Beautiful piece, but I do have a question/comment

With no apparent adjustment for width, are you concerned that after the body is on, removing the crossmember and reinstallation might have a problem getting the throughbolts aligned? I would be concerned that the frame might spread just a little when the crossmember is removed.

Just a thought....

Thanks for your concern/comment.

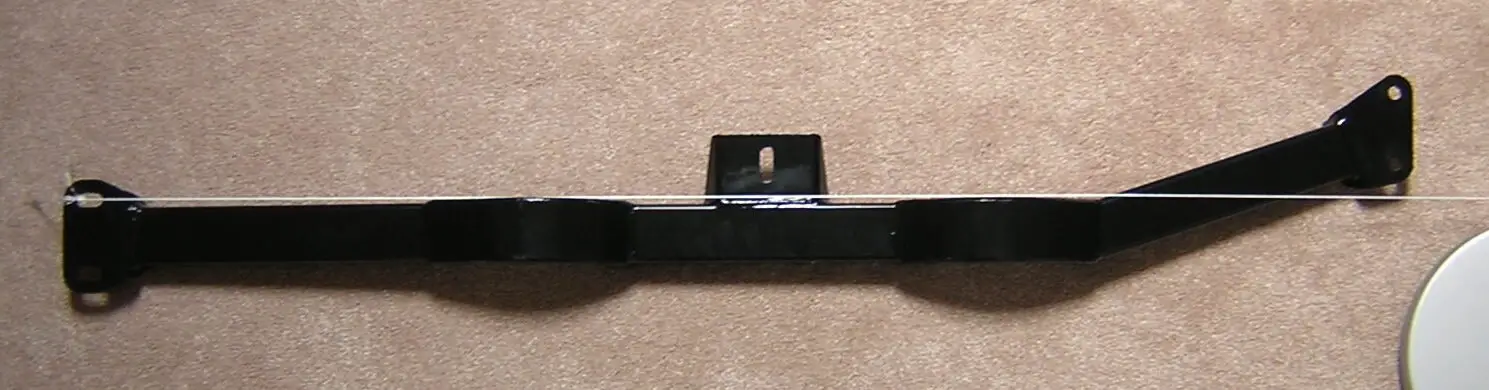

While the crossmember in that pic was still in the mockup stage (frame mount only tack welded in place), I have since completed the fabrication and install.

Yes, your are correct, at first it took a bit of finagling to get the bolts installed through the brackets. I made it a bit easier by opening up the bracket holes slightly oversize. A short aligning bar through the bracket and into the crossmember helped move it into place more still.

The framerails had spread slightly after boxing in the sides, but I pulled them back into place with a 3" heavy duty ratchet strap wrapped around the rails while the body was still off. I pulled them together slightly more than was needed, then when I released the tension and the rails relaxed, the crossmember aligned perfectly and the bolts slid right in.

The body is currently back on the frame and all the body mount bolts are installed and snugged down again, so I know the alignment between the body and frame is still within spec.

I'm not too concerned about having any difficulty removing or reinstalling the crossmember in the future with the body on as I can't see the framerails spreading much while they're bolted to the body. The center body mount bolts are within about 6" of the crossmember mounting points, so this should help to keep things anchored in place.

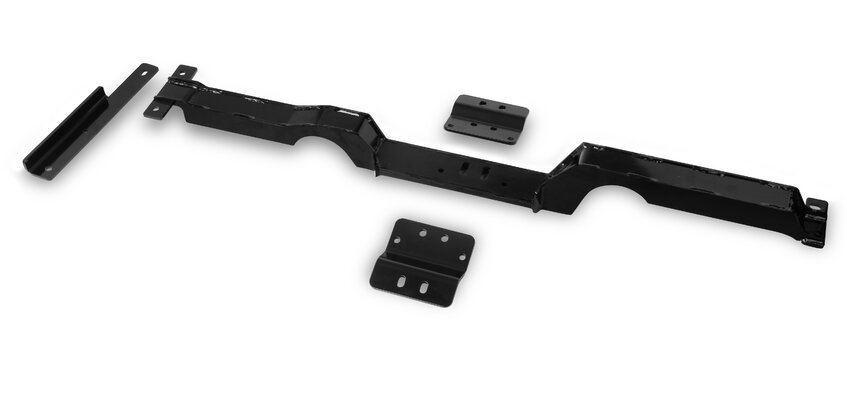

If you look close in this pic, you can see part of the driveshaft safety loop that I incorporated into the crossmember. It's a two piece design, allowing me to unbolt the upper portion to make transmission/driveshaft/crossmember removal and installation easier as well.

In this one, you can see the mount has been shortened, finalized, and welded in permanent. Don't mind the maze of tubing, they're all mockup pieces when I was planning out the fuel delivery and return system and the airline to the front air spring.

It's a very busy piece of real estate!

I'm happy to report that everything fits, clears the body and works beautifully together.

🙂

Thanks for your interest and comments/concerns!

Donovan