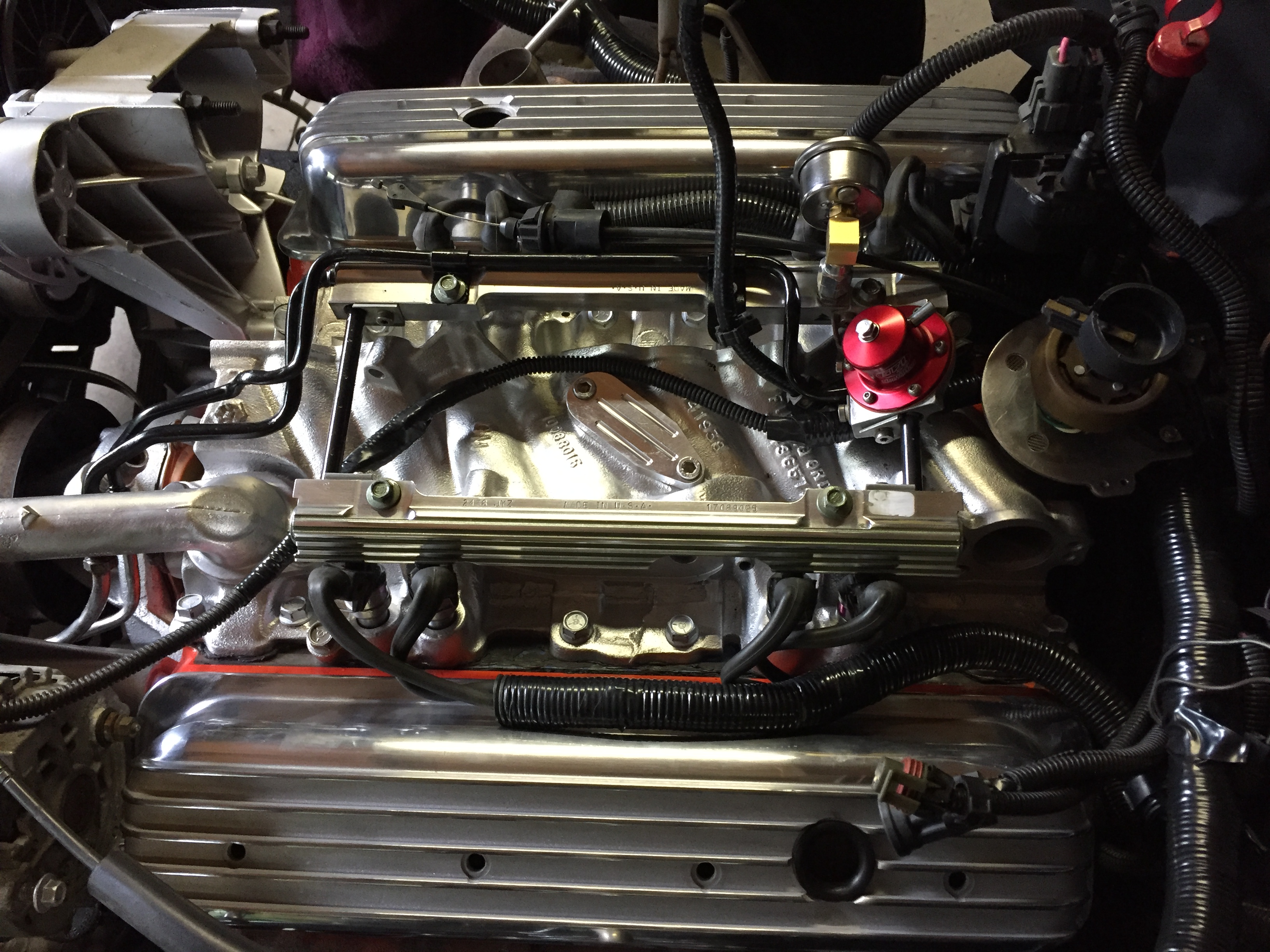

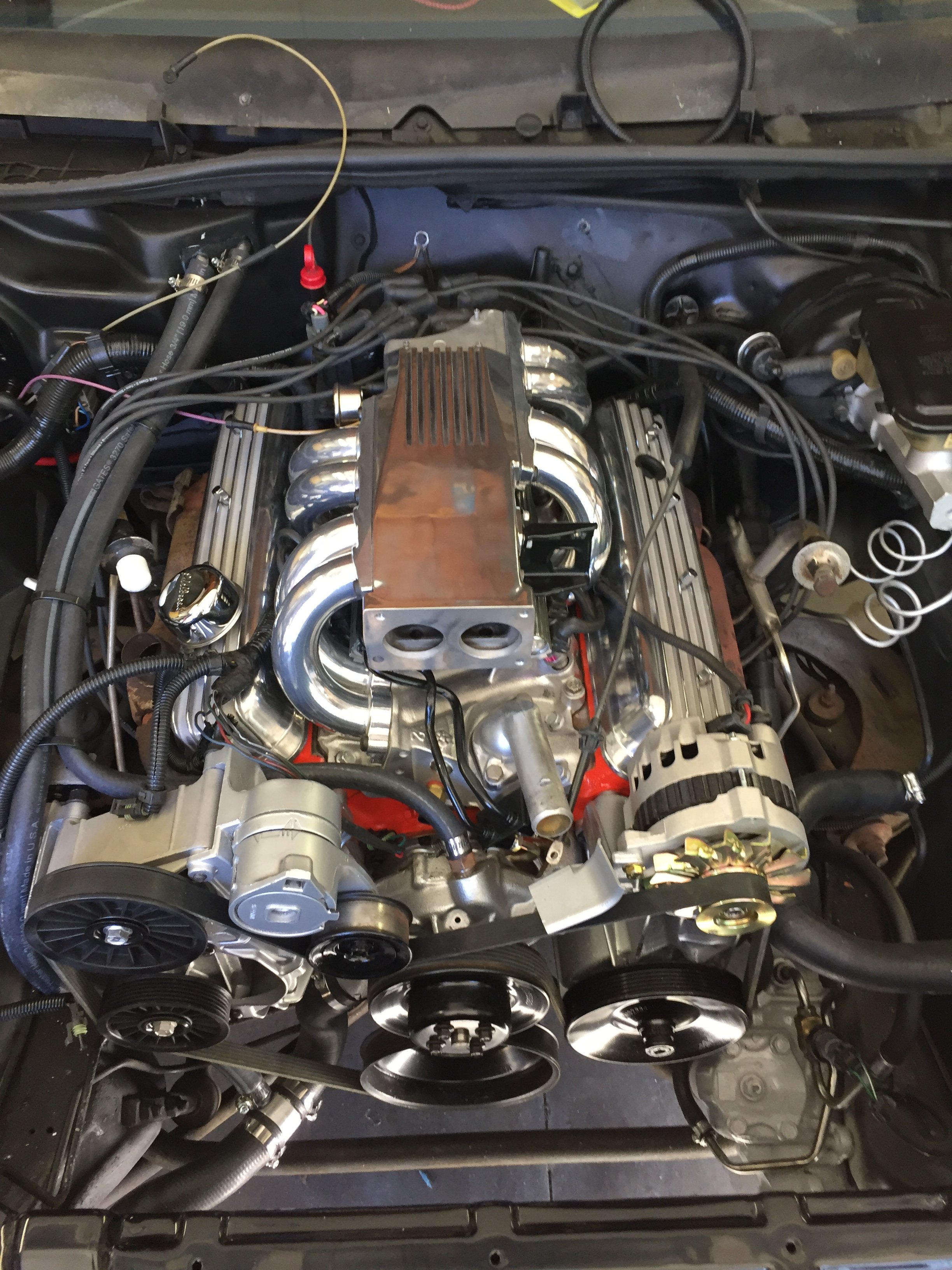

Intake Assembly: When looking for a used intake assembly, you will find that it is easier to find an older 85-89 MAF intake than it is to find one of the 90-92 MAP intakes. In addition, the later intakes usually cost more. You do not necessarily have to buy a 90-92 intake if you want to run a MAP system, and you don't necessarily need to buy an 85-89 intake if you want to run a MAF system. Actually, you can run any ECM and harness on any intake with little work.

Keep in mind that you need an intake that will bolt to your cylinder heads. The bolt pattern changed in 87, so if you have 86 or earlier heads, you need an 85 or 86 manifold base. The four center bolt holes are angled differently on the 87-92 intakes. A stock TPI intake with not work with Vortec, or LT1 heads. However, you can run TPI on Vortec heads if you use an aftermarket intake manifold from Scoggin Dickey.

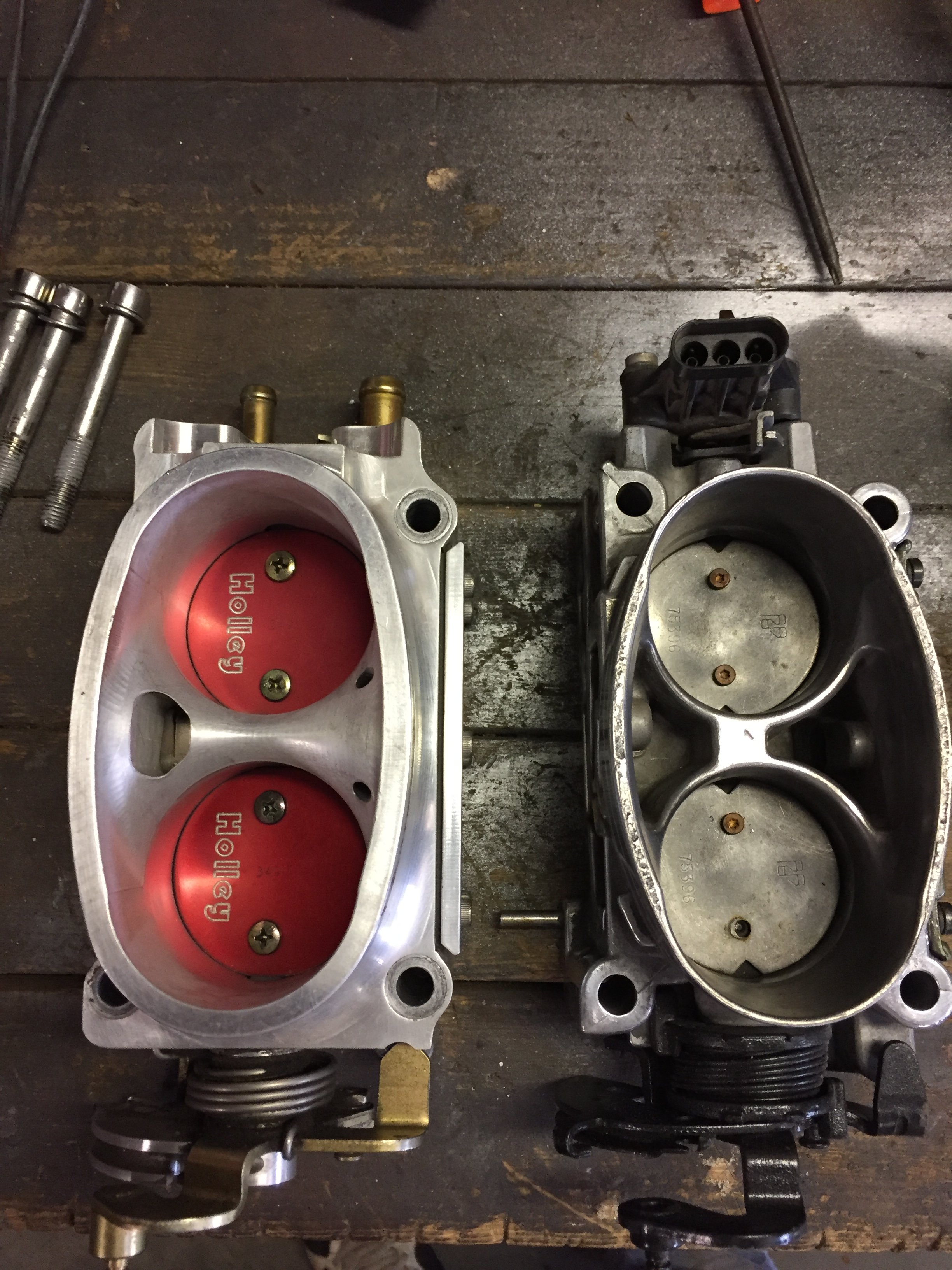

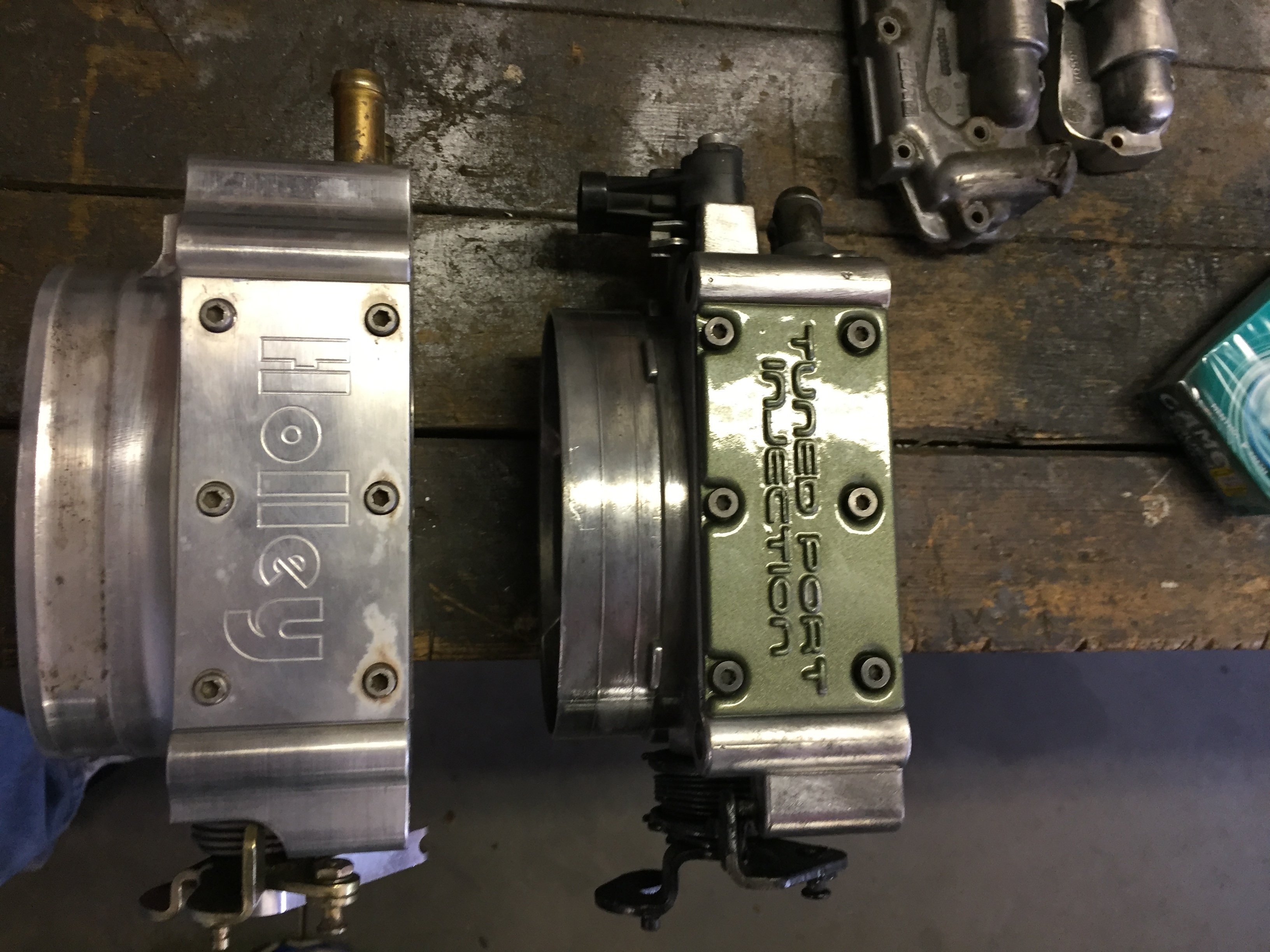

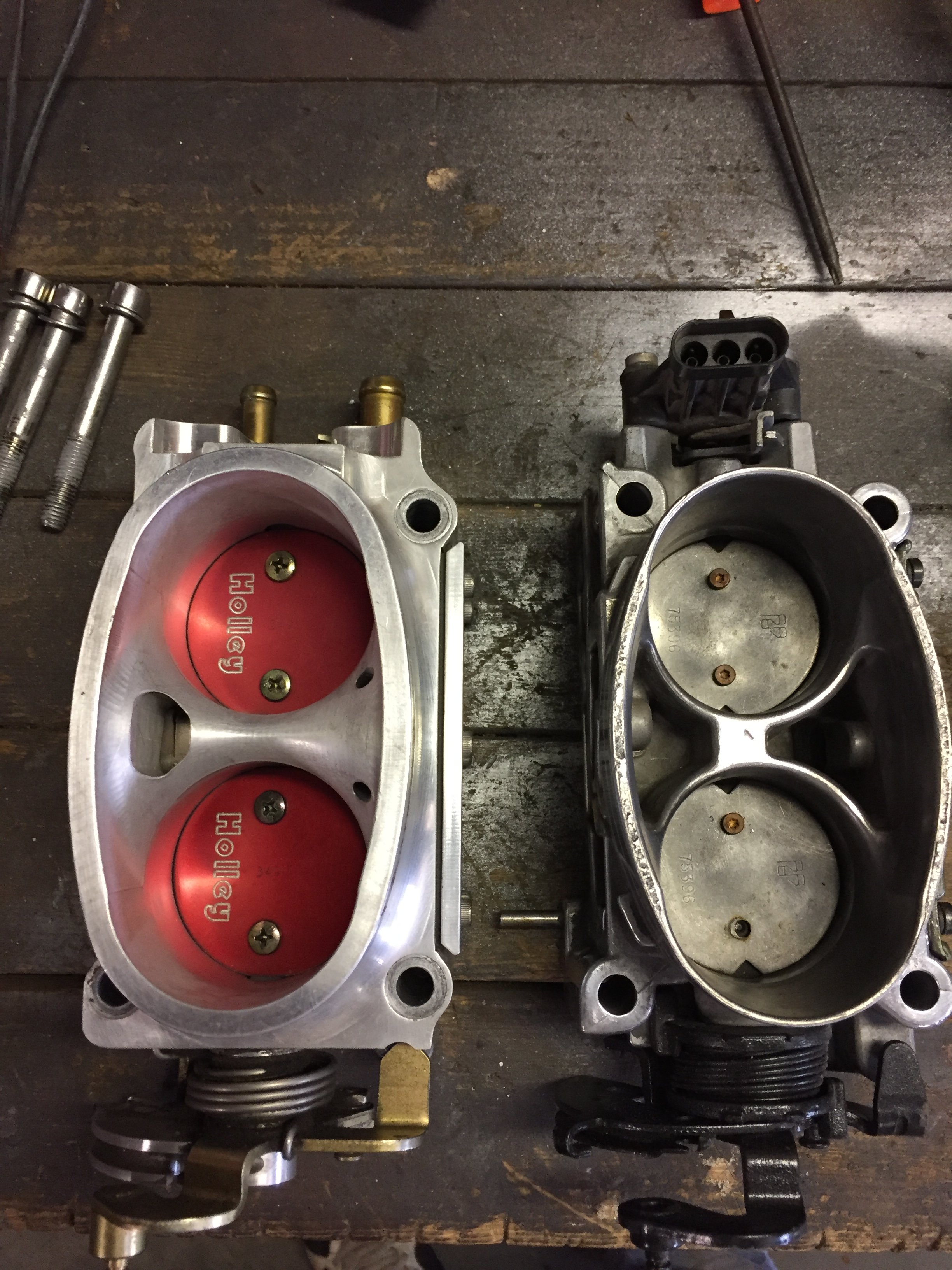

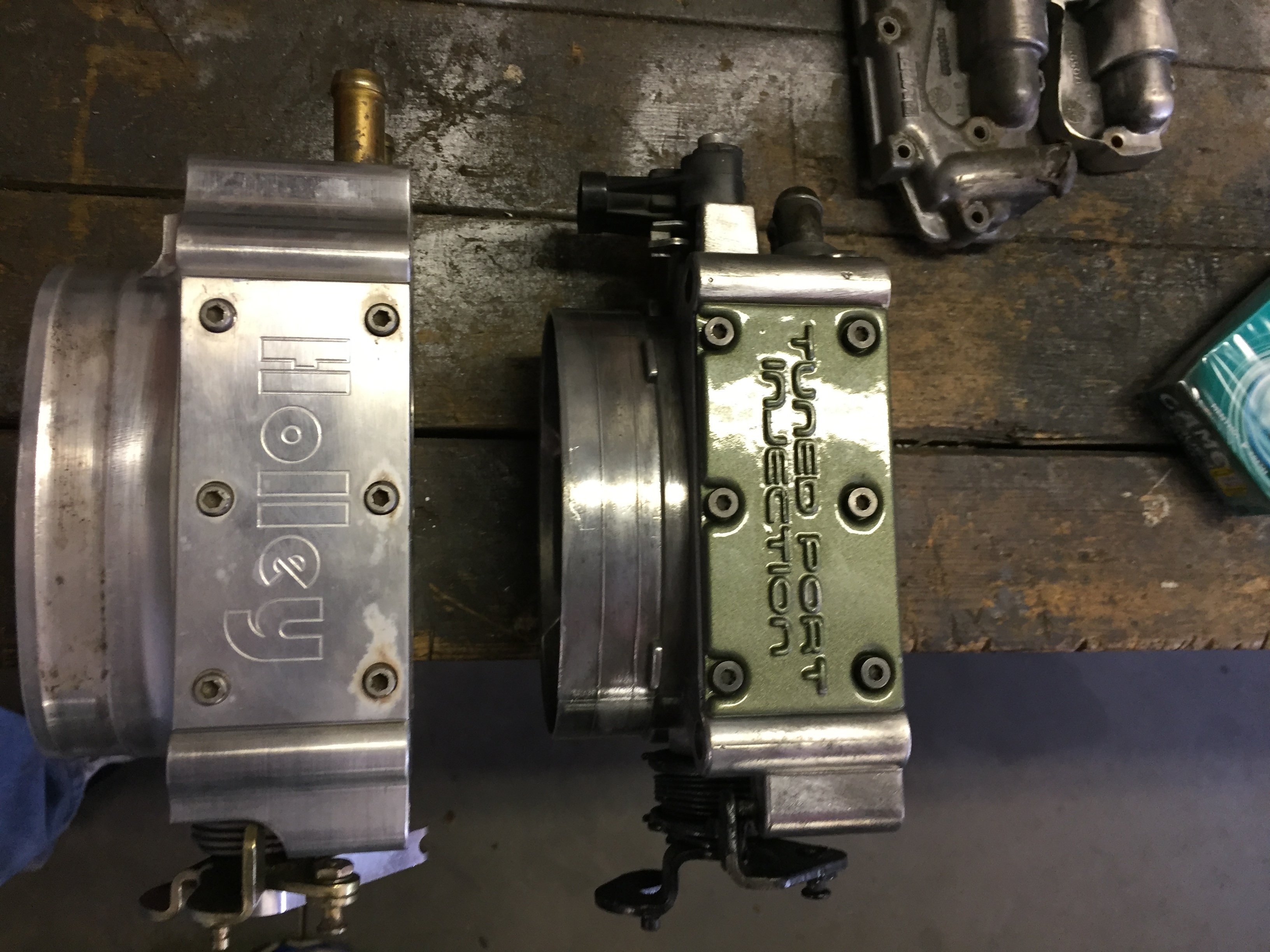

When you purchase an intake, it will usually include the manifold base, a pair of runners, plenum, fuel rails, and throttle body. Most of the time, some of the bolts are missing, and some of the brackets may be missing as well. Make sure that you have a throttle bracket on the driver side of the plenum, as this is where the accelerator cable mounts. Also, the thermostat housing is an item that is often missing, so make sure you have one before beginning your install. Your intake may or may not include sensors, but if they are included, they should be tested to make sure they are functional

Injectors: If you will be using a stock PROM, then you must stay with the stock sized injectors for your engine size. All 305 TPI engines used 19 lb injectors, and all 350 TPI engines used 22 lb injectors. The Corvettes did not have larger injectors, as people often believe.

Alot of people suggest running 305 injectors on a 350 by raising the fuel pressure (this requires an adjustable regulator). This can be done, but barely anyone does it properly. In order for 19 lb injectors to behave like 22 lb injectors, your fuel pressure must be raised from 43.5 psi (stock setting) to about 56 psi. This will put extra stress on your fuel pump. A much easier way to go about running a different injector size is to have the injector size changed inside the PROM. We offer this service for a very low rate, contact us for details.

ECM and PROM: Once you decide what type of TPI system you would like to run (MAF or MAP), you can read through our ECM and PROM article for more information on the differences between each. You can find the article here:

http://tpiparts.net/ecms_and_proms/

Wiring Harness: The harness you decide to use will depend on what type of TPI you decide to use, and what ECM you choose. For example, if you have decided to run a 90-92 system (MAP), you can use a 1227730 ECM (mounts in the passenger compartment) or a 1227727 ECM (mounts in the engine compartment). Each computer will use a different harness, as the ECM connectors are different, and the harness dimensions change as well. Obviously, the earlier MAF computers will use a different harness as well. The 85 TPI harnesses will work only with the 1226870 ECM, and the 86-89 TPI harnesses will work only with the 1227165 ECM.

Sensors: The sensors needed for a MAF intake are very similar to those needed for a MAP intake. There are few differences. The most obvious difference is the lack of mass air flow (MAF) sensor in the 90-92 setups. Instead, a manifold absolute pressure (MAP) sensor is used to measure engine load (basically, engine vacuum). Likewise, the 85-89 setups do not use a MAP sensor. These used a mass air flow sensor to calculate air being drawn into the engine.

The second difference between the two pertains to the knock sensors. The 85-89 TPI setups used two different knock sensors (one for 305s, the other for 350 engines) from the 90-92 setups, which also had two different knock sensors (one for 305s, the other for 350 engines). They physically look the same, but will not interchange. In other words, an 85-89 TPI knock sensor is different from a 90-92 TPI knock sensor. Same goes for the 350 knock sensor.

The throttle position sensor (TPS) used on 85-89 TPI setups has elongated slots for the mounting bolts. This allows for the sensor to be adjusted to proper voltage (.54 volts). The 90-92 TPI setups did not have an adjustable throttle position sensor. On these setups, TPS voltage is not as critical. However, an adjustable TPS may be used on the 90-92 setups if so desired.

The ECM for 90-92 TPI setups are designed to run on a 4000 pulse per mile vehicle speed sensor (VSS). On the other hand, the 85-89 TPI ECMs are expecting a 2000 pulse per mile signal. Many of the early TPI vehicles with a cable driven speedometer, had the VSS mounted behind the speedometer. The later MAF setups with an electric speedometer had a VSS buffer box mounted behind the dash. The VSS signal runs to the buffer, and the ECM grabs the VSS signal from the buffer box. The buffer box is also responsible for controlling cruise control and the speedometer. The later 90-92 models had the VSS mounted on the transmission, and ran directly to the the ECM. In this case, the ECM handles the signals which run to the speedometer, and cruise control.

Cables: Regardless of what type of TPI intake you choose, you will require an accelerator cable. This will attach to the driver side of the throttle body. The type of cable you need will depend on your throttle body. The 85-88 throttle bodies used a stud to attach to the (14080202) cable. The 89-92 throttle bodies have a swing arm, the cable (10163822) for these wraps around the swignarm, and then locks in place with a small bar at the tip of the cable.

If you will be using a 700R4 or 2004R transmission, then you will also need a TV cable which attaches to the throttle body on one end, and to the transmission on the other. This is responsible for controlling your shift points. 85-88 GM # 25521263 & 89-92 GM #10163879

Fuel Pump: You will need a fuel pump capable of providing 45 psi of fuel pressure. This can either be an in-tank pump, or an external pump. For stock or mild engines, a stock replacement fuel pump is adequate. If you have a moderate or large cam and aftermarket heads, you should consider a pump that can supply a higher volume of fuel. Note that this does not mean higher pressure (psi).

Gaskets and O-rings: At the very least, you will need a gasket kit to install your intake. This includes manifold to head gaskets, runner to manifold gaskets, runner to plenum gaskets, throttle body to plenum gasket, and distributor gasket. It is not necessary, but it would be a good idea to replace the fuel injector o-rings while you have the unit apart. You will find that the new o-rings will slide into the manifold and into the fuel rail much more easily if you coat them with petroleum jelly. Although it is not necessary to disassemble the fuel rail, you may wish to replace all the fuel rail o-rings as well.

Bolts: Most used intakes will include hardware. However, there are usually bolts with stripped heads, or bolts that are missing. All TPI intakes came from the factory with Torx bolts. These can be a little annoying to work with. They have a star shaped indentation in the center of the bolt, and often round off. Although this is a minor item in the list of needed parts, its often overlooked until the end of the project. Allen head bolts are fairly popular among Tuned Port enthusiasts because they are readily available, and easy to work with.

Relays: As you can imagine, you will need relays to get your car running. The exact relays you need will depend on your harness. If you are using a MAF harness you will need a fuel pump relay, MAF power relay, MAF burnoff relay (86-89 MAF only, 85 doesn't use one), and possibly a cooling fan relay (only if you are running electric fans). If you are using a Speed Density harness, you will need a fuel pump relay, and possibly a cooling fan relay (only if you are running electric fans).