Did a little more tidying up and got the work bench cleared of so I could start making a mess. Full disclosure: this is all dirty metal (mill scale, rust, oil) from my boxes and boxes of scrap. I didn't clean F all. So the contamination was expected. I started on 1/8" and went down to 1/16", and tried 1/16" filler rod on both.

View attachment 173389

All killer, almost no filler.

View attachment 173390

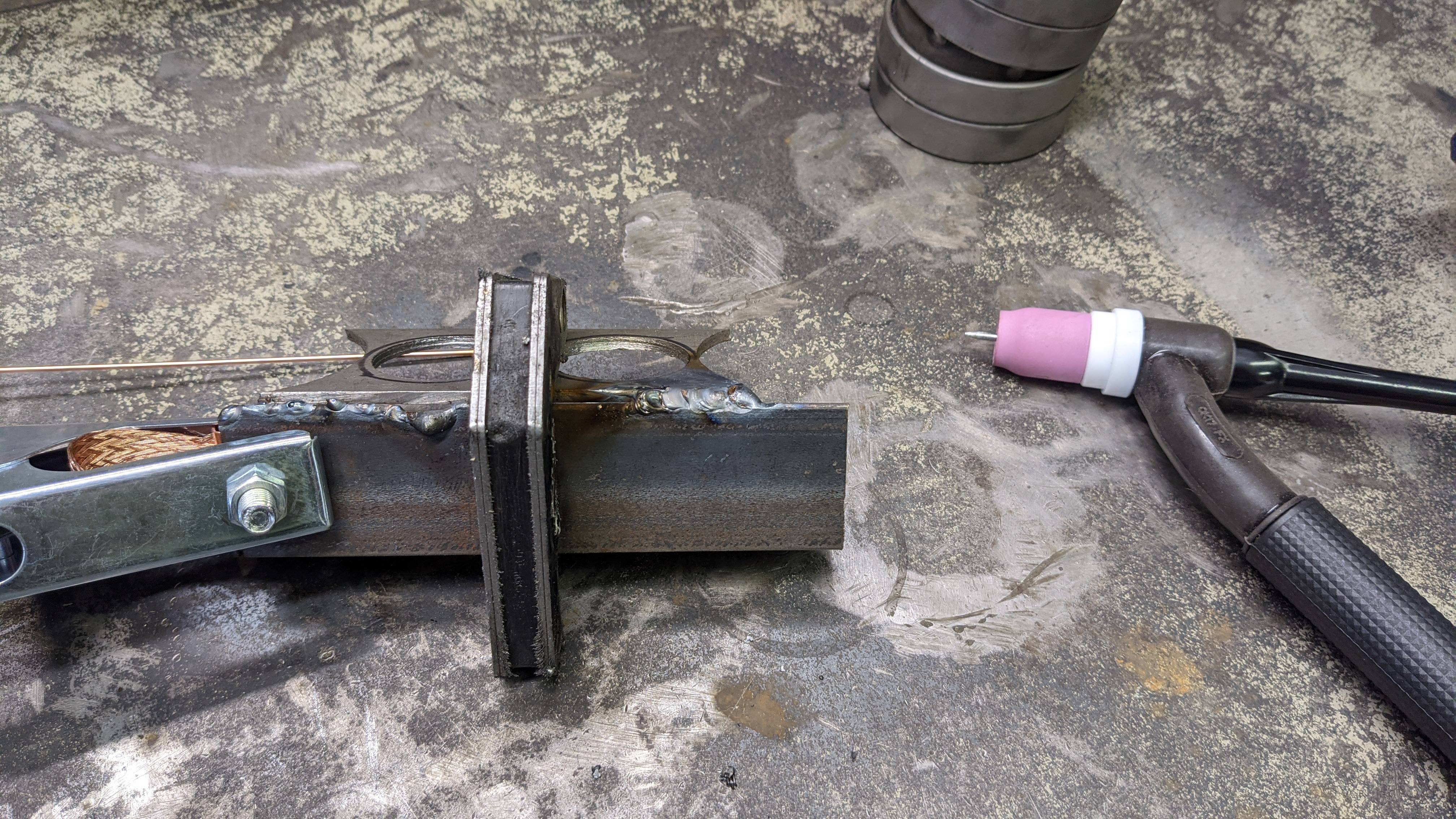

Penetration!

View attachment 173391

So far I've made some puddles, pushed some filler rod into some puddles, and mostly just fused metal together without filler rod by manipulating the base metal and the puddle. I deliberately tried using the wrong sized tungsten and amount of amperage to see what would or wouldn't happen. Mostly boogers and blow through. Dipped the tungsten a few times too - I just need to slow down and be more attentive. Lastly, I am not seeing the puddle as well as I would like - and I may be limited by my welding mask. I'll try the one I got Natasha for Christmas before getting another.

Overall not bad for an hour of farting around.