This is more for shop organization than the Elk, so I'm posting here. I really needed to address this right away and get some of these wheels to a guy:

View attachment 252941

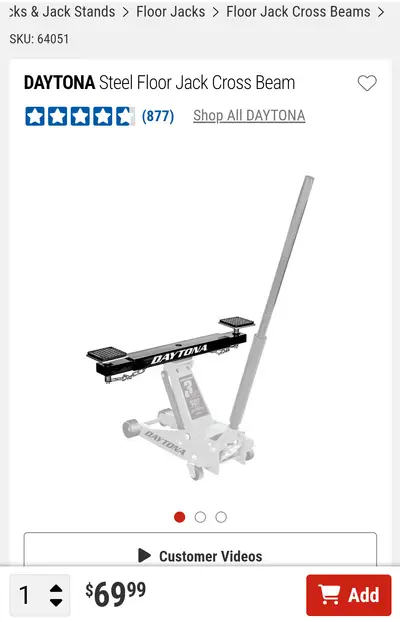

So I picked up a Daytona steel cross beam for one of my hydraulic jacks. Ya know, this deal from H.F.:

View attachment 252940

Apparently it's intended for jacks with cups that screw on, and mine just slip fit. That meant a bolt and nut were needed, and a 4" long 1" dia. cap screw fit the bill, though not perfectly. It also only fits the hole on one of my jacks, and luckily there's no obstruction to tightening the nut. Without a socket large enough I just used a Crescent wrench to tighten it into place with the beam twisted against the jack handle. It still pivots and extends freely. A 6x6 aided in the lifting process, though the cups are adjustable and also gave height to a jack I pulled from a dumpster long ago. Note Gina's brake fluid puddle (left) and trans fluid puddle (right).

View attachment 252943View attachment 252944

The block was long enough to contact both lower control arms, preventing the suspension from drooping as I raised the car. It made pulling the wheels out very easy as opposed to maxing out the jack and simultaneously using far too many boards. Which, uh, is how it got up there in the first place. That El Camino dropped to the floor numerous times when I drunkenly struggled to set it atop those wheels/ tires long ago, and this is INFINITELY BETTER. Now I've got a tiny bit more room, 6 fewer wheels & tires, and a new tool that'll help me relocate the '86 truck cab.

View attachment 252942View attachment 252945

Any bets on what's in the fridge? It's been so long that I honestly don't remember. And try not to be jealous of my Batman sheet on the Elk.