fully welded in, and in all it’s bare metal glory.

I tried to take a couple of pictures from some little different angles so y’all can get a feel of what it’s like up close and moving around it.

Words cannot describe how great it feels to finally get to this point. Such a relief.

I obviously still have the last 2 small sections to figure out and fabricate/weld in, but the next step is actually to mock the seats back up and locate the optimal position for the E-brake handle. Then the seats will come back out and I can cut out/weld in the small pocket I made for it way back when I got the handle kit.

From there, it’ll probably be onto cutting off the tailpipe flanges, rotating the pipes slightly, and welding the new flanges back on. I have to do this before the last floor pieces get installed so that I can see and check the clearances to the floor crossmember stanchions.

THEN, it’ll be onto trying to figure out the last 2 floor pieces over the pipes, quite possibly the most difficult ones to make.

In other news, just as I finished this driver’s side piece, I hit 100 hours on the new screw compressor:

Think that doesn’t sound like a lot? It’s not, really, as far as screw compressors are concerned, but think about how far you would have to drive to accumulate 100 hours. That’s quite a bit. Couple that with the fact that this is only since April, and I can only work on the car on evenings and weekends.

Think I use my compressor a lot??

That’s all for now gents, onto the next stage!!

D.

Yesterday I made a run to the dump to dispose of some old fluorescent tubes now that the shop has been upgraded to all LED replacements. While I was at it, it was time to get rid of all the old scrap sheetmetal that has been accumulating as I’ve been cutting and fabricating. It was quite a bit!

On the car, I’ve been logging in some serious time, and putting in work behind the welding helmet and grinders.

Hot off the welding torch (the metal is probably still warm) I JUST finished the large section of the driver’s side floor pan.

Here it is finally, fully welded in, and in all it’s bare metal glory.

I tried to take a couple of pictures from some little different angles so y’all can get a feel of what it’s like up close and moving around it.

Words cannot describe how great it feels to finally get to this point. Such a relief.

I obviously still have the last 2 small sections to figure out and fabricate/weld in, but the next step is actually to mock the seats back up and locate the optimal position for the E-brake handle. Then the seats will come back out and I can cut out/weld in the small pocket I made for it way back when I got the handle kit.

From there, it’ll probably be onto cutting off the tailpipe flanges, rotating the pipes slightly, and welding the new flanges back on. I have to do this before the last floor pieces get installed so that I can see and check the clearances to the floor crossmember stanchions.

THEN, it’ll be onto trying to figure out the last 2 floor pieces over the pipes, quite possibly the most difficult ones to make.

In other news, just as I finished this driver’s side piece, I hit 100 hours on the new screw compressor:

Think that doesn’t sound like a lot? It’s not, really, as far as screw compressors are concerned, but think about how far you would have to drive to accumulate 100 hours. That’s quite a bit. Couple that with the fact that this is only since April, and I can only work on the car on evenings and weekends.

Think I use my compressor a lot??

That’s all for now gents, onto the next stage!!

D.

That floor is art, Donovan, much too nice to cover up with carpet. A lot of skill showing there!

I second the note above Donovan. Your work is amazing. A testament to your patience and skill. What are your plans for the floor once its complete? Are you going with carpet or insulation (or both)?

That floor is art, Donovan, much too nice to cover up with carpet. A lot of skill showing there!

Thanks Mike, I appreciate the compliment.

I second the note above Donovan. Your work is amazing. A testament to your patience and skill. What are your plans for the floor once its complete? Are you going with carpet or insulation (or both)?

Thanks Jeff.

Both when I’m done actually.

The order will be:

Epoxy brushed on by hand in only the areas that will get seam sealer, seam sealer (in the joints and crevices), then a couple coats of epoxy sprayed over top of everything. But the epoxy won’t happen for a while yet, fairly soon I hope to be pulling the body back off the frame to put it on a rotisserie. Final grinding of the welds on the underside and some hammer and dolly work will need to be done, probably along with touching up a few welds along the way.

No sense in applying the epoxy to the inside yet if I’m potentially going to burn it touching up pinholes.

Then, before the interior goes back in, everything will get a layer of DynaMat or equivalent, then a layer of jute and finally carpeting with mass backing. I want the interior as smooth and quiet as will be possible, with no squeaks, rattles or resonance. Hopefully like closing the door on a brand new Mercedes.

Absolutely outstanding. I have no other words.

None needed Tony, thank you!

This is my goal as well. I will be watching patiently.I want the interior as smooth and quiet as will be possible, with no squeaks, rattles or resonance. Hopefully like closing the door on a brand new Mercedes.

It really is only just a floor pan, but that doesn’t mean I should half-@$$ it together and cut corners on it. I look at all work to be done on the car as an opportunity to learn more and always strive to get better, no matter if it’s visible or not.

I really can’t help it, it’s the perfectionist in me. For those that aren’t perfectionists, they really won’t ever understand.

I believe that there is a time and place for every type of work. I'm so glad you've chosen the Juggernaut to display what patience, time and effort can yield. ABSOLUTELY beautiful craftsmanship my friend. Your attention to the smallest of details is astounding - and it shows. Great work D!

I hold off on looking at your updates for weeks so as to see the progress of the build when I finally do start on 4-5 pages of updates, but it's hard to not click on this thread every time I see a post.

Damn............the wait is it worth it.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.