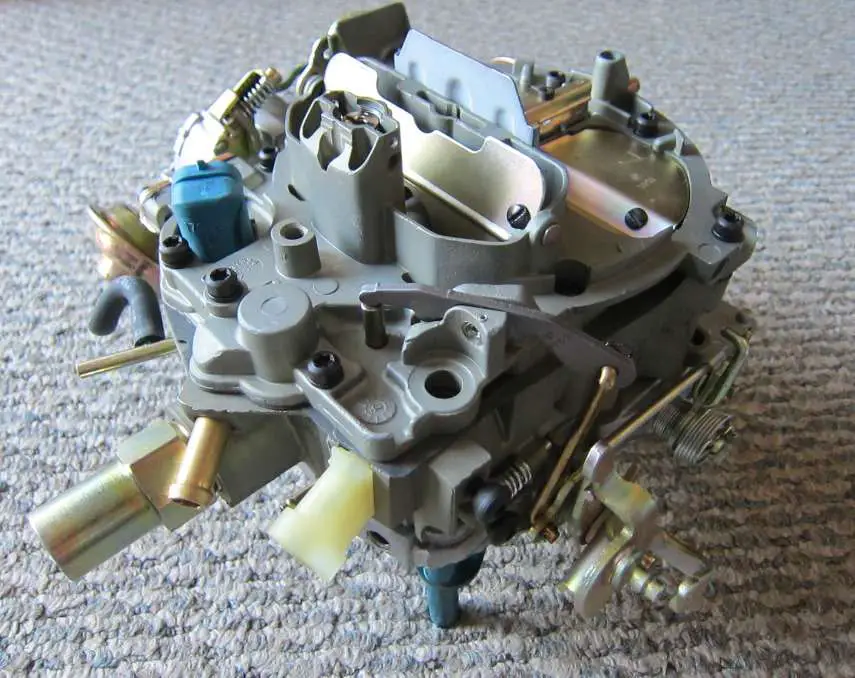

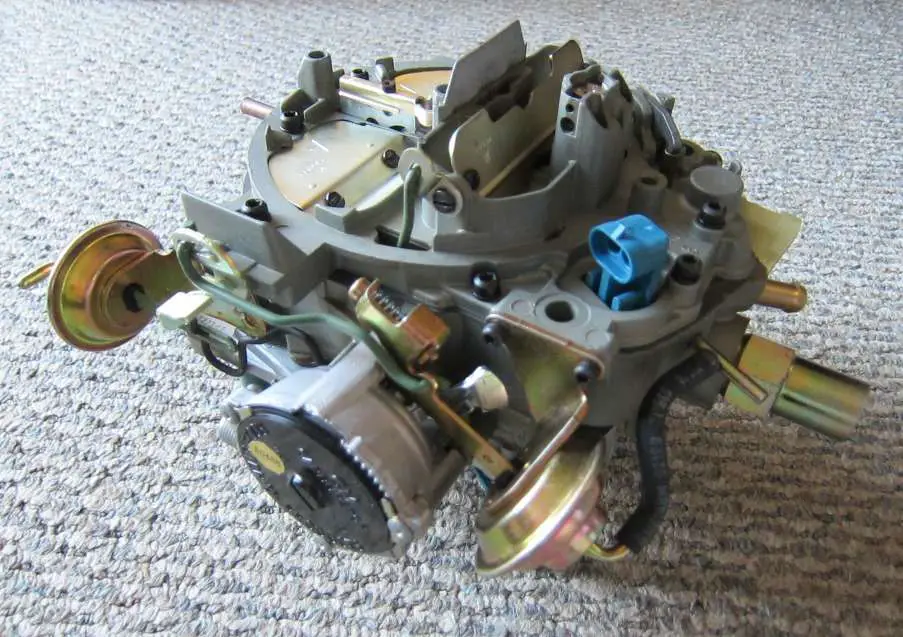

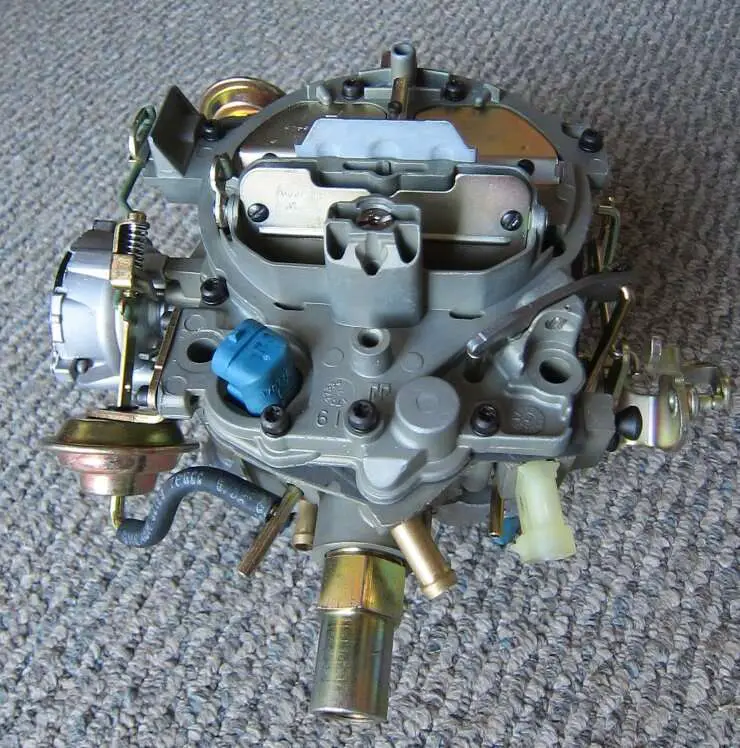

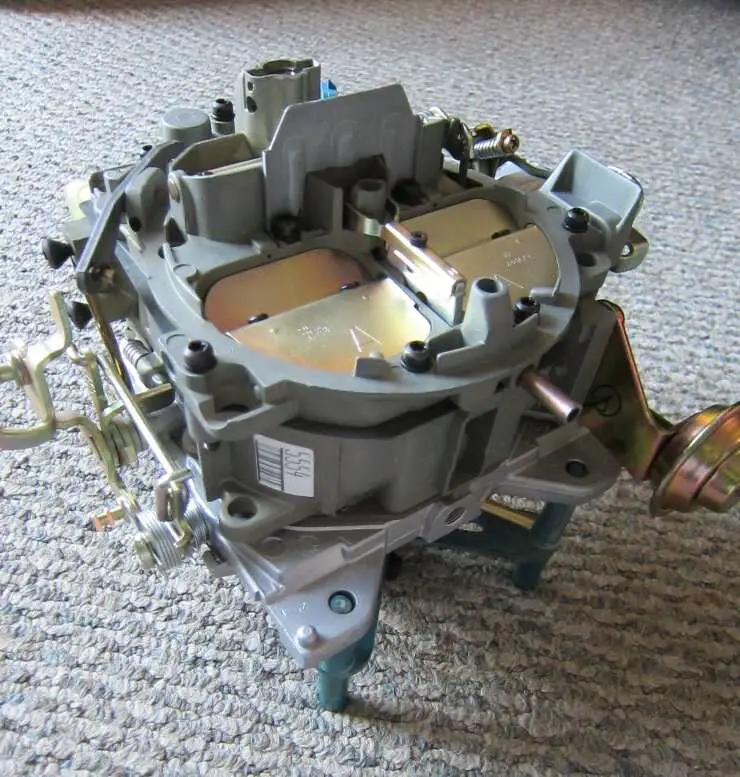

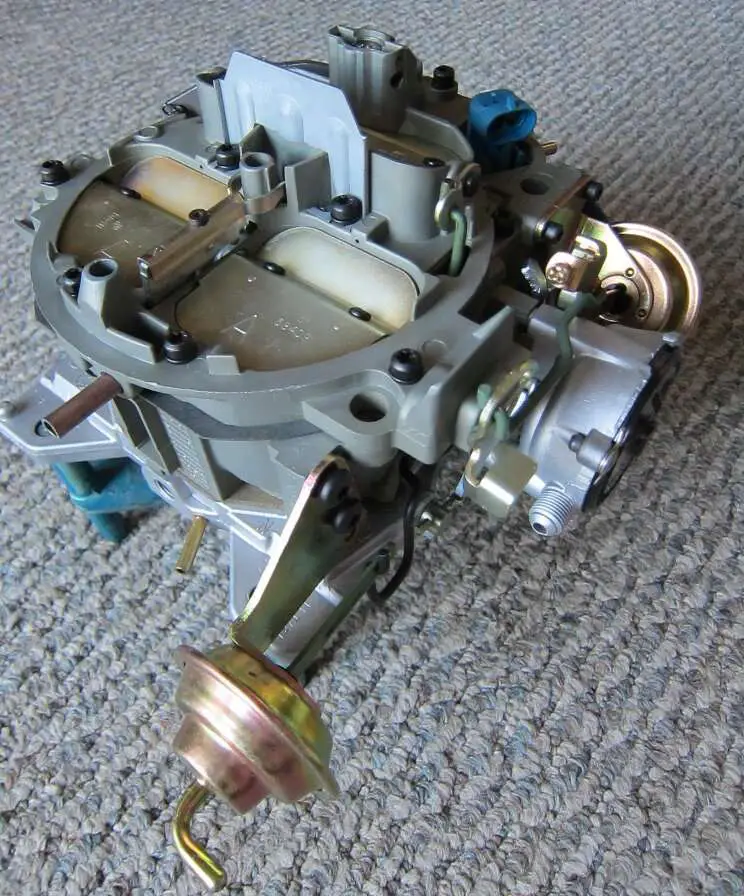

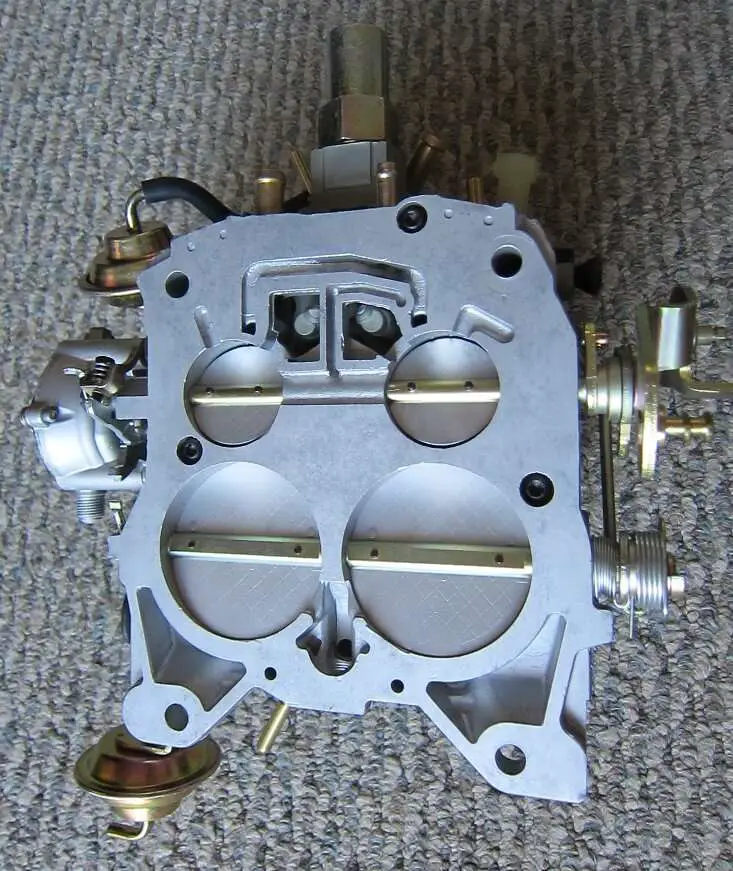

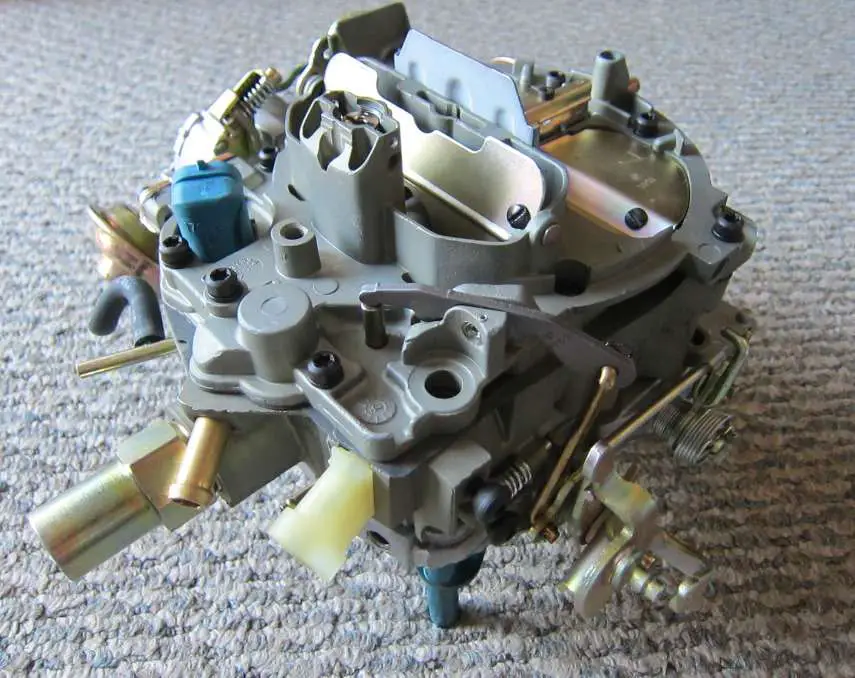

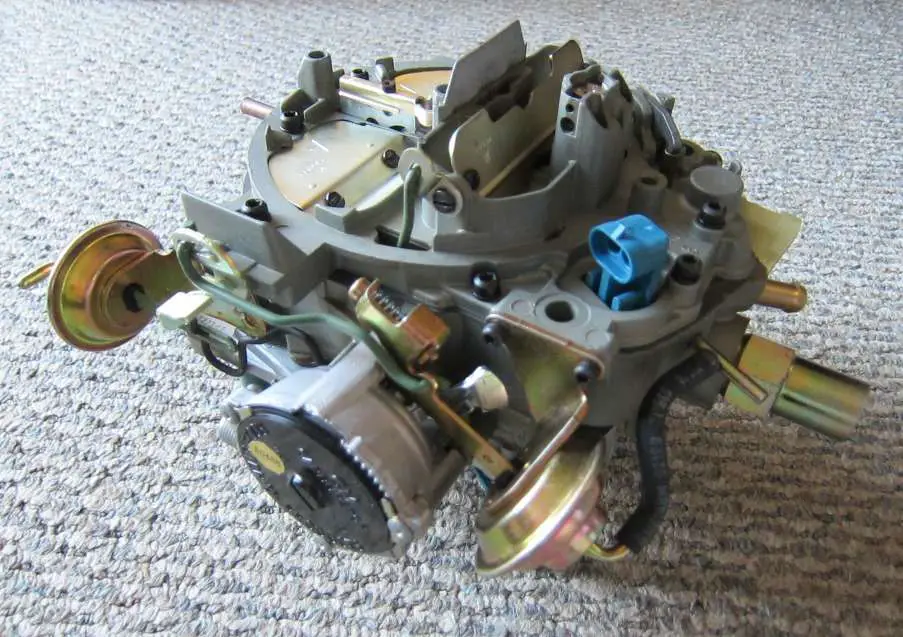

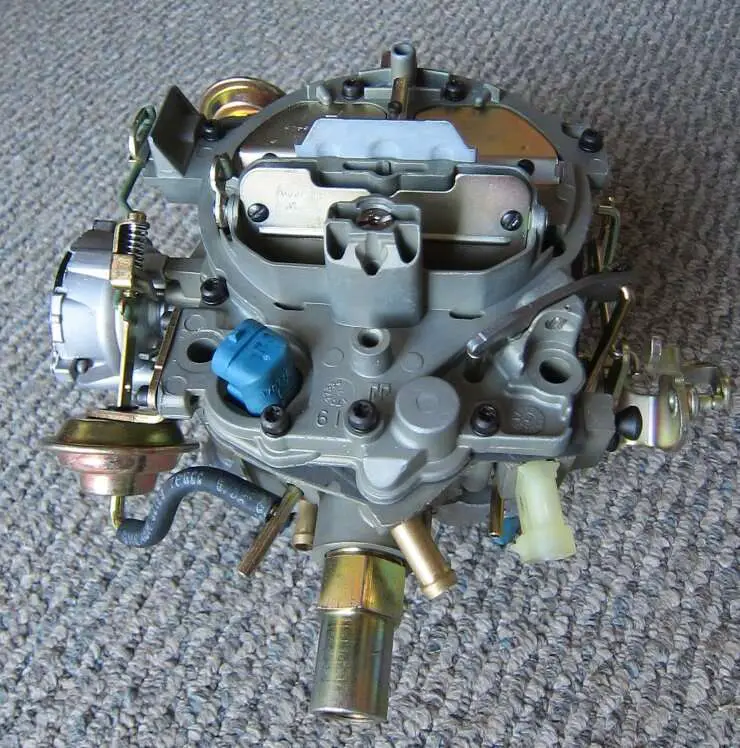

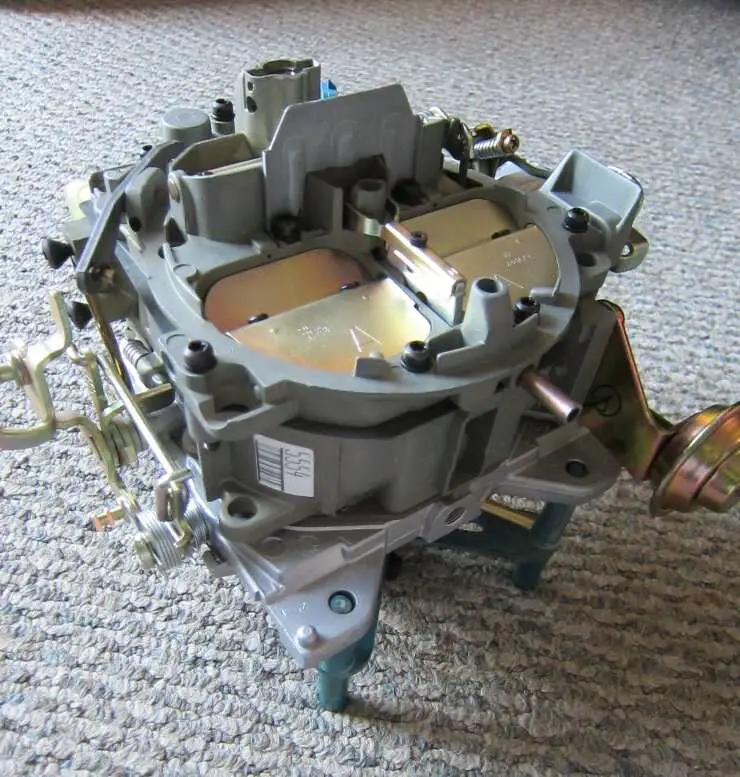

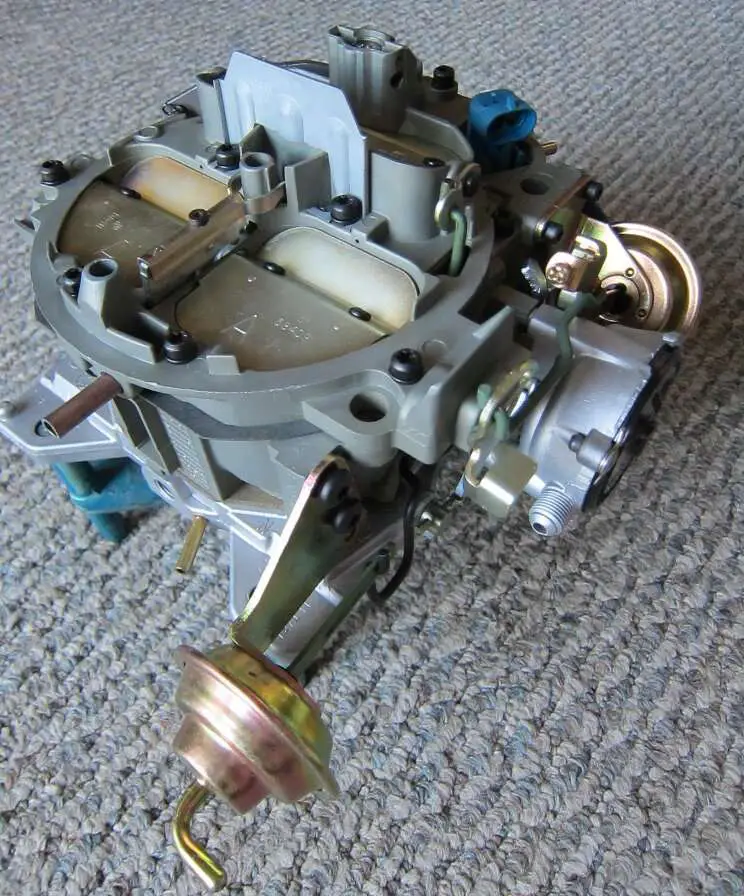

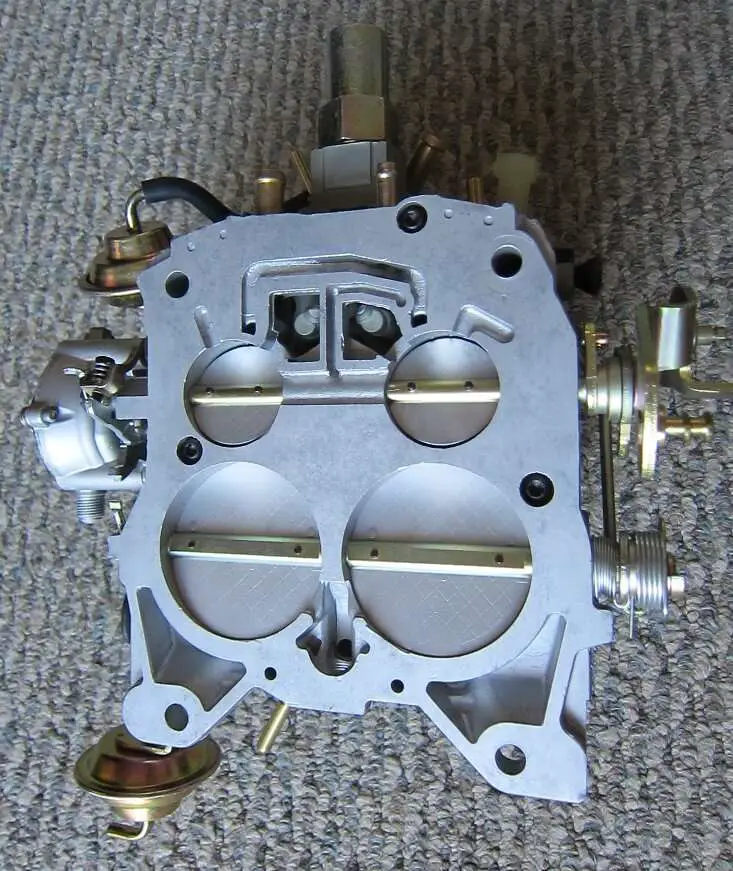

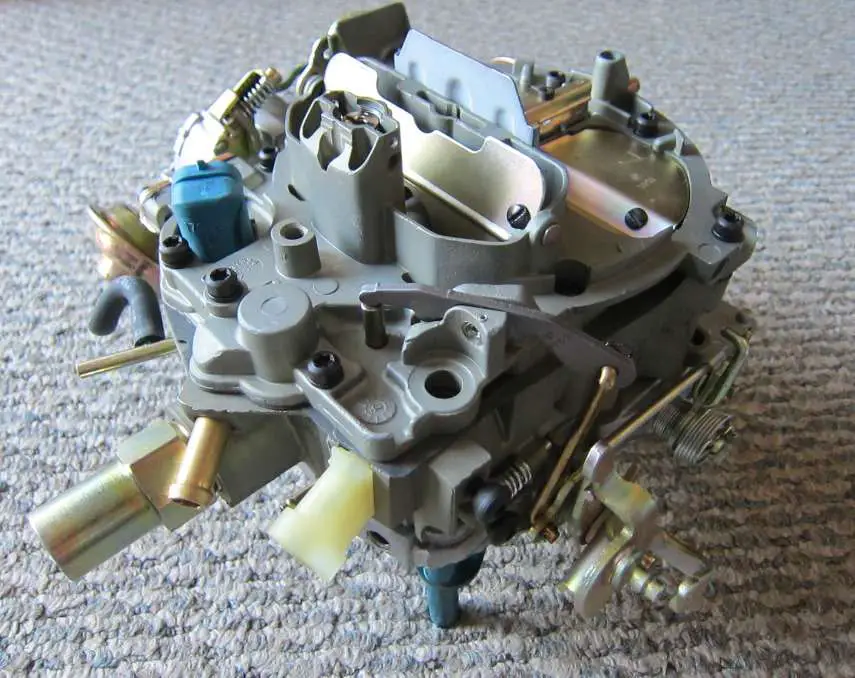

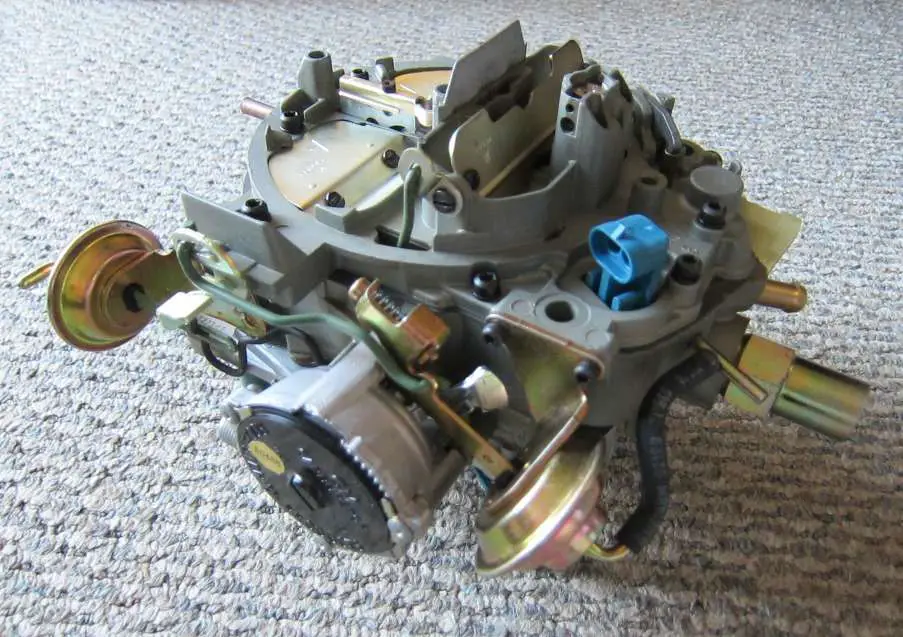

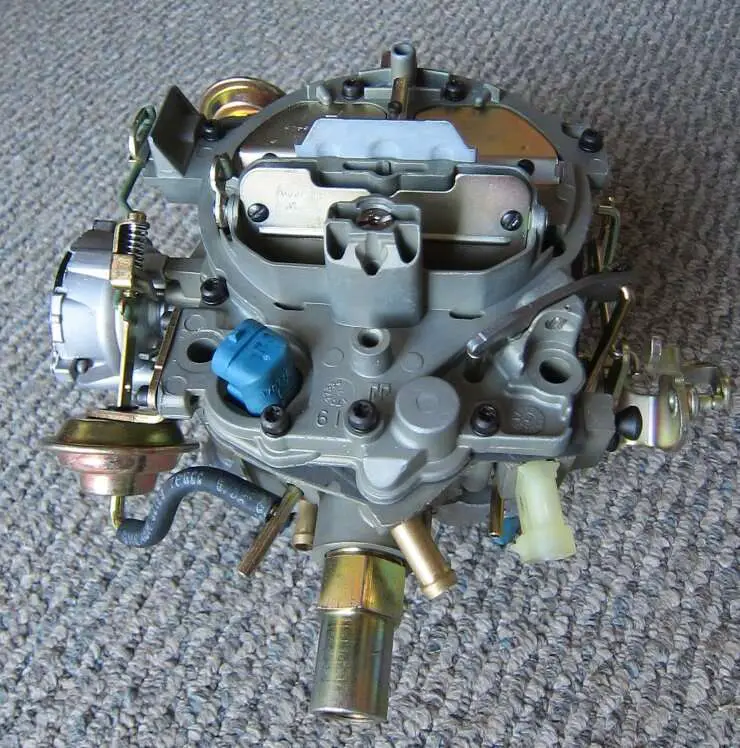

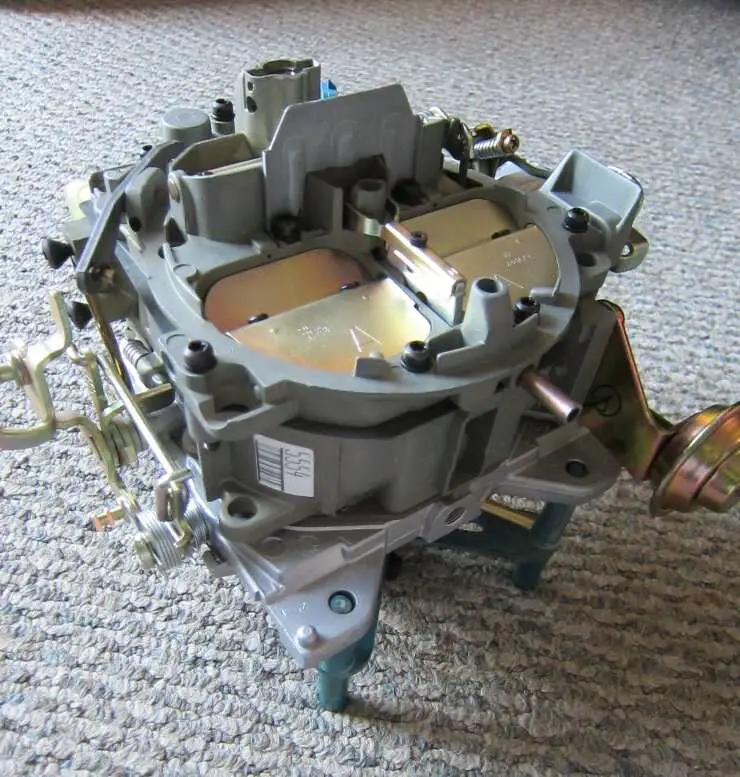

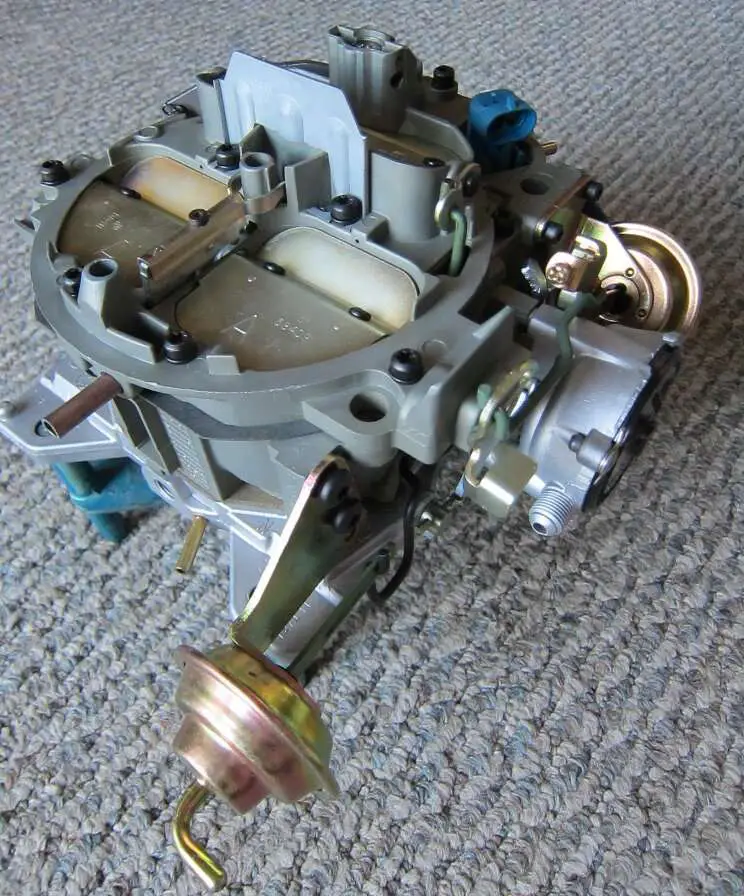

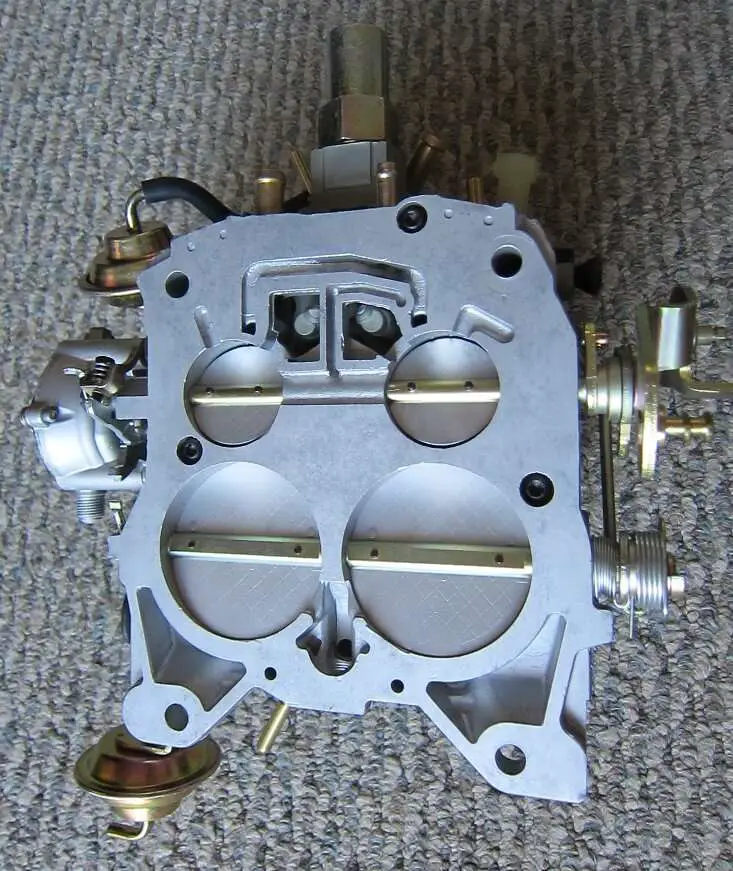

Here's pics of the final product. Now I'm going to bag it, tag it, and put it in a box until it's needed.

Thank you! I just hope someone saves their E-jet because this thread helped them fix it instead of listening to those that don't understand this type of carb.Excellent and very detailed write up Mike, and a beautiful job too. Thank you for sharing this with the forum, as usual your contributions are invaluable. I commend you sir!

Thanks for the support. Either fortunate or unfortunate, this type of carburetor doesn't lend itself to lots of mods and still being able to play well with the CCC system. It's a LEAN azz carburetor from the factory and emissions is the concern. Even though there are some sections of it, like the secondary circuit, that the ECM doesn't even look at, the cruising and start up can be a real PITA if things aren't set to specs. I've learned a ton more every time I do one of these carbs. Maybe one day I'll figure out how to actually live with the CCC and still set it up for better performance without regards to being super-lean but still be emission friendly. Or maybe not.You did an excellent job rebuilding that carburetor. What I like about it more is the detailed pictures and you explaining how each part goes together and there function.

Thanks for reading it. Your (I'm assuming) Monte has the 4ME with electric choke and has a few different spec settings, but for the most part it will follow much of the same setup as this one.Thank you so much for all your time that you put into this write up and all the adjustments.

This will be very helpful for when I rebuild my carb.

Rick

Well, thanks, I guess. I still have a lot to learn. Hopefully looking at this thread shows you that if you can rebuild a regular non-computer Quadrajet, you can do 90% of a CCC E-jet.Yes you are correct mine is the 4ME with electric coke. So will all the other adjustment be right on mine except for the choke.

I have rebuilt carbs before in the 70's but never an electric carb. They scare me.

From reading your post you must be a Master mechanic or a Parts manager.

You sure know your stuff.

Just a quick note on the desktop power supplies, while simply using it to provide power to the TPS reference signal isn’t enough to justify buying one, they are great at “reviving” dead automotive batteries….if you have a couple weeks/months to keep cycling it (charge/discharge rinse/repeat)I did this on the Frankencarb, and took the pics, so this is more for procedure. You do not have to do this part if you don't want to take the time to do it. Theoretically, you just bolt it on and crank it up, then set it per specs when it goes into closed loop. But in case you see some problems on the bench, it's better to fix it now before it lands on the car. Just one less PITA thing. If you're pressed for time, just do it on the car.

What we're trying to accomplish here is to simply get in the ballpark for TPS setting on the bench so that you are "close" when you crank up the car. You still may get a code for high or low TPS voltage while doing it on the car. That's ok, you'll clear all codes anyway once you're done adjusting. This will simply speed up the TPS adjustment on the car. Plus, it's exactly what you'd be doing on the car anyway, so you can get a bit of practice in on it before you actually do it.

Recall you did NOT install the TPS cover plug (along with the Lean and Rich stop plugs) as you want to ensure adjustability during closed loop operation. You'll install the plugs later after you get the stops where you want them and the TPS fully adjusted.

Using a 5.0 volt DC power supply, I rigged up power to the TPS reference signal. I realize this will not be the exact voltage you'll see on the car, but it will still be pretty close. If I had one of those whamodyne adjustable power supplies, I could dial in exactly what I need, but you will STILL need to check it on the car anyway. I wouldn't use it enough to justify the expediture to get one. I already had the 5V DC power supply, so I'm using it.

Starting at the top, recall you have an A, B and C connection points as you go down the connector. A is the 5V DC in reference signal from the ECM. B is the variable signal return BACK to the ECM. And C is the common, or ground. Hook up the voltmeter to check the voltage going in and you can see it's a tad higher than 5V. It's very likely and not unusual that you may see slightly less than 5V on the car. Which is ok, the point is the ECM will see a differential voltage and calculate the throttle "position" from this. It is extremely important that you get the TPS position set as close as you can to 0.41V at 550 RPM in drive. It's not going to kill anything if you're at 0.40 or 0.42, but if you can get it set at 0.41, that's as good as you can get.

You can see the reference voltage here at 5.14V DC. A tad higher than what you'd see on the car's actual ECM reference voltage for the most part, but that's ok. We're just ballparking it here on the "bench".

View attachment 202734

And now you can adjust your curb idle screw to 550 simulated rpm (just a wild guess on the curb idle), and ensure the choke isn't engaged and you're off the fast idle steps. Adjust the TPS adjusting screw with a suitable tool as you can see in the picture to get your output reading at terminal B (middle terminal) to 0.41V DC and you're golden. It's pretty sensitive trying to get 1/100ths of a volt, so take your time and do it slow. Once adjusted, let it settle out. Crack the throttle open and return it and see if it returns to 0.41V. Don't worry about a couple hundredths of a volt, but you don't want it going all wild on you and throwing codes.

View attachment 202735

And with that, we are DONE DONE with this carburetor! Now it's ready to bolt on and do the operational setup on the car. A few tweaks and it should run like a new one again!

Good luck everyone. I hope this little rebuild thread can help you out.

EDIT: Just wanted to add that I edited post #15 to add the ohm check across the body and terminals for the MC Solenoid. I meant to show that, but forgot. So I went back and added it. Super simple check, but hard to do once you put the carb back together.

Yes you are correct mine is the 4ME with electric coke. So will all the other adjustment be right on mine except for the choke.

I have rebuilt carbs before in the 70's but never an electric carb. They scare me.

From reading your post you must be a Master mechanic or a Parts manager.

You sure know your stuff.

Do you happen to have a list of the different setting specifications for the TPS voltage on different models? I can’t find it anywhere for my 1983 E2ME that’s on a Buick 231 that came from the factory in my 1983 Cutlass Supreme Brougham. I’ve bought 3 different brand rebuild kits in the last year, and it’s not on any of the sheetsHere's pics of the final product. Now I'm going to bag it, tag it, and put it in a box until it's needed.

View attachment 202772

View attachment 202773

View attachment 202774

View attachment 202775

View attachment 202776

View attachment 202777

View attachment 202778

View attachment 202779

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.