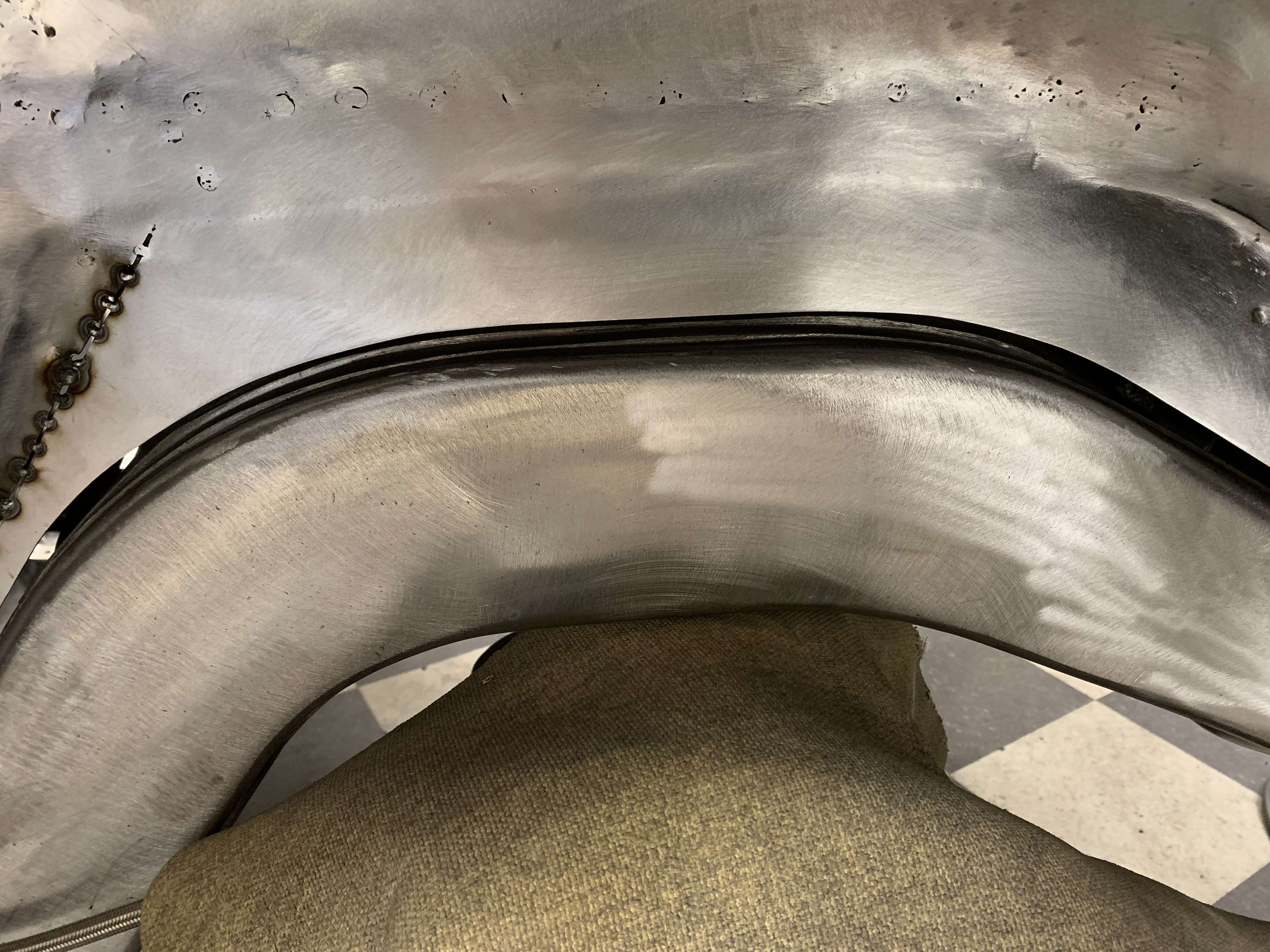

Progress on the driver’s side rear wheelwell close out panel has been slow, but steady.

Mostly fighting rusty/thin original metal, and porosity issues. Especially in the transition from flat behind the wheel to the areas facing the back of the tread. I’d strike an arc, only to have it deposit some material and blow away all around it. Attempt to fill that in, and a different area would blow away. Over and over again.

Immensely frustrating to say the least.

But I’ve kept after it, in the most stubborn way that is my own, and it’s starting to come together. Still a little bit of porosity in a few spots, but nothing compared to what I’ve already had to contend with. The epoxy and spray-on truck bed liner I plan on coating the entire underside with will fill those in and seal them off.

The dark spot near the middle of the previous picture isn’t rust, just a very deep factory spot weld.

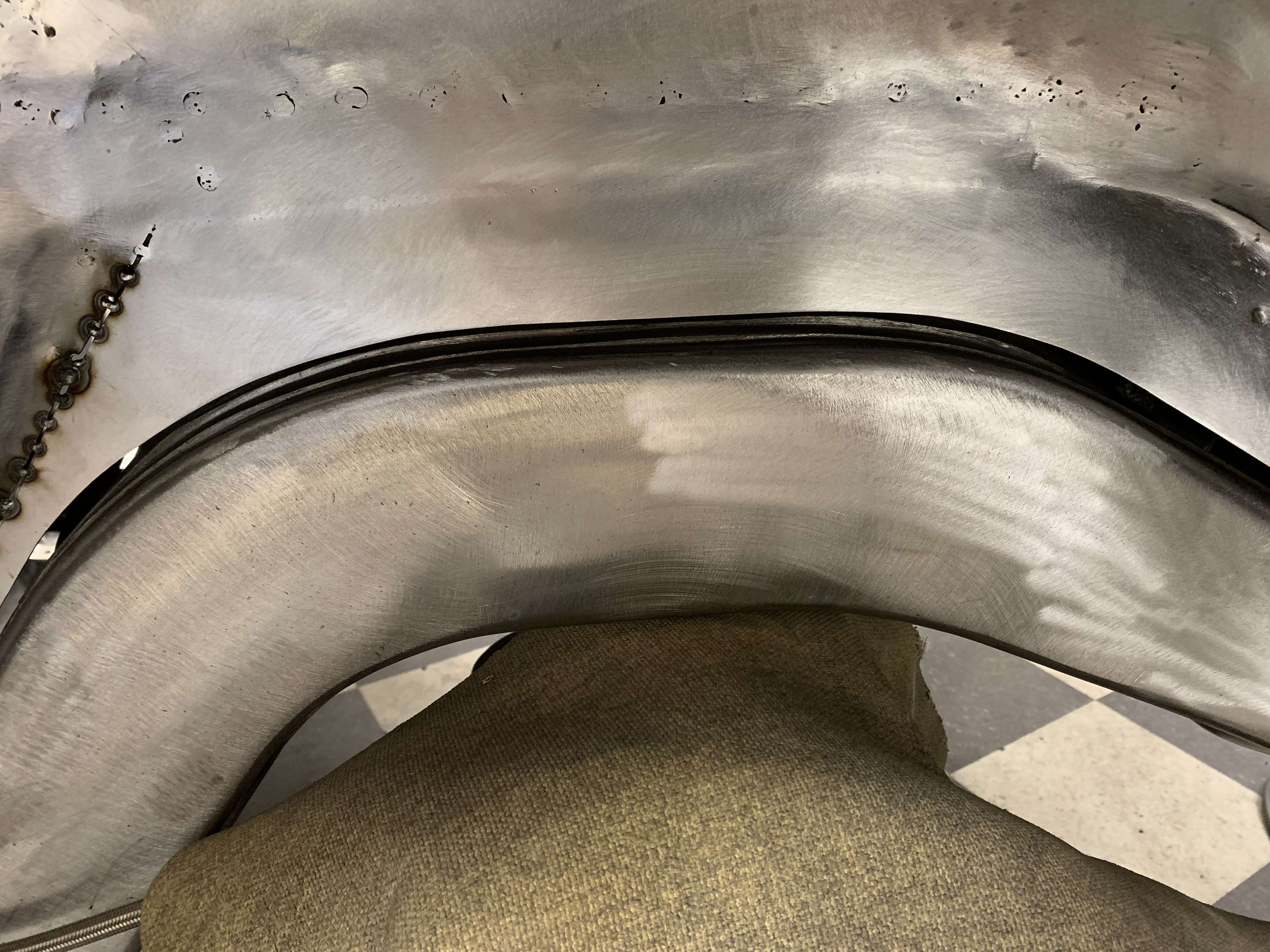

Definitely glad I undertook this though, the difference between before and after is significant:

All for now,

D.

Mostly fighting rusty/thin original metal, and porosity issues. Especially in the transition from flat behind the wheel to the areas facing the back of the tread. I’d strike an arc, only to have it deposit some material and blow away all around it. Attempt to fill that in, and a different area would blow away. Over and over again.

Immensely frustrating to say the least.

But I’ve kept after it, in the most stubborn way that is my own, and it’s starting to come together. Still a little bit of porosity in a few spots, but nothing compared to what I’ve already had to contend with. The epoxy and spray-on truck bed liner I plan on coating the entire underside with will fill those in and seal them off.

The dark spot near the middle of the previous picture isn’t rust, just a very deep factory spot weld.

Definitely glad I undertook this though, the difference between before and after is significant:

All for now,

D.