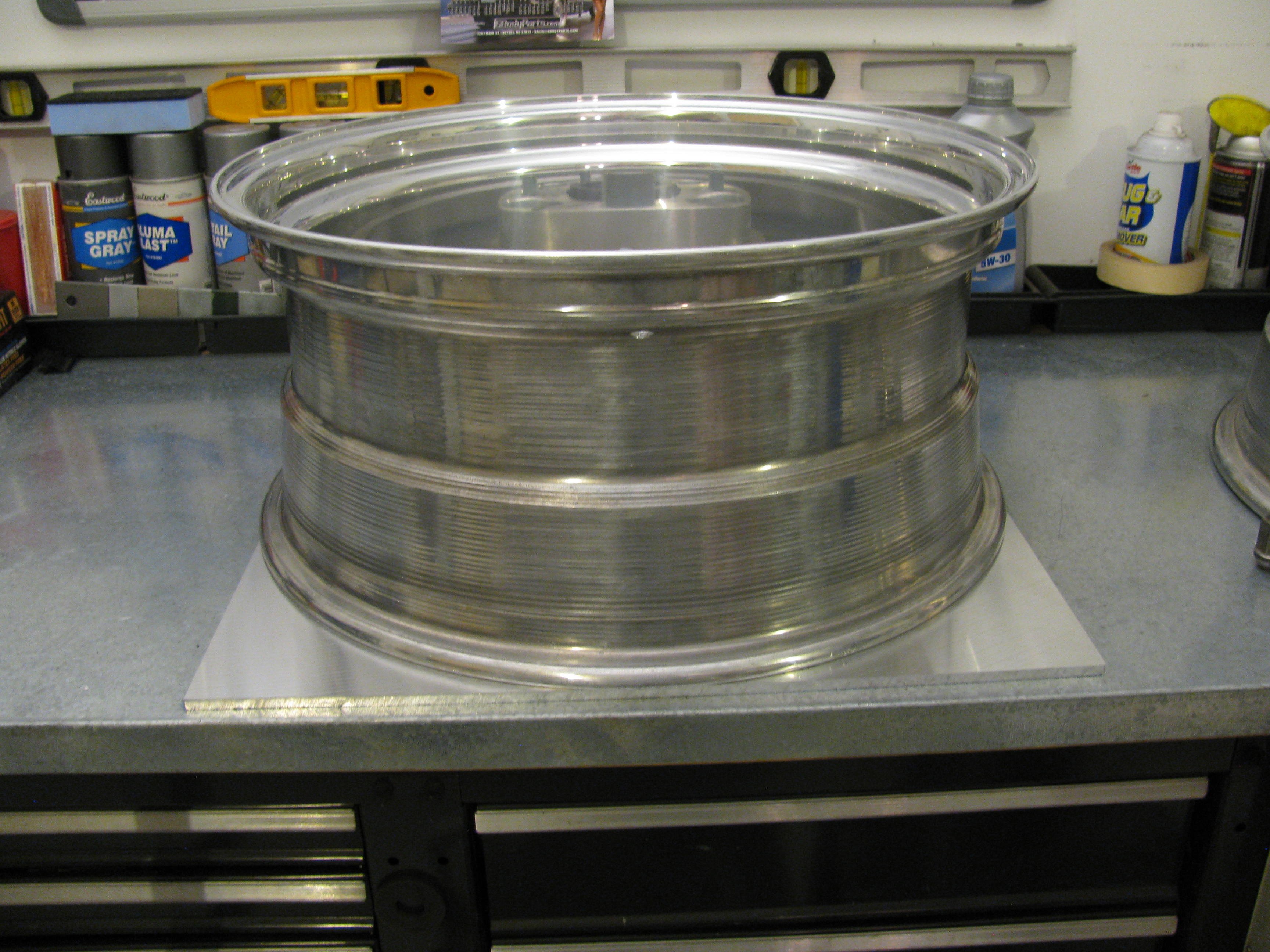

Assembling my SSIII Billet wheels. This is a little nerve racking. If I screw it up, it's a pain getting it back apart. Here I go anyway.

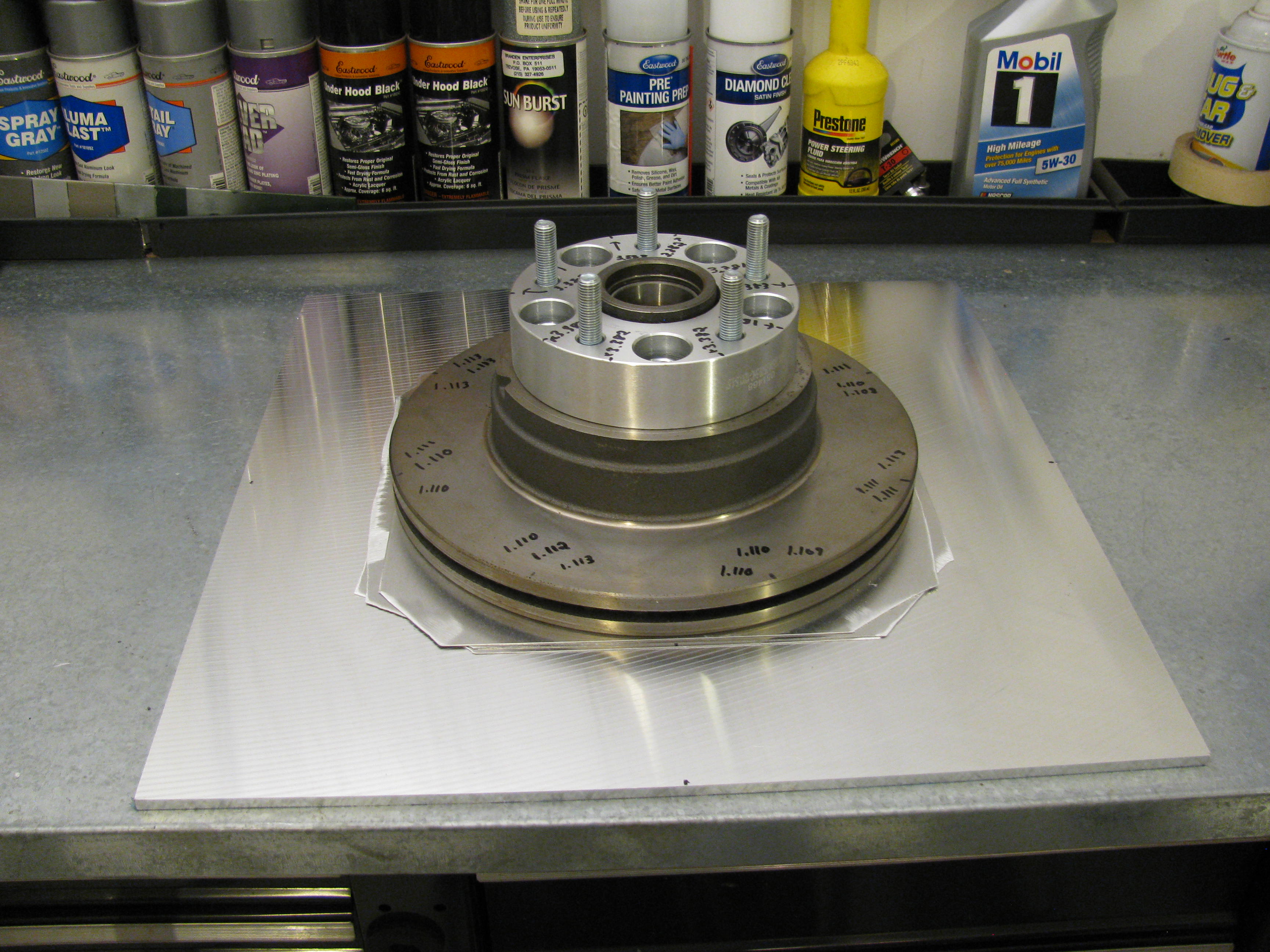

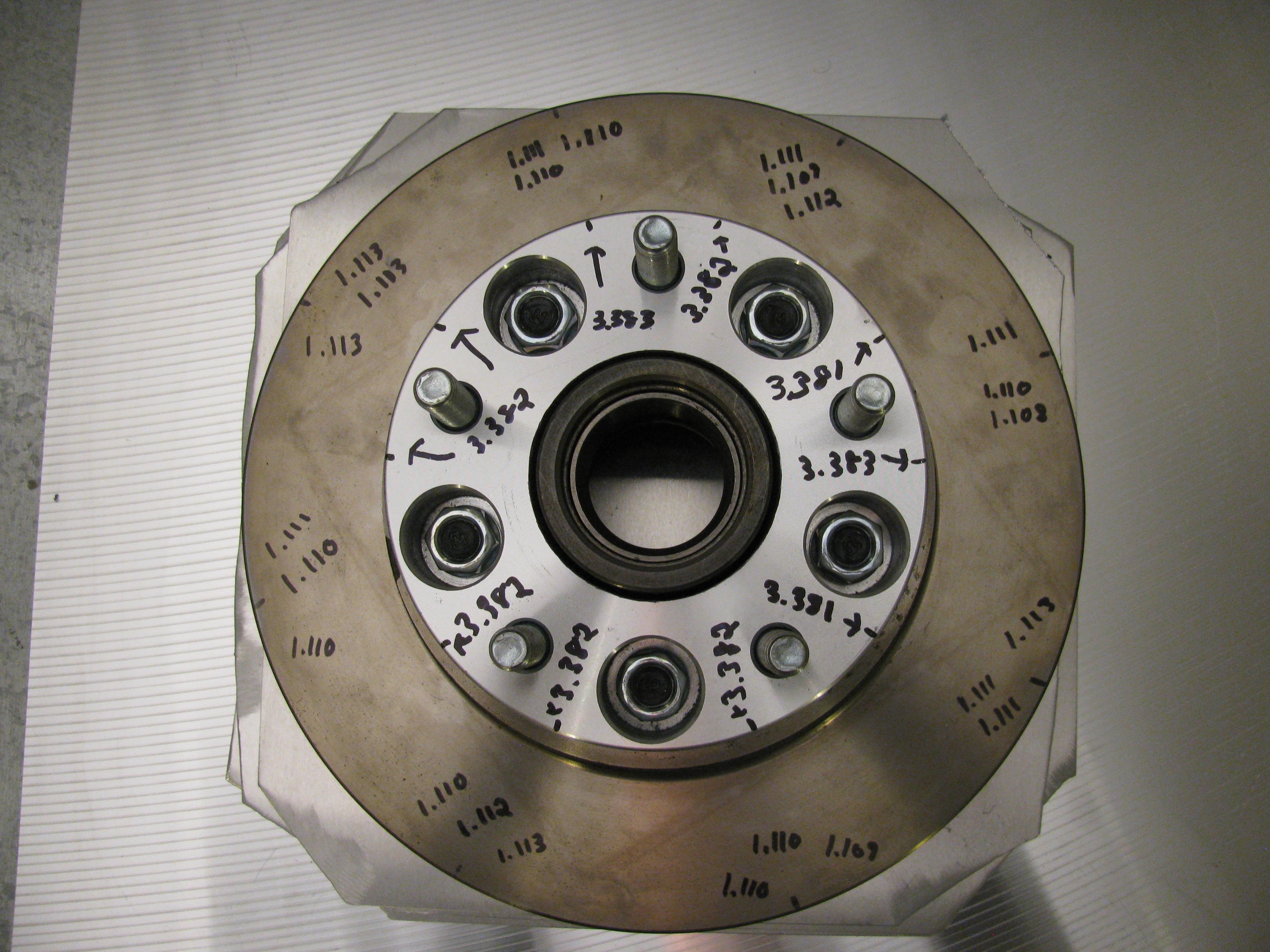

I first had to make a jig to mount my centers. It had to be at the correct backspace (4") and be acceptably level. I ended up buying an aluminum decking plate cut to my specs. They guarantee it is flat to within 0.015 of an inch. I found it to be dead flat. I next had to come up with something to hold the center in place. I used a 1LE Camaro rotor as the base, and then a bolt on wheel spacer to get the exact height I needed.

I made multiple height checks all the way around the fixture. I had about a 0.004 variance. My understanding from people in the field is that an acceptable runout can be as high as 0.035. I think I'm good.

Next thing to do is put the center in the freezer for 3 hours or so. At the 2 hour mark, I put the hoop in the oven set at 400 degrees. At the three hour mark I pull the center and bolt it to the fixture.

Then I run and use the oven mitts to carry the hoop out and lower it on to the center.

Obviously this is a pic demo, as I have to be quick installing the the two together. Once I have the hoop valve stem hole lined up where I want it, I go take a beverage break (for a few hours) When I come back, the center has warmed up and the hoop has cooled down. They are now press fit together and ready for TIG welding.

That's all for now. I've been gathering parts for the 442 to get going on some more progress (TH400 Trans, Pistons, Rods, etc). More to come.

Hutch