I have a 2008 Sierra with a Gen IV 5.3L LMG (Cathedral Port, DOD, Flex Fuel). By 50k miles I had a ticking lifter. I ran it until 82k miles and then did the DOD delete. I changed the cam. I swapped to the GM Performance Parts Hot Cam (219/228 .525/.525 on a 112 LSA). I don't advocate this in your situation but I wanted to point out that you absolutely can put a Gen III cam in a Gen IV engine. The Hot Cam is a Gen III cam. In your case, I would absolutely recommend pulling the cam for inspection and since there has been a problem with two lifters, for the cost, I would put in a new cam. You can get a delete kit that will have a stock grind cam and it will come as a Gen IV grind that has a single cam gear bolt. You can buy a delete kit that includes a plug in tuner to tune out the DOD. If you want to put a mild cam in it while you are at it, then you'll probably need the services of a tuner. If you put a mild cam in it, make sure the valve springs are compatible. The LS6 springs (19420455) are good to .550 lift and they are a production piece so you don't have to worry about how long they will live.

If you do end up putting in a Gen III, three bolt cam, the LS2 is a Gen IV (58x crank, 24x cam) engine with a three bolt gear.

- 12586481 - Cam sprocket

- 12556127 - Cam sprocket bolt

I put in a new timing chain while I was at it. Just a stock chain for an LS2. I don't have a part number handy. I chose to replace the cam retainer plate as it has an embossed O-Ring on it. Many have re-used it with no issue.

- 12589016 - Cam retainer plate

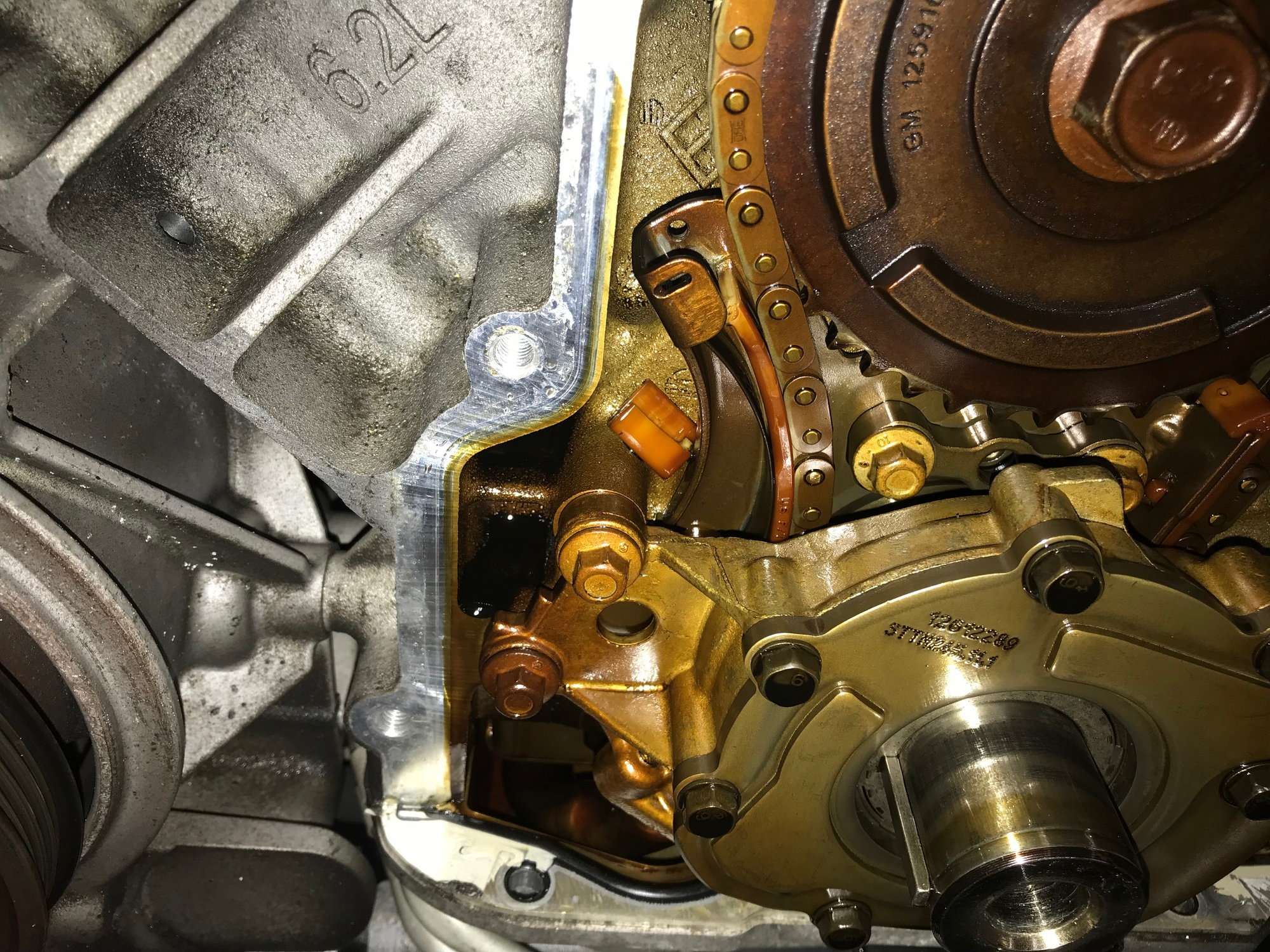

The Gen IV engines have a spring loaded timing chain tensioner that has plastic guides. Mine was broken at 82k miles. The Chain was rubbing metal and the chunks of plastic were lying in the pan. I chose to retrofit to the LS2 style timing chain dampener. I've read of others with this problem and I've also read about high mileage engines where the Gen IV spring loaded tensioner was fine. I like "keep it simple stupid" so I went with the simpler design. Gen IV style (this one is broken):

View attachment 216313

LS2 and earlier style:

View attachment 216314

The LS2 style damper will bolt on any Gen IV engine. Part number 12588670. It's available from many sources.

If it were me, for a non-performance build I'd buy the delete kit with a stock non-DOD cam. It will have the lifter trays (12595365) - four required and a set of lifters - 12499225 (LS2/LS7 Lifter Kit). You will also need a set of push rods. Part number will depend on what you do with the cam. If you were to use a LQ4 cam then I would think LQ4 push rods would be what you want but I would measure to be sure.

I taped the electrical connector that plugged into the valley cover into the harness. I used an LS7 valley cover (12570471) but it has a nipple out the right front for a crankcase breather that is unneeded, and I had to cap off. There is a smooth Gen IV non-DOD valley cover (has o-rings on the bottom side where the solenoids are on the DOD cover).

I left my DOD oil pump. You absolutely do want to change the o-ring on the pick-up while you are in there. It's not a big deal to do. The center of the crossmember under the engine unbolts and makes dropping the pan a snap. It is also possible to do without pulling the pan. You want the red o-ring 12584922.

If I had it to do again, I would have replaced the pressure relief valve in the oil pan with a new one (12608835) as the spring is said to get softer over time and I would have installed the deflector (12639759 - this is a design improvement to prevent oil consumption - they didn't exist when the engine was built) on it to make sure it couldn't spray oil on the rotating assembly. Some just choose to remove the relief valve and plug the threaded boss in the oil pan. It's a metric thread so an oil pan drain plug will fit it. I think it's better to have the safety of the bypass and I don't have any issues with oil pressure. I would think in colder climates, you'd want to retain the bypass.

Going back together, I initially tried to go back with new stock torque to yield head bolts. I found it impossible to properly torque them and then use the torque angle gauge to torque them to spec with the engine in the truck. The rear cylinders under the cowl were especially problematic. Perhaps with a digital tool on a breakover bar, it could be done. I ended up throwing in the towel that weekend and ordered a set of ARP head bolts that I could just torque to spec. I know some reuse the head bolts and just give them some ooga-duugas with the impact gun but I won't put my daily driver together like that.

Same thing with the balancer bolt. Getting that thing torqued to spec and then getting the appropriate torque angle in the vehicle was more that I wanted to mess with. It can be done. I just went with an ARP that I could torque to spec and reuse if I ever took it apart. Speaking of the balancer, the Chrysler style puller that you can get on the loan a tool (long fingers) will pull it if you don't have a puller.

Those engines are fairly famous for having broken exhaust manifold bolts. I have headers on my engine so I choose to upgrade to ARP stainless steel manifold bolts. I think it was money well spent.

Many of the gaskets can be reused (valve covers, intake, oil pan, timing cover) but I didn't want to chance it. I did my swap over ten years ago and it now has 130k miles on it so it turned out fine. I probably spent too much money on it but I didn't want it to leak and I needed it to be reliable.

If I was in your shoes, I would buy a DOD kit that has the cam, lifter trays, lifters, push rods, valley cover, gaskets and a plug in tuner to tune out the DOD. Those weren't around when I did mine. I recently saw this video. I follow Advanced Level Automotive on YouTube. Guy is a diagnostic genius and he's local to me which makes it interesting. He did a video on a DOD delete and I thought it was well done. Worth a watch since you are about to do one. That's all I can think of for now. PM me if you have a question. I'm glad to help.