1987 Cutlass Build

- Thread starter 84dragcutlass

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

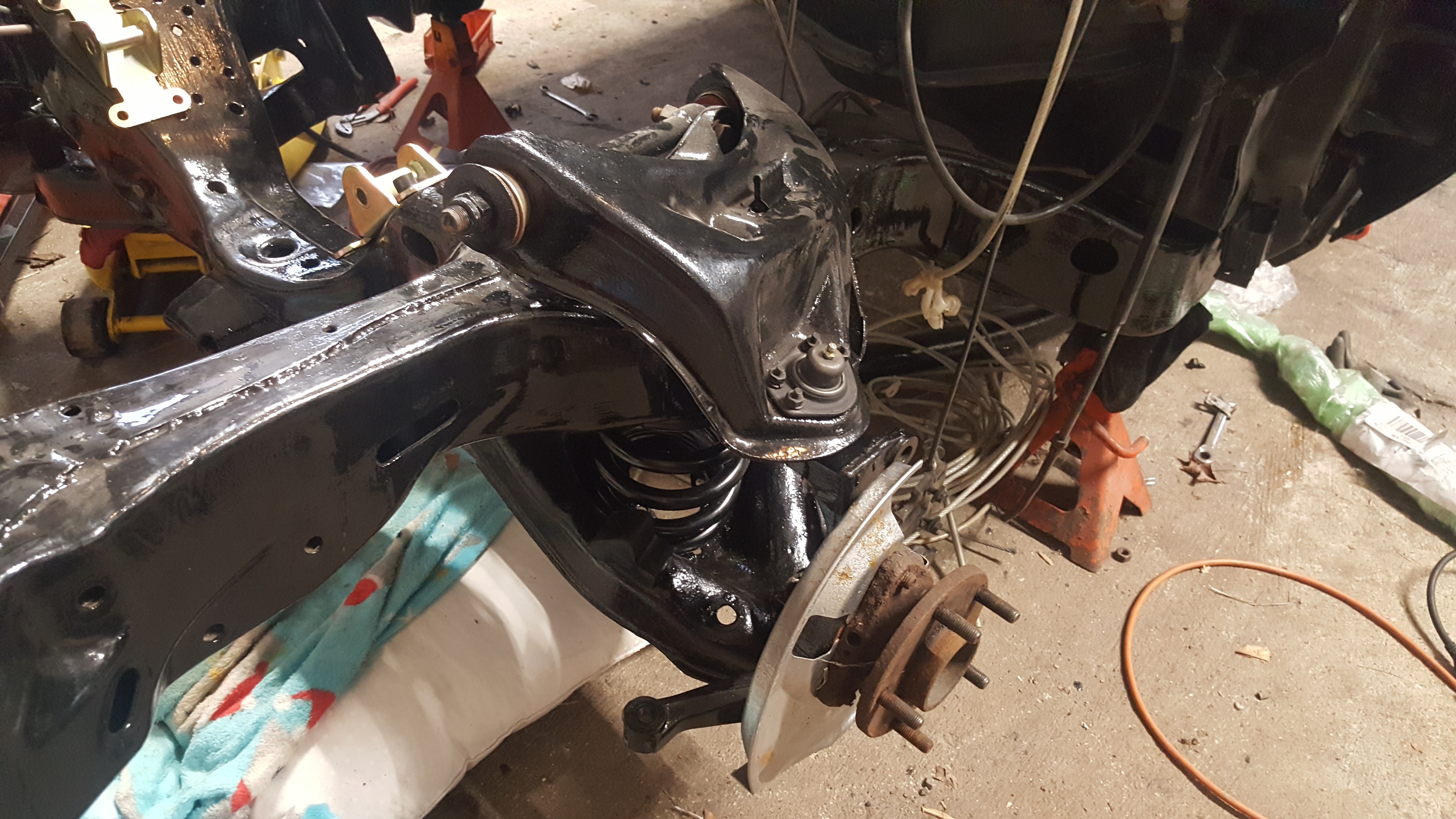

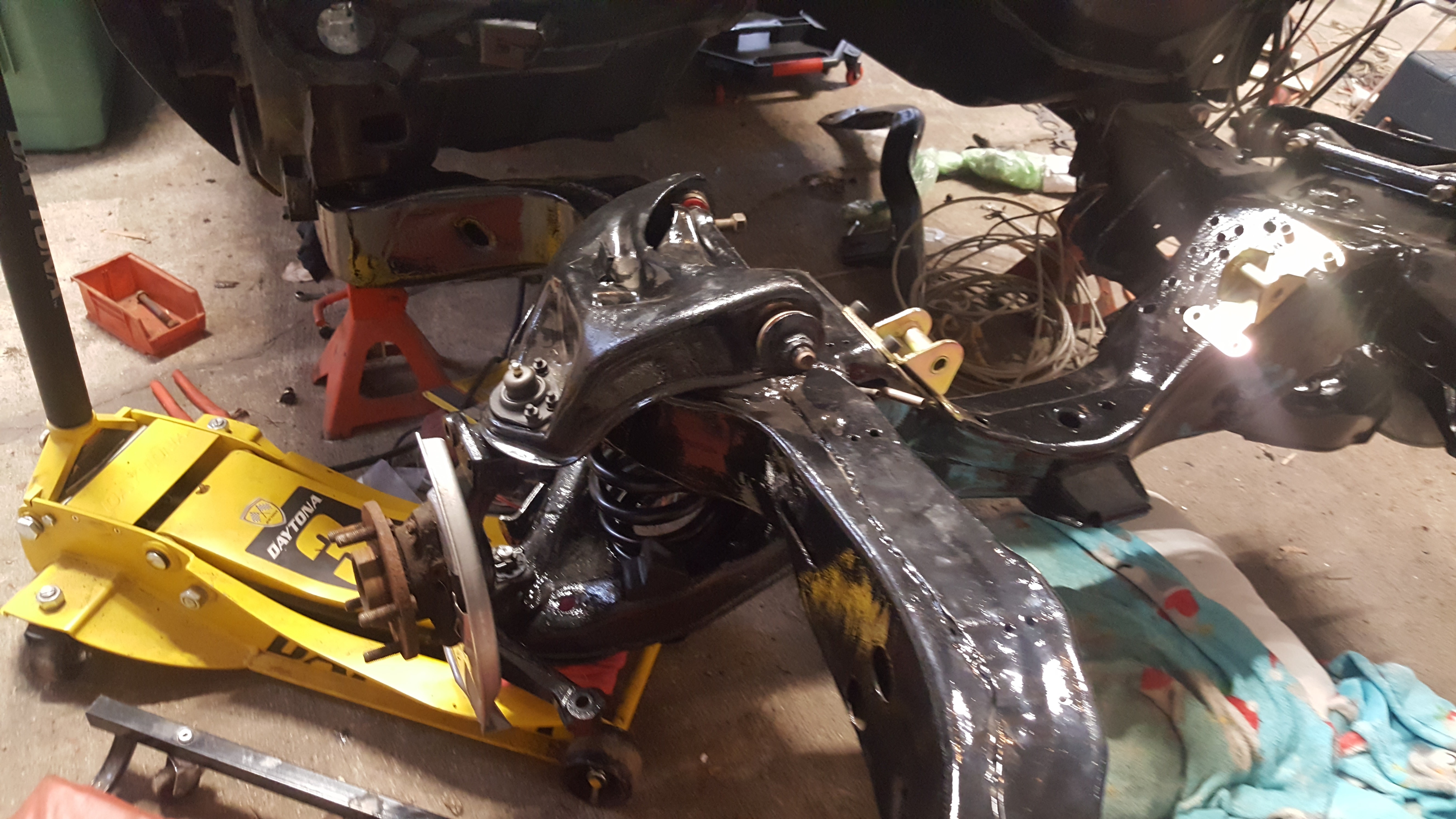

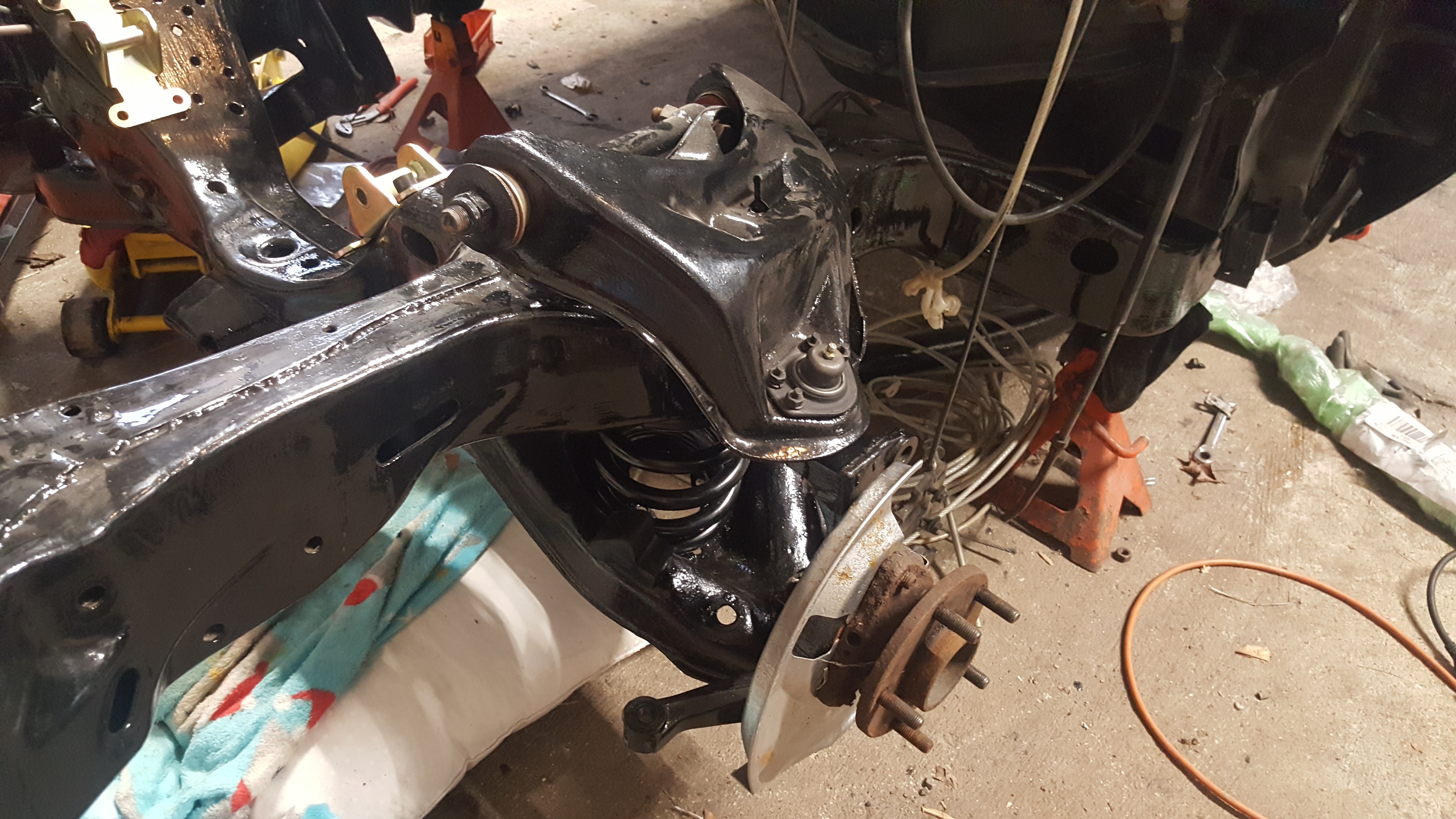

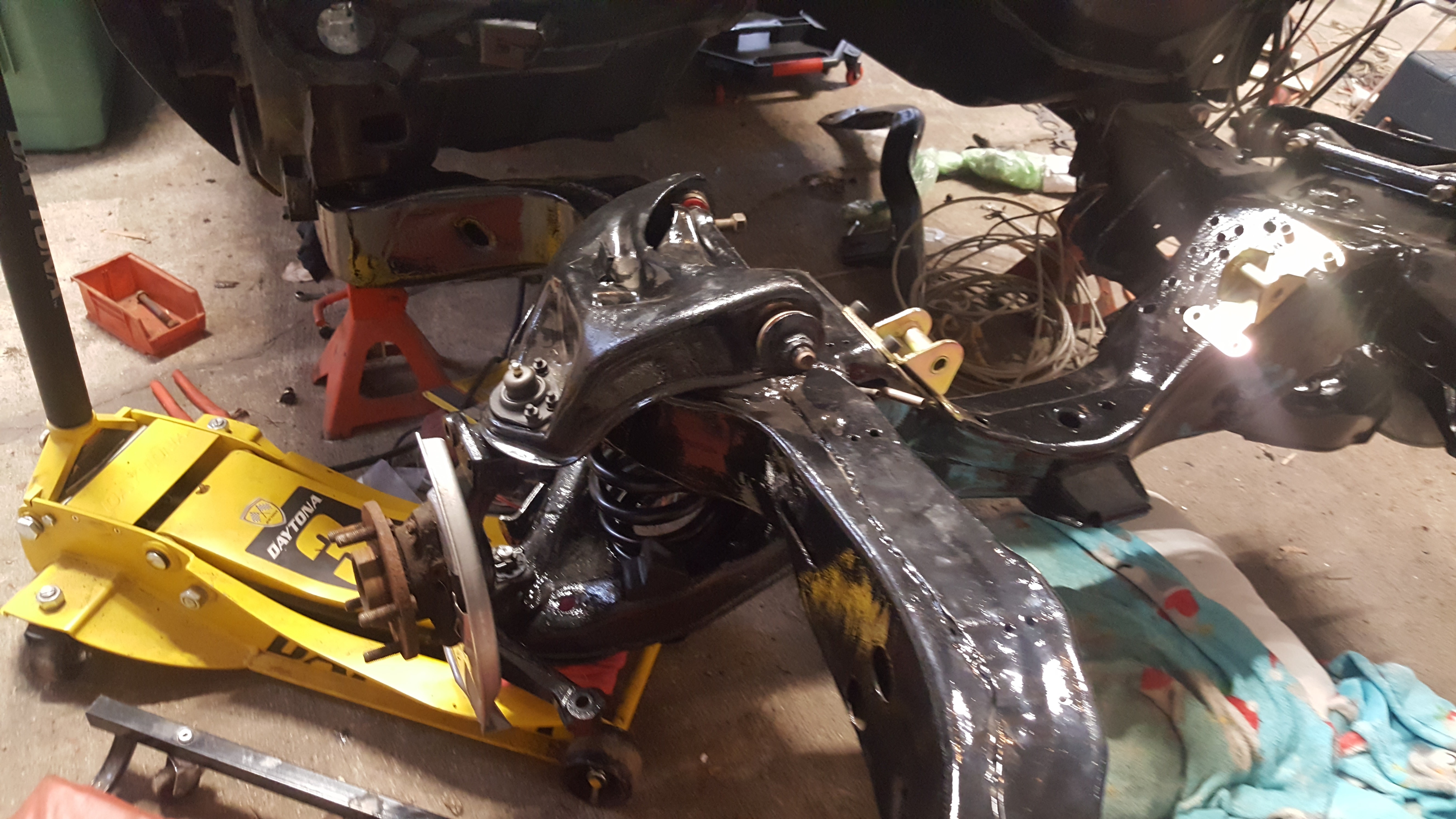

Small update as i have been on and off with vertigo and its limiting me on what i can be crawling around doing on the car. My son and i were able to get the front suspension back together before i got too dizzy and sick to continue.

Blazer brake upgrade up front, currently have used hubs on there for mock up. New ones are in the garage awaiting the studs to be punched out and larger ones put in for the AERO wheels to go on. Recently got that package in the mail from speedway motors, full set of new studs and lugnuts. Next is wheels. But for now here is the rest of the front put together. The springs are new for a Diesel powered cutlass with AC. I figured since my engine is heavier but im not running any AC components the springs should work okay.

Cat bed under the car for my wifes stupid mean *ss cat to sleep on... got to be in the garage so the poor thing doesnt turn into a frozen cat pop outside...Next up will be shocks, wheel studs, and rear brakes. Quickly running up to time that this thing will be sitting on its wheels again.

Blazer brake upgrade up front, currently have used hubs on there for mock up. New ones are in the garage awaiting the studs to be punched out and larger ones put in for the AERO wheels to go on. Recently got that package in the mail from speedway motors, full set of new studs and lugnuts. Next is wheels. But for now here is the rest of the front put together. The springs are new for a Diesel powered cutlass with AC. I figured since my engine is heavier but im not running any AC components the springs should work okay.

Cat bed under the car for my wifes stupid mean *ss cat to sleep on... got to be in the garage so the poor thing doesnt turn into a frozen cat pop outside...Next up will be shocks, wheel studs, and rear brakes. Quickly running up to time that this thing will be sitting on its wheels again.

Yeah im new to it so im figuring that out, also noticed that if i feel myself getting a little dizzy to stop what im doing before it gets bad. Doctor gave me medicine called antivert to see if that helps.Vertigo needs to go away. I suffer from it too. Not fun when it kicks in. You have to watch you head and eye movements. It's difficult when rolling around a creeper looking up and around things. It can be managed. Keep focused.

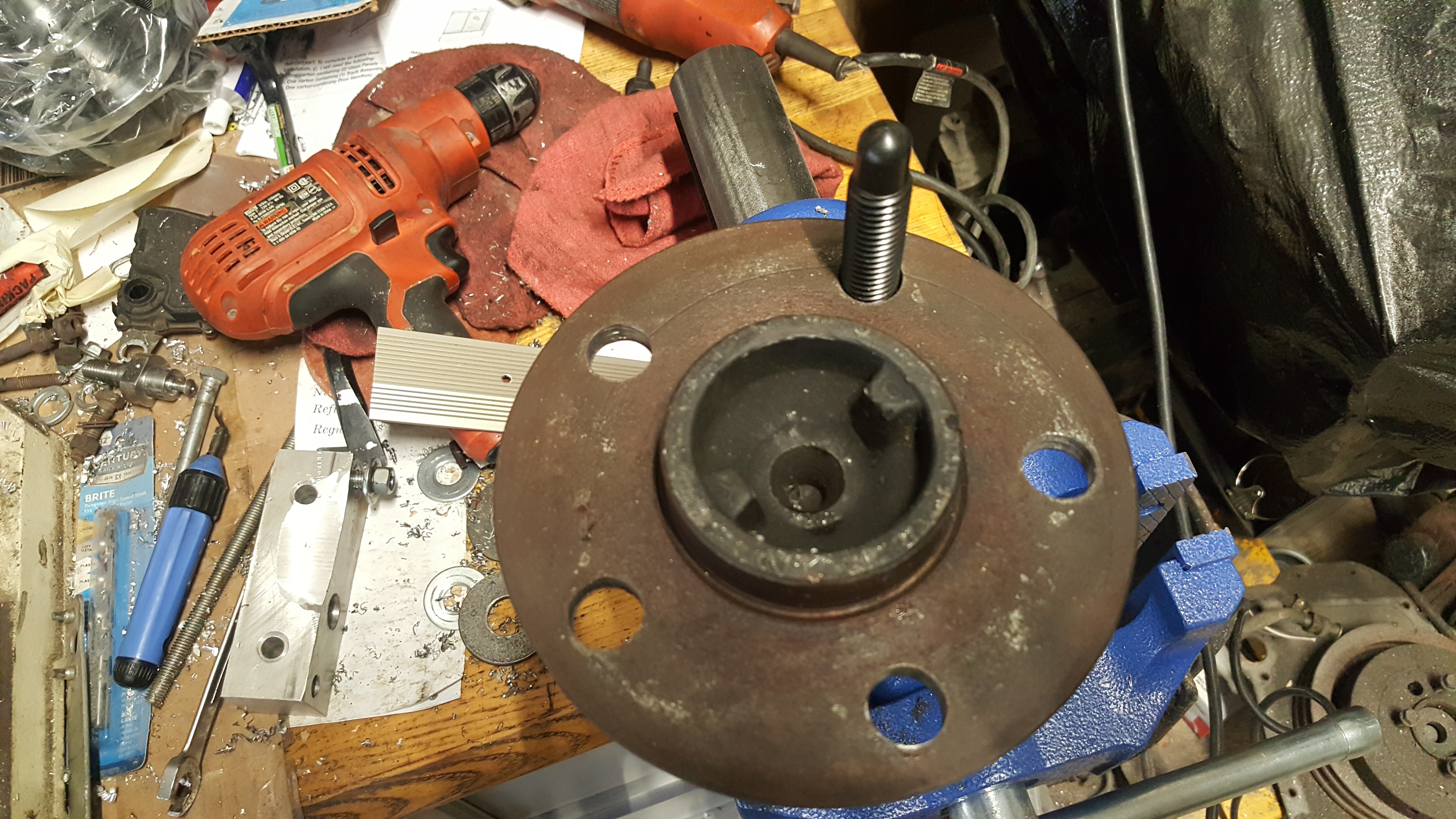

Okay time for an update on the rear axle, which is good news being that its one step closer to being on its wheels. So when starting all this "put race wheels on a street car" thing started i knew i would have to change out the studs for larger ones. Not really because i was afraid of breaking the stock ones but because the AERO wheels i want to run on this thing require a larger stud with 45 degree lug nuts. More about that later... First off i wanted to tackle the rear drums and because the car has been stripped down for so long i had forgotten how the rear brakes went back together. But after sitting for a while with the rear brake kit i got that sorted out. Before:

After:

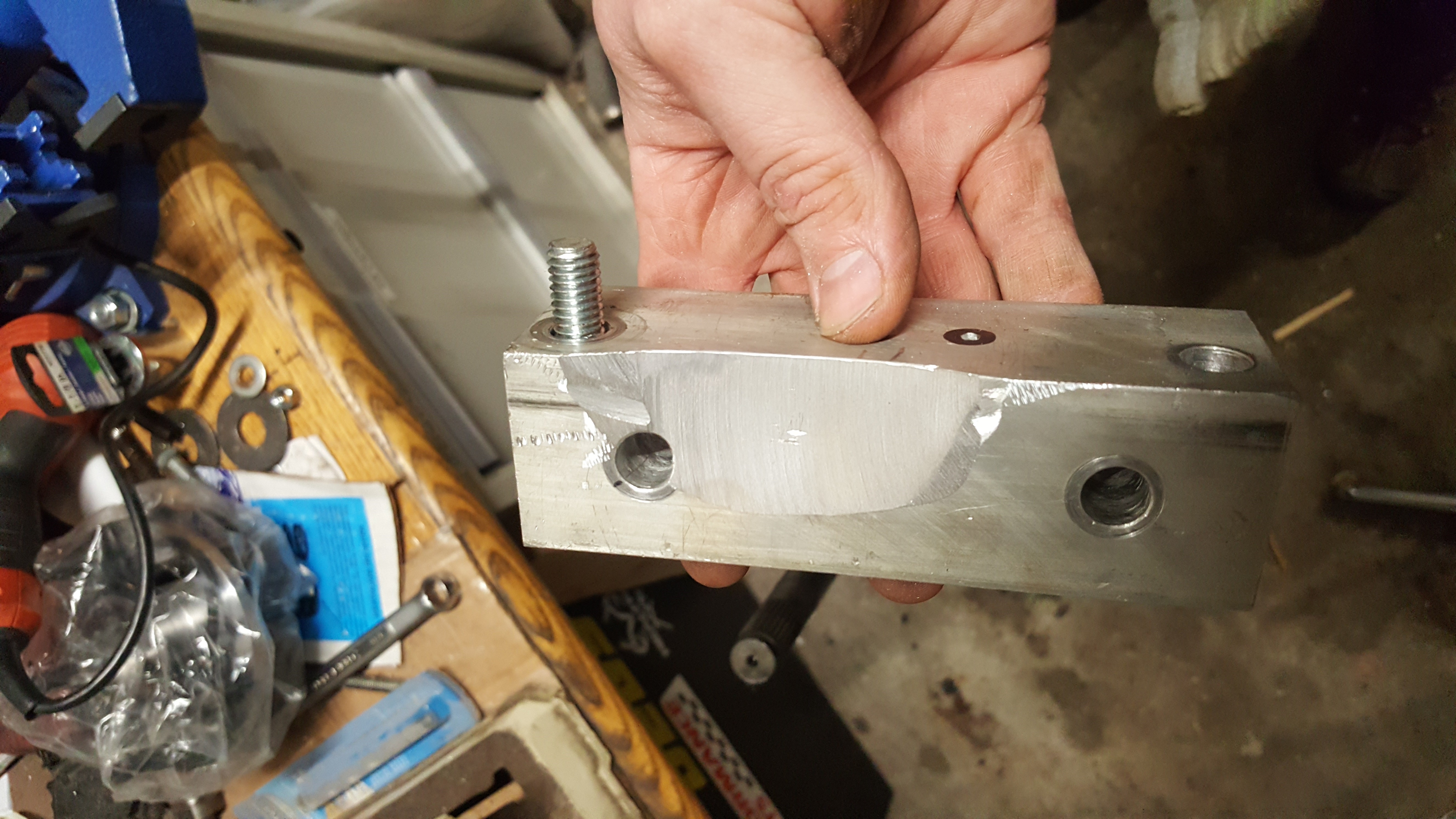

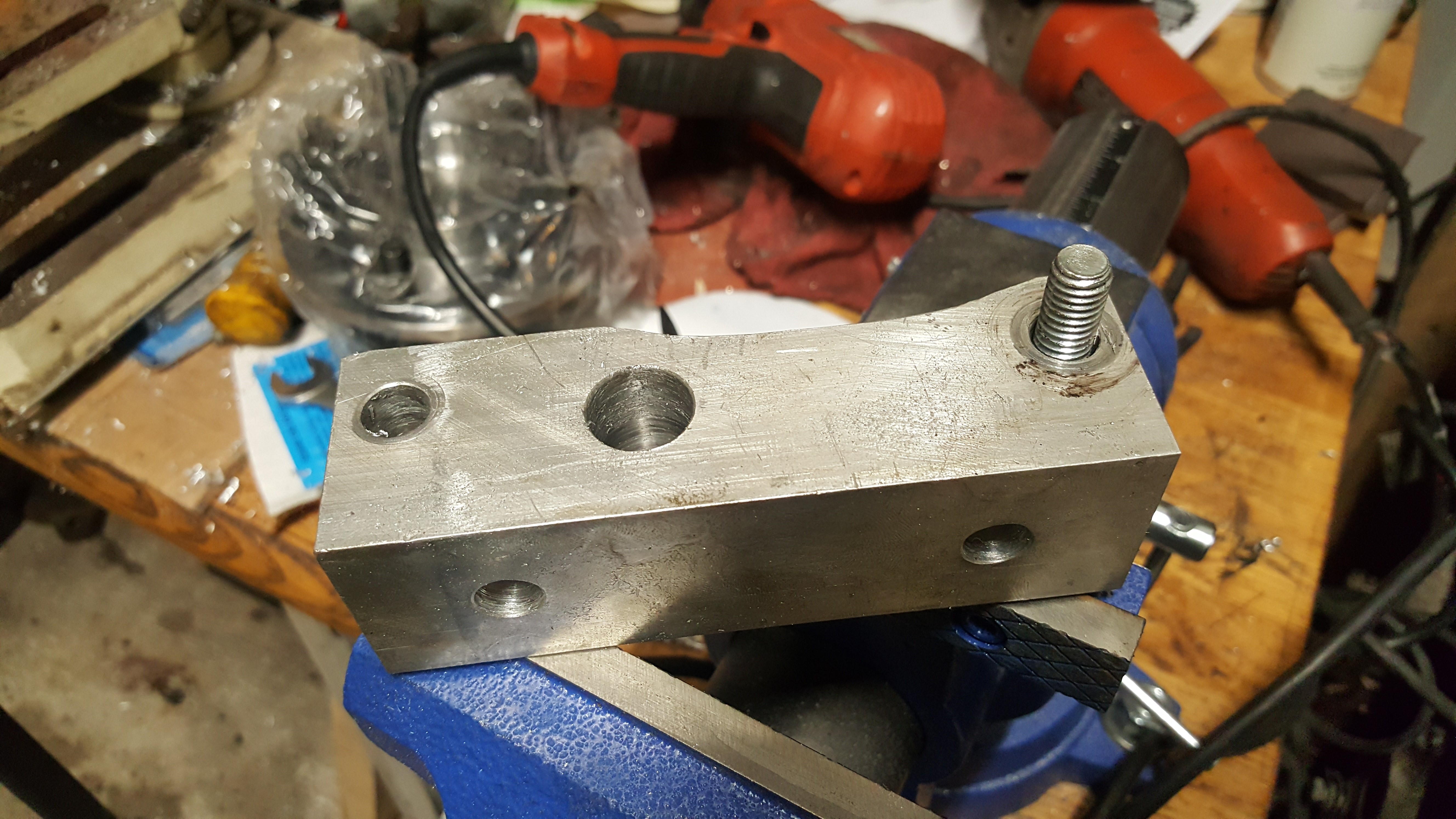

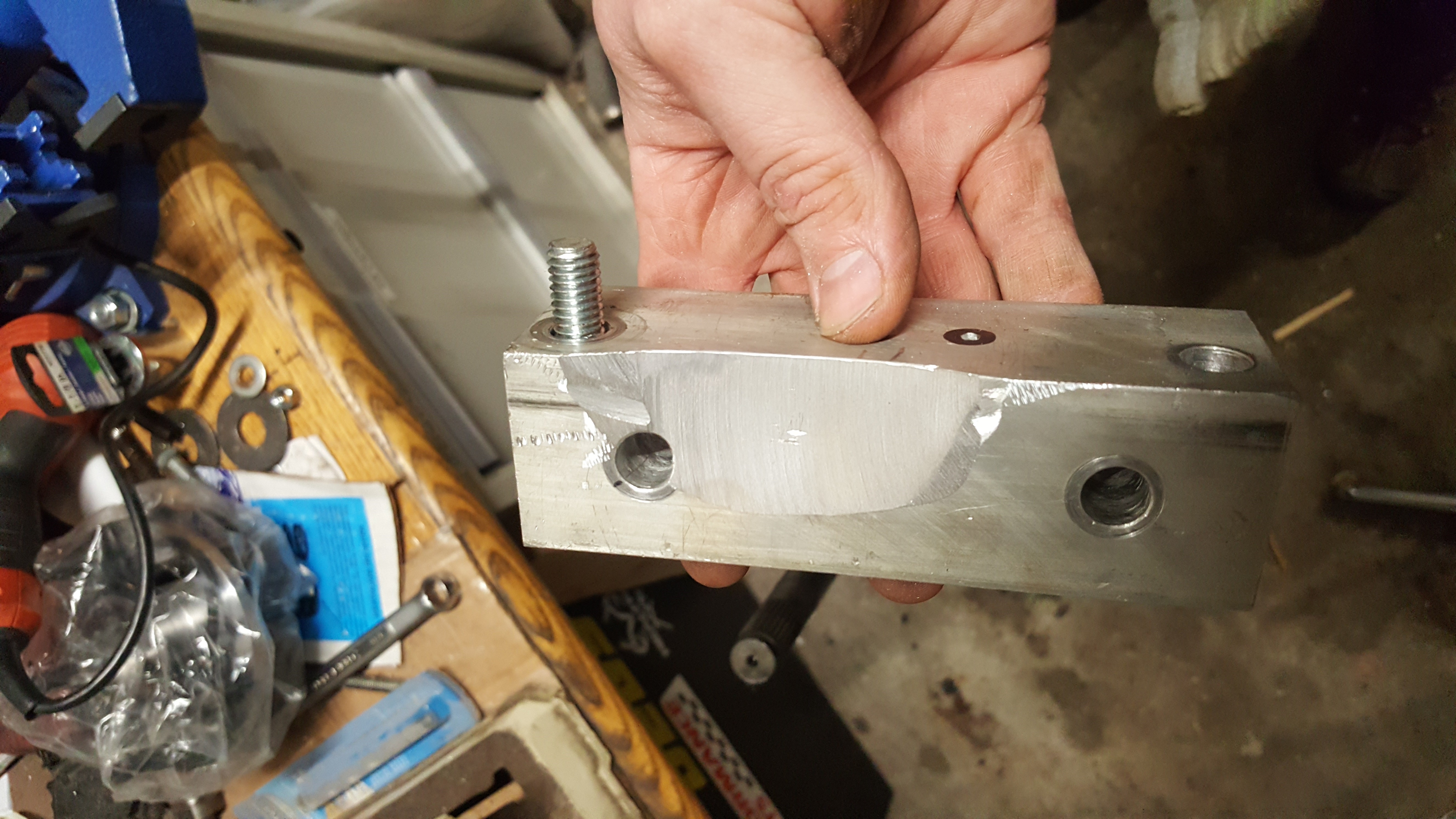

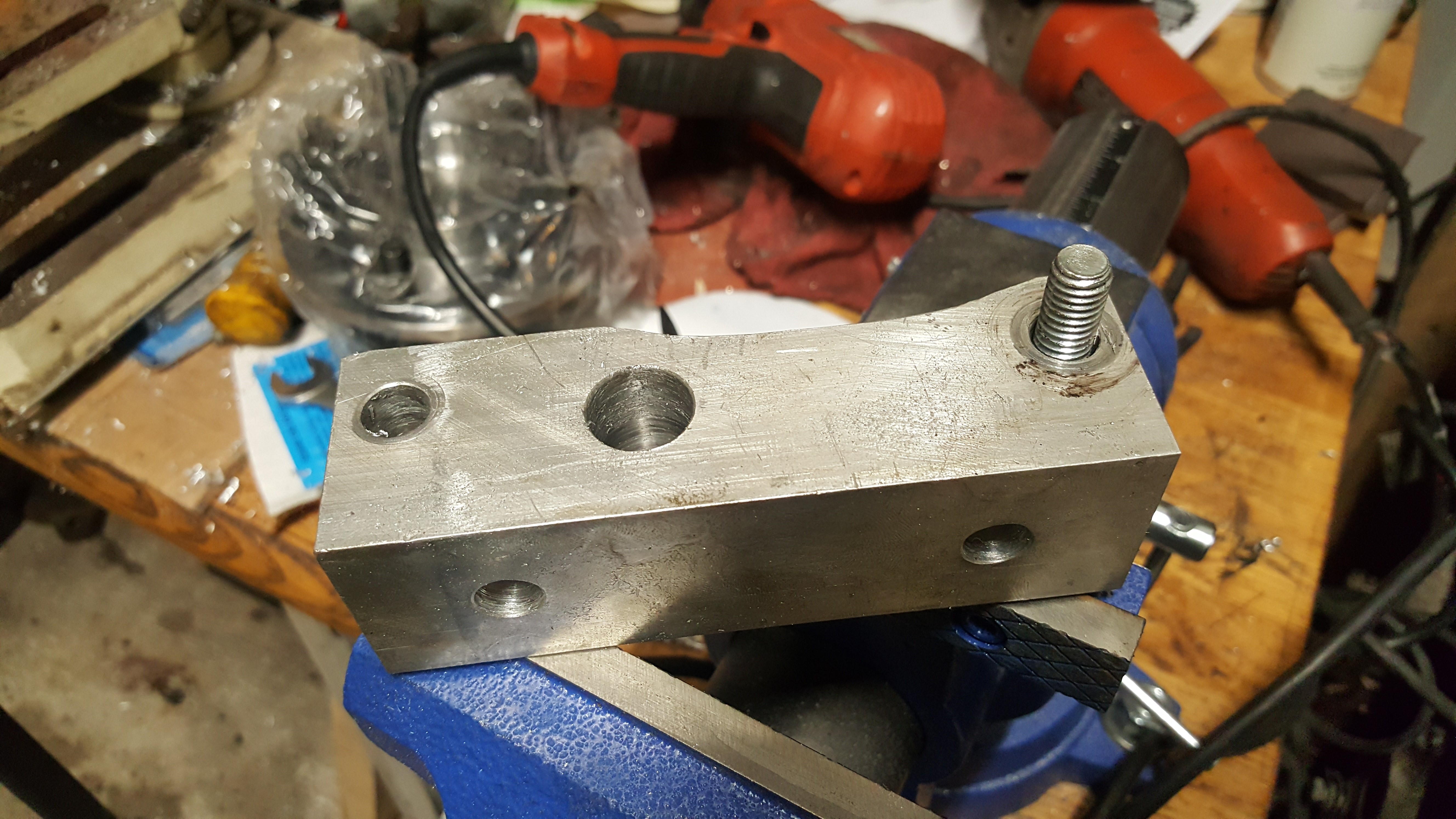

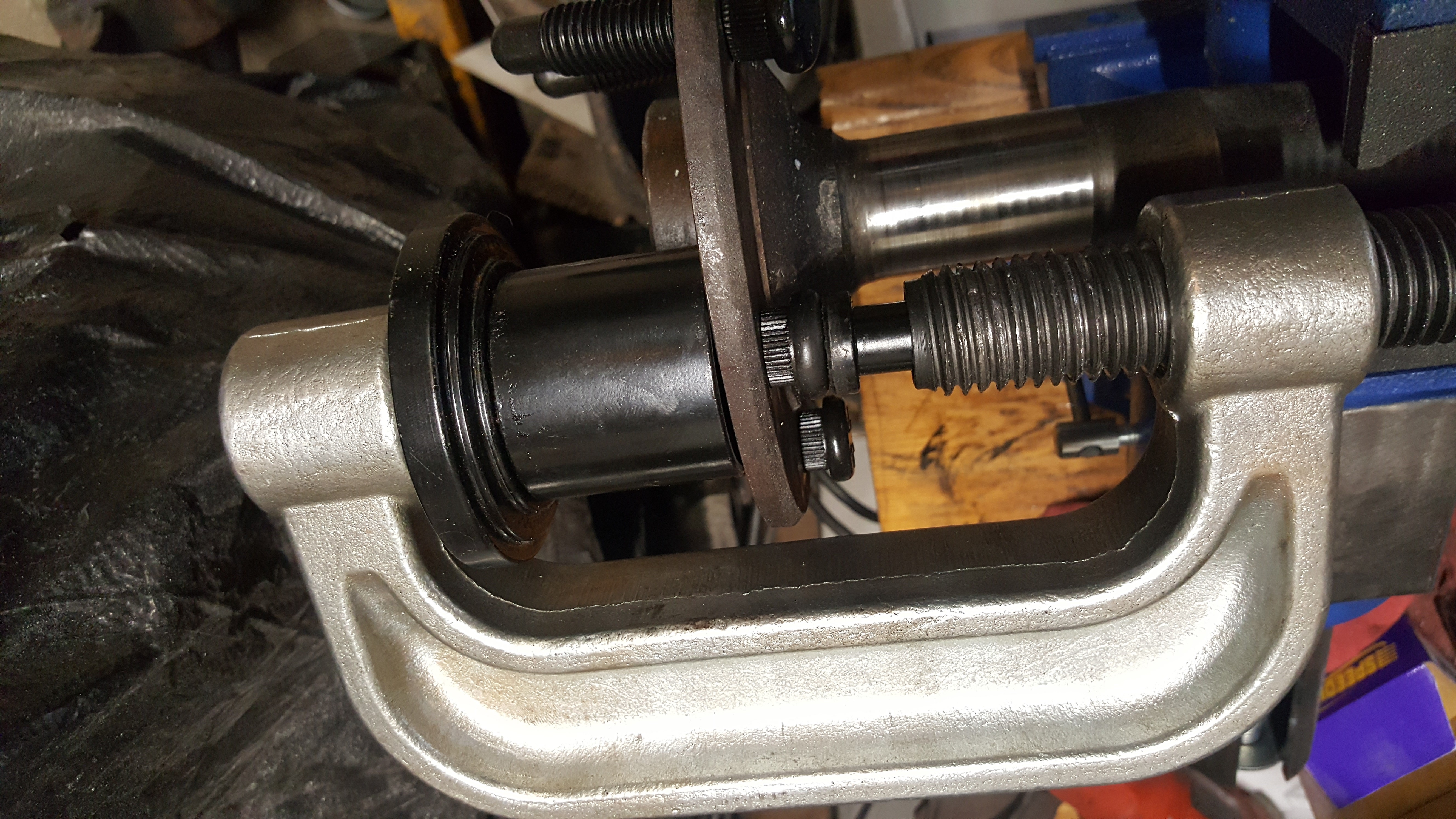

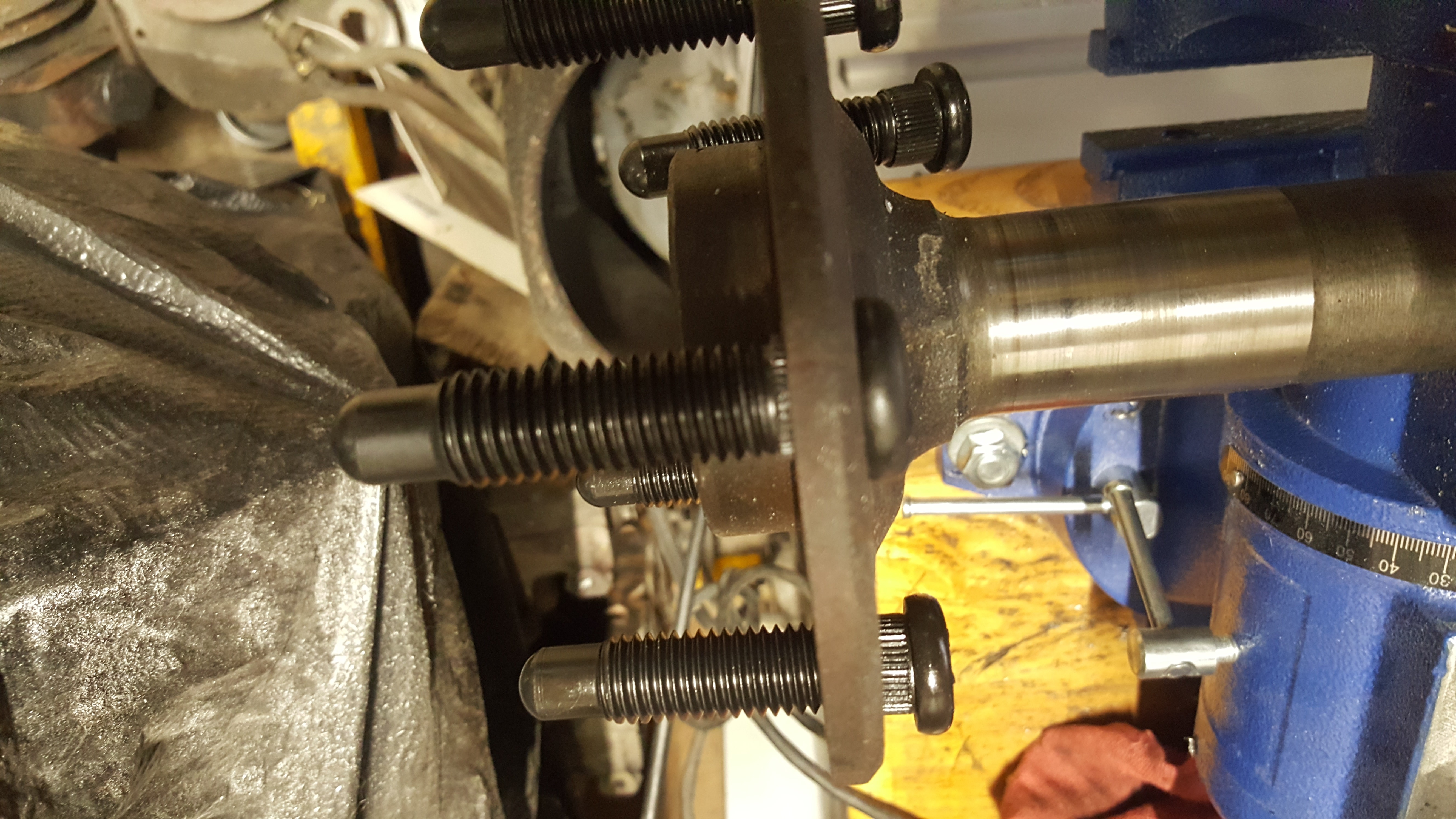

So once all that was done (and go figure ive lost my brake pliers) i went on to the axles themselves. I got a kit from speedway motors to do the studs which included the correct size drill bit, the studs, and the lug nuts i would need. I first pressed out all the stock studs which was easy with a ball joint press and thats when i realized i had a problem. My realization was that i had no way to keep the drill straight when i drilled these holes out. A drill press would have helped however the axle itself seemed to hit on mine no matter what orientation i put it in. A google search revealed that it seems common to wing it and free hand drill them with varying levels of success. The main issue was that if i drilled the hole off angle the stud could push in at that same angle and even 1 degree at the hole could mean that my wheels would not go on to the tip of the 3 inch long studs. So i decided to make a jig for it. I know that from center to center on the holes of a 5 x 4.75 is 2.792 so i did some measuring and found an aluminum block that would work. I used a carriage bolt on one end that seated into the aluminum so that it wouldn't turn. This would be how i would clamp it down, and at the 2.792 center point i used the drill bit from speedway to drill the correct size hole through the block that would be my guide. i had to grind a notch in the side to clear the round area in the middle of the axle flange.

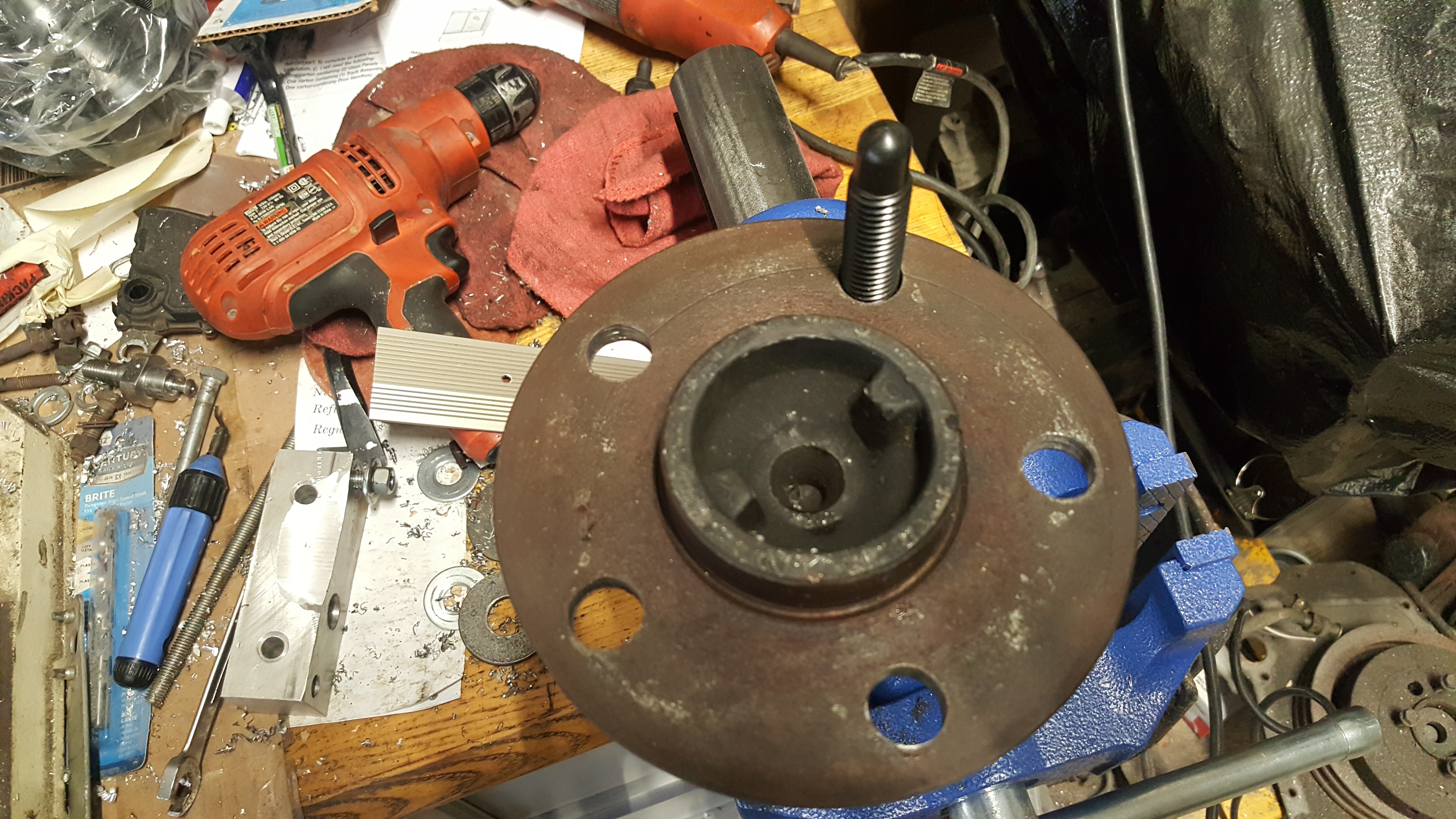

After the block was finished it was time to put it to use. For each hole i would use the bolt to line up through the stud hole next to the one i was drilling and using a nut and washer from the other side i could clamp it down. Then it was a simple matter of drilling it out to the correct size and moving on to the next hole.

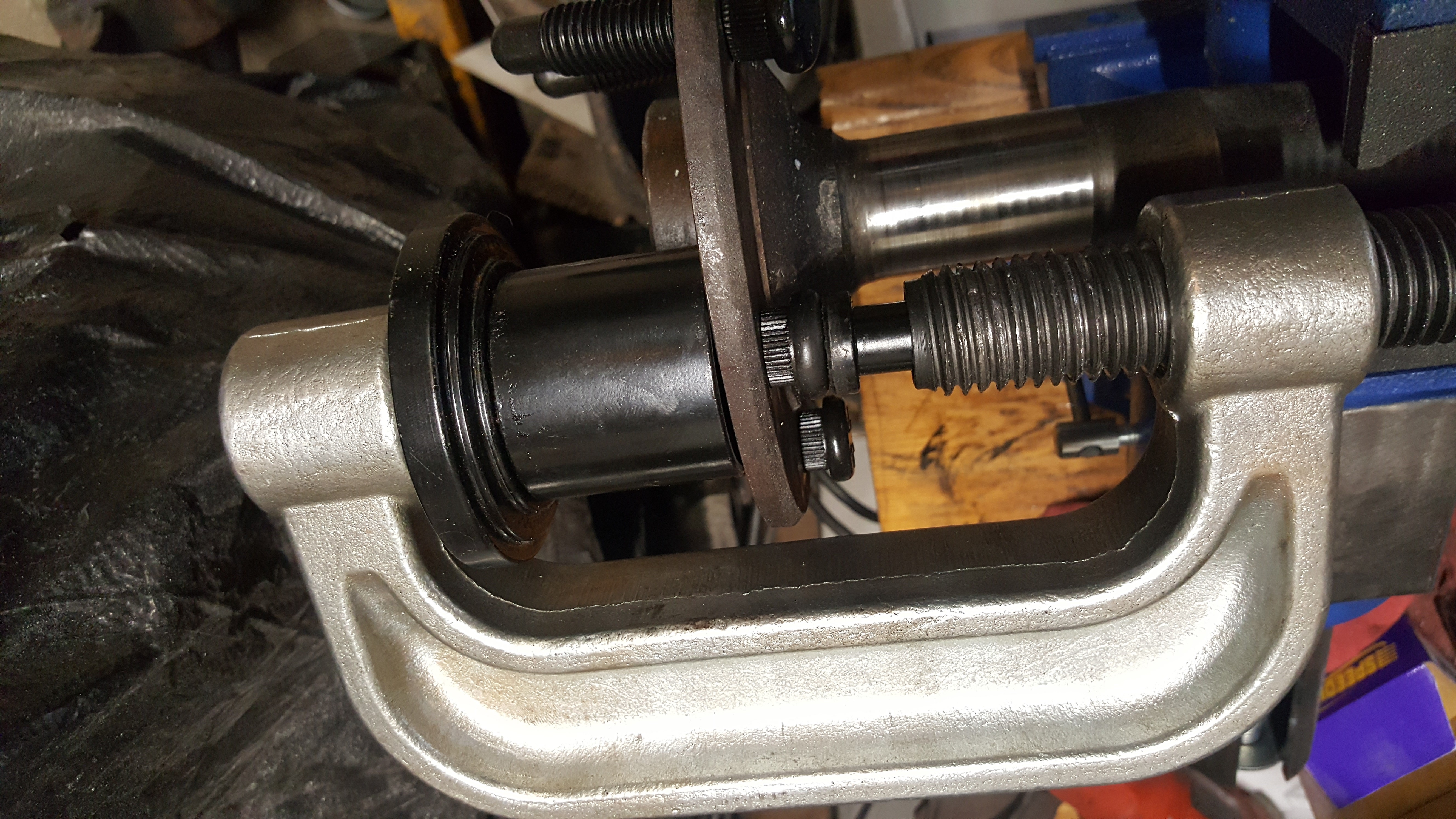

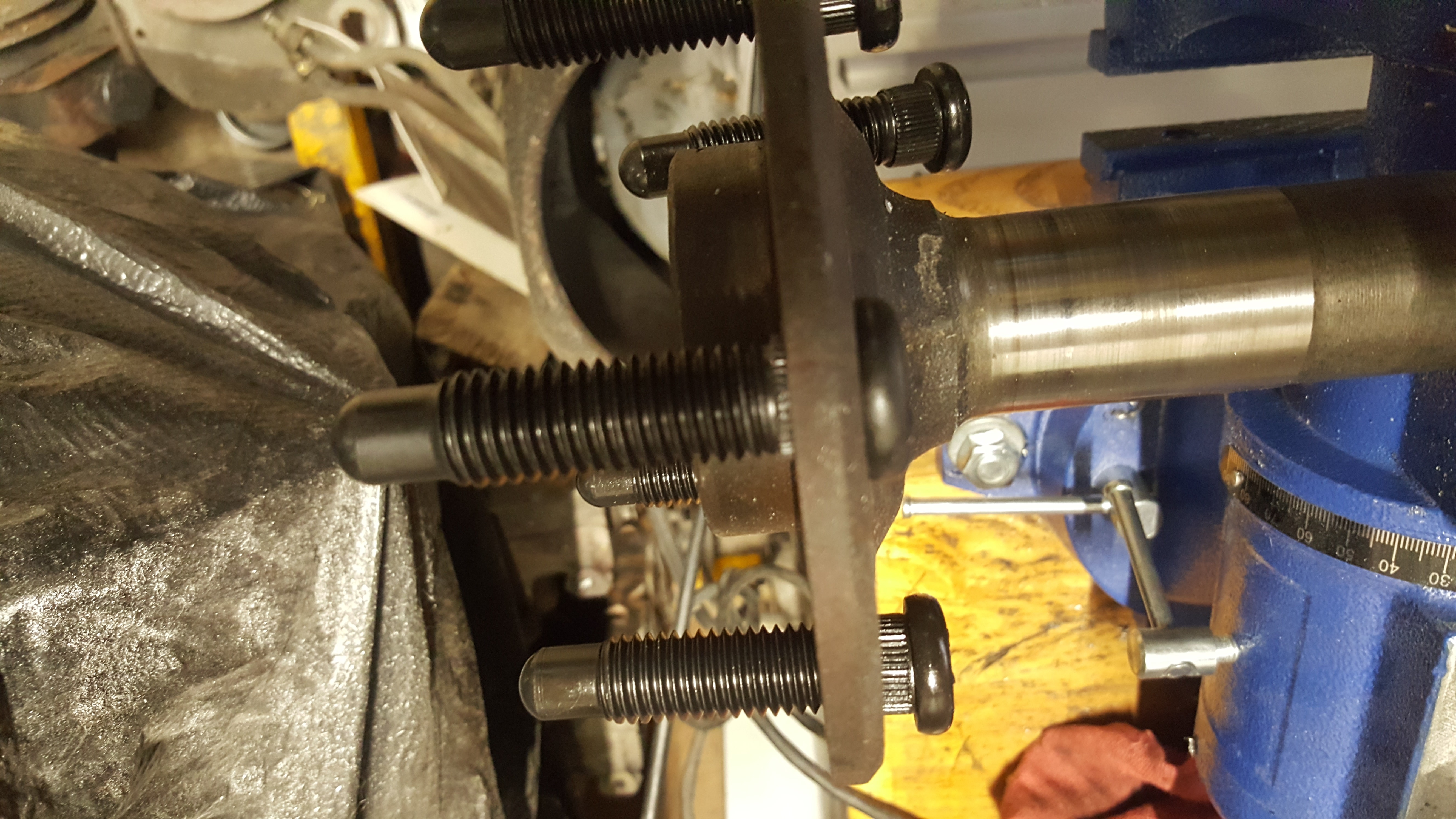

So after all the holes were drilled out and the burrs were removed it was time to start putting the studs back in. I've seen some nice tools for installing studs before that pull it through using a lug nut but i already had my ball joint press so i put that to work instead. After lining everything up they pressed right in and just that easy i have some new straight studs for the wheels to go on. Its a small step but its a big win for this project.

After:

So once all that was done (and go figure ive lost my brake pliers) i went on to the axles themselves. I got a kit from speedway motors to do the studs which included the correct size drill bit, the studs, and the lug nuts i would need. I first pressed out all the stock studs which was easy with a ball joint press and thats when i realized i had a problem. My realization was that i had no way to keep the drill straight when i drilled these holes out. A drill press would have helped however the axle itself seemed to hit on mine no matter what orientation i put it in. A google search revealed that it seems common to wing it and free hand drill them with varying levels of success. The main issue was that if i drilled the hole off angle the stud could push in at that same angle and even 1 degree at the hole could mean that my wheels would not go on to the tip of the 3 inch long studs. So i decided to make a jig for it. I know that from center to center on the holes of a 5 x 4.75 is 2.792 so i did some measuring and found an aluminum block that would work. I used a carriage bolt on one end that seated into the aluminum so that it wouldn't turn. This would be how i would clamp it down, and at the 2.792 center point i used the drill bit from speedway to drill the correct size hole through the block that would be my guide. i had to grind a notch in the side to clear the round area in the middle of the axle flange.

After the block was finished it was time to put it to use. For each hole i would use the bolt to line up through the stud hole next to the one i was drilling and using a nut and washer from the other side i could clamp it down. Then it was a simple matter of drilling it out to the correct size and moving on to the next hole.

So after all the holes were drilled out and the burrs were removed it was time to start putting the studs back in. I've seen some nice tools for installing studs before that pull it through using a lug nut but i already had my ball joint press so i put that to work instead. After lining everything up they pressed right in and just that easy i have some new straight studs for the wheels to go on. Its a small step but its a big win for this project.

Okay so busy time, the front blazer hubs are done ( no pictures of that because its a drill who cares) actually took those over to my buddies shop and he has a baby mill so i was able to drill the front hubs straight and exactly where they needed to be. So when i put the new studs in the front i decided to just put the studs in the freezer for a while and use a stack of washers, one of the lug nuts, a little grease, and my impact gun to draw the studs through the holes. Worked extremely well and only took about 5 minutes to have all the studs installed. I then moved on to finally finishing the driver side rear brakes so that i could have that off my list as well.

I got the restored gas tank installed with the restored straps and was finally able to finish up the complete pain fuel lines. Now the big moment arrived, i finally received the wheels and tires! This has been a moment i have waited on for a long time, to see a Gbody on AERO wheels. So for a teaser for whats to come i have added in a picture of those below. Let me know what you think. The tires are just a set of Mastercraft Avenger GTs and to be honest those are for a personal nostalgia touch for me because my very first Gbody was a 1979 El Camino and the tires i chose as a broke teen were Mastercraft. As soon as i get these mounted things start getting really interesting because i will finally be able to start test fitting the engine and i will roll the car outside and jack it up on its side and pressure wash the underside to finish up the cleanup. Should be a good start to the spring. Admittedly im going to have to lower the rear of the car, its sitting on jack stands right now on the axle and i can tell it will be high.

I got the restored gas tank installed with the restored straps and was finally able to finish up the complete pain fuel lines. Now the big moment arrived, i finally received the wheels and tires! This has been a moment i have waited on for a long time, to see a Gbody on AERO wheels. So for a teaser for whats to come i have added in a picture of those below. Let me know what you think. The tires are just a set of Mastercraft Avenger GTs and to be honest those are for a personal nostalgia touch for me because my very first Gbody was a 1979 El Camino and the tires i chose as a broke teen were Mastercraft. As soon as i get these mounted things start getting really interesting because i will finally be able to start test fitting the engine and i will roll the car outside and jack it up on its side and pressure wash the underside to finish up the cleanup. Should be a good start to the spring. Admittedly im going to have to lower the rear of the car, its sitting on jack stands right now on the axle and i can tell it will be high.

Sure when i sit in it and say vrrrroooooom knock knock knock knock. Will be moving on to engine install after the cleaning the under side step

I always wanted to do a NASCAR style G-bod. Those wheels are necessary to get there. Looking forward to seeing them wrapped in rubber and on the car.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 104

- Replies

- 1

- Views

- 641

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.