I got the passenger side A arm installed last night and am working through the last bits of my alignment so not much to report there. Its that whole turn something, make a measurement, do trig, and repeat. Kinda brain draining so I'm doing a bit each night so I don't gouge me eyes out from all the math I am doing at 10pm.

The good news, and one of the main reason I went with these arms is to gain header clearance. They work!

🙂 I actually had the stock arm cut to clear the arm so they have a lot of clearance now.

And what in the flying spaghetti god is going on here?

As you may have known if you keep up, I did the flex fuel conversion on the car this spring and have been unable to read ethanol content in the computer It went to default which was 37% flex. I was always getting a low frequency error with a p0178 if recall. I had to go real deep and damn near shipped the car to a pro tuner but I stuck at it and I think I solved it.

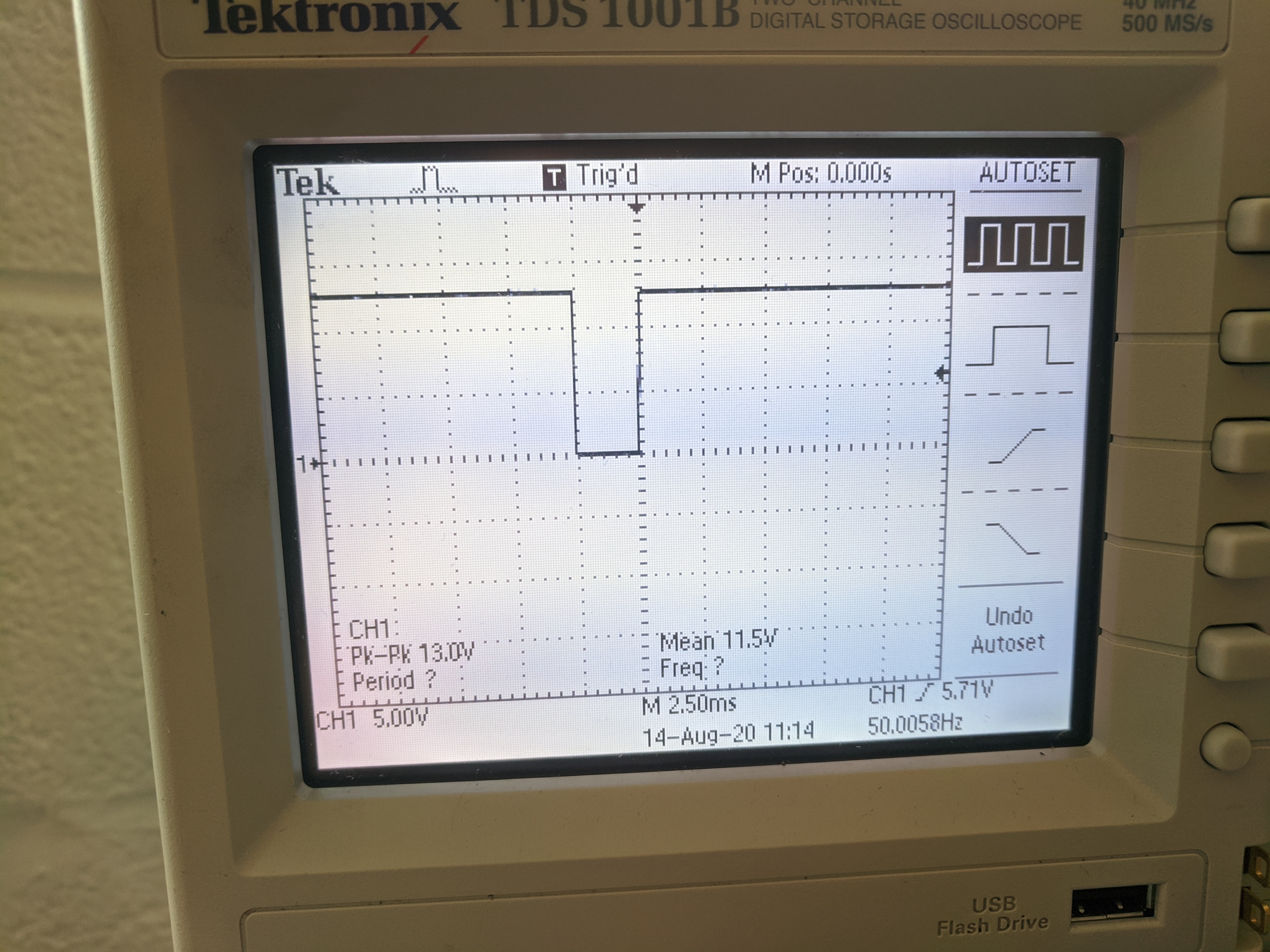

1st I thought i had a bad sensor since I wasn't able to read a 50-150hz signal at the pcm with a borrowed multimeter. My electrical engineer buddy said frequency is tough to measure with a miltimeter and you need an osciliscope really.

2nd I looked at the tune REALLY good and still didnt find anything, the PCM was a factory flex PCM so it shouldnt have an issue

Side tangent I got stuck into was the PCM sometimes wont poll the sensor but I found that is probably BS and a tangent I shouldnt have got down.

3rd I emailed a few people and got the same response, check ground! check power! check continutity! I did all of those things 20 times and no solution

4th I gave up and bought a new flex sensor, installed and no fix

5th I dug REAL deep and found you need a 2k pullup resistor between the signal wire and the voltage supply in order to measure with a DMM or scope

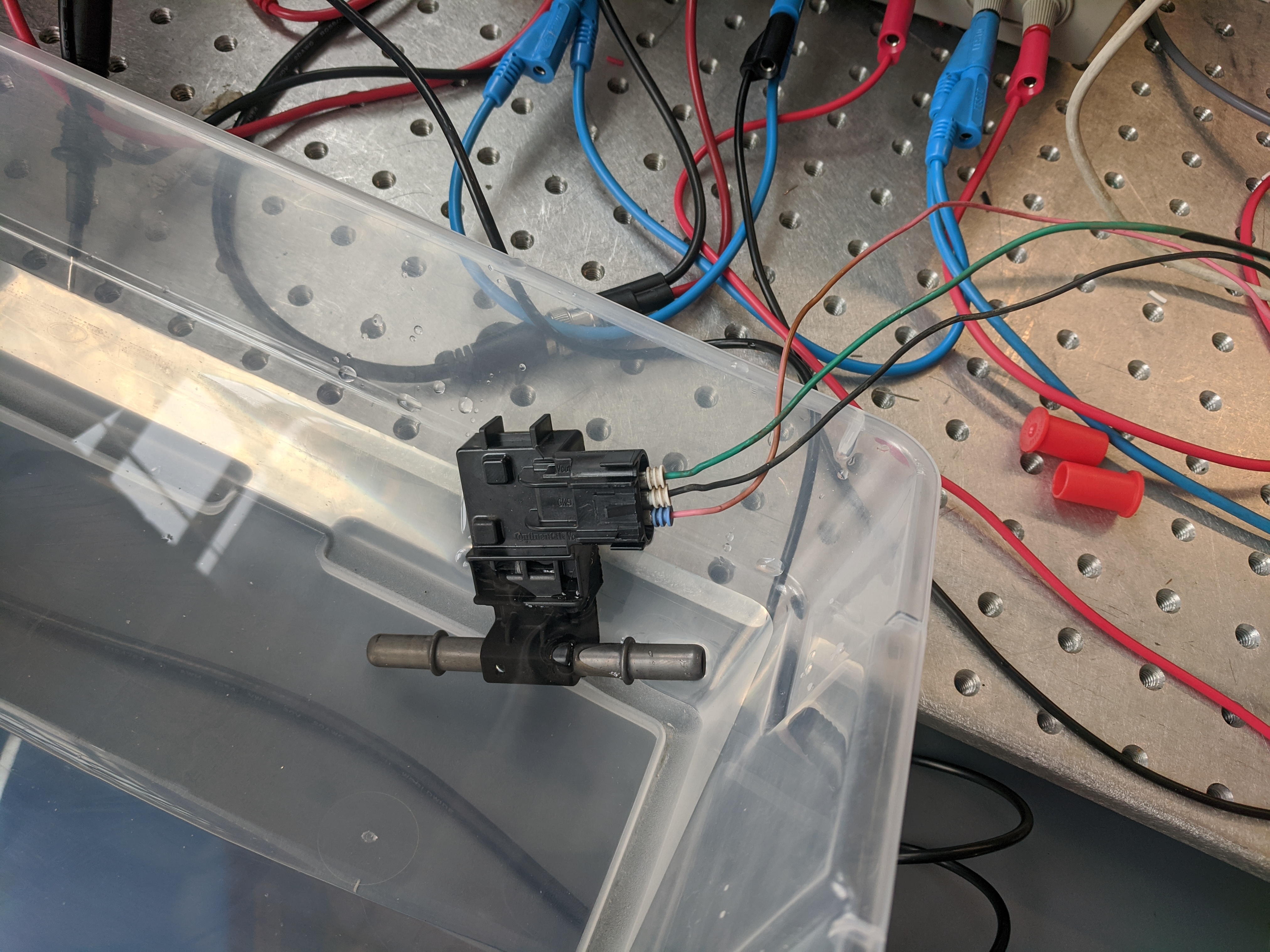

6th I brought my old sensor to work (my university lab) and used the oscilloscope and a resistor and a cup of water to check frequency, finally a breakthrough, the old sensor was always OK, I was able to read frequency

7th I tried reading frequency on the car with the multimeter using the 2k ohm resistor to 12V under the hood where it plugs into the PCM, no go, really noisy 5khz signal and nothing useful

8th I tested the spare old sensor with the multimeter, it worked. OK, either the sensor on the car is bad or the wiring is bad somehow

9th I put the pullup resistor in the signal wire running to the PCM to 12V under the engine bay and removed the wiring harness to the sensor under the car and stripped the insulation on the soldered joint where I spliced the GM flex plug into the old rear 02 sensor wiring that I repurposed for power, ground and signal. I was measuring signal 2" from the sensor and still nothing.

10th I cut the damn signal wire and moved the pullup resistor directly between the spliced power wire and the signal wire 2" from the sensor. FINALLY I got signal. It turns out SOMETHING in the old rear 02 sensor wire i repurposed was causing the signal to get all jumbled up. It always had continuity but might be a resistance wire, has a slight short in the insulation or something

11th I reran a new wire from the flex sensor on the passenger side to the cut off factory flex signal wire on the drivers side of the harness by the trans (since this harness was always a factory flex harness and I never knew). I then moved the pullup resistor back under the hood and measured on the signal wire pin going to the PCM. It works, good.

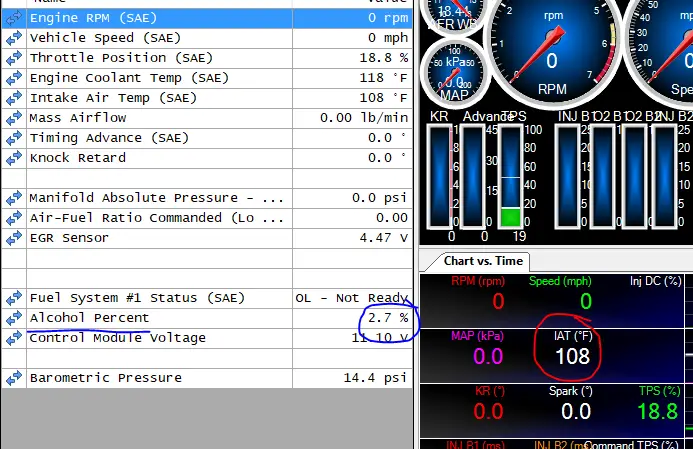

12th I plugged in the signal wire to the PCM and connected my HPtuners, no signal. SOB

13th I remembered I had the non flex PCM installed so I quick swapped the PCM to the 02 flex tahoe PCM

14th I reconnected HP tuners and TADA

2.7% flex, eff yeah.

I'll fully admit, this took 6 months to figure out and took a good amount of my troubleshooting brain power. Each step was probably a few hours of reading matched with a few hours of hardware troubleshooting. I'm guessing I have 70 hours in solving this problem. Not kidding. All because I saved my self 5 minutes 6 months ago and reused the rear 02 signal wire.

I still have to pull a new wire and solder it in place but that's a task for another day.

Ohh, BTW, that 108F intake air temp is maybe a bit elevated since I idled the car for 20 seconds, but its not far off. It was 95 today with all the humidity or some BS and that's too hot for me. If the high temp never gets above 0F for me, it's cold. If the temp never gets below 75F all day, it's hot in my books. I can tell you for the past 4 days it's been hot.