US Mags would not fund me having their wheels polished locally nor would they pay for the return shipping to do it right. That's beyond a dick punch. But, I had my local guy look at them and he suggested the Meguiars Brilliant Solutions Metal Polishing Kit would go a long way to removing the scratches these wheels have. So, I will give it a try. And, if they need more TLC, I've done enough business with them that they said $30/wheel max would cover it.

Given the 1/2 *ss polish job, I got concerned about the over all construction quality so I went ahead and had the wheels spun today for true-ness, and then had them put the Bridgestone RE760s on. Worst wheel required only 4 1/2 oz., [2] wheels were just less and just more than 2 oz., and [1] wheel just required a 1/2 oz. That ain't bad. These wheels are quite heavy. So I at least got some well made wheels for my money. They just half-assed the final polish.

So, once I get a satisfactory finish, I will go ahead and apply the 442 tape stripe around the periphery of the rim lip and then . . .

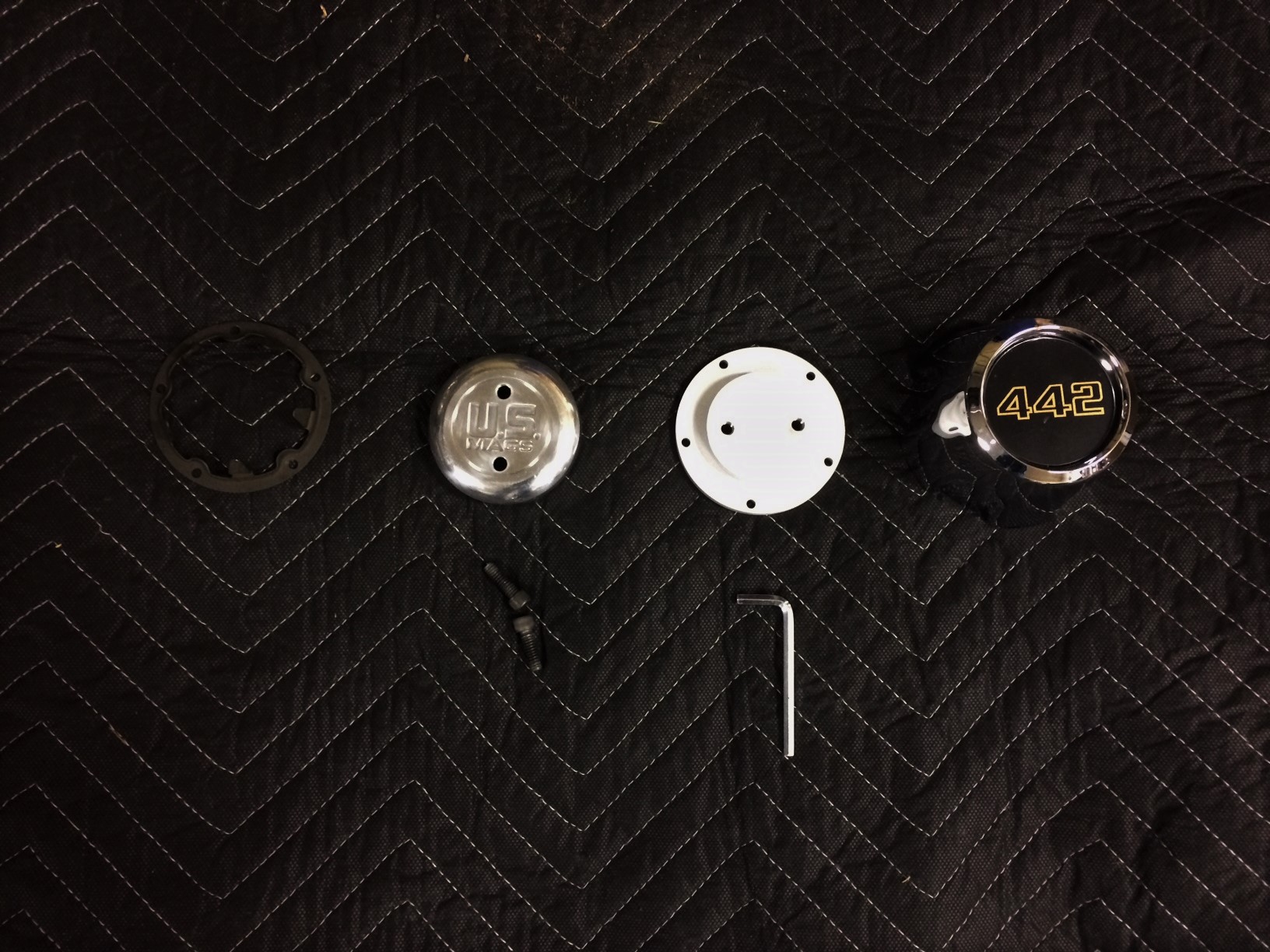

We are indeed building adapter caps for the factory SSIII 442 caps to snap on to. I took all of that stuff to a shop in town today too. Should be done mid-next week. I was ready to just mill the centers of the US Mags caps down enough to apply an adhesive backed 442 center to but this is proving problematic with the way US Mags chamfers the outside periphery of their center cap. By the time you get about .060 out of the center to accommodate the adhesive backed 442 overlay, there would only be between .020-.030 of material left around the edges. So, the first time you have to remove the cap, you tap on the back a little too hard and you might well bust through that thin of material just trying to get the rather tight [o-ringed in] center cap out. So, they will indeed look like this [minus the scratches]!

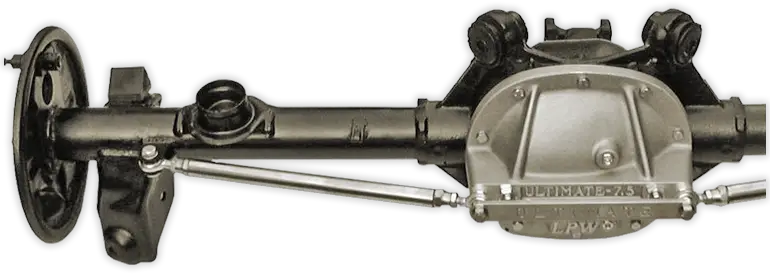

Beyond that, the rear end is STILL NOT in town. I have had too much other general life stuff and my health getting in the way of that. Seems like I have been in "next week" mode for 6 months on that rear end even though I've only had all the rebuild parts for less than a month. I guess truth be known, about 6 months ago was when I tried to etch/paint the entire rear end and put on a TrickFlow cover and discovered all the metal filings in the rear end fluid. Not to mention that etch/paint product didn't work very good. So, blast and coat and a complete rebuild is the way to go anyway.

I did work some more on the power shelf and the interior. Console is ready to pull and the door panels are completely loose just hanging there. Almost ready to slap dynamat everywhere. Then I can try one more time to get that ABS headliner up.

That reminds me I need to take before and after pics of the dynamat and soundsystem install.

And, I got new knobs for my Retro head. They don't quite match the factory knobs but I like them better than the cheap black plastic button type knobs that came on the unit. What do you think?

Given the 1/2 *ss polish job, I got concerned about the over all construction quality so I went ahead and had the wheels spun today for true-ness, and then had them put the Bridgestone RE760s on. Worst wheel required only 4 1/2 oz., [2] wheels were just less and just more than 2 oz., and [1] wheel just required a 1/2 oz. That ain't bad. These wheels are quite heavy. So I at least got some well made wheels for my money. They just half-assed the final polish.

So, once I get a satisfactory finish, I will go ahead and apply the 442 tape stripe around the periphery of the rim lip and then . . .

We are indeed building adapter caps for the factory SSIII 442 caps to snap on to. I took all of that stuff to a shop in town today too. Should be done mid-next week. I was ready to just mill the centers of the US Mags caps down enough to apply an adhesive backed 442 center to but this is proving problematic with the way US Mags chamfers the outside periphery of their center cap. By the time you get about .060 out of the center to accommodate the adhesive backed 442 overlay, there would only be between .020-.030 of material left around the edges. So, the first time you have to remove the cap, you tap on the back a little too hard and you might well bust through that thin of material just trying to get the rather tight [o-ringed in] center cap out. So, they will indeed look like this [minus the scratches]!

Beyond that, the rear end is STILL NOT in town. I have had too much other general life stuff and my health getting in the way of that. Seems like I have been in "next week" mode for 6 months on that rear end even though I've only had all the rebuild parts for less than a month. I guess truth be known, about 6 months ago was when I tried to etch/paint the entire rear end and put on a TrickFlow cover and discovered all the metal filings in the rear end fluid. Not to mention that etch/paint product didn't work very good. So, blast and coat and a complete rebuild is the way to go anyway.

I did work some more on the power shelf and the interior. Console is ready to pull and the door panels are completely loose just hanging there. Almost ready to slap dynamat everywhere. Then I can try one more time to get that ABS headliner up.

That reminds me I need to take before and after pics of the dynamat and soundsystem install.

And, I got new knobs for my Retro head. They don't quite match the factory knobs but I like them better than the cheap black plastic button type knobs that came on the unit. What do you think?

Last edited: