Still wrapped up in metal work on the hood this week.

I'm trying to get as much metal work on the hood done as possible with it in place. I've already spent a TON of time adjusting all the panels (hood, hinges, bumpstops, fenders, header panel etc) as best I can within the factory adjustment parameters.

Now it's time to go custom and fine tune all the gaps to where I feel they should be.

So with that being said, one area that has always irritated me beyond belief is where the back corners of the hood, top back corners of the fenders, and the top front of the doors all convene.

From the factory, there's a chrome strip that runs across the back of the hood. It meets up with tiny little chrome trim pieces that sit on the top back corners of the fenders, then continues on to tie into the wide chrome belt mouldings on the tops of the doors.

With the custom 3" raised cowl section on the new hood, the chrome strip along the back is out. Which is totally ok with me, as I had planned to eliminate it all along anyways.

Same with the goofy tiny pieces that sit on the tops of the fenders. I always hated those pieces anyways, as they usually loosen off and flop around not lining up to anything. That, and they never appeared to be the right shape anyways. So those are gone too.

The fronts of the wide belt mouldings on the tops of the doors has a nice shape to it that doesn't look out of place to start the chrome trim that frames the side windows. So those will stay.

My biggest pet peeve with this area is that there isn't continuity of a consistent line across all three panels. And because they're all so close together, it's terribly obvious and sticks out like a sore thumb. Especially when the chrome trim pieces are removed.

So, as mentioned before, time to get custom.

My thoughts on panel gaps is that the car should look like it was formed out of one single piece of steel, and then the openings were cut into it with a laser or something. It's that simple. Clean, consistent gaps the same width all the way through.

With that thought and philosophy in mind, that's how I decided to approach fixing up these areas.

Y'all might think I've totally gone off my rocker this time, but I actually physically welded all three panels together in this area. It seemed to me that it would be easier and look more correct if I could work all three panels together at the same time.

The pictures should tell the tale.

This is the passenger's side with the chrome trim pieces already removed, the hole in the top of the fender for the stud of the trim piece welded up, and the primer sanded back.

It really doesn't look that bad in the pictures, but as I said earlier I spent a ton of time trying to align everything as best as possible. Trust me when I say it looks worse in person.

The driver's side:

So, full steam ahead. Fire up the glue gun and get to it!

😀

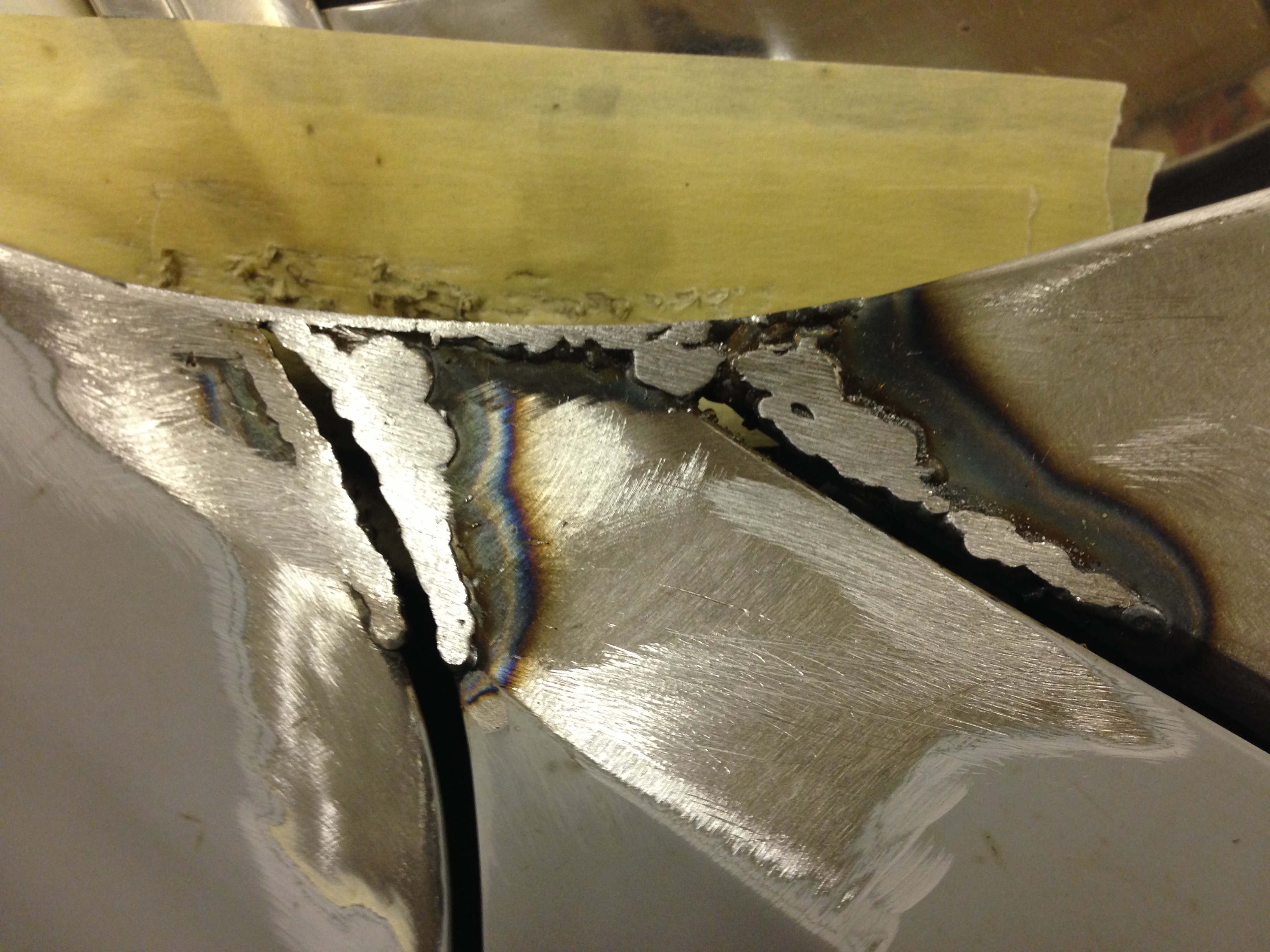

Yup, that's right, I totally just welded all three panels together!

😱

It's a good thing that I don't mind filing, as I would say about 95% of the welds were FILED down, not ground down.

The little air powered grinder I usually use would have been too aggressive and wouldn't work in these tight confines anyways. The tops of the welds were lightly dressed with the grinder just to smooth out the lumps and make it easier to start the file. The rest was done by hand.

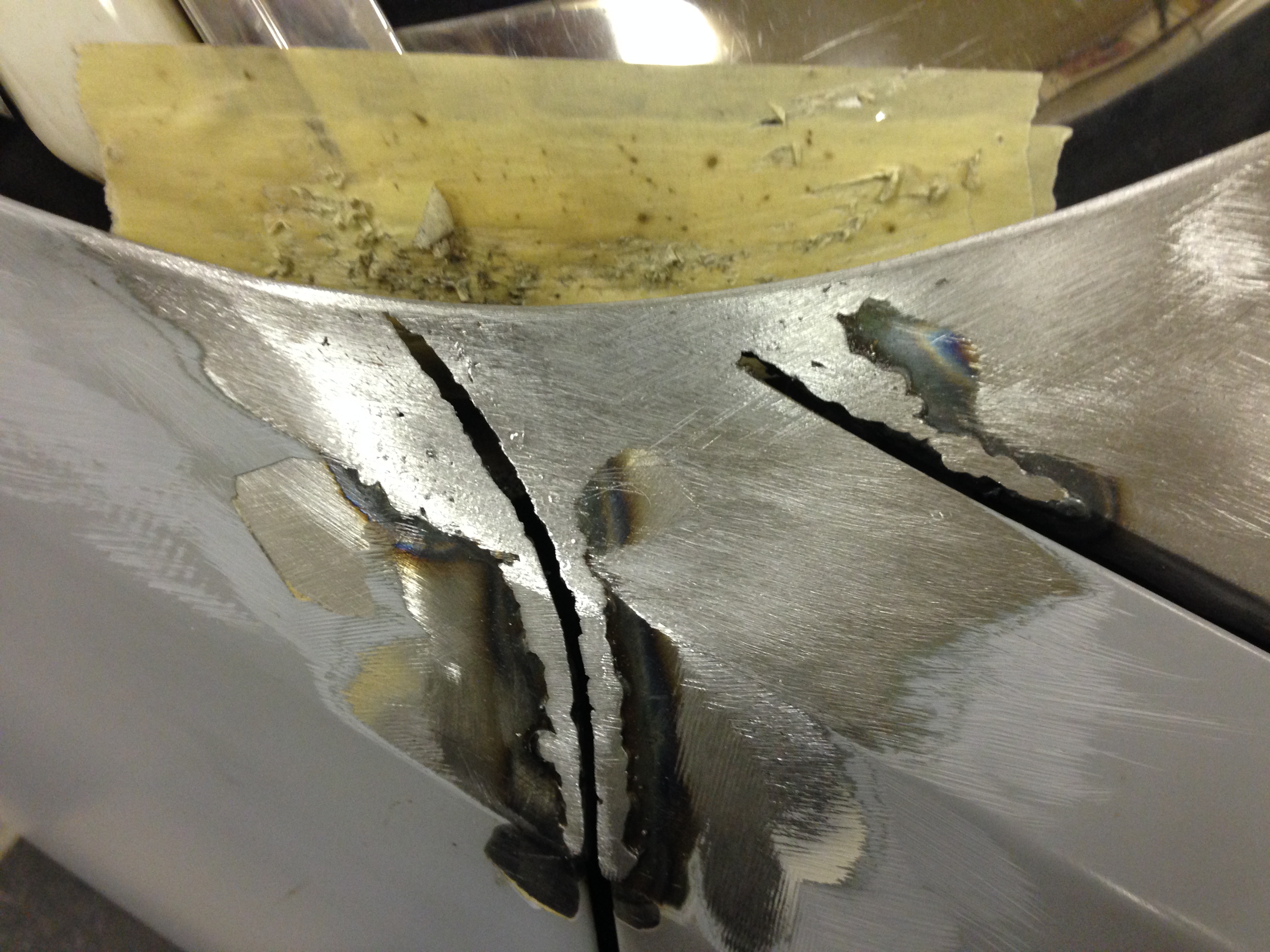

Here's a couple "in progress" pics so you can see the progression. I had a couple of "oh sh*t, what have I gotten myself into this time?" moments, but I just kept after it, filing and shaping the panels together.

Eventually, it started to look like something...

Once I had the curvature across the top right and the faces filed flat, I cut the openings back between the panels, and dressed down the edges with the files. I checked my progress with a piece of 3/16" flat stock that I'm using as my panel gap gauge. This should work well, and leave me with about an 1/8" gap after paint and primer.

The next pic shows the gap finished between the hood and fender:

Continued >>>