I'm a 17th grader!!!

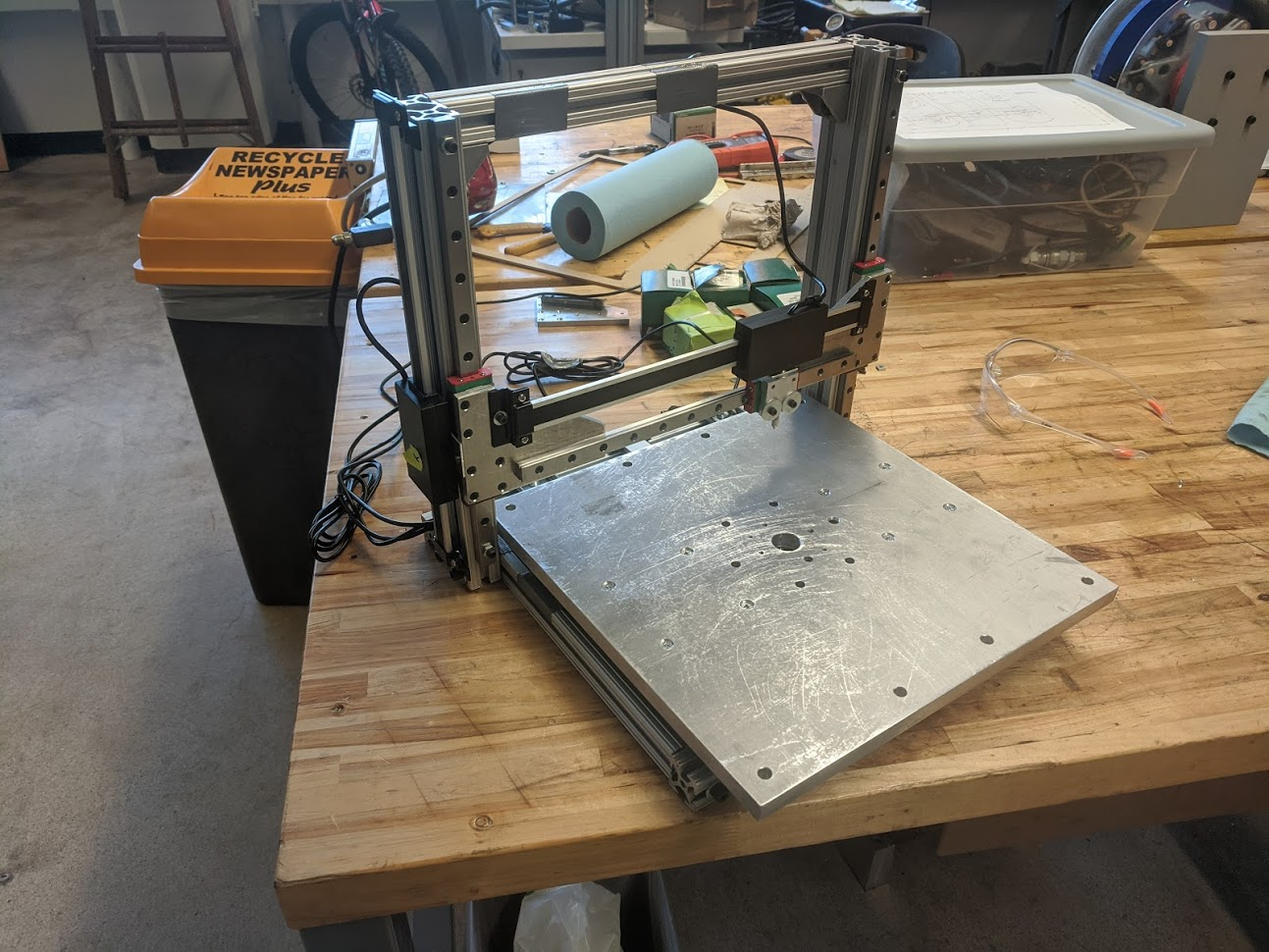

Being back in Engineering school means I have access to a well equipped machine shop again. One of my master's classes is interfacing microcontrollers into mechanical systems. A class mate and I are building a mini coordinate measuring machine. Readouts are $30 units off fleabay. They read down to 10 micron or a bit less than 0.0005". Not too shabby! Pretty happy with the structure so far. Been in the shop for half a dozen hours this week, feels good to be back to cutting chips since I spent quite a few hours on a bridgeport 3-7 years ago.

The machine shop is pretty well equipped but its a lot of undergrads that don't know their arse from an endmill. There is one crusty old machinist that tries to run around and help people but he is overwhelmed. I am a moderately accomplished machinist so I am down there throwing levers, switches and stuff pretty damn fast. He asks me a basic question every now and then, I tell him why I am doing it, he realizes I know what I am doing and leaves me be.

I was inadvertently a total dbag to an undergrad yesterday. Being closer to 30 than 20, and sorta looking the part with a beard and being over 6ft tall, along with working fast, people keep asking me for help. No problem, I am willing to help, I worked as an apprentice in the univ machine shop as an undergrad under a retired master tool maker. I helped people a lot, its just been 3 years.

There was 3 guys that needed to counterbore some holes for some 3/8 socket head cap screws in an existing part. They were trying to decide how large to make the counterbores for the bolt heads. They were saying "oh we can just make it a bit bigger than the head" and a bit of me died inside since there is a standard for that and realized nobody ever teaches that to you in engineering school so I'll throw them a bone. I keep a mini machinery handbook in my pocket when im machining for easy decimal to fraction conversions, tap and clearance drill specs, ect. My book had the exact table they needed so I took it out of my pocket, flipped it to the page and handed it to one of them and said "read it". I finished cleaning up, put the tools away since I was done and came back. They were confused. They didn't know what a F drill or a #8 drill bit was. Silly freshmen!

Well I told them what to generally do and what tools to get, one of them asked how to do something (find a hole center) and I said use a center finder. Long story short, of those 3 guys, only two were asking for help, the 3rd was the part time undergrad shop help that was trying to help the other two. I swooped in and inadvertently destroyed 90% of the instructions the part time help was telling the other two guys. I bet he felt crushed, I apologized when I realized I basically said everything he told them to do was wrong.

Anyways, it reminds me I gotta rescue my 70 year old behemoth lathe out of my buddies house 3 hrs away and get it into my house. I miss machining car parts. I could do a bunch of whacky stuff as an undergrad since I had 24hr access to the weld and machine labs. I think the staff would look at me funny if I brought a cylinder head for machining or some turbo piping for tig welding in.