Ha I forgot this. I had a small tool pouch that I brought to take the seat out and apart to get the track. I finished, payed, and went home. It wasn't until three days later that I unpacked my tool bag to put them back in my tool box. That is when I found my 13mm socket and a 3/8 drive ratchet wasn't in there.

By this point the yard was closed for the weekend. On Monday morning I went back and the ratchet was right where I left it...on the floor of the 86 I left it in. Glad there isn't a lot of traffic to that car. They didn't even charge me a storage fee 😉

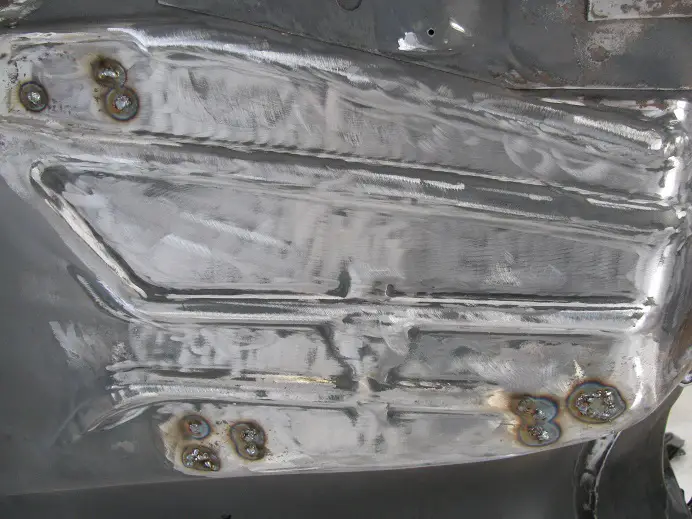

Got some welding done. More later

Hutch

By this point the yard was closed for the weekend. On Monday morning I went back and the ratchet was right where I left it...on the floor of the 86 I left it in. Glad there isn't a lot of traffic to that car. They didn't even charge me a storage fee 😉

Got some welding done. More later

Hutch