So that can be done after the seals. Depending when it arrives? And you know I got the dule fan set up that cuts out due to the heat. I was informed that a toggle switch in cabin will have to be utilized?

Can you talk about this air cut off as far as the cold case fan set up. ? The education in great and Im appreciative Thanks man Dez

No, fix it at the same time as the seals because replacing it will need to the refrigerant to be evacuated out again so it should be done at the same time the system is "open" for the compressor sealing washers.

As for the Electric Fans...Trinary switch is the way to go imho.

Here is one example of using binary/trinary switches for AC and Electric Fans, there are many of them, search YouTube for Trinary Switch.

The switch in the back of your compressor is for safety that would interrupt the compressor clutch if the pressure goes to high in the system, which could very well happen if your FANS are not on at all with the AC working. Not enough air over the condenser (in front of your radiator) will cause high pressures in the system. If you go with trinary switch, then you don't need that broken switch in the back of your compressor anymore as it will take care of the over pressure protection for the compressor, as well as the fans to come one with AC pressure. In effect you will end up with two ways that the electric fans turn on, with engine temperature and ac hi pressure, ITOW only when the temps or pressures require it.

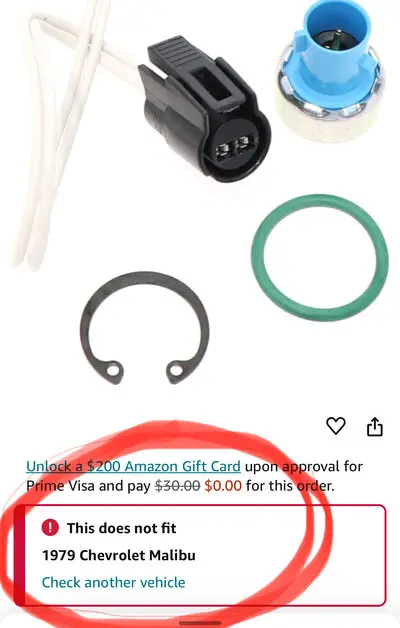

The trinary switch is typically installed on an existing High Pressure port fitting on the system, I see you have the r134a port (black cap) on your line into the evaporator. You really can't use that unless you get a tee fitting, or some other way to use it for both your service port, and the trinary switch port. I have something like this on mine, but it's a different port thread size so not sure what's available in a TEE for your situation. This is why I strongly suggest you take it to an expert as there are a lot of variations on threads, fittings, etc that are too long to list.

When you take it to an AC shop that knows what they're doing, which I highly recommend (no offense to you or your skills) they can easily add in a port for the trinary switch in various ways, then wire it up like described in the video(s).

Otherwise, you can just go with toggle switch that you always have to remember put on with the AC, or wire it up so when you're AC is turned on it will enable the fans to run automatically just like they do when the engine temp switch does.

I don't particularly like toggle switches for this or that, and prefer things to work on their own like OEM setups, but that's me. My buddy didn't listen to me and loves his toggle switches till he came out one day and had a DEAD battery.

Good luck with your repairs, and finding a local AC service shop to help you get it going again.