What did you do to your shop today?

- Thread starter RecklessRegal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hang 'em, and then put stuff you can afford to forget about in them. Works every time.

Today became interesting about the time I checked the mail and found that the top caps for the handlebar risers that I had fitted to an Indian front end project had come in. That merited a trip downstairs to the basement shop, which led, in turn, to an hour or so of soritng out "stuff". You know, the detrius and mechanical debris that tends to accumulate or get left behind as you move from project to project.

So when I decided to replace OBN1 and OBN2 (Old Bench Number 1 and Old Bench Number 2) with their new and structurally stronger versions, a lot of what used to sit on those bench tops just got tossed into boxes and totes and moved out of the way. With the caps carefully installed, it became a "While you're here" opportunity to sort through the leftovers and either bin them as useful or needed, or resign them to the trash can, or to whatever recycling was appropriate. It also let me find and consolidate other parts and components so that they could be moved out to the shop and lost out there.

One side note to all this is that, on the way by it, I took a quick peek at leveling bubble on my wheel truing stand and had a quick HuH! moment as the bubble was just nicely inside the inner ring. Basically all I had done with it was to move it off the old bench and onto the storage top and then move it back again so finding that its new home surface was flat and plumb was an unexpected bonus. Just meant that all the putzing and kvetching that I had done to get the bench framed together correctly was worth it.

Nick

Today became interesting about the time I checked the mail and found that the top caps for the handlebar risers that I had fitted to an Indian front end project had come in. That merited a trip downstairs to the basement shop, which led, in turn, to an hour or so of soritng out "stuff". You know, the detrius and mechanical debris that tends to accumulate or get left behind as you move from project to project.

So when I decided to replace OBN1 and OBN2 (Old Bench Number 1 and Old Bench Number 2) with their new and structurally stronger versions, a lot of what used to sit on those bench tops just got tossed into boxes and totes and moved out of the way. With the caps carefully installed, it became a "While you're here" opportunity to sort through the leftovers and either bin them as useful or needed, or resign them to the trash can, or to whatever recycling was appropriate. It also let me find and consolidate other parts and components so that they could be moved out to the shop and lost out there.

One side note to all this is that, on the way by it, I took a quick peek at leveling bubble on my wheel truing stand and had a quick HuH! moment as the bubble was just nicely inside the inner ring. Basically all I had done with it was to move it off the old bench and onto the storage top and then move it back again so finding that its new home surface was flat and plumb was an unexpected bonus. Just meant that all the putzing and kvetching that I had done to get the bench framed together correctly was worth it.

Nick

Worked on my tool boxes a bit over the last couple of days. Picked up a new (to me) Kennedy Riser to go with the rollaway and top boxes. Then cleaned and oiled all the slides on the riser and top box. Picked up some black felt to replace some of the torn up pieces in a couple drawers as well as add some to the bottom drawer of the riser. Turned out pretty good I think.

Attachments

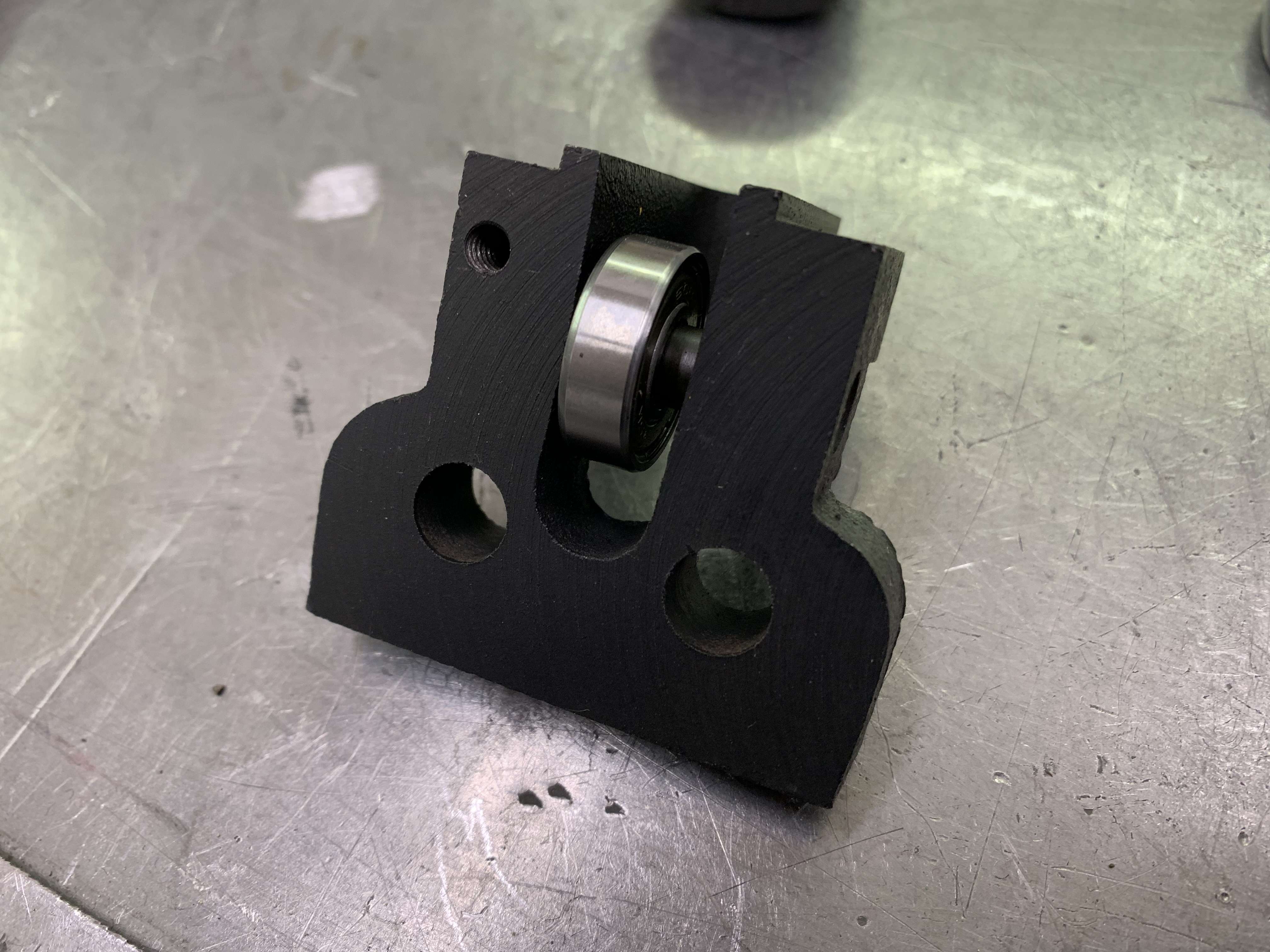

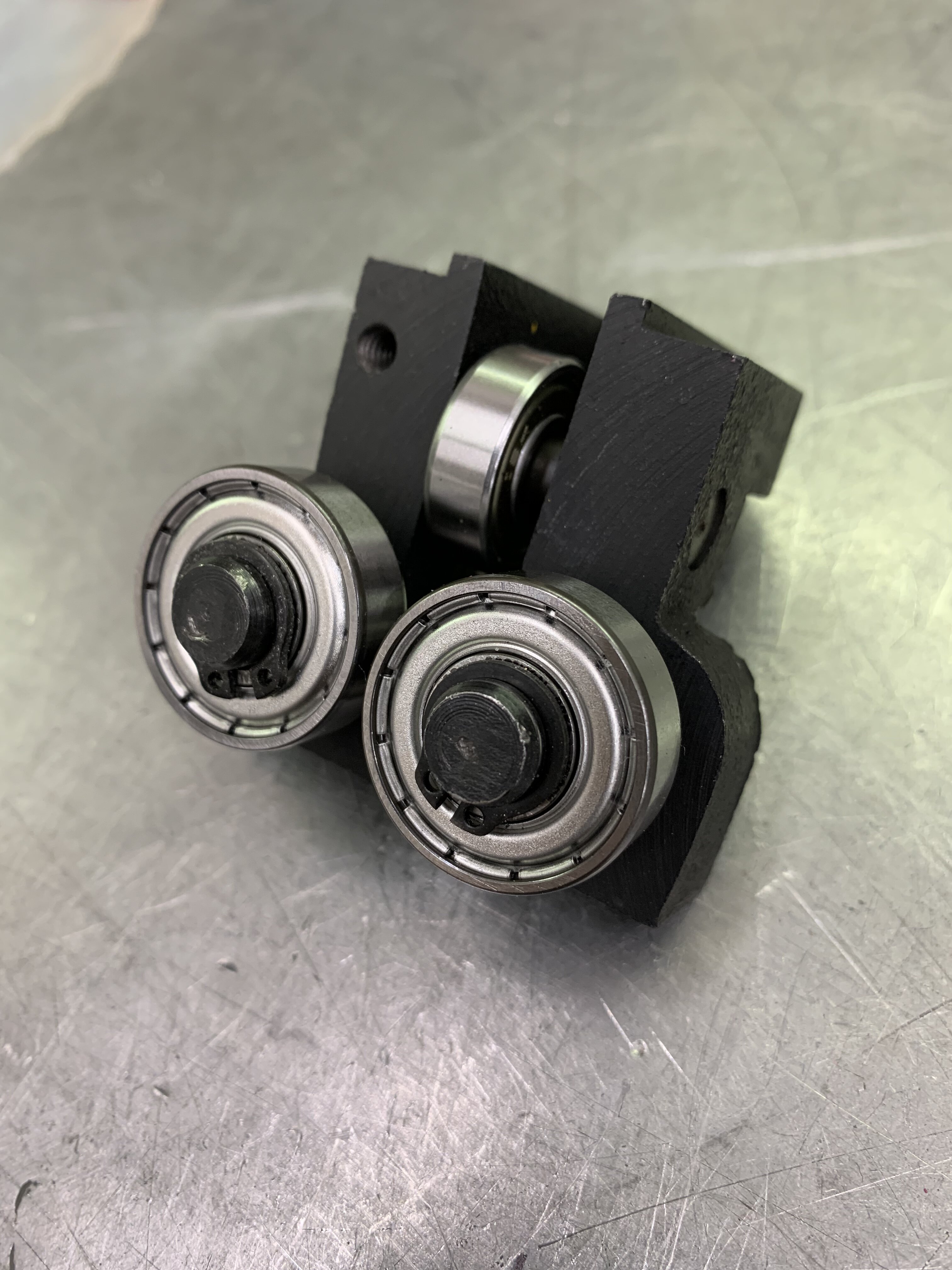

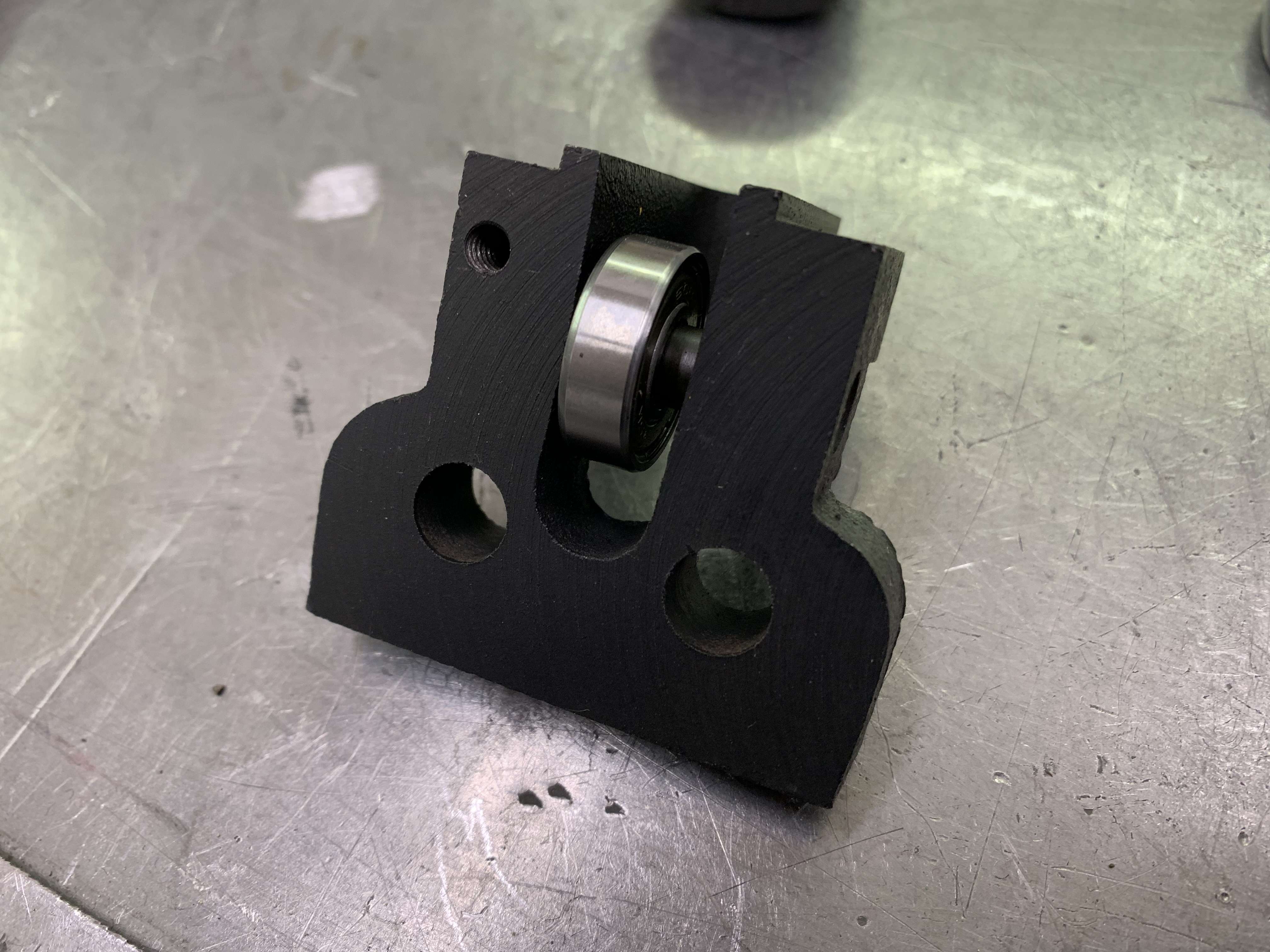

Some much needed maintenance on the metal cutting bandsaw. I’ve had a cracked upper guide roller for several years now, and finally after over a year of being on back order, they showed up the other day.

Somehow the cast iron had cracked, and the only thing holding it together was the drive pin for the center roller bearing.

Once I had it out and the side rollers out, I realized that it was actually cracked in two places. I’m lucky the whole thing didn’t come apart on me in the middle of a cut.

New ones came complete with the center rollers already installed.

I was originally just going to reinstall the original side roller bearings, but once I got them off, they were chunky and badly needed replacing as well.

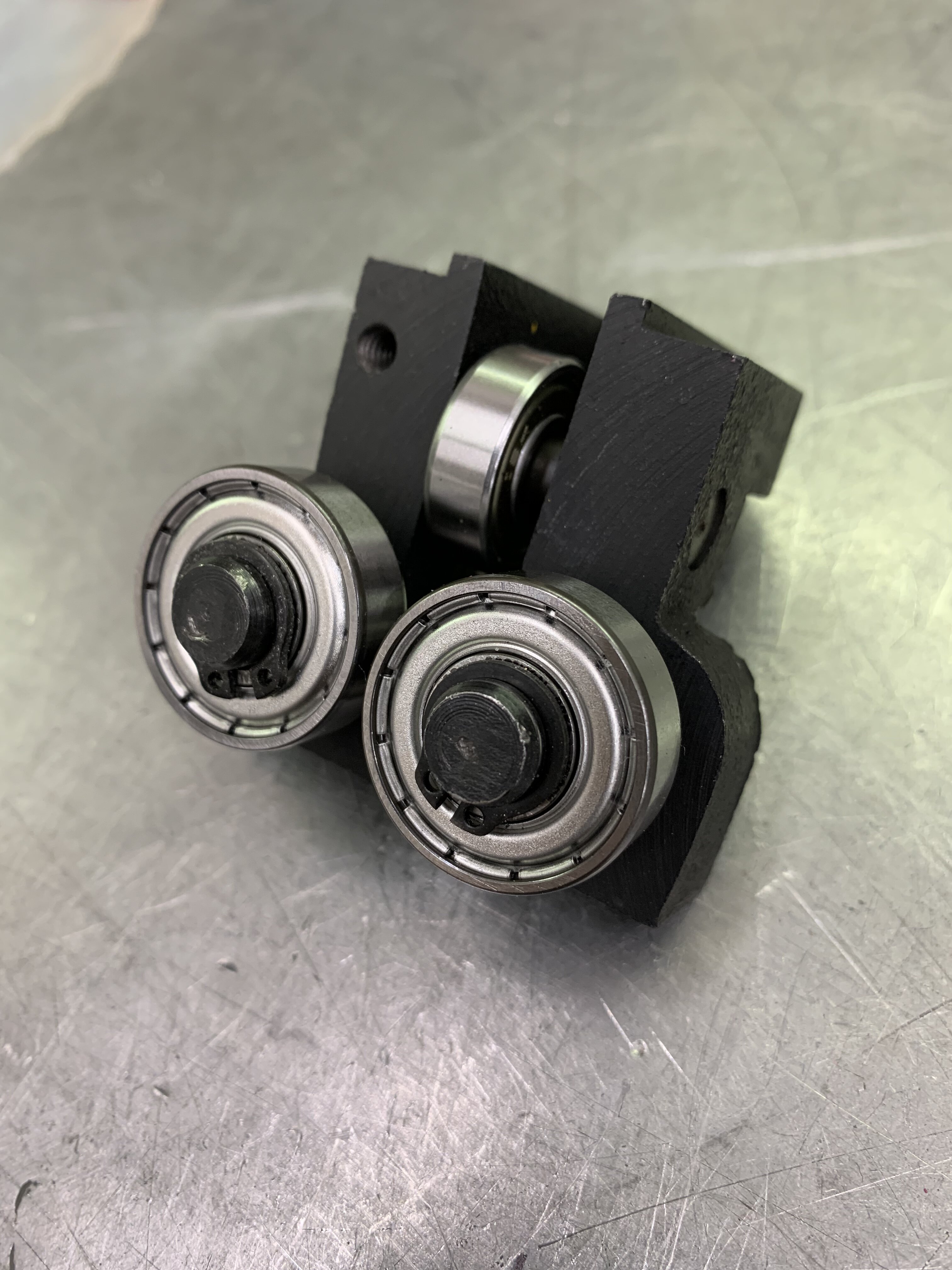

So, picked up some new side roller bearings today, and got them changed out too. One of the two new roller guides reassembled with new bearings:

Done, and much better now. I’ll keep the non-cracked one as a spare in case this ever happens again.

Somehow the cast iron had cracked, and the only thing holding it together was the drive pin for the center roller bearing.

Once I had it out and the side rollers out, I realized that it was actually cracked in two places. I’m lucky the whole thing didn’t come apart on me in the middle of a cut.

New ones came complete with the center rollers already installed.

I was originally just going to reinstall the original side roller bearings, but once I got them off, they were chunky and badly needed replacing as well.

So, picked up some new side roller bearings today, and got them changed out too. One of the two new roller guides reassembled with new bearings:

Done, and much better now. I’ll keep the non-cracked one as a spare in case this ever happens again.

Wait.... You didn't bevel the edges? Smooth the casting lines or weld fill any unnecessary holes?!? You just changed bearings and installed them???Some much needed maintenance on the metal cutting bandsaw. I’ve had a cracked upper guide roller for several years now, and finally after over a year of being on back order, they showed up the other day.

View attachment 213347

Somehow the cast iron had cracked, and the only thing holding it together was the drive pin for the center roller bearing.

View attachment 213351

Once I had it out and the side rollers out, I realized that it was actually cracked in two places. I’m lucky the whole thing didn’t come apart on me in the middle of a cut.

View attachment 213352

New ones came complete with the center rollers already installed.

View attachment 213353

I was originally just going to reinstall the original side roller bearings, but once I got them off, they were chunky and badly needed replacing as well.

View attachment 213354

So, picked up some new side roller bearings today, and got them changed out too. One of the two new roller guides reassembled with new bearings:

View attachment 213355

Done, and much better now. I’ll keep the non-cracked one as a spare in case this ever happens again.

View attachment 213356

View attachment 213357

What's going on here?

Worked on cleaning my pig pen up, then a little on the Malibu. Had the heat cranked to 70° and it's working well.

Worked on cleaning my pig pen up, then a little on the Malibu. Had the heat cranked to 70° and it's working well.

View attachment 213373

View attachment 213374

You suck!!

Just kidding! Maybe next year I'll move up to propane heat!

My old fuel oil forced air furnace worked good, but not as good as this. Should've done it a long time ago. Even better was the floor space it freed up.You suck!!

Just kidding! Maybe next year I'll move up to propane heat!

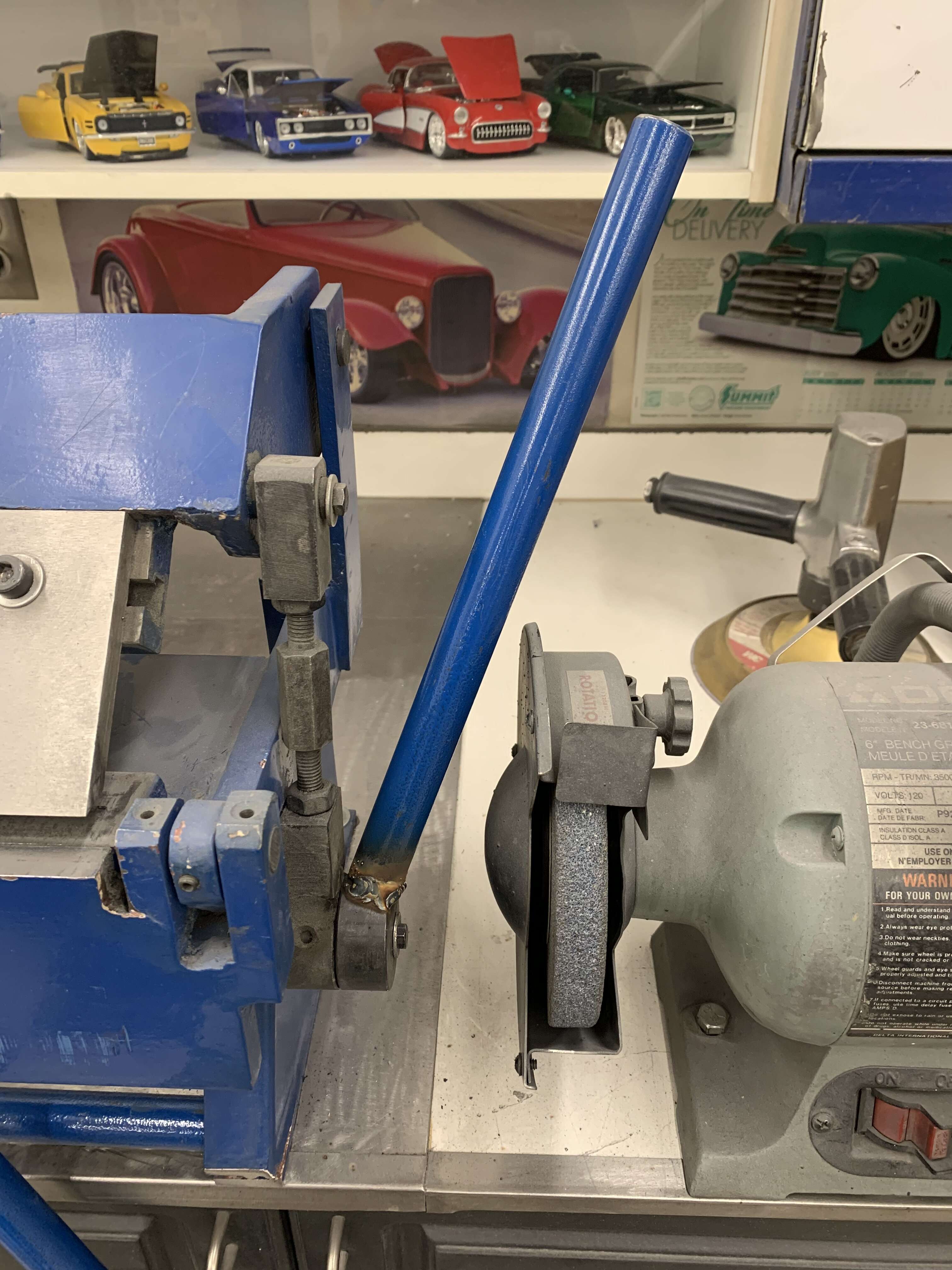

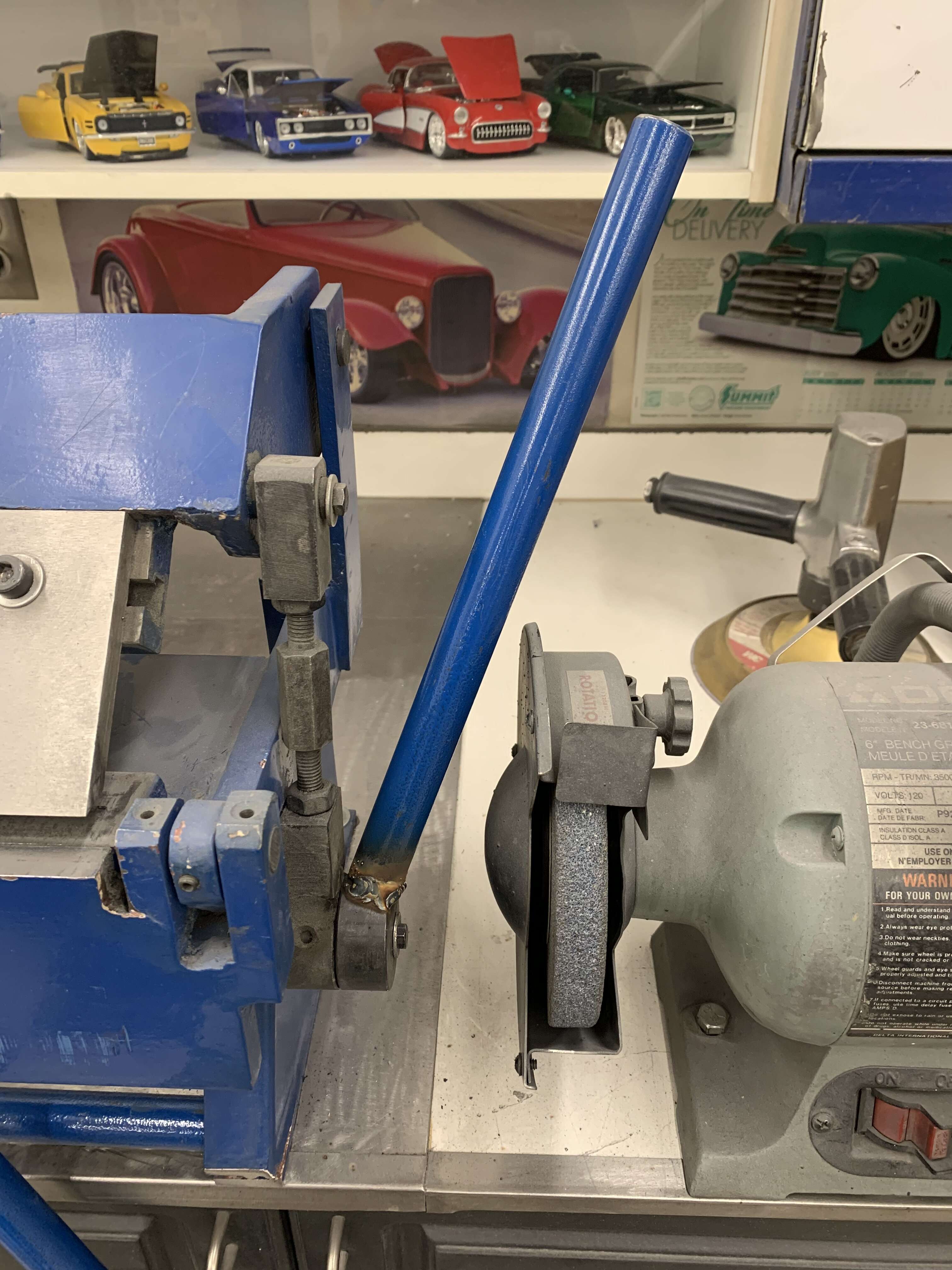

Another improvement to a piece of shop equipment, this time the metal brake, albeit unplanned.

Got tired of the finger clamp handle bending and being too short, this time it actually broke and sheared off almost flush with the eccentric cam.

So this time I did what any self respecting car guy would do, cut a piece of sched 40 pipe off at a 15 degree angle and welded the prick directly onto the eccentric cam.

Won’t have any more problems with it now, but it’s these little unexpected diversions that pop up that sap the momentum out of what you’re trying to work on.

Grrrr.

Got tired of the finger clamp handle bending and being too short, this time it actually broke and sheared off almost flush with the eccentric cam.

So this time I did what any self respecting car guy would do, cut a piece of sched 40 pipe off at a 15 degree angle and welded the prick directly onto the eccentric cam.

Won’t have any more problems with it now, but it’s these little unexpected diversions that pop up that sap the momentum out of what you’re trying to work on.

Grrrr.

Similar threads

- Replies

- 100

- Views

- 4K

- Replies

- 242

- Views

- 11K

- Replies

- 319

- Views

- 17K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.