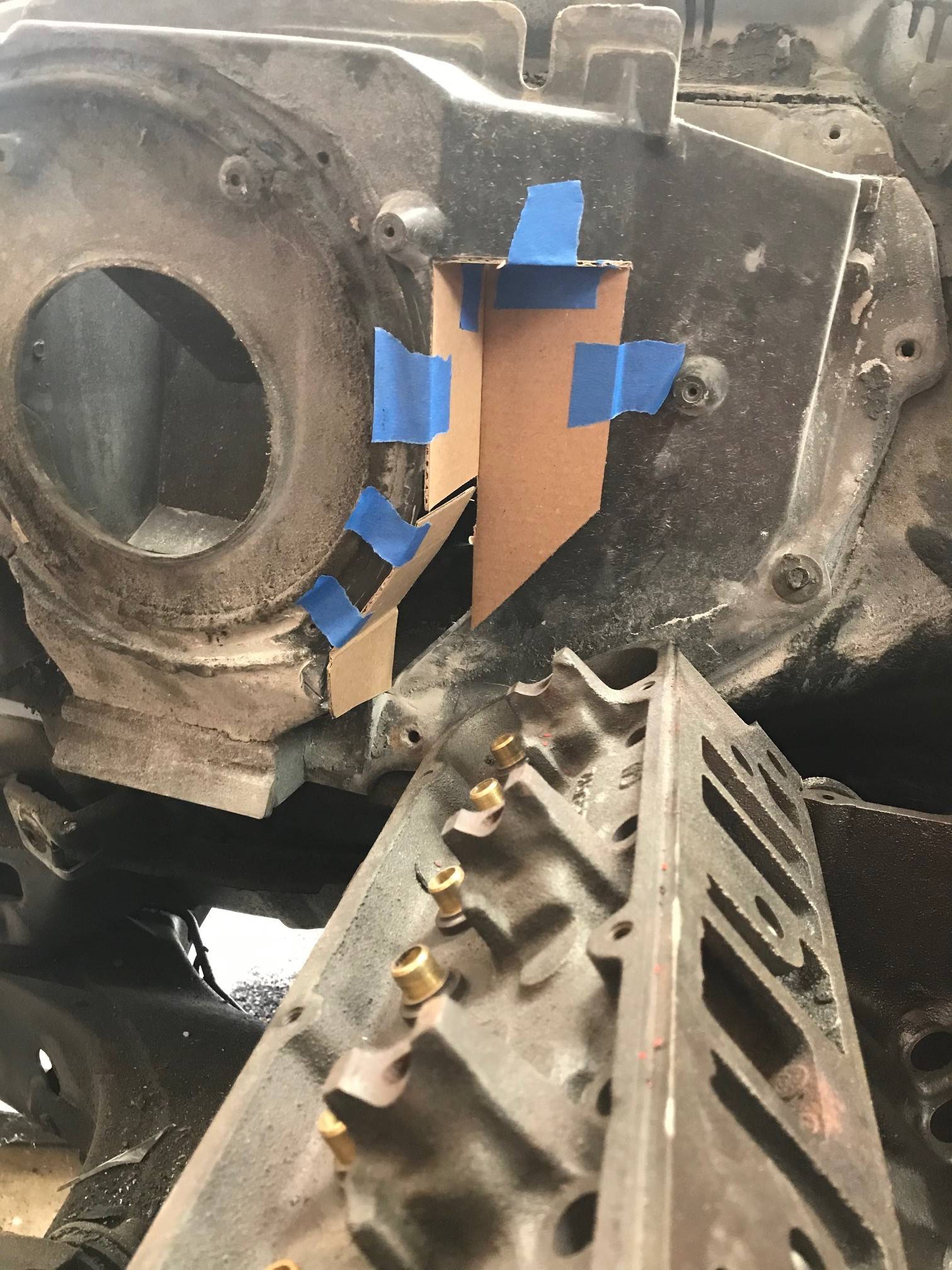

If you have not cut the shift hole yet, might I suggest that you cut conservatively small, then bolt the eng/trans in again to be sure of the correct location, then open up larger from there.Mar. 11, 2021: Well, it's been quite some time since my last post. And while I'd love to show some massive amount of glorious progress, I don't have a whole lot to show. But over the last 2 months I have been able to make a few more little steps that get me closer to being ready to lift the body and finally start refurbishing the frame. I purchased all new steering componets, all new front & rear suspension parts, and new motor & trans mounts from RockAuto. I also scored a deal on a Saginaw 4 speed trans, so I was able to get the engine/bellhousing/trans mocked up in the car. I got some cuts made in the HVAC box so it clears the passenger side valve cover, and I was also able to lay out exactly where the shifter hump needs to be mounted.

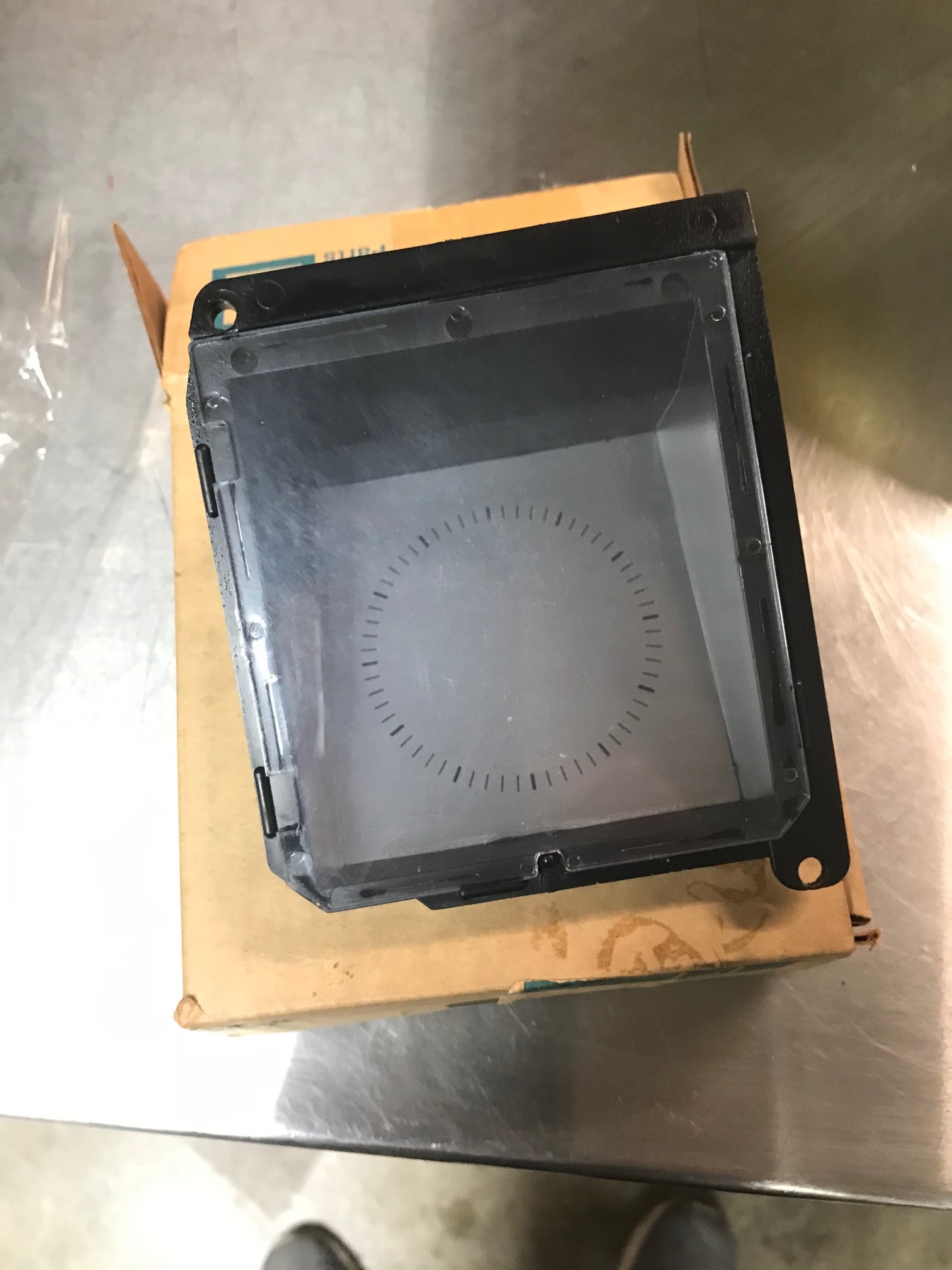

Yesterday I received quite possibly my favorite part ever. It's just a gas gauge, but it's a MANUAL TRANS gas gauge (i.e. no P RND21 at the bottom), and it's NOS! I knew they had existed, but I've never come across one before, and having it makes me super excited about my goal of making this car look, taste, & smell like an orginal manual trans car.

Saginaw 4 speed.

View attachment 170174

Engine/Bellhousing/Trans ready to be mocked up.

View attachment 170167

Engine/Bellhousing/Trans bolted in (for now)

View attachment 170168

HVAC box modifications so far.

View attachment 170169

View attachment 170170

View attachment 170171

Layout for shifter hump placement.

View attachment 170172

NOS manual trans gas gauge.

View attachment 170173

My '78 Caballero is a factory stick shift model. The "cut" through the hump looks like it was done with a torch, and then the bulbous part welded over. I see your layout lines are nice and sharp. It will look good and give plenty of working room when finished.