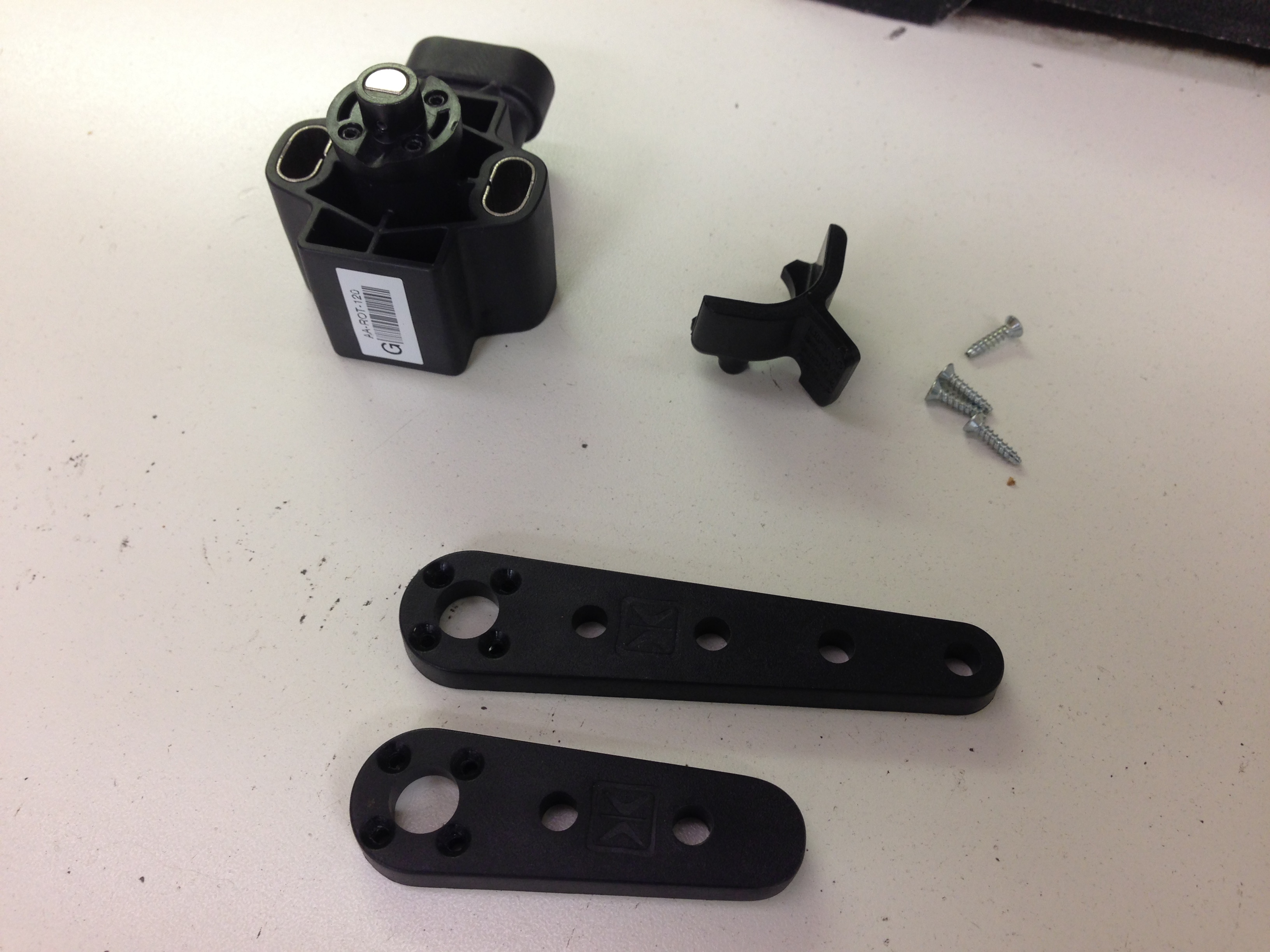

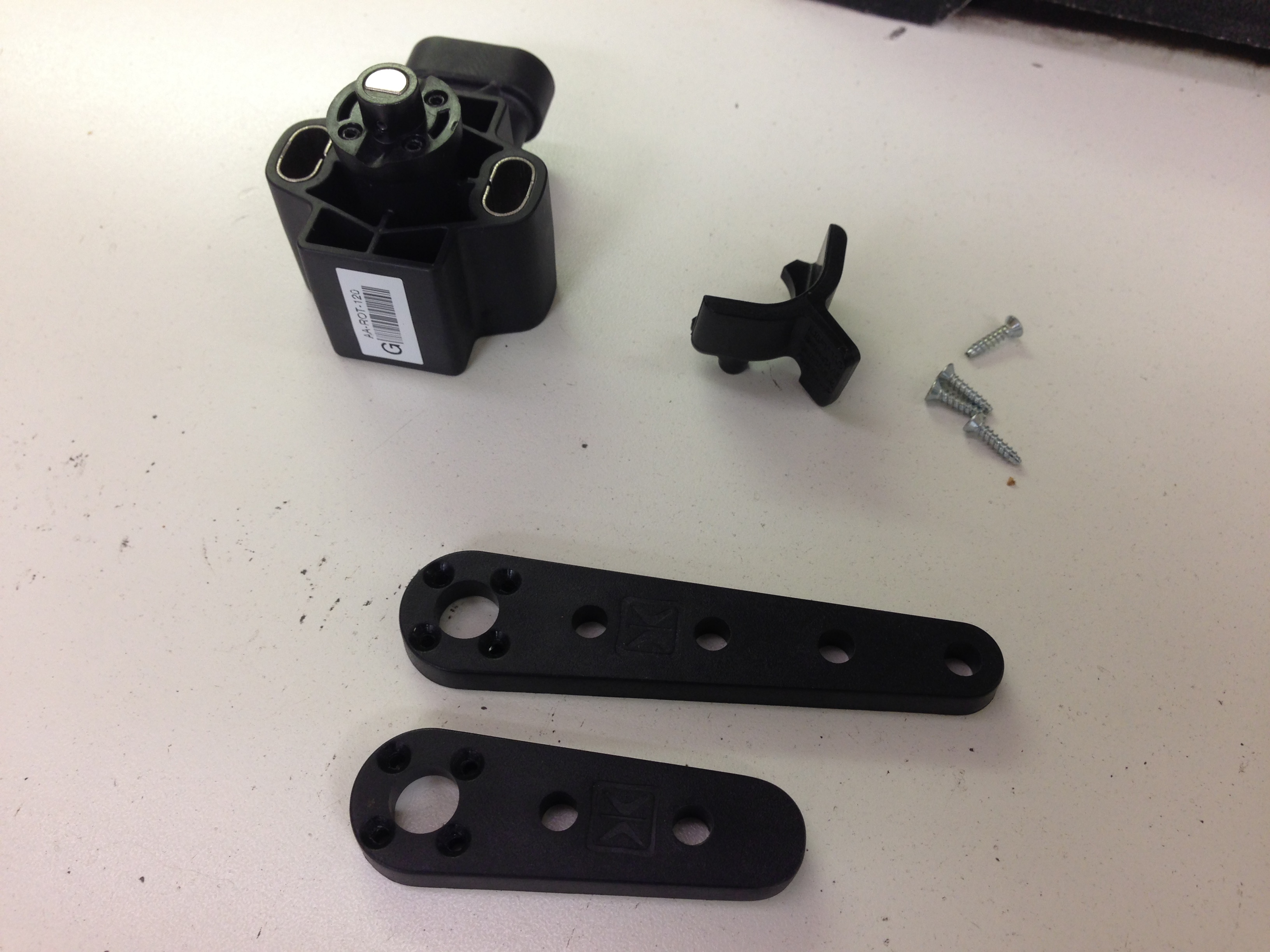

With my anal-retentive tendencies, I wasn't satisfied with the look of the two unused holes hanging off the end of the arm past where the linkage mounted.

After some quick checking of clearances on the driver's side rear location, I found that the driver's side arm would have to be shortened for sure to avoid contact with the air and rear brake lines on that side anyways. So both rear sensor arms came off, and got cut down, shortened, and smoothed out to a clean radius that closely matched factory:

As with most modifications, once the first side is figured out, the second side is usually a lot quicker and simpler. And so it was on the driver's side, with the exception of one little hiccup...

Rather than drilling through holes and bolting on the sensors with the supplied machine screws and nuts, I wanted to be able to mount them with just the machine screws. So I had been drilling and tapping the holes as I went along. Well, as luck would have it, the tap I was using snapped off almost perfectly flush with both sides of the frame on the very last hole. 😡

After much cursing and fighting with it for a bit, I decided to cut my losses for the night and shut things down. I've been doing this long enough now, that I realize sometimes it's better to walk away from things for a bit and go back another time and tackle the problem with a clear mind rather than continuing beating a dead horse.

This mentality paid off when the next night after some contemplation I realized (through more good luck than good planning) that my rear firewall side panels were still removable providing near perfect access to the busted tap and sensor location.

With that firewall panel removed, I was rewarded with just that. A couple good whacks with a decent sized BFH and a sharp punch broke up the broken chunk of tap and it fell out. I cleaned up the offending hole, and ran a new tap through the hole to ensure the threads were good, and bolted up the sensor. Problem solved!

In this next pic, you can see the proximity of the arm to the air and brake lines, and the necessity to shorten up the arm:

Now that the sensors and their associated components were installed, the last things to be done were to shorten up the wiring that goes to them and plug them in.

I'll spare you the enthralling details of shortening, crimping, heat shrinking, etc on the wiring, and just skip to the completed pic:

So that's pretty much it. Obviously the driver's side wiring was similarly shortened and routed, and that concludes the rear sensor install. Believe it or not, these were probably the easier of the 4 sensors to install, not much to take into account due to the simple "up or down" movement of the rear suspension.

The fronts however, may prove to be much more challenging. Less available real estate to mount things, harder to hide or at least make it look "purdy", and more components and moving parts to take into account and avoid.

That task will be the next one to take on, wish me luck and tune back soon to see how I fare with that...

Thanks for checking in everyone!

D.

After some quick checking of clearances on the driver's side rear location, I found that the driver's side arm would have to be shortened for sure to avoid contact with the air and rear brake lines on that side anyways. So both rear sensor arms came off, and got cut down, shortened, and smoothed out to a clean radius that closely matched factory:

As with most modifications, once the first side is figured out, the second side is usually a lot quicker and simpler. And so it was on the driver's side, with the exception of one little hiccup...

Rather than drilling through holes and bolting on the sensors with the supplied machine screws and nuts, I wanted to be able to mount them with just the machine screws. So I had been drilling and tapping the holes as I went along. Well, as luck would have it, the tap I was using snapped off almost perfectly flush with both sides of the frame on the very last hole. 😡

After much cursing and fighting with it for a bit, I decided to cut my losses for the night and shut things down. I've been doing this long enough now, that I realize sometimes it's better to walk away from things for a bit and go back another time and tackle the problem with a clear mind rather than continuing beating a dead horse.

This mentality paid off when the next night after some contemplation I realized (through more good luck than good planning) that my rear firewall side panels were still removable providing near perfect access to the busted tap and sensor location.

With that firewall panel removed, I was rewarded with just that. A couple good whacks with a decent sized BFH and a sharp punch broke up the broken chunk of tap and it fell out. I cleaned up the offending hole, and ran a new tap through the hole to ensure the threads were good, and bolted up the sensor. Problem solved!

In this next pic, you can see the proximity of the arm to the air and brake lines, and the necessity to shorten up the arm:

Now that the sensors and their associated components were installed, the last things to be done were to shorten up the wiring that goes to them and plug them in.

I'll spare you the enthralling details of shortening, crimping, heat shrinking, etc on the wiring, and just skip to the completed pic:

So that's pretty much it. Obviously the driver's side wiring was similarly shortened and routed, and that concludes the rear sensor install. Believe it or not, these were probably the easier of the 4 sensors to install, not much to take into account due to the simple "up or down" movement of the rear suspension.

The fronts however, may prove to be much more challenging. Less available real estate to mount things, harder to hide or at least make it look "purdy", and more components and moving parts to take into account and avoid.

That task will be the next one to take on, wish me luck and tune back soon to see how I fare with that...

Thanks for checking in everyone!

D.