So here is my logic why Holley's "we put the engine where it belongs and perfected the driveline angles" logic doesn't deliver the benefit for the increased cost.

CTS-V oil pan is 1.83" deep (lets round up and say 2"), holley is 1.25".

An LS with th400 is roughly 42" from center of mount pads to trans tailshaft.

If both the spohn mounts and holley mounts are optimized (for arguments sake they are) you get .75" lower front engine (being generous) with a holley vs. CTS-V pan.

arctan(.75/42)=1°.

The holley kit gets you 1 degree.

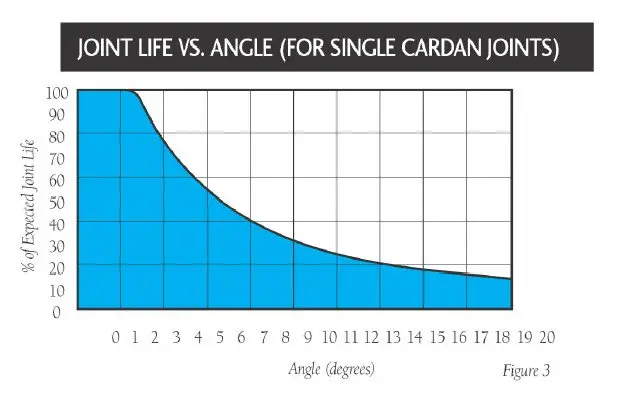

Say stock is 1.5 degrees, now you are at 2.5 degrees. You lost maybe 10-20% U joint life.

Spicer themselves say 60-100k warrantied life on u joints.

https://www.dennysdriveshaft.com/c1...3.219_x_3.219_1.062_1.125_outside_snap_r.html

15% loss of life over 80k miles means they will "on average" loose 12k mile life of warrantied life. I doubt I will ever put 50k miles on my LS swap car, and likely build a driveshaft with 1350 u joints or replace them from progressive mods over the life of ownership so although optomizing u joint life in an OEM application makes sense where you design stuff to make reliability goals, that 1 degree matters, but in a hotrod application that 15% extra u joint life isn't worth it.

Worst case you loose 20% u joint life, best case (if I use .58" lowered like the pans are) you get a 0.8° angle improvement which is a 8-10% (depending how you look at the graph) maybe 8% u joint life improvement.

Basically, if you lift a pickup/suv 2" in the back and keep the engine stock you are increasing your driveline angle the same amount that the using a "wrong" driveline angle in the G body swap situation.

TLDR- driveline angles matter but there isn't enough improvement to make it pay (for the cost in my view) that you will ever notice less failed driveline parts. Maybe a slight vibration if you hit a resonance, but your poly bushings, loud exhaust, and big cam is going to so over power that you will never see it.

People raise and lower their car 1-3" and nobody cares about driveline angles, caring about 1 degree in the trans is worth it in OEM applications but by modding your car you submit to lowering design life of factory components for performance or looks.

View attachment 113449

https://www.pirate4x4.com/tech/billavista/PR-shaft/index2.html