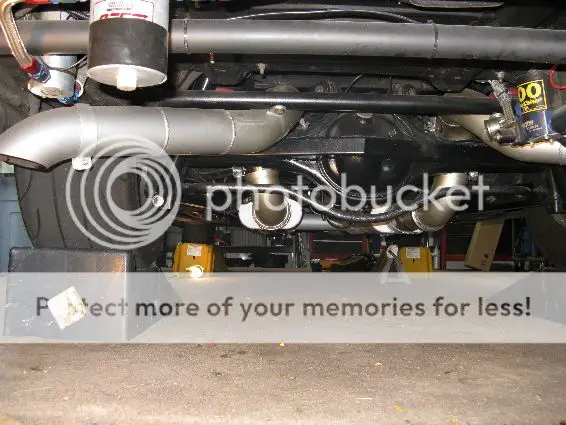

It's a hollow steel tube that bolts to each frame rail behind the core support. It is just ahead of and parallel to the sway bar. You can see it in a few of the pictures in this page of my build thread......For us non GP owners...what does the GP frame bar look like?

...and I'm a cheap basa, my work time is cheap

https://gbodyforum.com/threads/space-city-1982-gp-build.55501/page-5