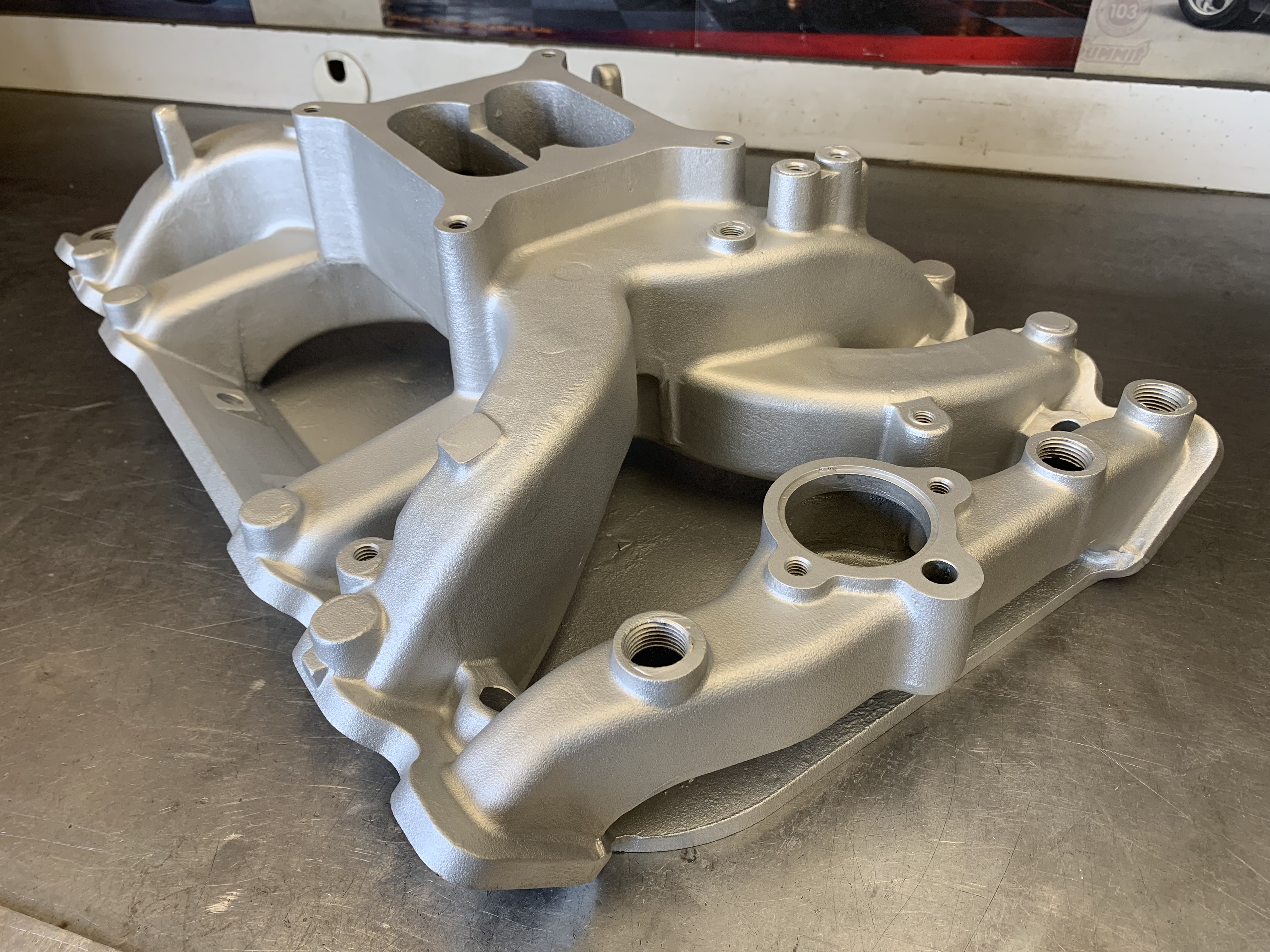

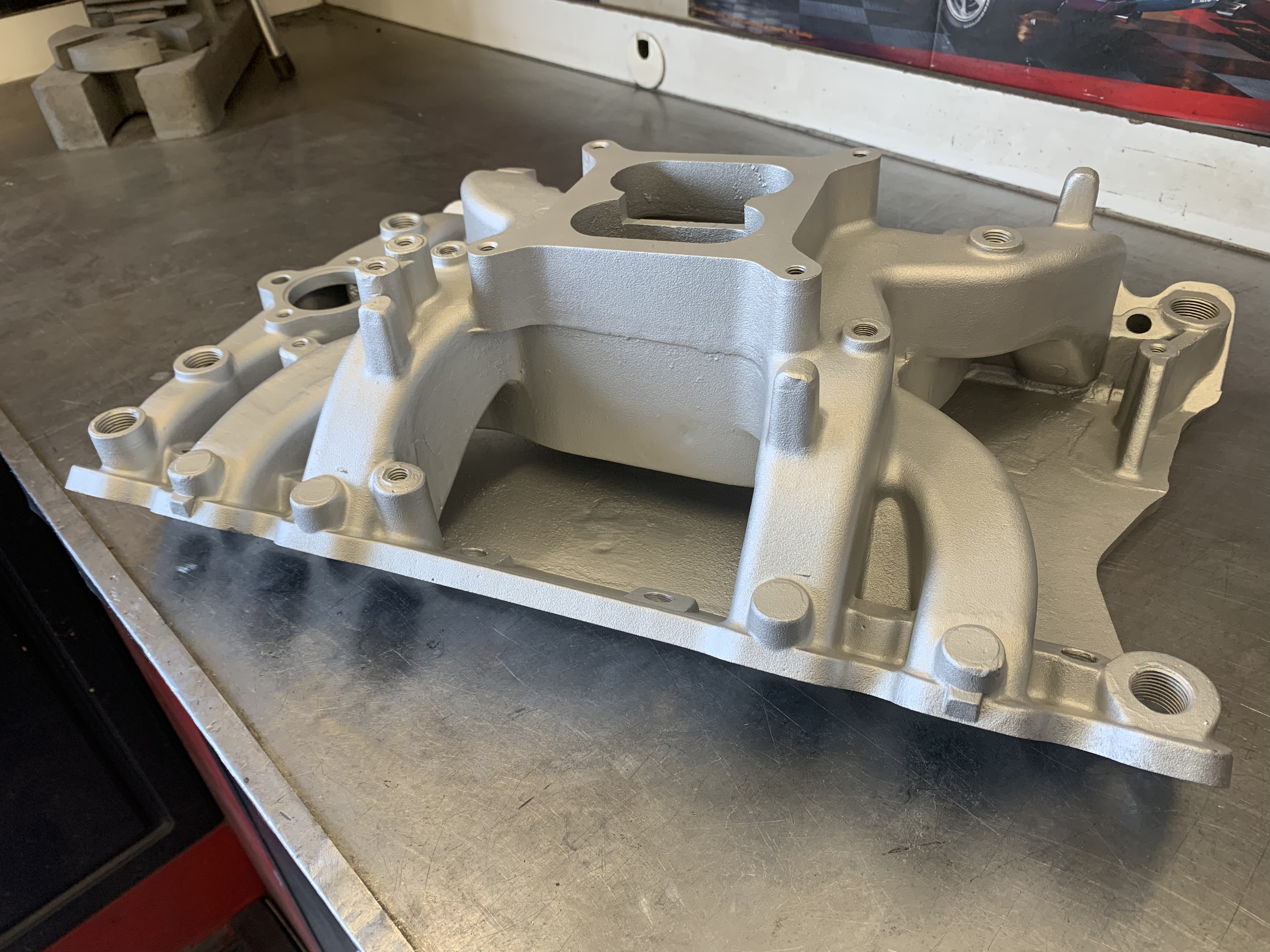

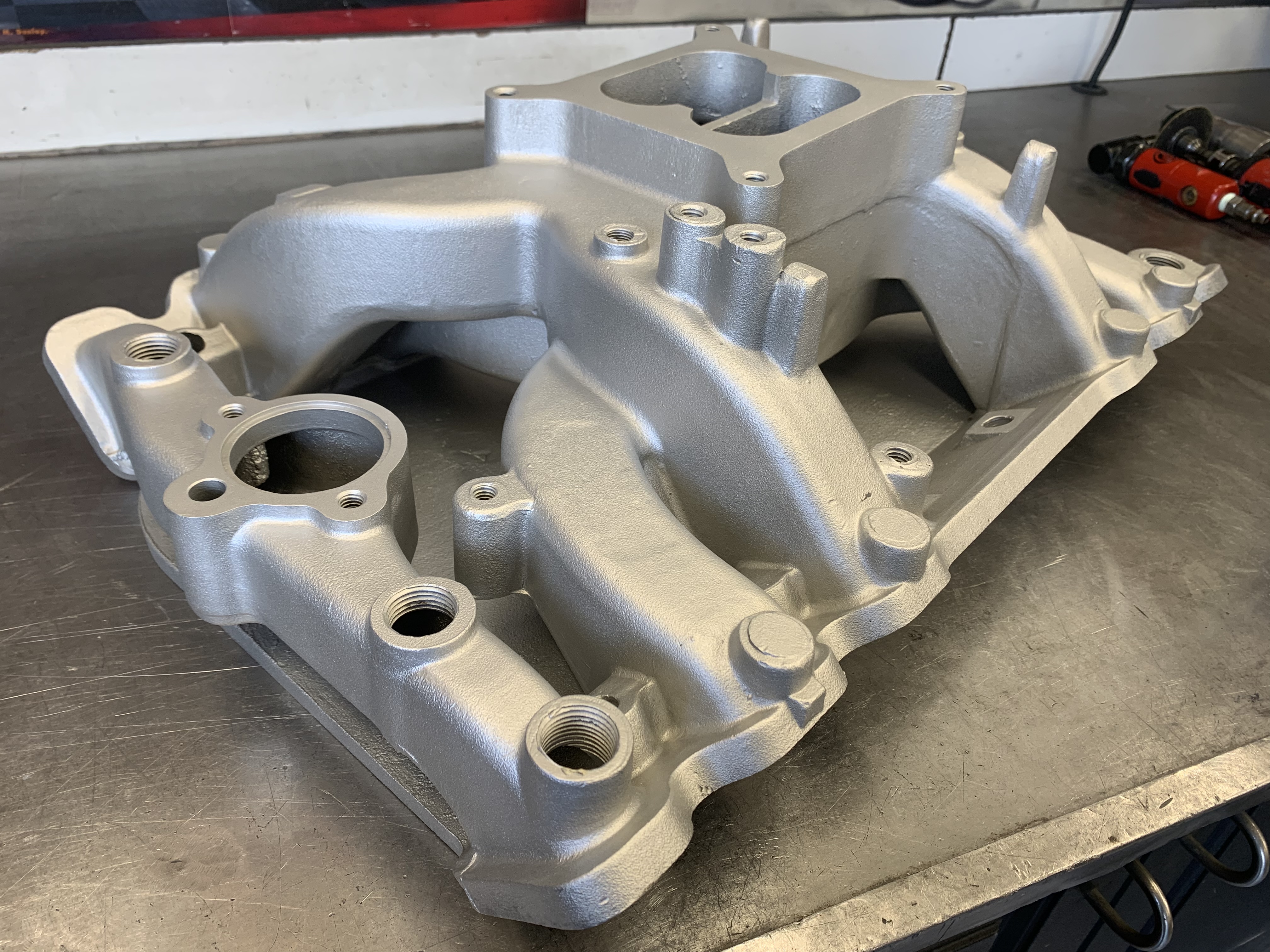

Better deals than the Red Deer swap meet. Pretty much retail here.

Good score!

Good score!

Come on you didn't want to leave that advanced vacuum hyperloop on that manifold?

Better deals than the Red Deer swap meet. Pretty much retail here.

Good score!

Another huge bonus and wish a SBO version existed, bosses to easily convert to SEFI. Mine cost me $900 US to convert my RPM. And yes, Procomp sold rail kits for that intake for SEFI.

Looks like you could make that intake EFI ready pretty easy! That'll really wake up the 455!

Donovan, going back in time here. I recently found out that mounting belts that far away from the seat isn't a great idea. I'm not a physics major but it has something to do with leverage and length of belts that during a collision applies more force AND due to the stretch of excessive belt length, can cause the seat to actually buckle and collapse causing great bodily harm. Saw pictures of the collapse with belt mounting as you have. If wanted I can find article or video for you. I know it would be a royal pita to change what you have but for safety sake I feel that you should do some digging into this issue.Well guys, this will be kind of a special post for y’all today. It’s geared more towards the guys who have had trouble visualizing what I’ve had planned and have been working towards all these months.

With the floor and rear firewall now essentially done, I wanted to get the interior panels trimmed and fitted to the redesigned floor. I had intended to start with the lower rear panels, but quickly realized I actually had to start with the B pillar mouldings. One whole night spent just trimming and modifying these:

View attachment 213038

View attachment 213040

View attachment 213041

View attachment 213033

The fit as you can see is very good, nice and tight with no gaps to look like they came that way. Don’t worry, these aren’t actually rare factory black B pillar mouldings, they’re blue ones that have been dyed black at some point in their life. And they’re not in the greatest of shape either. The plastic is starting to break down and get crumbly, and the stand-offs inside for the top two screws are split and crushed.

I’ve gotta source some better condition factory replacements, I’m not terribly enamoured with the looks of the aftermarket replacements available out there.

With the B pillar trims fit, I could move onto the lower rear pieces. The uppers I modified several years ago when I first had the firewall welded in, so that was a bit of a time saver. They just needed a little refinement to make them perfect. Careful measuring, and careful cutting:

View attachment 213036

If you’re squeamish and the thought of cutting rare, one year only, factory black interior panels (which these are), you might wanna look away!

After several more hours of trimming and test fitting, I had both upper and lower rear panels fit nicely, with the new attachment holes drilled and the factory screws reinstalled. Pleased with how it was coming together, I naturally decided to take it to the next level.

Dug the large roll of jute out of the shed, cut and fit pieces to fit the floor, then cleaned up the racing harnesses and seats. Then installed all the pieces into the car for a final test fit and photo op.

So here ya go, this is for all the guys that seemed to have trouble visualizing my end goal. Naturally the jute will be covered with carpet and there will eventually be DynaMat sound deadening underneath it, but for now it covers up the bead rolling details that seemed to distract everyone.

No more words, just pictures for your perusal, but one final note: I have something special planned for the missing insert panels in the back, but you’ll just have to wait to see what that is.

Enjoy.

View attachment 213042

View attachment 213043

View attachment 213044

View attachment 213045

View attachment 213046

View attachment 213047

View attachment 213048

View attachment 213049

View attachment 213050

View attachment 213051

View attachment 213052

View attachment 213053

View attachment 213054

View attachment 213055

View attachment 213056

View attachment 213058

View attachment 213057

View attachment 213059

D.

Donovan, going back in time here. I recently found out that mounting belts that far away from the seat isn't a great idea. I'm not a physics major but it has something to do with leverage and length of belts that during a collision applies more force AND due to the stretch of excessive belt length, can cause the seat to actually buckle and collapse causing great bodily harm. Saw pictures of the collapse with belt mounting as you have. If wanted I can find article or video for you. I know it would be a royal pita to change what you have but for safety sake I feel that you should do some digging into this issue.

I recall the anchors were @ the rear seat firewall.Which post # is that? Pics aren't showing in the quote.

I recall the anchors were @ the rear seat firewall.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.