I took over Quality Assurance on our shift a couple of weeks ago because management would rather take advantage of my knowledge than give me my raise that's over a year past due and keep me in the booth. That decision will come to haunt them when production dips due to parts like you see in the following photos, each representative of many more like them. I mean a lot. In fact, some got recoated and that went poorly so now they've got to be burned off and start the process all over again. Firing up that oven alone costs $800.

Meanwhile, I'm killing it on the floor by showing guys better ways to operate and streamline their process, catching bad parts like baseballs, and absolutely loving the lower stress level. Nobody thought I'd manage the insane heat because the paint room is air conditioned but they clearly underestimated a guy who ran kitchens for 12 years as an alcoholic (sober now). It takes waayy more than heat to break me. The plant manager's ineptitude is showing more and more and I keep looking better and better! So I said I don't paint without a raise, even if they "need" me back there. My supervisor backs me 100% on that too.

I earned even more respect and trust from my supervisor, everyone got a lesson in how difficult and detail oriented my job as a painter who puts up 2x the parts of the other shifts is, and I drew a line in the sand, man. That's what I did at work today.

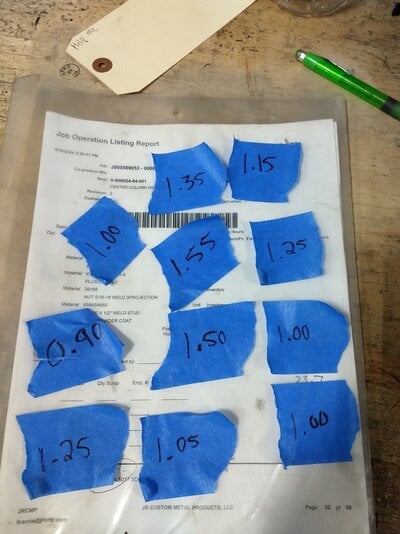

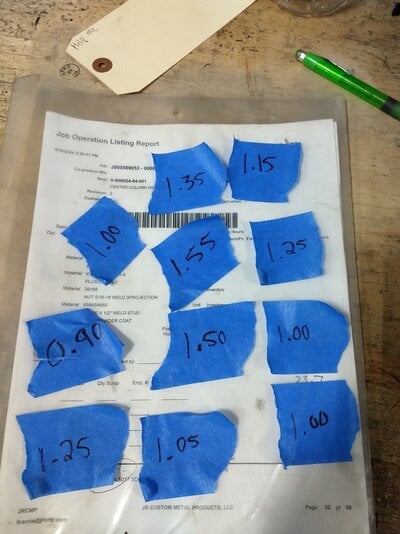

Super heavy.

Super light.

Looking for at least 2 mils thickness here.

We want a little less here.

The guy blowing water off the parts before they get painted sprayed a thousand droplets right onto painted parts in the 30 feet between the booth and cure oven. Repeatedly, over multiple days.

Wrong color, bro. Apparently 2nd shift added the wrong powder to an established paint hopper and then let their bad parts go out the door but I caught ours. And their mistake. HA!

I stopped taking pics after 20 separate incidents/issues over the span of four 12 hour shifts. The rumor mill has been proven wrong and I believe a change is gonna come...

Meanwhile, I'm killing it on the floor by showing guys better ways to operate and streamline their process, catching bad parts like baseballs, and absolutely loving the lower stress level. Nobody thought I'd manage the insane heat because the paint room is air conditioned but they clearly underestimated a guy who ran kitchens for 12 years as an alcoholic (sober now). It takes waayy more than heat to break me. The plant manager's ineptitude is showing more and more and I keep looking better and better! So I said I don't paint without a raise, even if they "need" me back there. My supervisor backs me 100% on that too.

I earned even more respect and trust from my supervisor, everyone got a lesson in how difficult and detail oriented my job as a painter who puts up 2x the parts of the other shifts is, and I drew a line in the sand, man. That's what I did at work today.

Super heavy.

Super light.

Looking for at least 2 mils thickness here.

We want a little less here.

The guy blowing water off the parts before they get painted sprayed a thousand droplets right onto painted parts in the 30 feet between the booth and cure oven. Repeatedly, over multiple days.

Wrong color, bro. Apparently 2nd shift added the wrong powder to an established paint hopper and then let their bad parts go out the door but I caught ours. And their mistake. HA!

I stopped taking pics after 20 separate incidents/issues over the span of four 12 hour shifts. The rumor mill has been proven wrong and I believe a change is gonna come...