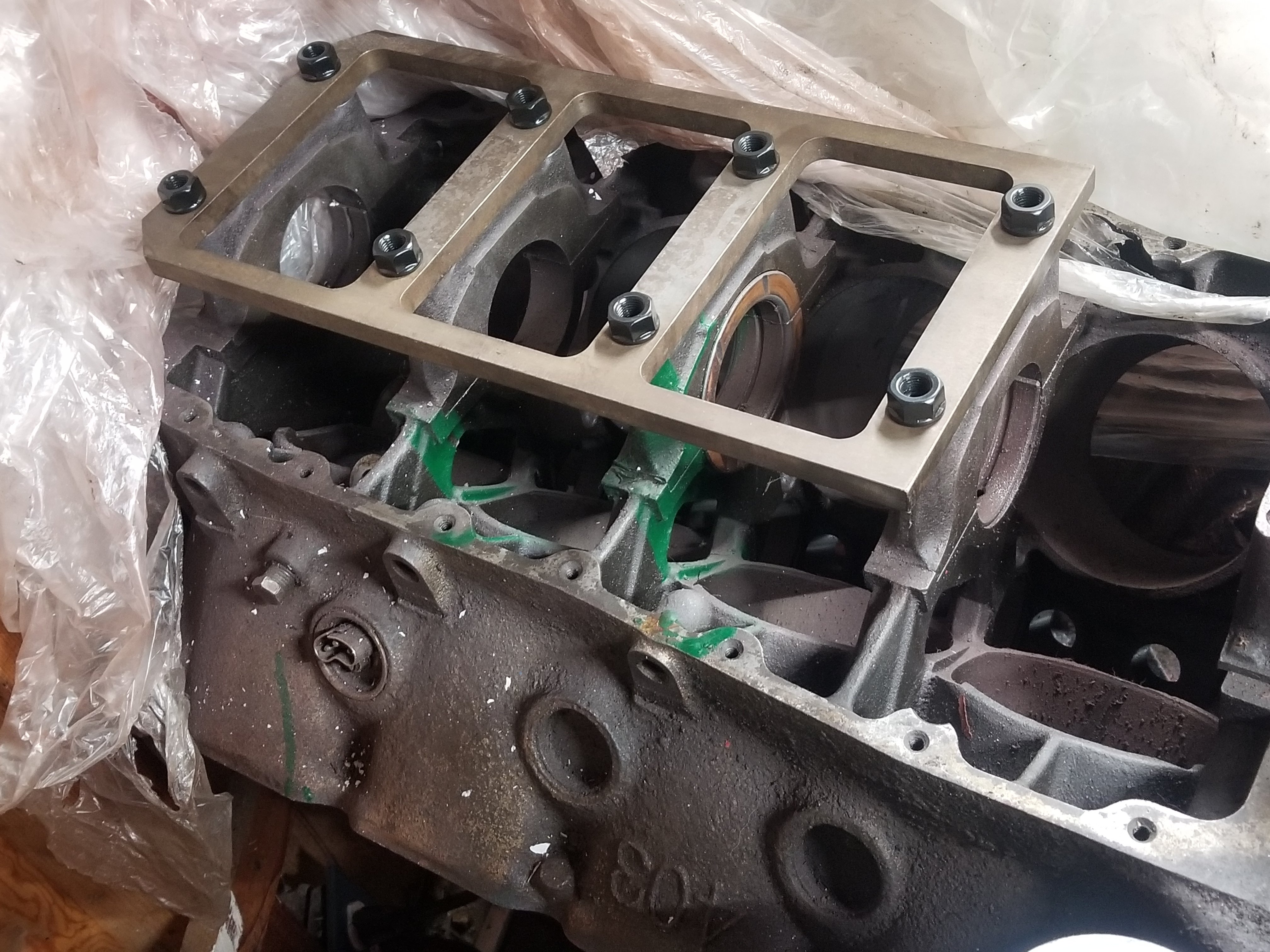

So I hooked up my Equus timing light with a tach and strung it through the cab. I have an Autometer tach ordered to work with the Mallory 6AL box. I have the idle set about perfect, 950 in park 700 in gear. It seems I have another governor that shifts at 3000 rpm full throttle, good for this bent rod motor. Also the lock up torque converter drops it exactly 300 rpm. Some claim 200 to 250 rpm, I always find them drop 250 rpm at minimum. Now the last time I ran a 2004R in this car with the same 2300 stall with 235/60R14 it ran at 100 rpm higher than I calculated, 1700 rpm vs 1600 rpm at 60 mph. I am thinking and others have found the same, BFG Radial TA's are shorter than advertised. With the Cooper Cobra radials 275/60R15, I run 1400 rpm at 60 mph, exactly what calculated. Both speedometers were checked with a GPS and right on. Of course the other side effect of the bent rod is I no doubt took out the rod bearing. Until I did that, this motor had exceptional oil pressure. I did slightly flood it the other day and had the choke pull off slightly rich and will probably adjust it slightly more. My point is at warm idle it drops to almost 0 and the oil light flickers on. I will probably drop the oil and put in some fresh 20W50. But honestly the most annoying part of this motor is the tick from the cam. None of the lifters are stuck, all move, checked while it was apart. Nothing is obviously flat but a lobe must be going. I actually ran an adjustable valve train and ran it so tight I bent pushrods, it was still there and still is with new bridges and rocker arms. Either way I will pick up the Ford studs this Summer, just need to figure out if it is the 302 or 351W that has the proper diameter studs that are 1/2 longer for the Halo so I can send the 403 block to the machine shop at the end of Summer.

Last edited: