With the rear ride height sensors installed and wired up, I wanted to address the issue of the E-brake bracket on the passenger side rubbing the framerail at full drop.

First tho, I tackled the surface rust that had accumulated on the framerail. The fibre wheel on the die grinder made short work of that without removing any additional material.

Then I cleaned up and reinstalled the rotor, caliper, and caliper bracket.

Next I turned my attention to the E-brake bracket itself. After carefully measuring the distance of the driver's side bracket to the frame at full drop, I found that I had 1/4" on that side.

Time to make the passenger's side match.

Rather than remove material from the bracket "stand-offs" and have the bracket possibly sit too close to the rotor, I determined that I actually had enough room on the bracket itself to simply move the hole for the cable further outwards.

Just to confirm this for my own piece of mind, I mocked up the cable in the bracket. You can see how much further outwards (or inwards on the bracket) I could go before I ran into interference with the side of the bracket. I could easily achieve my 1/4" by doing so.

The procedure for modifying the bracket went as such:

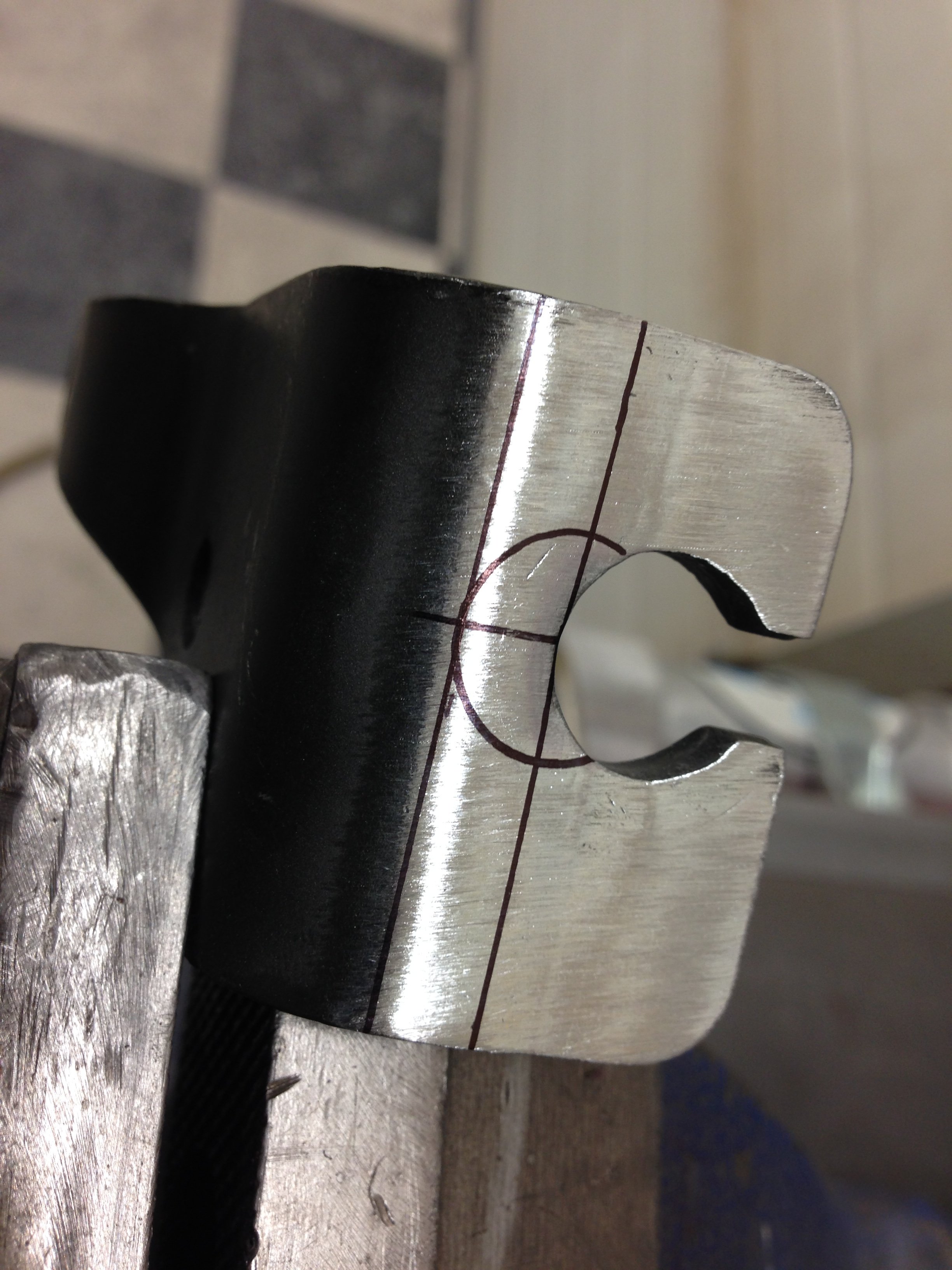

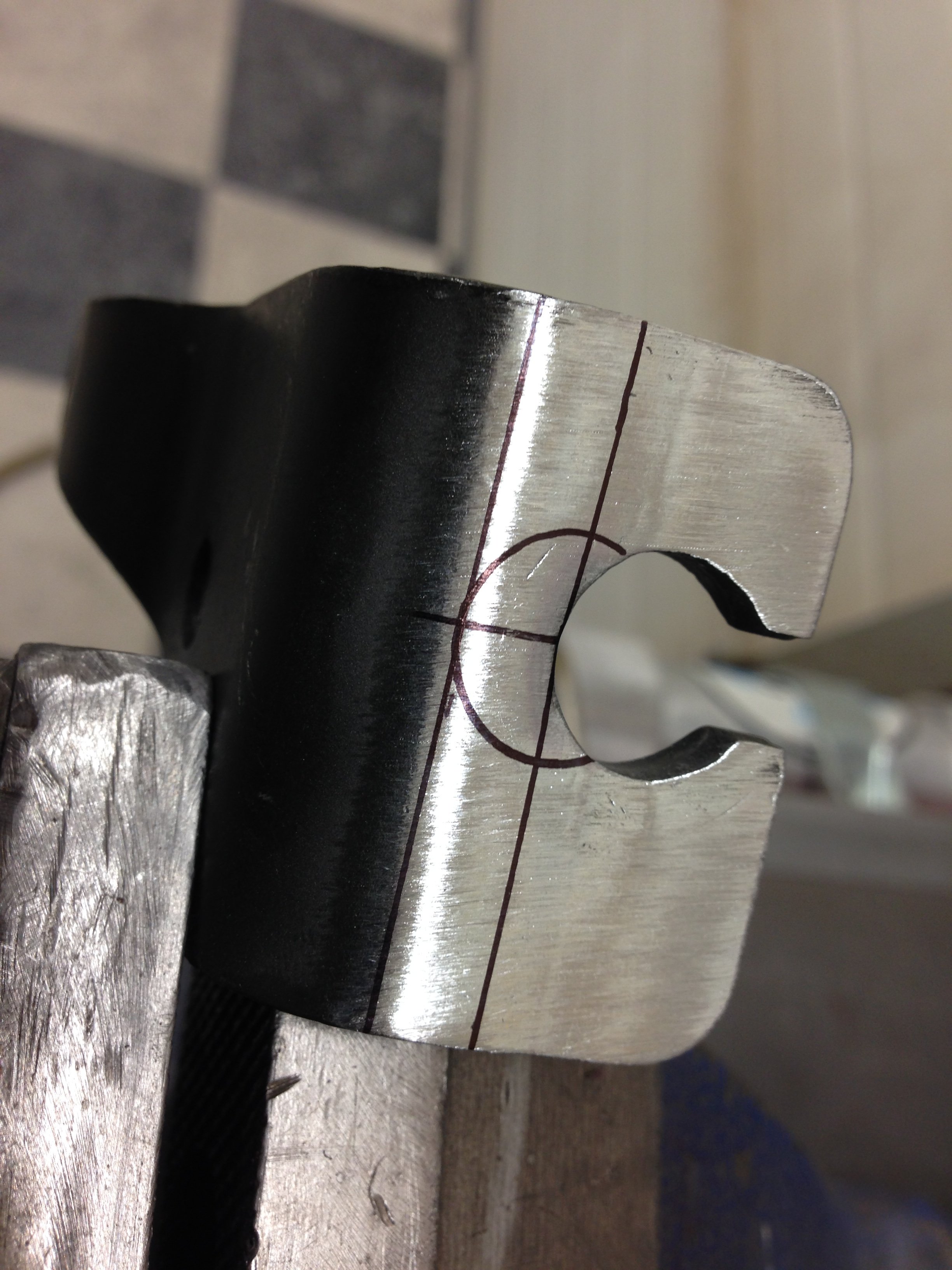

First the old coating was removed, and lines were drawn out at the edge of the hole, a 1/4" outwards, and the location of the new hole.

Using a straight shank burr on the die grinder, the new hole was opened up...

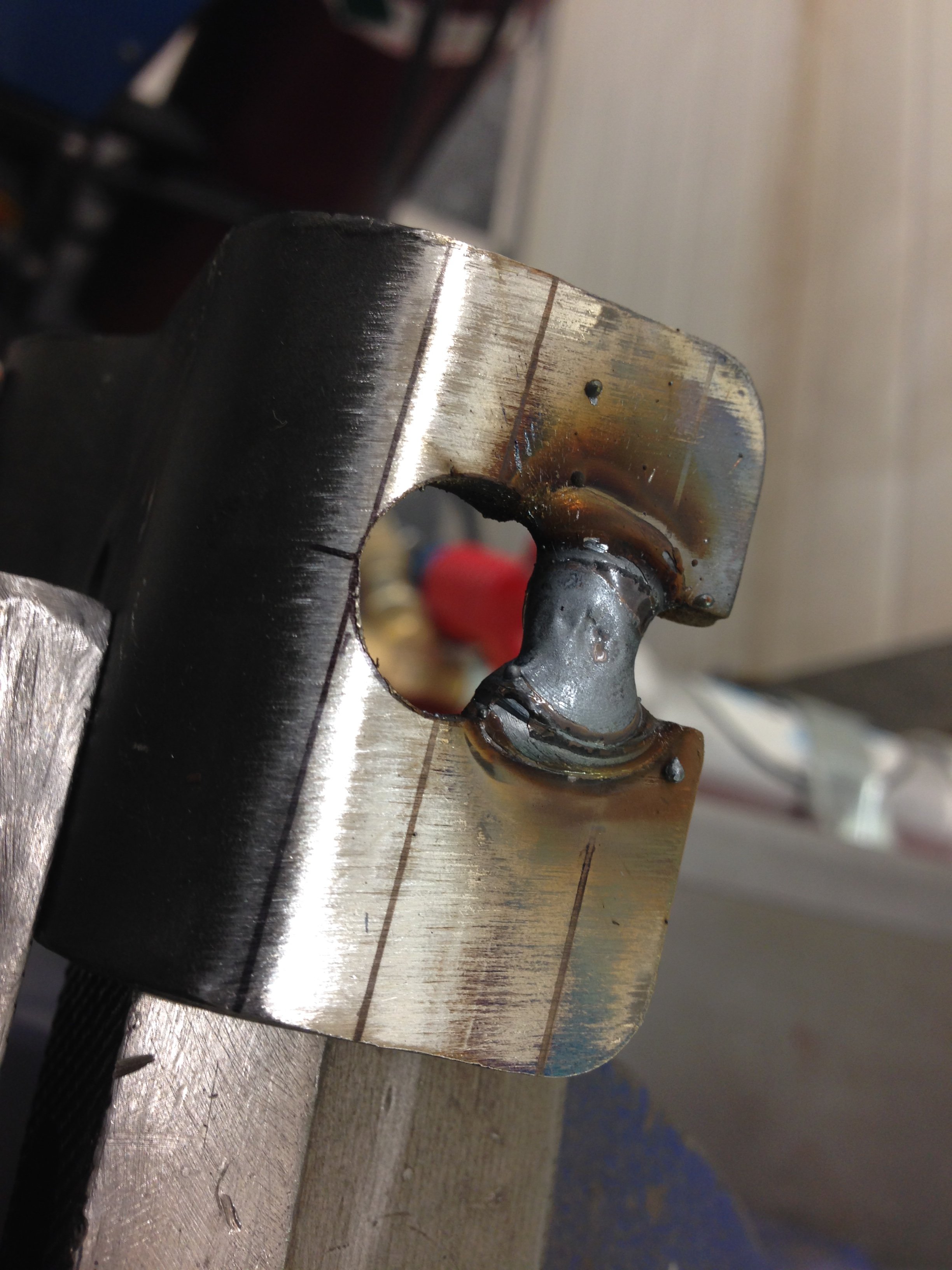

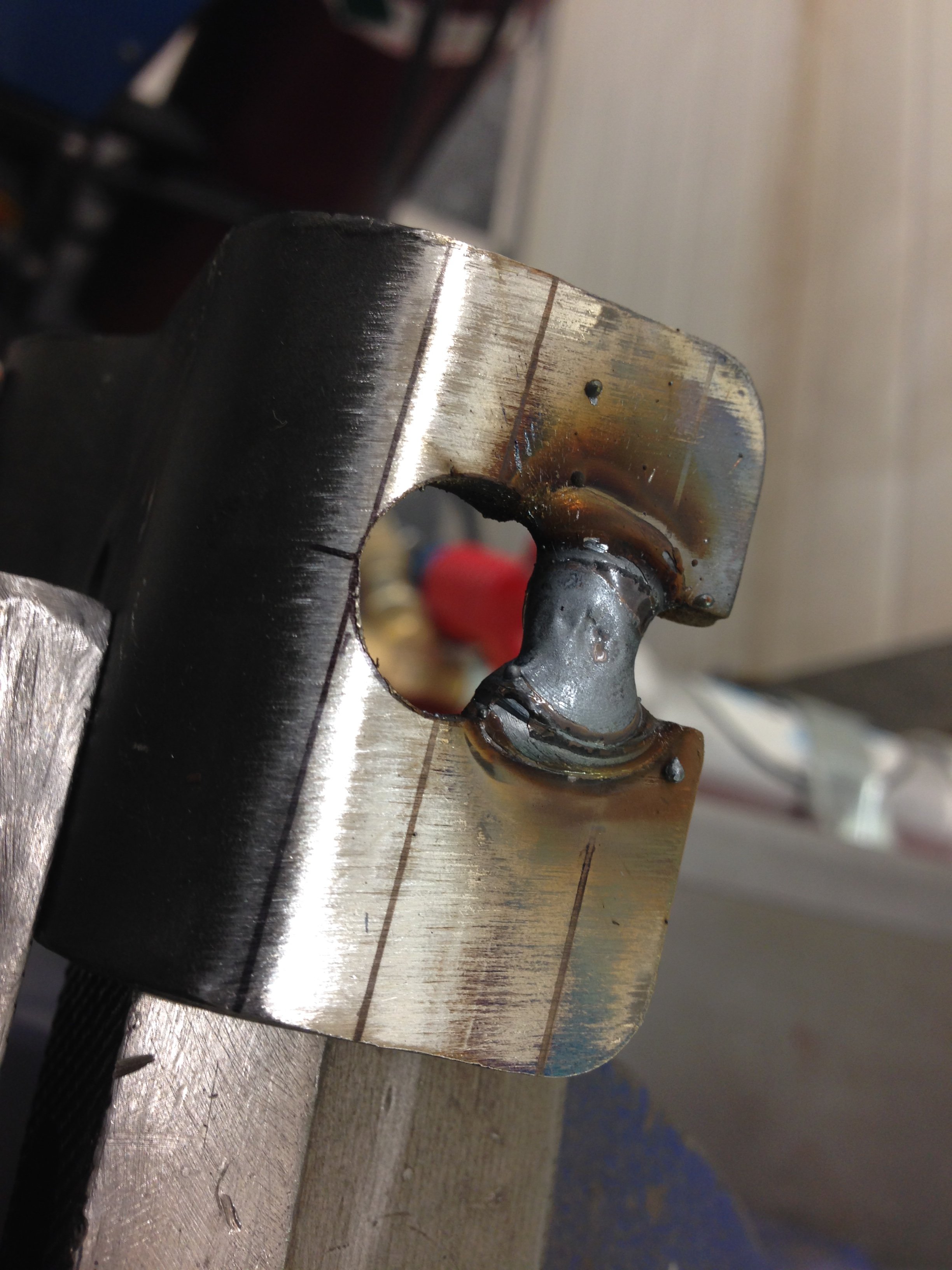

... and the majority of the old hole was welded shut.

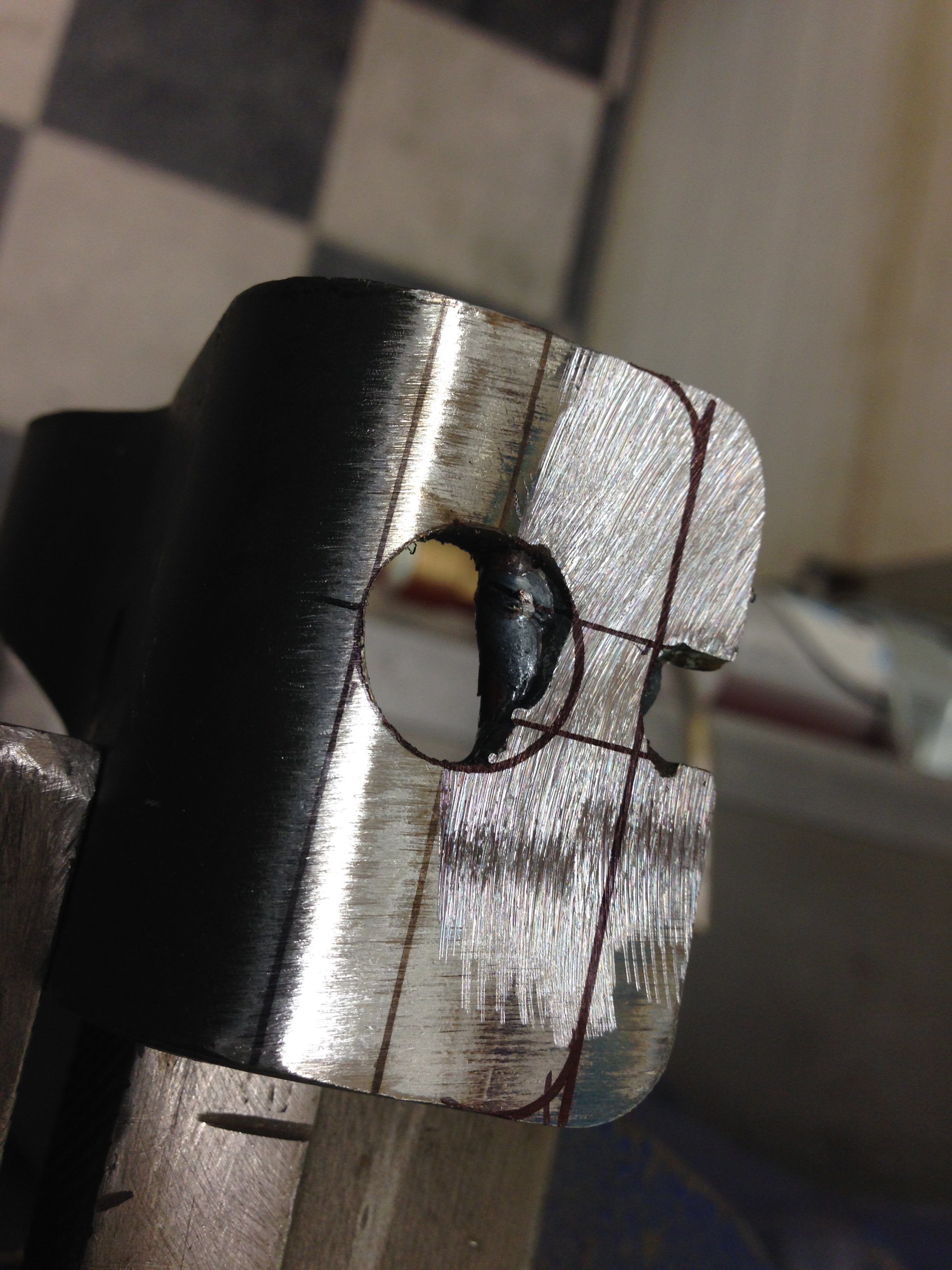

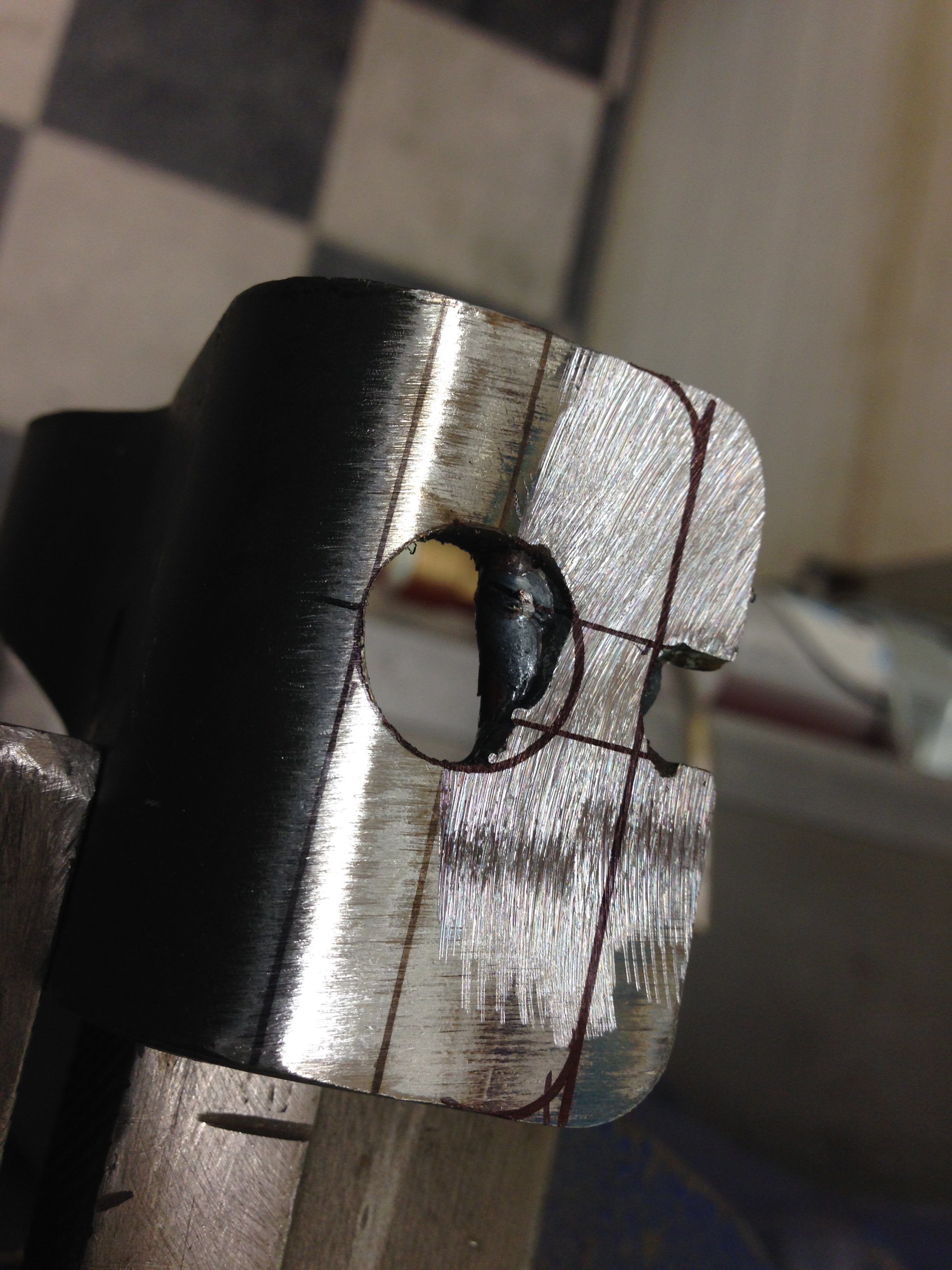

Once the weld was ground flush, new lines were laid out to mark where the cable relief needed to be added back in, as well as where the necessary 1/4" would be removed from the outer edge of the bracket, complete with radiussing the corners again.

After the necessary material was removed, a little chamfer was done on the hole with my countersink, the edges were dressed up with a file, and the whole assembly was given a quick sand with 120 grit on the DA.

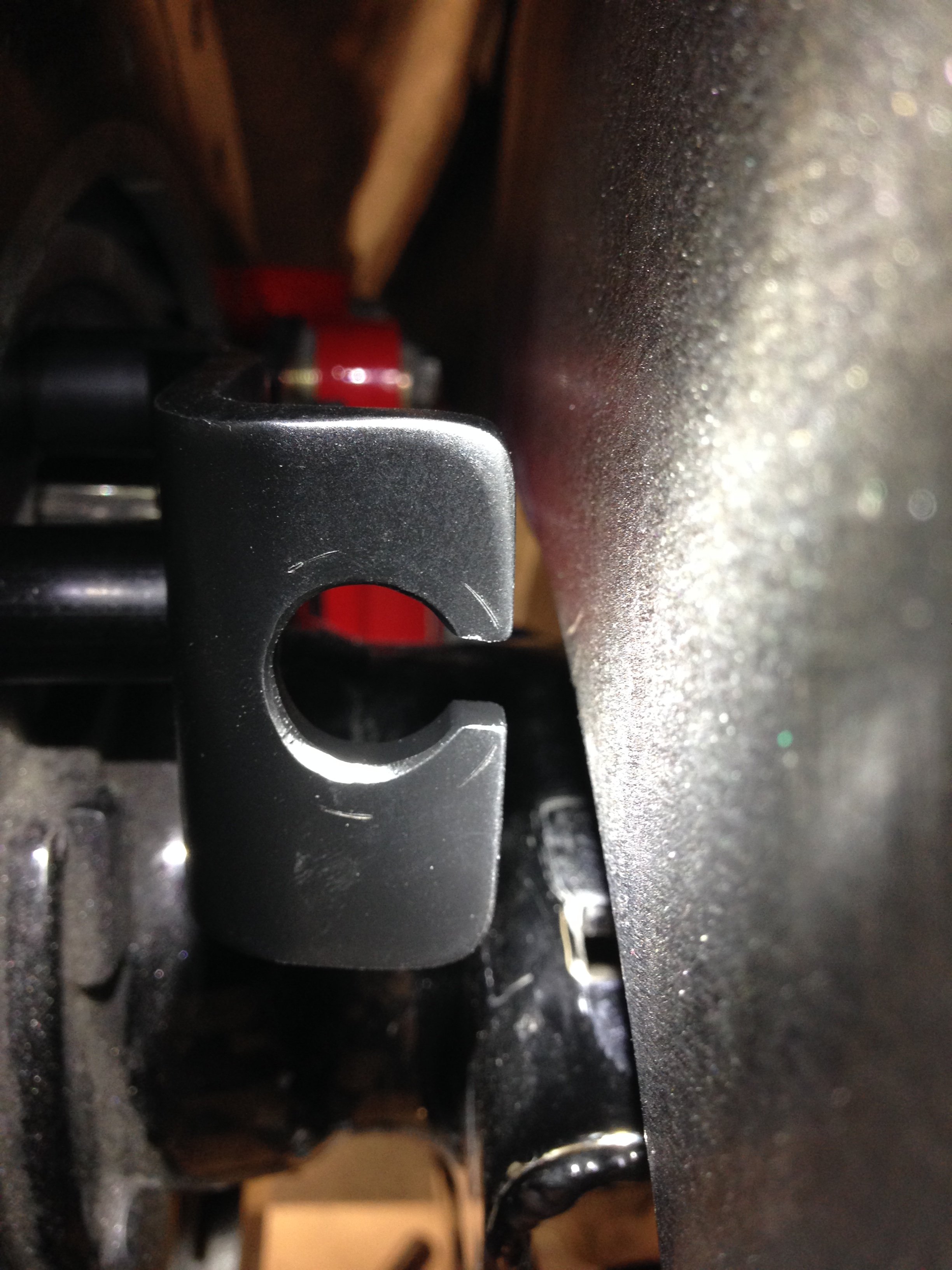

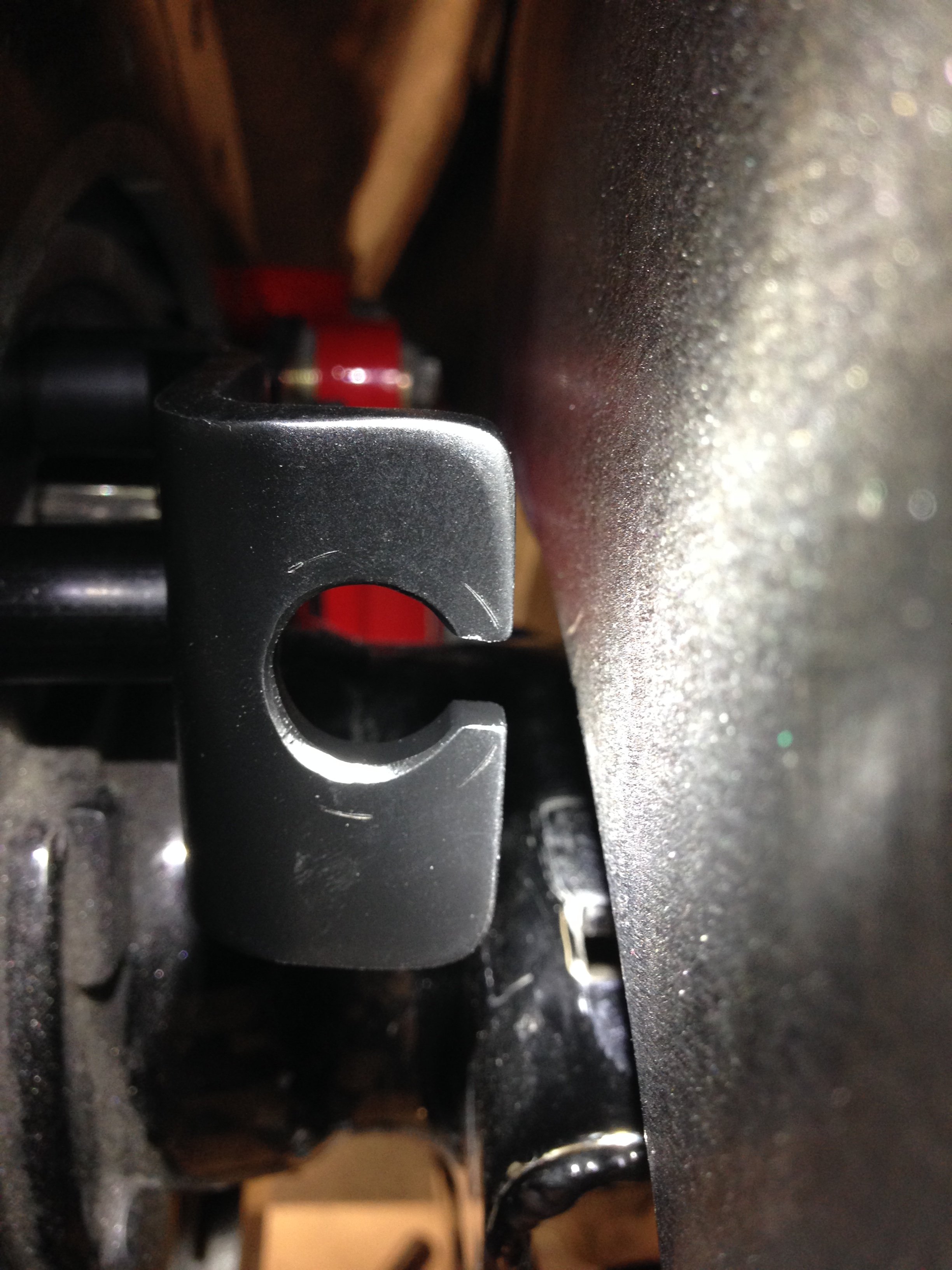

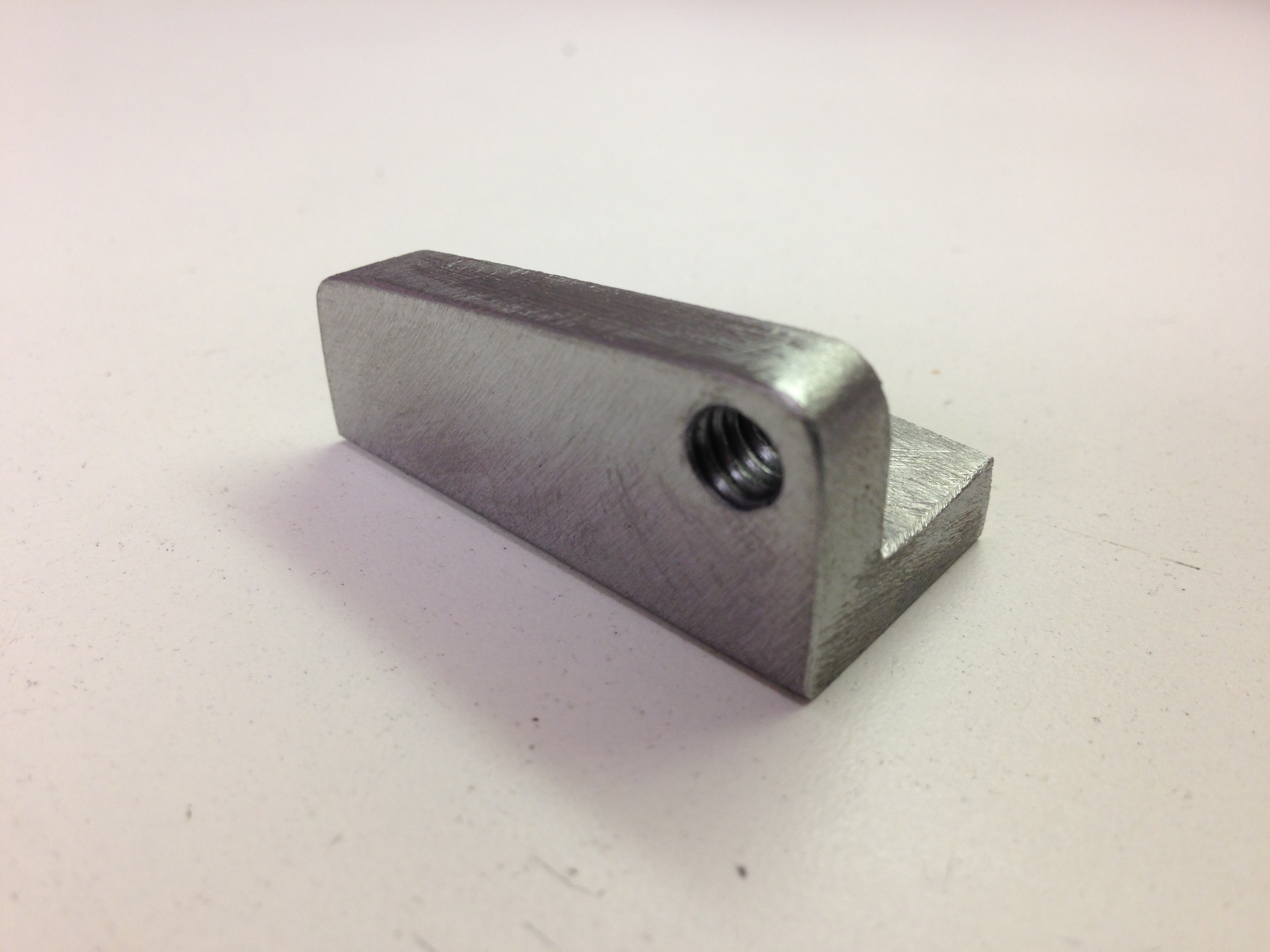

Here's the result:

After another mock up and test fit with the cable, I had to trim an edge of the inner washer to avoid it curling up on the side of the bracket once the nut was tightened. Other than that, all was good!

Satisfied with my "fix", I removed the cable and hung the bracket up for a couple light coats of satin black. Looks as if nothing has been done.

Once the paint had a chance to dry a bit, the bracket was reinstalled on the brake assembly and snugged back down.

Jacking the axel back up to its full drop position provided the assurance that I now had all the clearance to the frame I needed!

So that's it. Problem addressed, and solved quite effectively, I'd say. Best part is, visually it doesn't look any different than the driver's side, and it in no way affects operation of the E-brake actuation.

Next, I'll have a look at the bumpstops issue, and see if I can't come up with an effective solution there too before moving onto the front height sensors.

Thanks for checking back on the SECOND update today!

D.

First tho, I tackled the surface rust that had accumulated on the framerail. The fibre wheel on the die grinder made short work of that without removing any additional material.

Then I cleaned up and reinstalled the rotor, caliper, and caliper bracket.

Next I turned my attention to the E-brake bracket itself. After carefully measuring the distance of the driver's side bracket to the frame at full drop, I found that I had 1/4" on that side.

Time to make the passenger's side match.

Rather than remove material from the bracket "stand-offs" and have the bracket possibly sit too close to the rotor, I determined that I actually had enough room on the bracket itself to simply move the hole for the cable further outwards.

Just to confirm this for my own piece of mind, I mocked up the cable in the bracket. You can see how much further outwards (or inwards on the bracket) I could go before I ran into interference with the side of the bracket. I could easily achieve my 1/4" by doing so.

The procedure for modifying the bracket went as such:

First the old coating was removed, and lines were drawn out at the edge of the hole, a 1/4" outwards, and the location of the new hole.

Using a straight shank burr on the die grinder, the new hole was opened up...

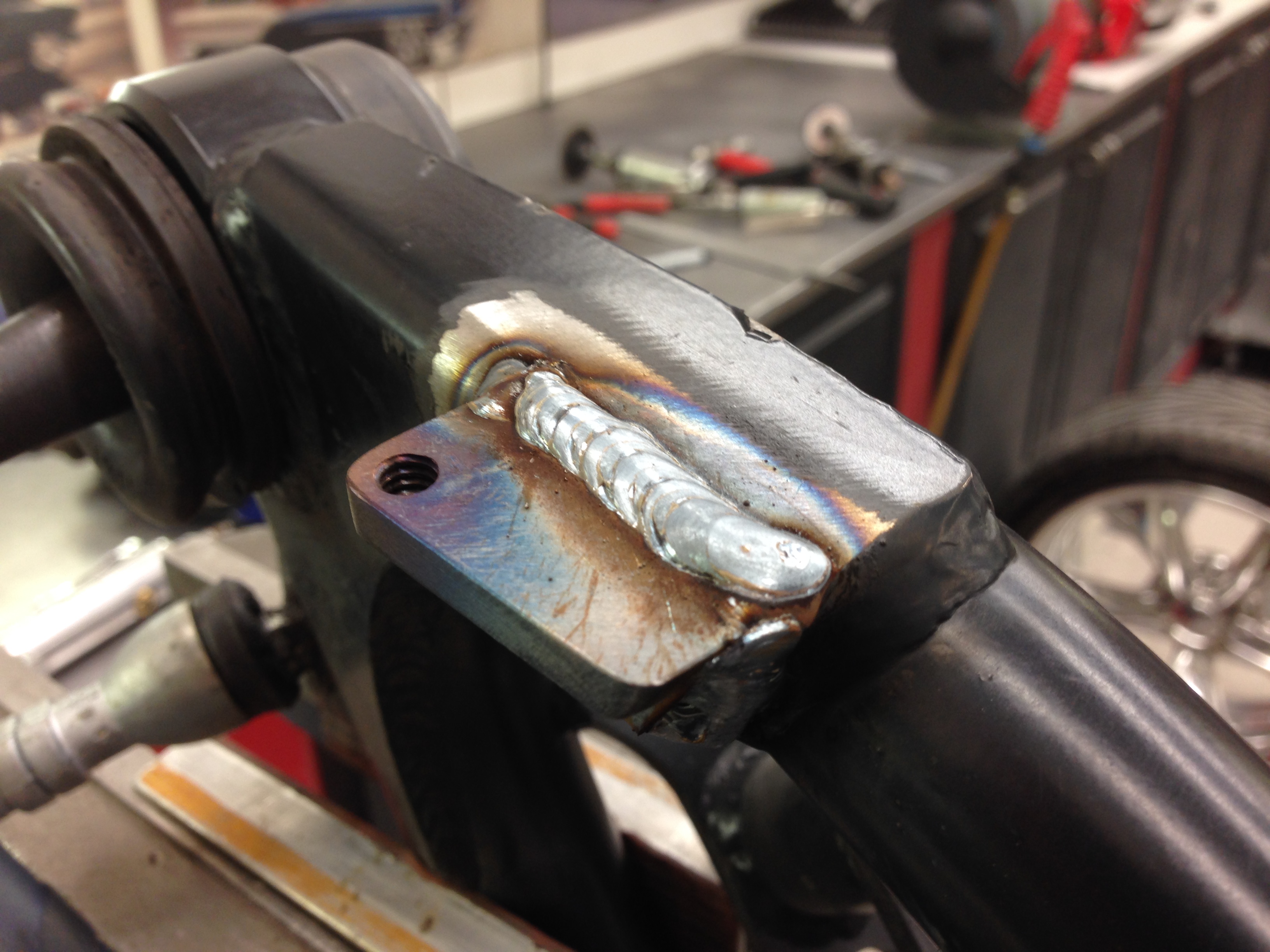

... and the majority of the old hole was welded shut.

Once the weld was ground flush, new lines were laid out to mark where the cable relief needed to be added back in, as well as where the necessary 1/4" would be removed from the outer edge of the bracket, complete with radiussing the corners again.

After the necessary material was removed, a little chamfer was done on the hole with my countersink, the edges were dressed up with a file, and the whole assembly was given a quick sand with 120 grit on the DA.

Here's the result:

After another mock up and test fit with the cable, I had to trim an edge of the inner washer to avoid it curling up on the side of the bracket once the nut was tightened. Other than that, all was good!

Satisfied with my "fix", I removed the cable and hung the bracket up for a couple light coats of satin black. Looks as if nothing has been done.

Once the paint had a chance to dry a bit, the bracket was reinstalled on the brake assembly and snugged back down.

Jacking the axel back up to its full drop position provided the assurance that I now had all the clearance to the frame I needed!

So that's it. Problem addressed, and solved quite effectively, I'd say. Best part is, visually it doesn't look any different than the driver's side, and it in no way affects operation of the E-brake actuation.

Next, I'll have a look at the bumpstops issue, and see if I can't come up with an effective solution there too before moving onto the front height sensors.

Thanks for checking back on the SECOND update today!

D.

Last edited:

!

!