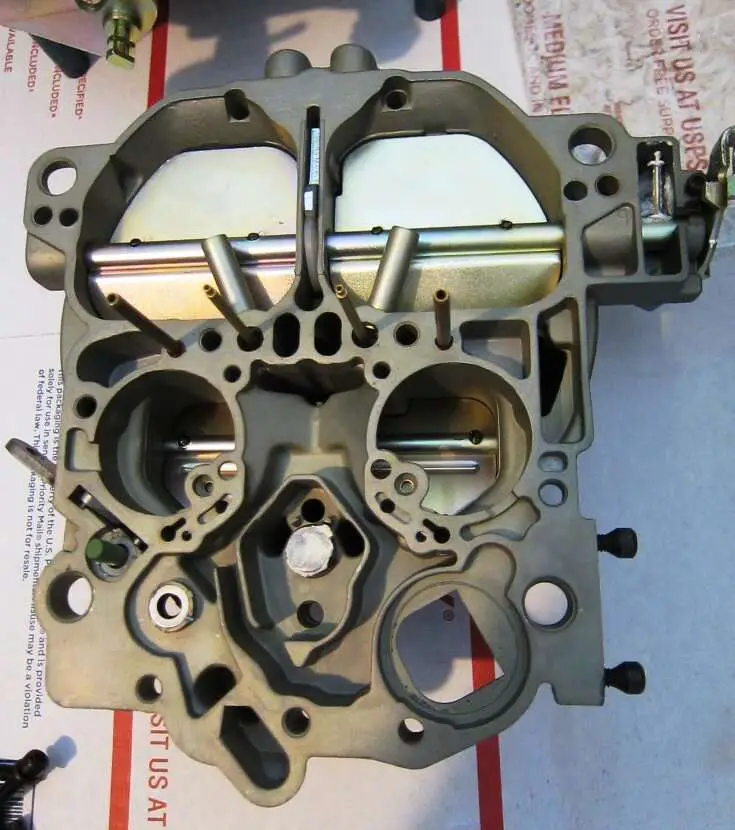

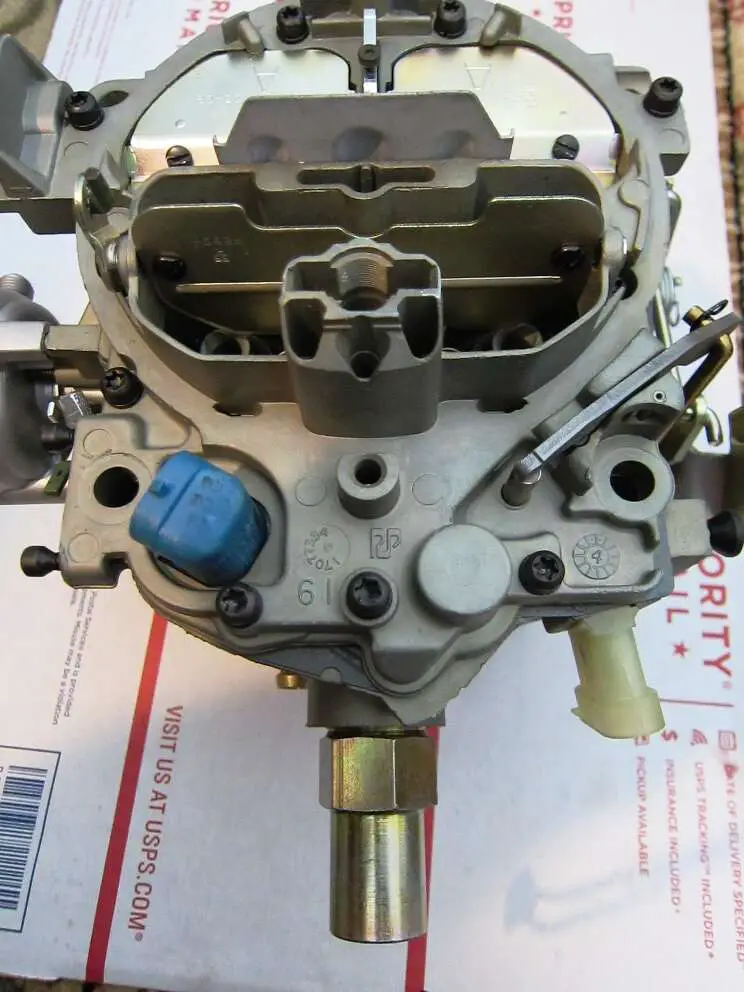

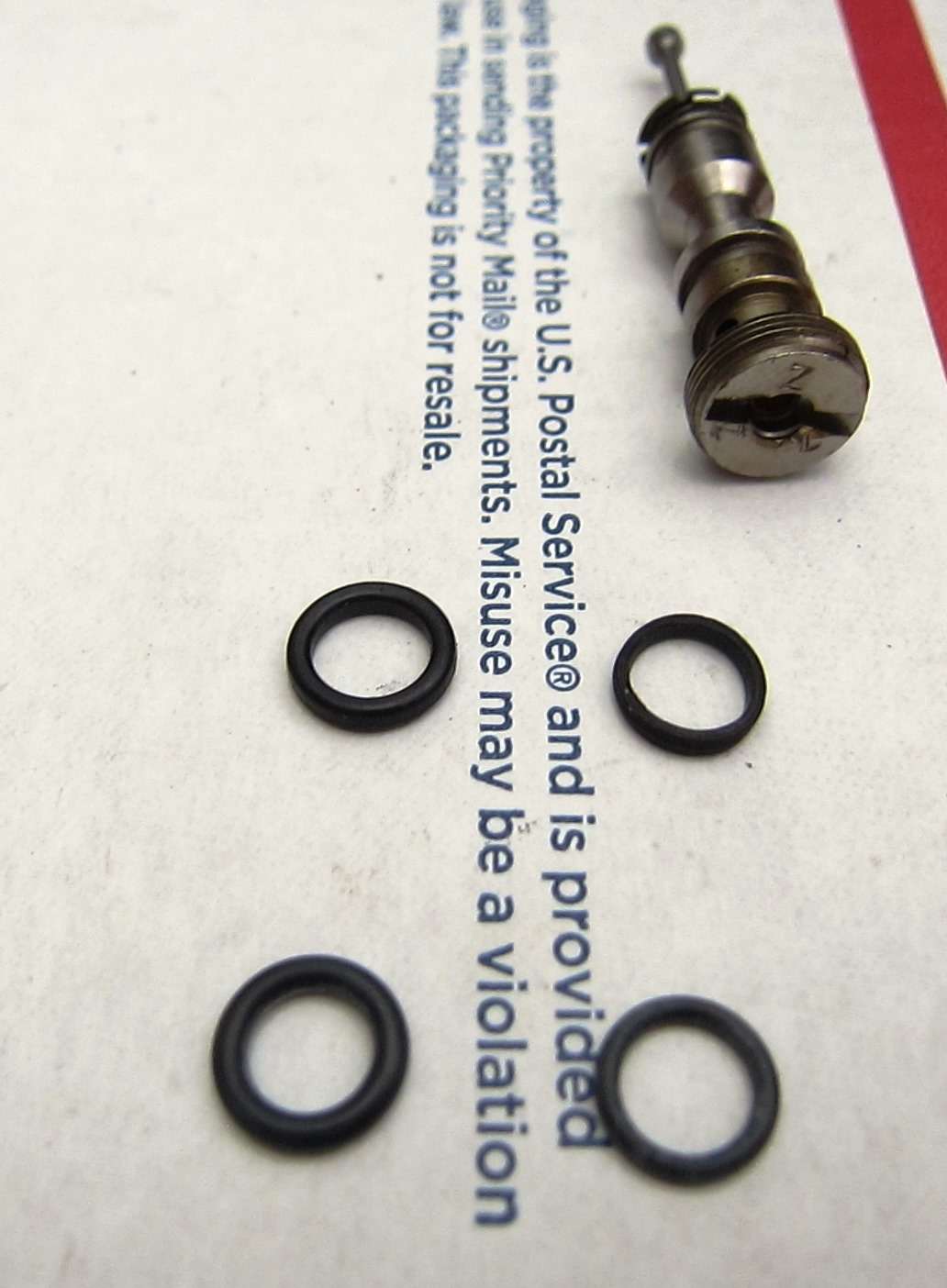

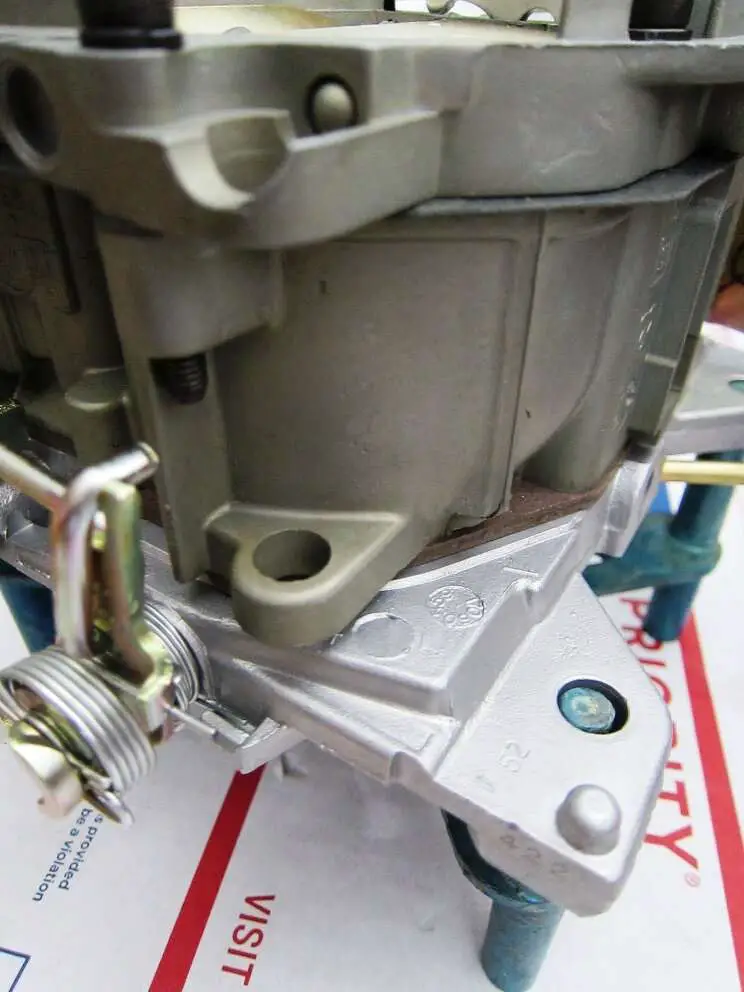

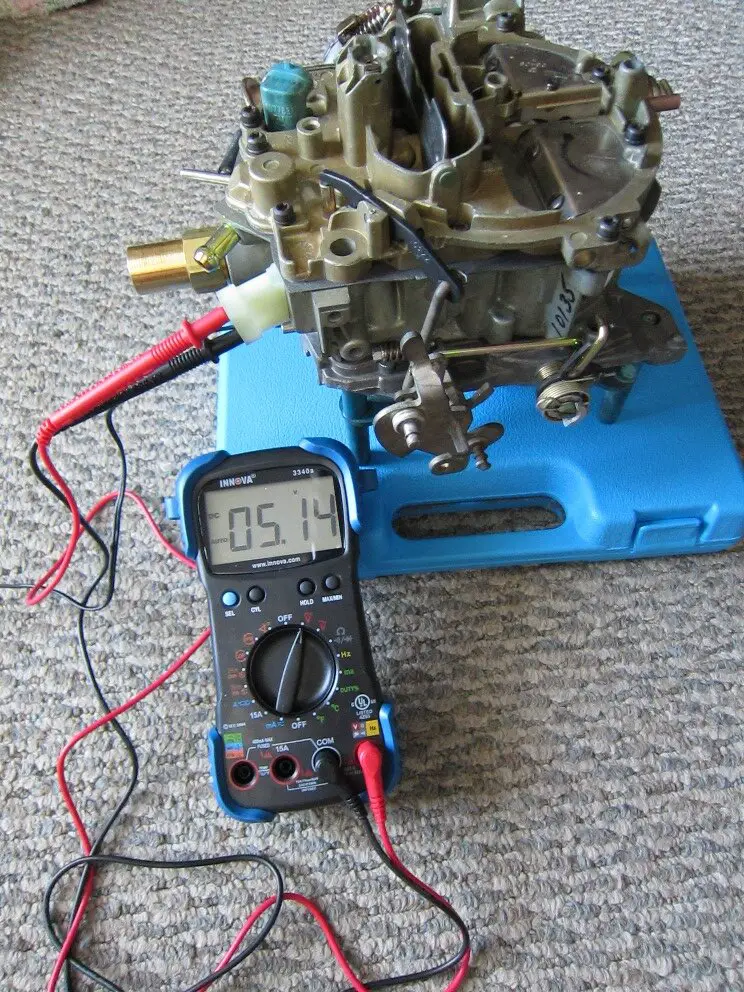

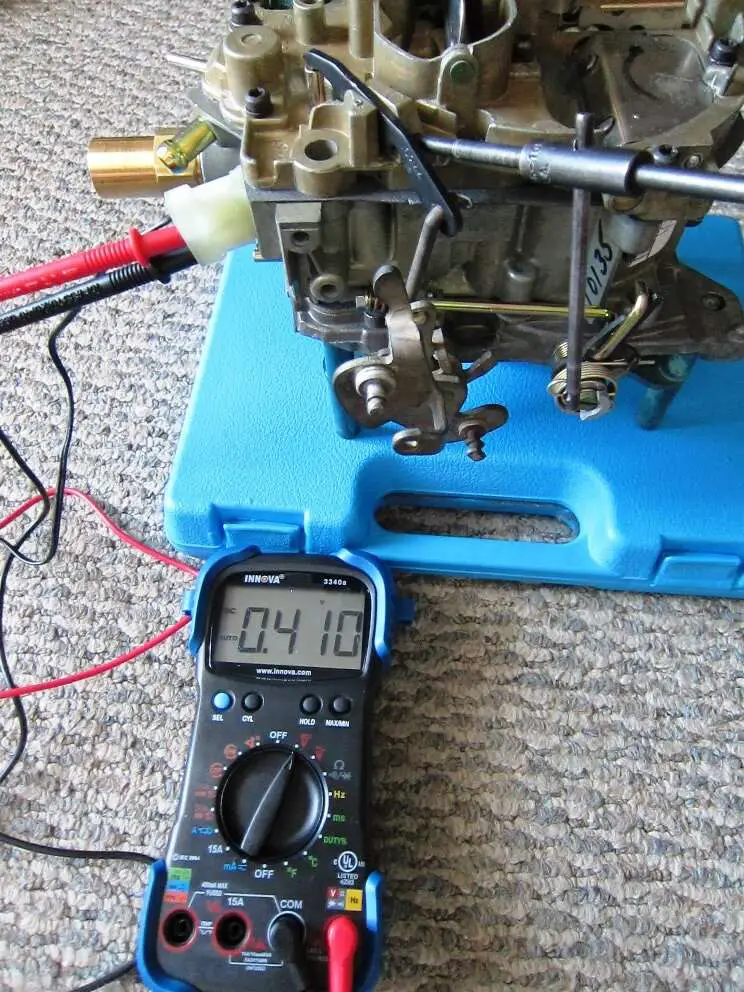

Before going further, I was thinking about this earlier, but forgot to mention it when I was posting the pictures of mating the throttle body to the float bowl. Before doing that, it would be your last chance to permanently seal the float bowl bottom machining operation plugs for the jets and accel pump. These got a bad rap early on for being prone to leaking. I've heard them called "Leaky Q's" and "Quadraleaks", etc. I've had a couple of older early 70s 442 carbs that did leak from the secondary plugs. However, after doing a lot of research, I've found that the earlier carburetors had the plugs that were sealed in a different manner than the "newer" carbs. In fact, it seemed like Rochester was always trying to improve their carburetors and they made changes constantly and did so even in the midst of production runs. I'm not saying the CCC carbs never leak at the plugs, but I've personally never heard of anyone's CCC carb leaking from there. The old-timer way I learned was to clean the plug area at the leak and clean all the other plugs while you're in there, dab in some mixed up JB Weld on all the plugs, let it harden, and be on your way. And it did work on those old 442 carbs. But nowadays there are even better ways to fix that instead of the band-aid job.

As the CCC carbs were basically the last of the line, they got a better quality seal job for those plugs. My carb showed no signs of leakage upon disassembly, so I believe going through all the steps of drilling out the plugs and tapping them for screw plugs, then ensuring you didn't close off passages, etc., would have been overkill for this carburetor. Just another chance to destroy a float bowl if things went sideways. JMO. Had I seen evidence of leakage, I'd definitely have done that. But, I didn't, so I'm sending it as is. During the cleaning of the bowl, I filled the innards with acetone and nothing got wet underneath on inspection, so I'm confident it's still in good shape there. If things go wrong down the road, it's not difficult to fix.

Ok, moving on.

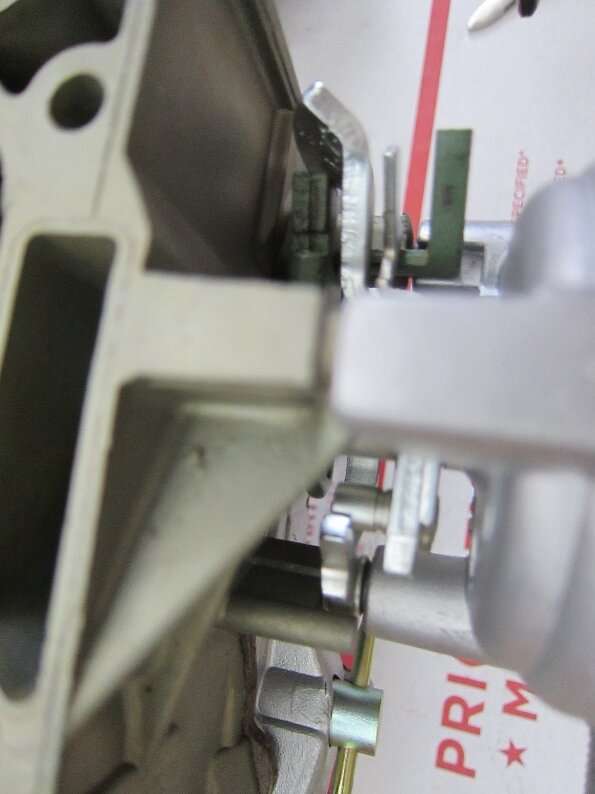

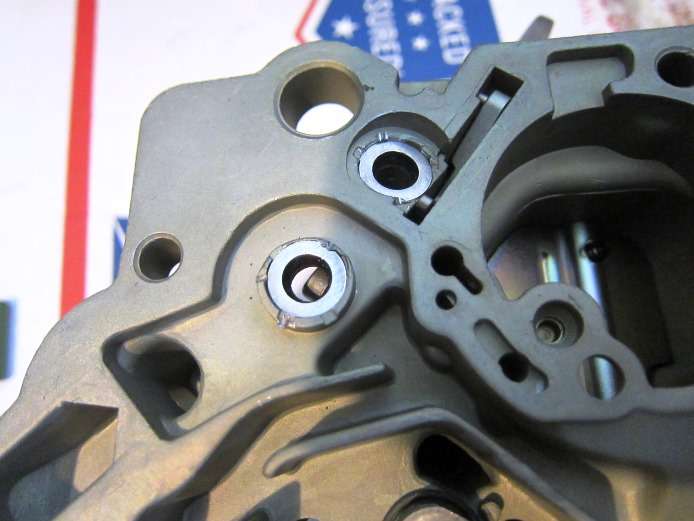

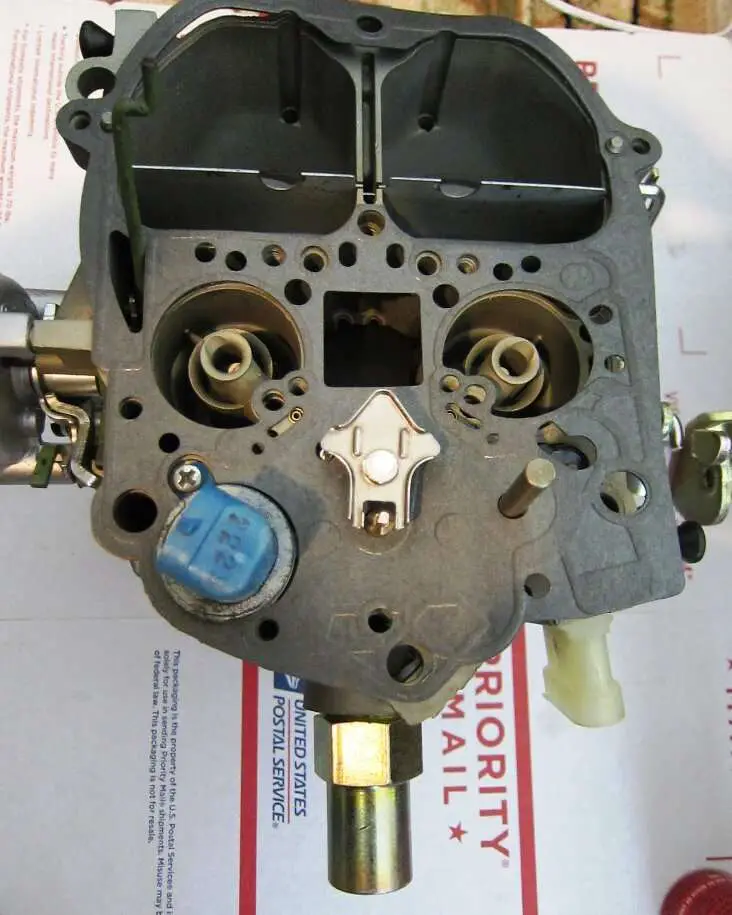

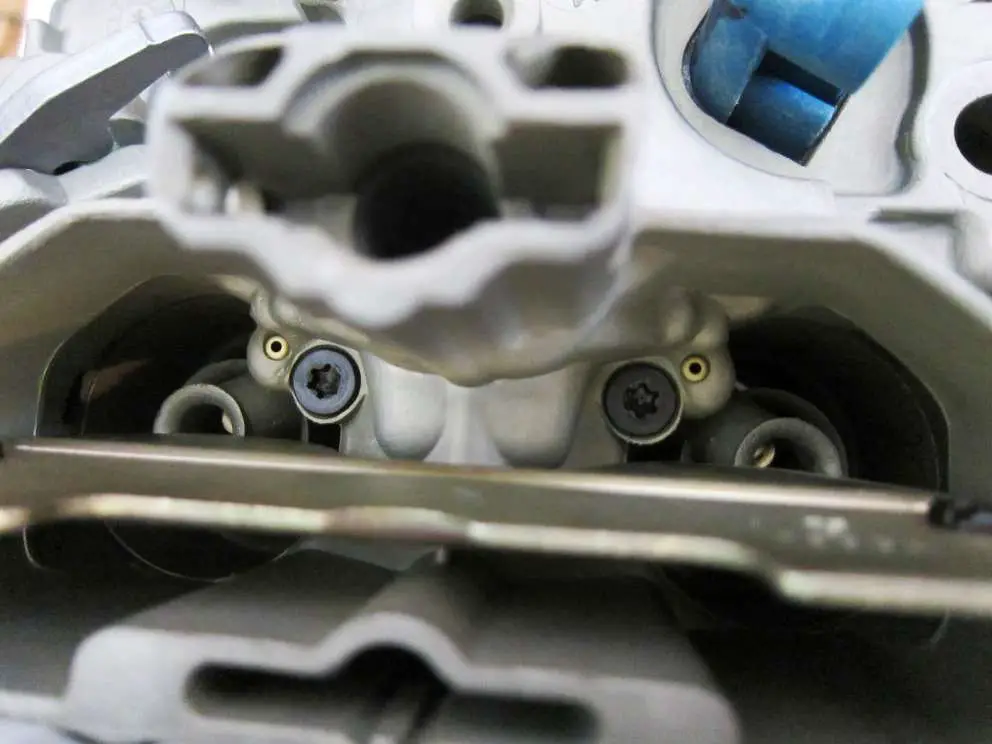

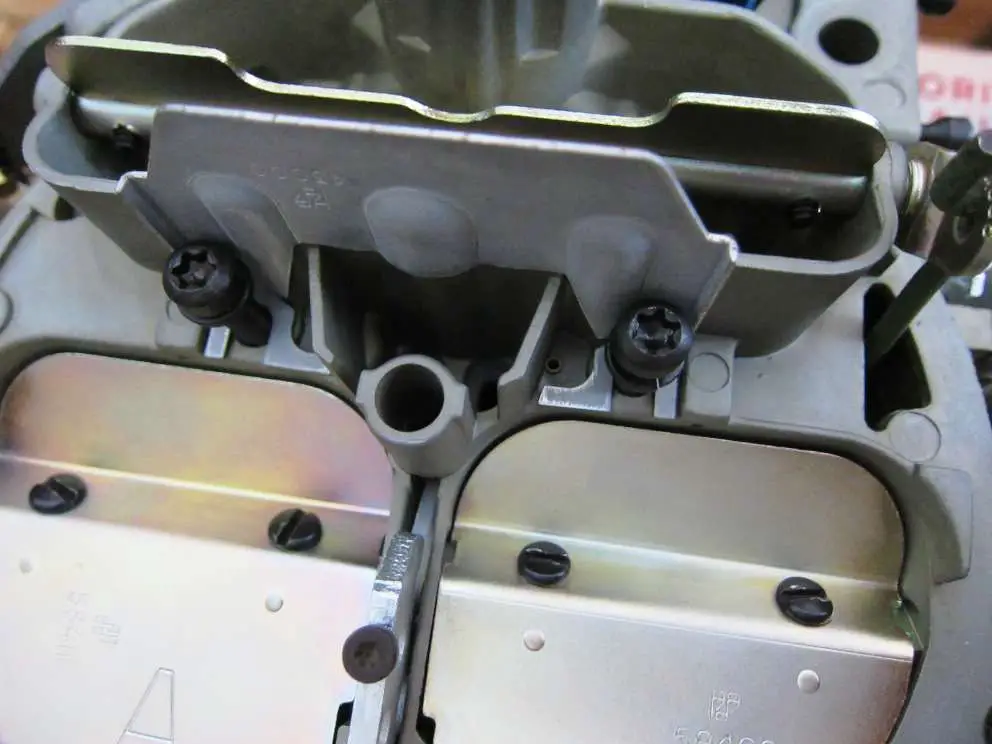

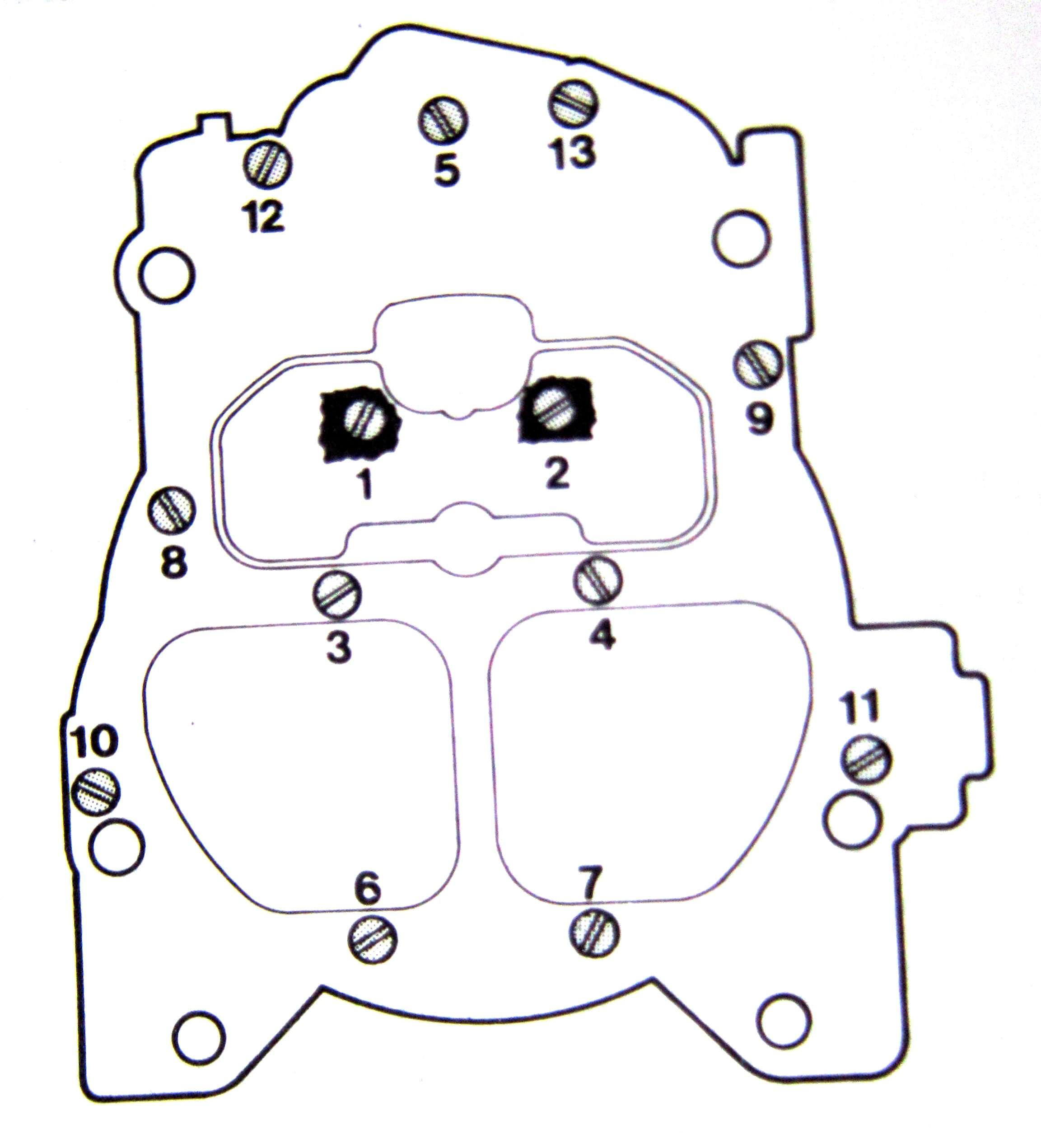

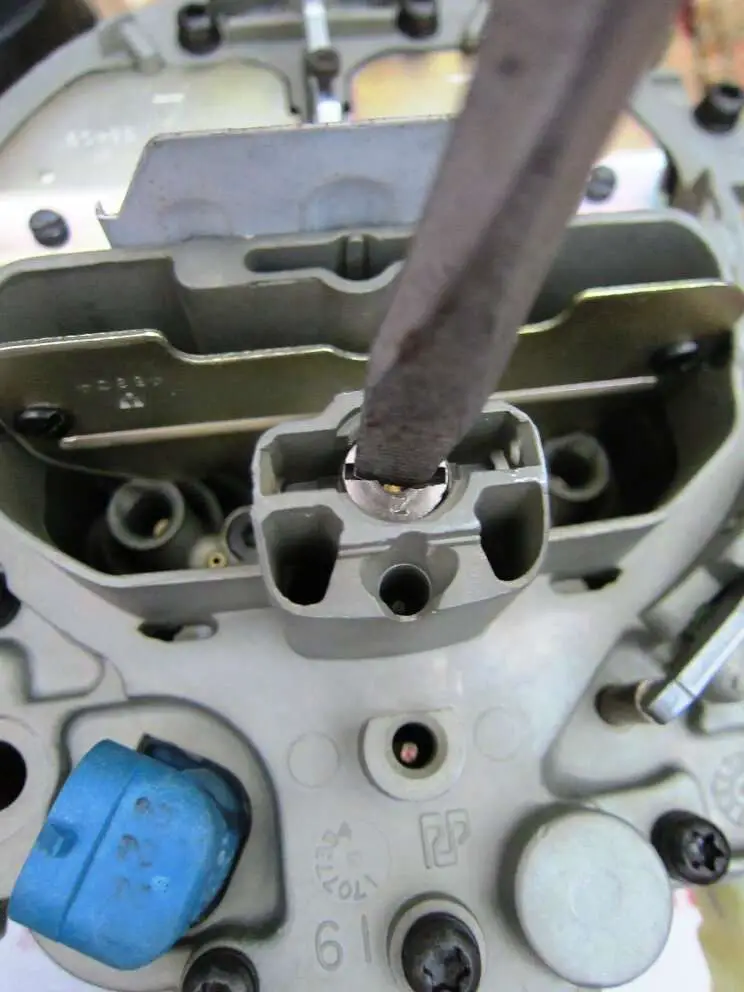

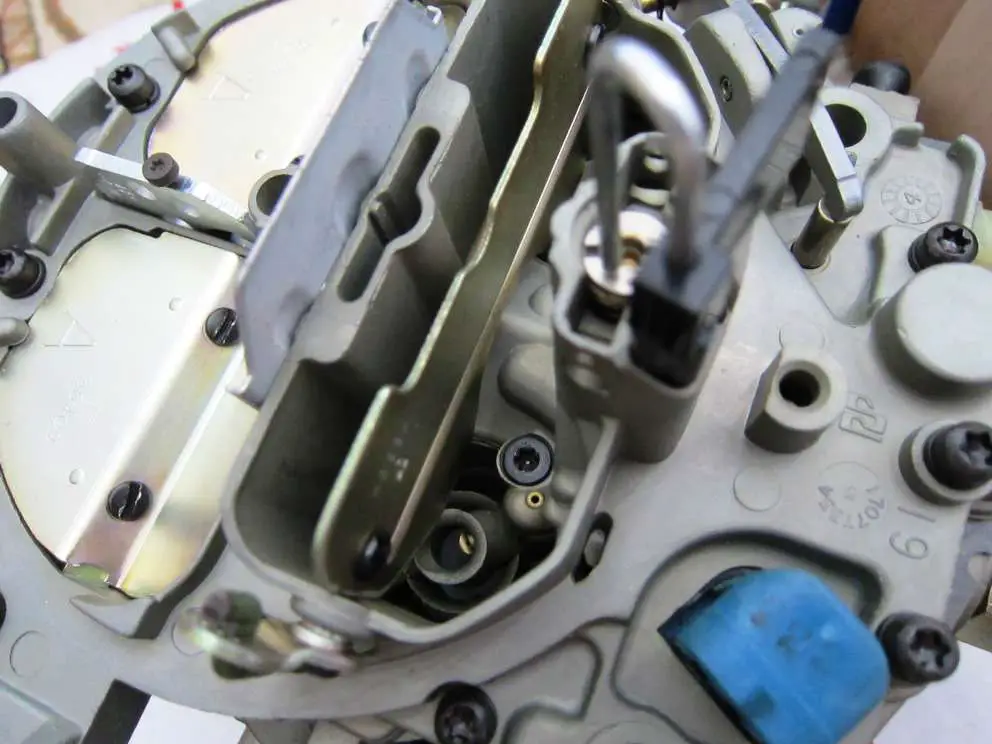

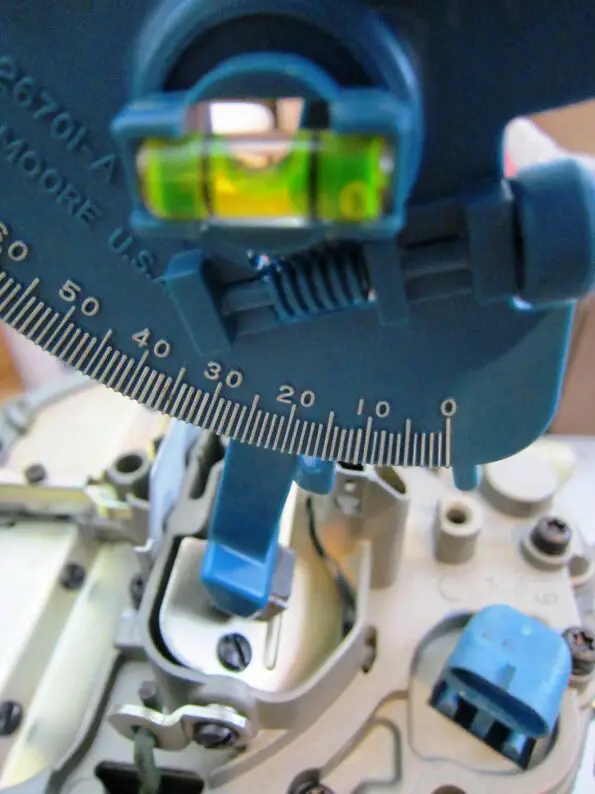

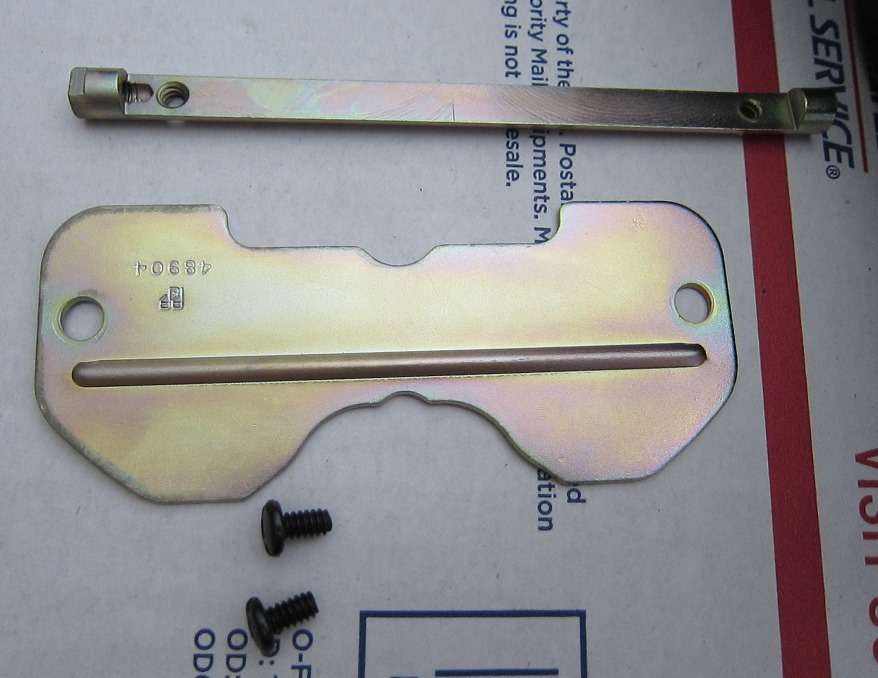

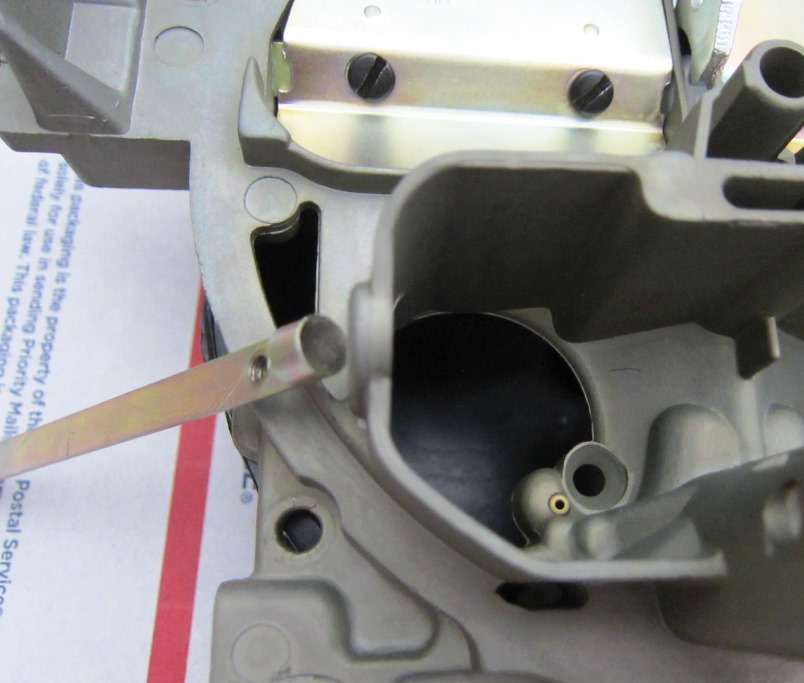

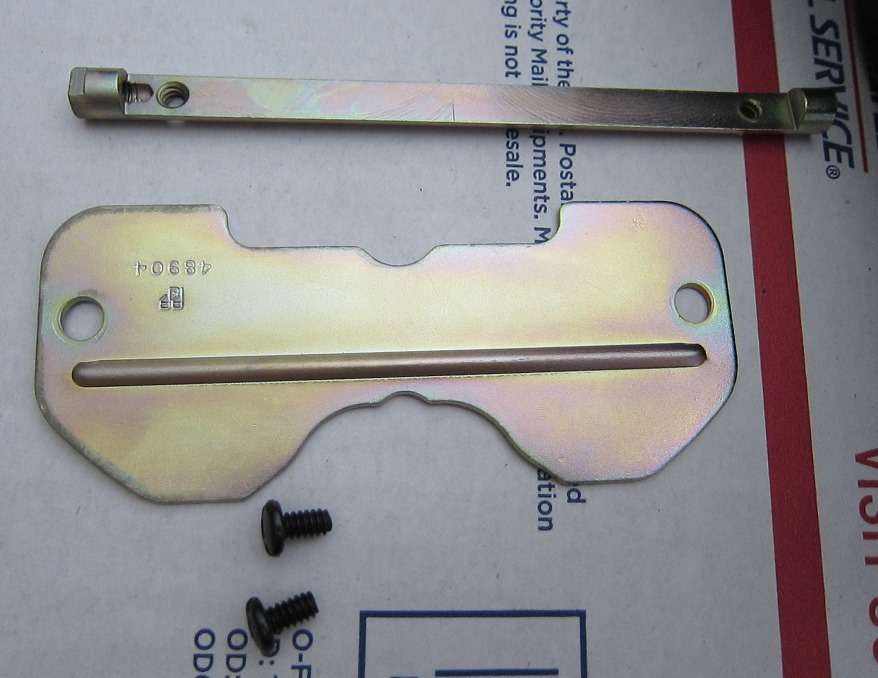

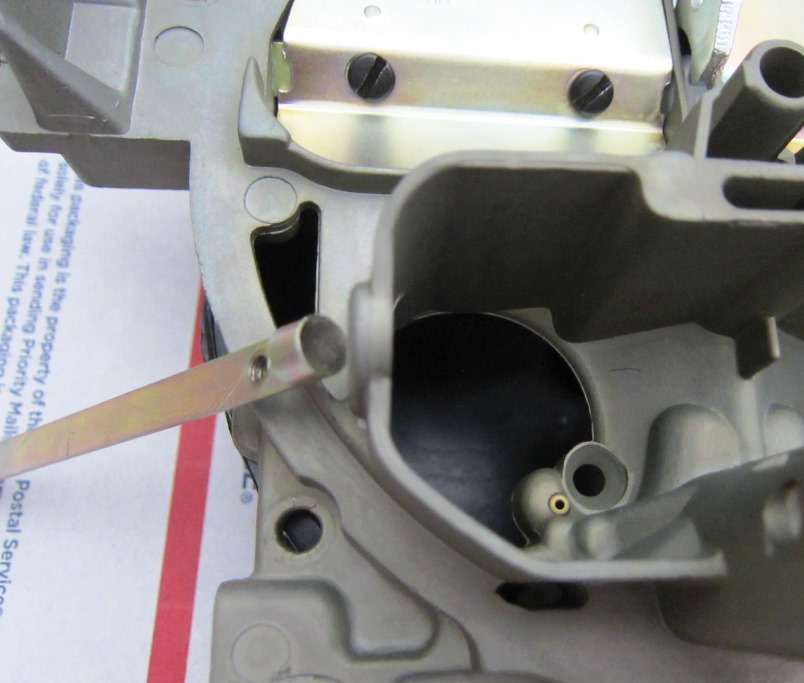

We still need to get the air horn ready to be installed, so we should probably install the choke plate and shaft. Again, shafts aren't normally removed when doing normal rebuilds, so you only need to do this if you fully disassembled the carburetor. Relatively easy procedure, but ensure you know which end goes to each side. Look at the ends of the shaft. One has a hole in it for a screw #30 to mount the choke flap lever #29. You must ensure the screw hole end winds up on the RH side, or choke housing side of the air horn. If not, and you install it backwards with loctite or staking screws on the flap, you'll be crying later. Know your ends. Follow the pictures and you'll be fine.

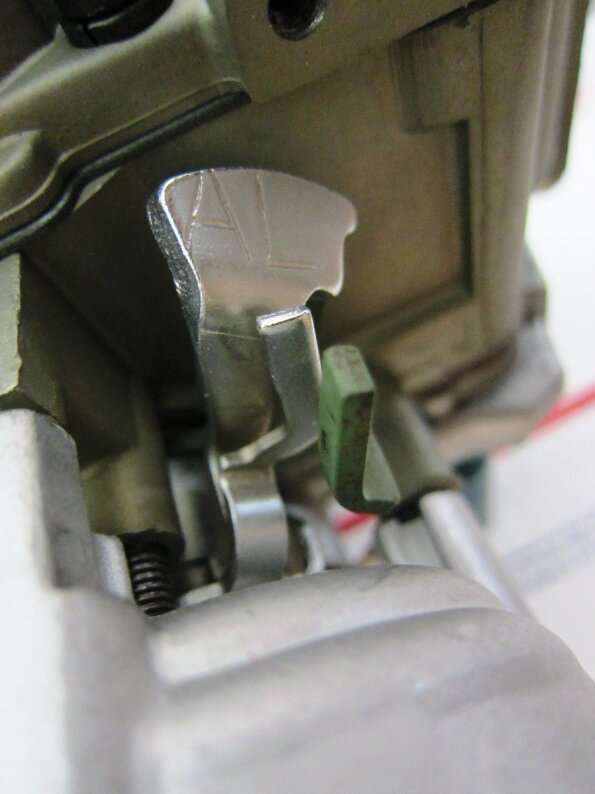

As usual with the screwed on plates, you'll need a little loctite or a means to support the screw from the backside in case you wish to stake the screw threads. This means the choke plate needs to be aligned in a manner to ensure it closes properly without interference. Again, I'm using loctite here so once you tighten down the screws where you want them, verify free operation of the choke, then carefully remove one screw, dab it with loctite, reinstall, and then do the other one. Again, verify proper operation. You'll only have a few minutes before the loctite sets up so ensure the parts move freely after installation. I want to maximize the working time as much as possible with the red loctite. You will too.

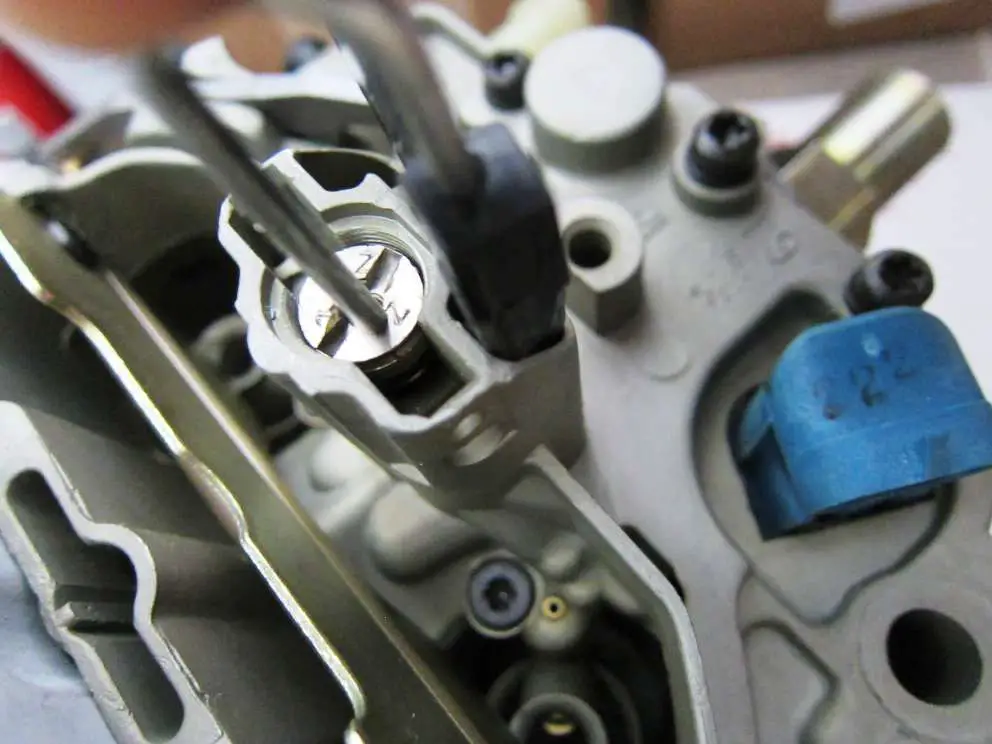

Note the choke flap strengthening feature in the middle of the flap. No, Rktpwrd didn't get hold of it on his metal roller, although I bet he could do it. The factory stamped a ridge into the flap to increase the rigidity of the flap. The flap will fit either way, but Rochester installed it with the part number up, and the raised part of the ridge up when the flap is closed. Will it make any difference? In this case, doubtful. You could argue that an arch (ridge up) is stronger than the ridge facing down as air flows down through the carb pushing on the flap, but c'mon, really? If there's a mystery reason I'm missing, I'll remove any doubt. I'm just going to do it the way RP did it. Raised ridge side up!

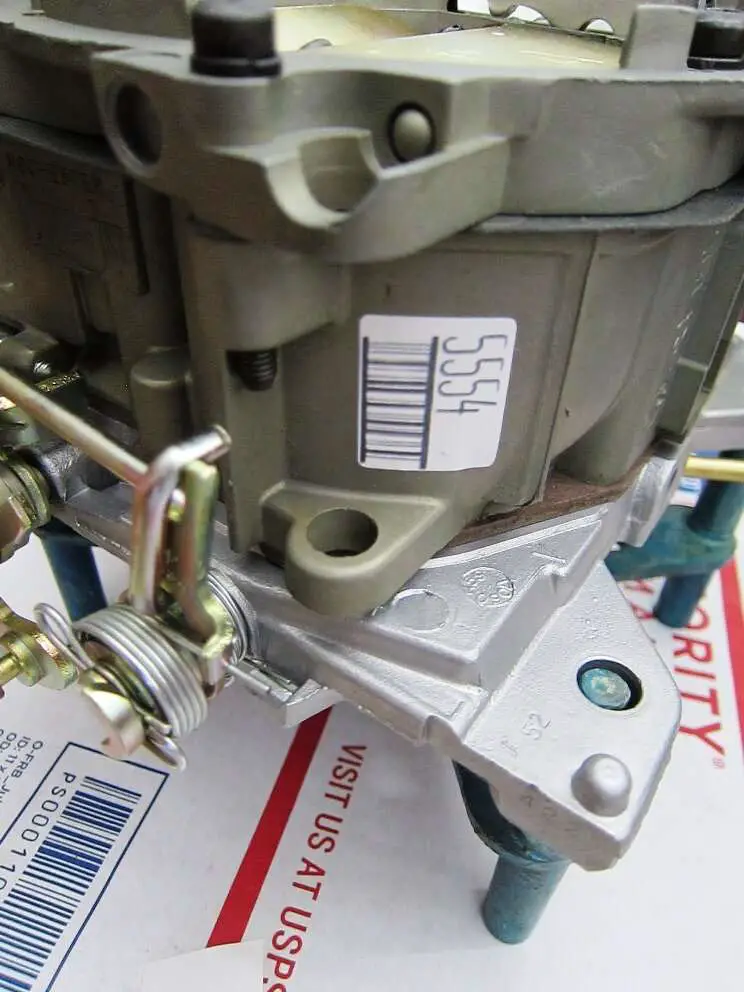

As far as the choke flap lever/screw, you DO NOT want any loctite on this screw. In the event you have to remove the air horn later on, you won't be able to if this thing is liquid welded. Or it would be extremely difficult by having to remove the choke assembly on the side of the carb. Yuk. Let's not even go there. NO LOCTITE on the choke flap lever screw!

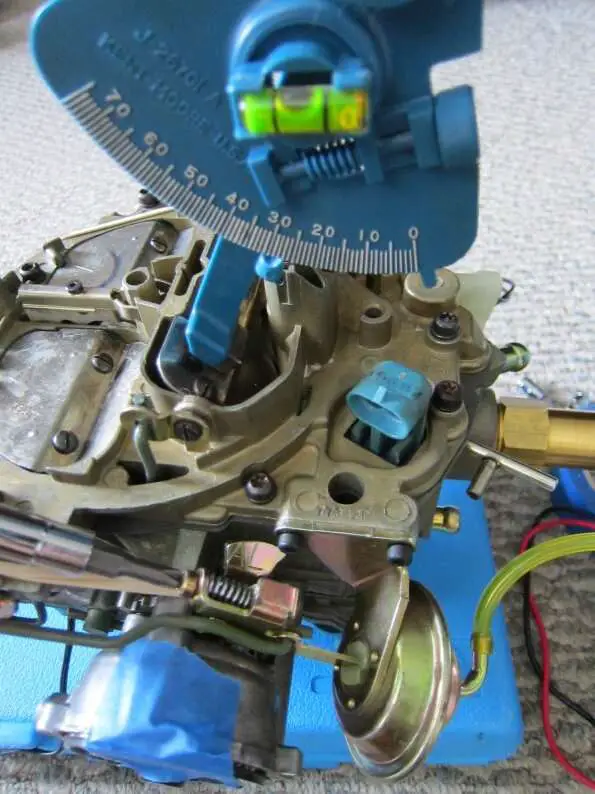

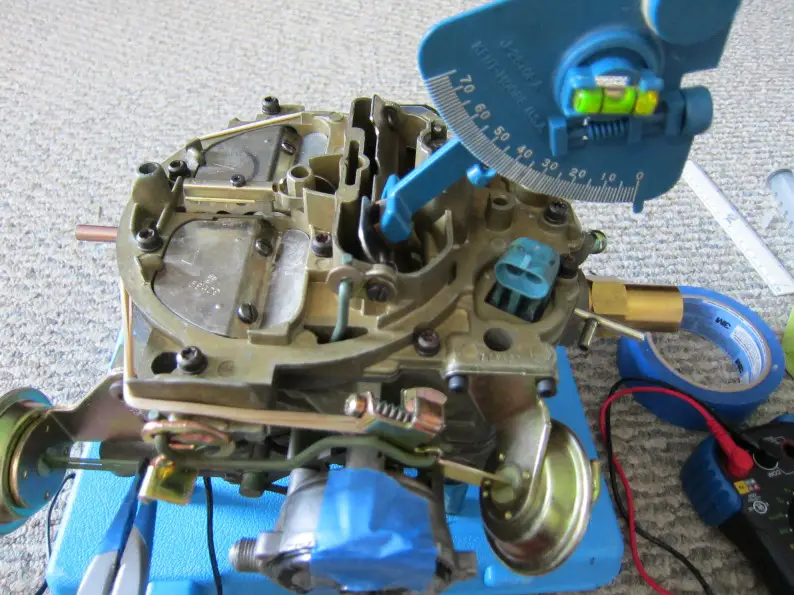

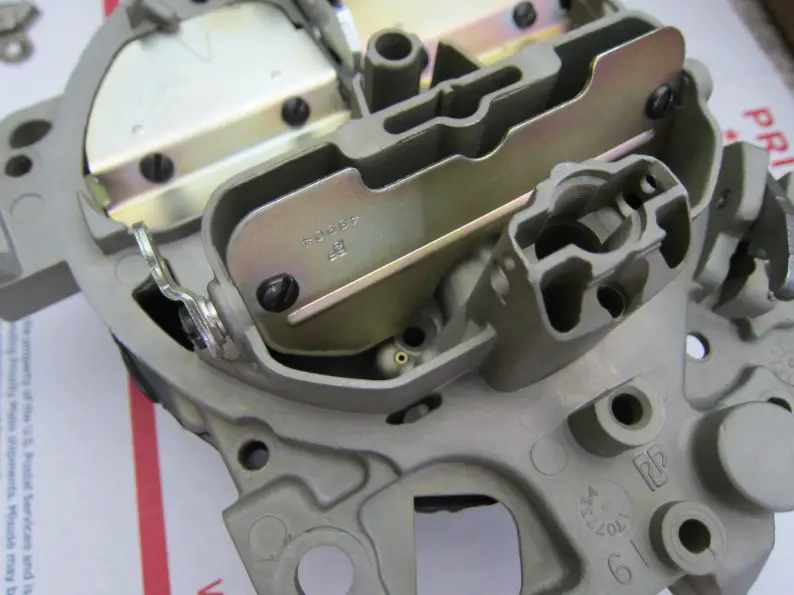

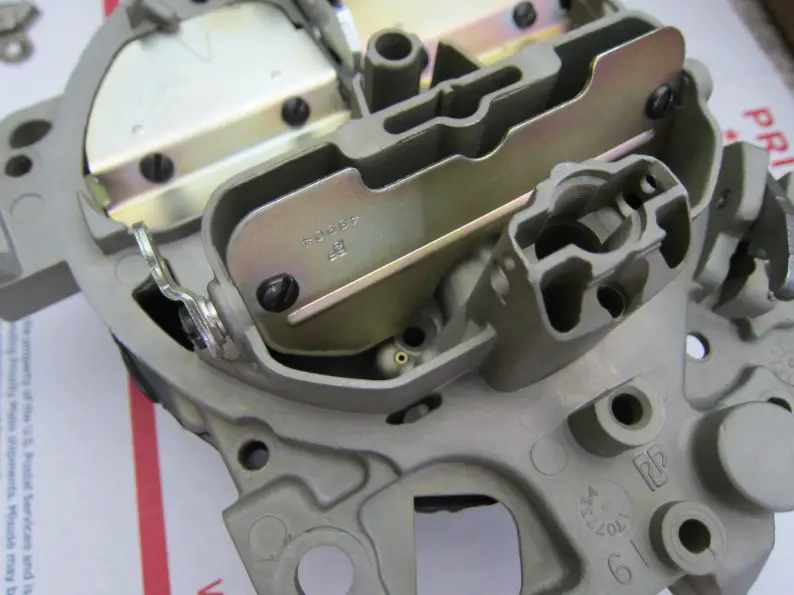

Here's the choke flap installed per the CSM.

We'll set it aside for now. We'll come back later, finish off the air horn prep, remove the flap lever screw, and install it on the choke rod when its time to place the air horn on the float bowl.

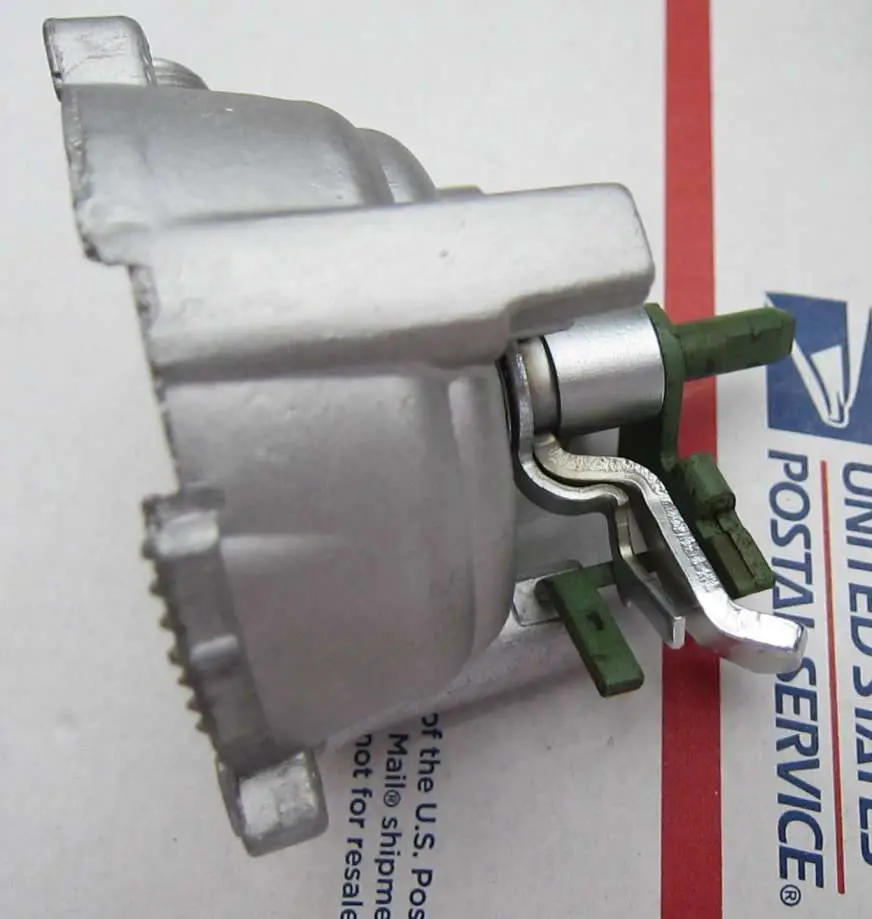

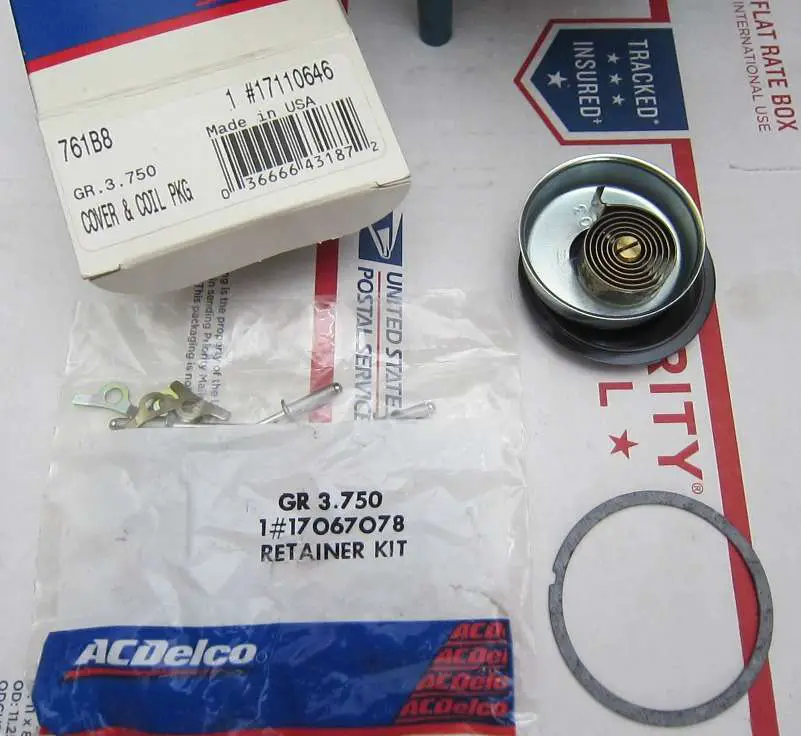

Next up, the choke assembly!

As the CCC carbs were basically the last of the line, they got a better quality seal job for those plugs. My carb showed no signs of leakage upon disassembly, so I believe going through all the steps of drilling out the plugs and tapping them for screw plugs, then ensuring you didn't close off passages, etc., would have been overkill for this carburetor. Just another chance to destroy a float bowl if things went sideways. JMO. Had I seen evidence of leakage, I'd definitely have done that. But, I didn't, so I'm sending it as is. During the cleaning of the bowl, I filled the innards with acetone and nothing got wet underneath on inspection, so I'm confident it's still in good shape there. If things go wrong down the road, it's not difficult to fix.

Ok, moving on.

We still need to get the air horn ready to be installed, so we should probably install the choke plate and shaft. Again, shafts aren't normally removed when doing normal rebuilds, so you only need to do this if you fully disassembled the carburetor. Relatively easy procedure, but ensure you know which end goes to each side. Look at the ends of the shaft. One has a hole in it for a screw #30 to mount the choke flap lever #29. You must ensure the screw hole end winds up on the RH side, or choke housing side of the air horn. If not, and you install it backwards with loctite or staking screws on the flap, you'll be crying later. Know your ends. Follow the pictures and you'll be fine.

As usual with the screwed on plates, you'll need a little loctite or a means to support the screw from the backside in case you wish to stake the screw threads. This means the choke plate needs to be aligned in a manner to ensure it closes properly without interference. Again, I'm using loctite here so once you tighten down the screws where you want them, verify free operation of the choke, then carefully remove one screw, dab it with loctite, reinstall, and then do the other one. Again, verify proper operation. You'll only have a few minutes before the loctite sets up so ensure the parts move freely after installation. I want to maximize the working time as much as possible with the red loctite. You will too.

Note the choke flap strengthening feature in the middle of the flap. No, Rktpwrd didn't get hold of it on his metal roller, although I bet he could do it. The factory stamped a ridge into the flap to increase the rigidity of the flap. The flap will fit either way, but Rochester installed it with the part number up, and the raised part of the ridge up when the flap is closed. Will it make any difference? In this case, doubtful. You could argue that an arch (ridge up) is stronger than the ridge facing down as air flows down through the carb pushing on the flap, but c'mon, really? If there's a mystery reason I'm missing, I'll remove any doubt. I'm just going to do it the way RP did it. Raised ridge side up!

As far as the choke flap lever/screw, you DO NOT want any loctite on this screw. In the event you have to remove the air horn later on, you won't be able to if this thing is liquid welded. Or it would be extremely difficult by having to remove the choke assembly on the side of the carb. Yuk. Let's not even go there. NO LOCTITE on the choke flap lever screw!

Here's the choke flap installed per the CSM.

We'll set it aside for now. We'll come back later, finish off the air horn prep, remove the flap lever screw, and install it on the choke rod when its time to place the air horn on the float bowl.

Next up, the choke assembly!