I understand completely, my bad, I reworded my previous post lol, to clarify what I meant by “threw me off” as in seeing the sensor in the trans and assuming it was the way it’s supposed to be since it had a 2wd tail shaft housing, not in regards to what you said about checking the sensors, you are more than helpful and I appreciate the input completely, sorry for the misunderstandingI don’t think I was clear. Both sensors and sensor connectors are the same, one is towards the front of the trans and the VSS is towards the rear. I’m curious if the FiTech datalogs input shaft speed?

Holley does and it’s extremely handy for determining converter slip %. The input shaft speed divided by rpm is converter slip %. It makes it simple to see where the converter is grabbing and where it isn’t.

the fitech only uses the VSS plug at the rear, it was just a one off issue with the trans I purchased, it had to have been 4wd and had the vss in the transfer case and they switched the tail housing and left the rear vss sensor with the dummy plug, or it was always in a 2wd vehicle, and some one at some point switched the sensor and dummy plug locations. 🤷🏻♂️ story of my life is finding and fixing things people messed with lol

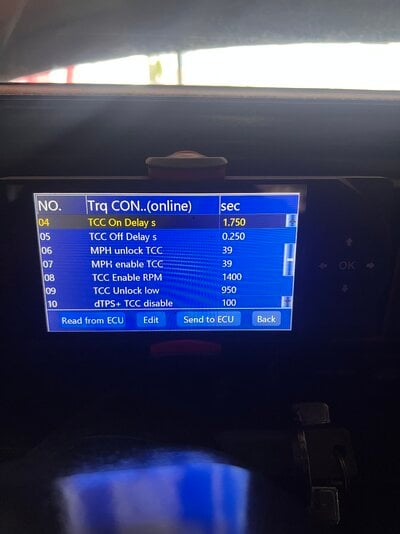

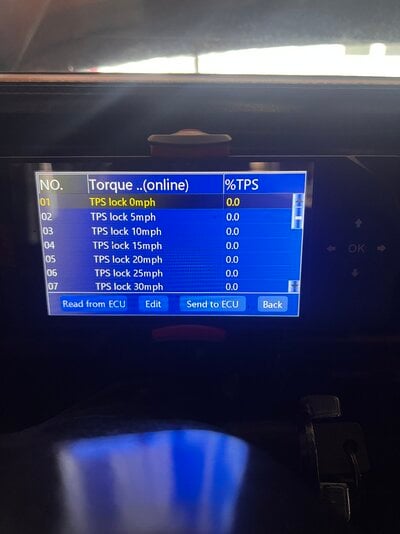

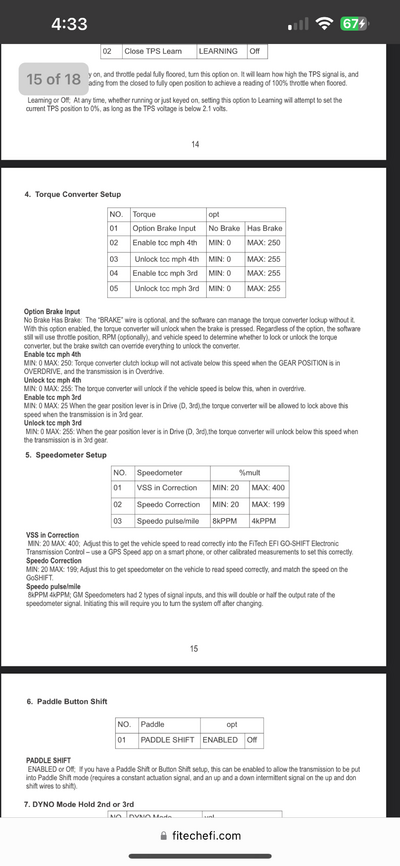

This is the only settings it gives me regarding torque converter specifically

Attachments

Last edited: