No, not a real update, but I've been confusing myself and perhaps some of you from day one on the cam I have in my big block. I started with the JM-22-25-10 which is a 230-236 D .512/.523 L which was just a bit too much for the ECM. I thought I backed down to a 226/230 .496/.512 but, when I went and looked, the next smaller Mondello cam was the JM-20-22 which is basically that Edelbrock Performer cam 224/234 .496/.520 so I assumed I yorglemeyered the numbers.

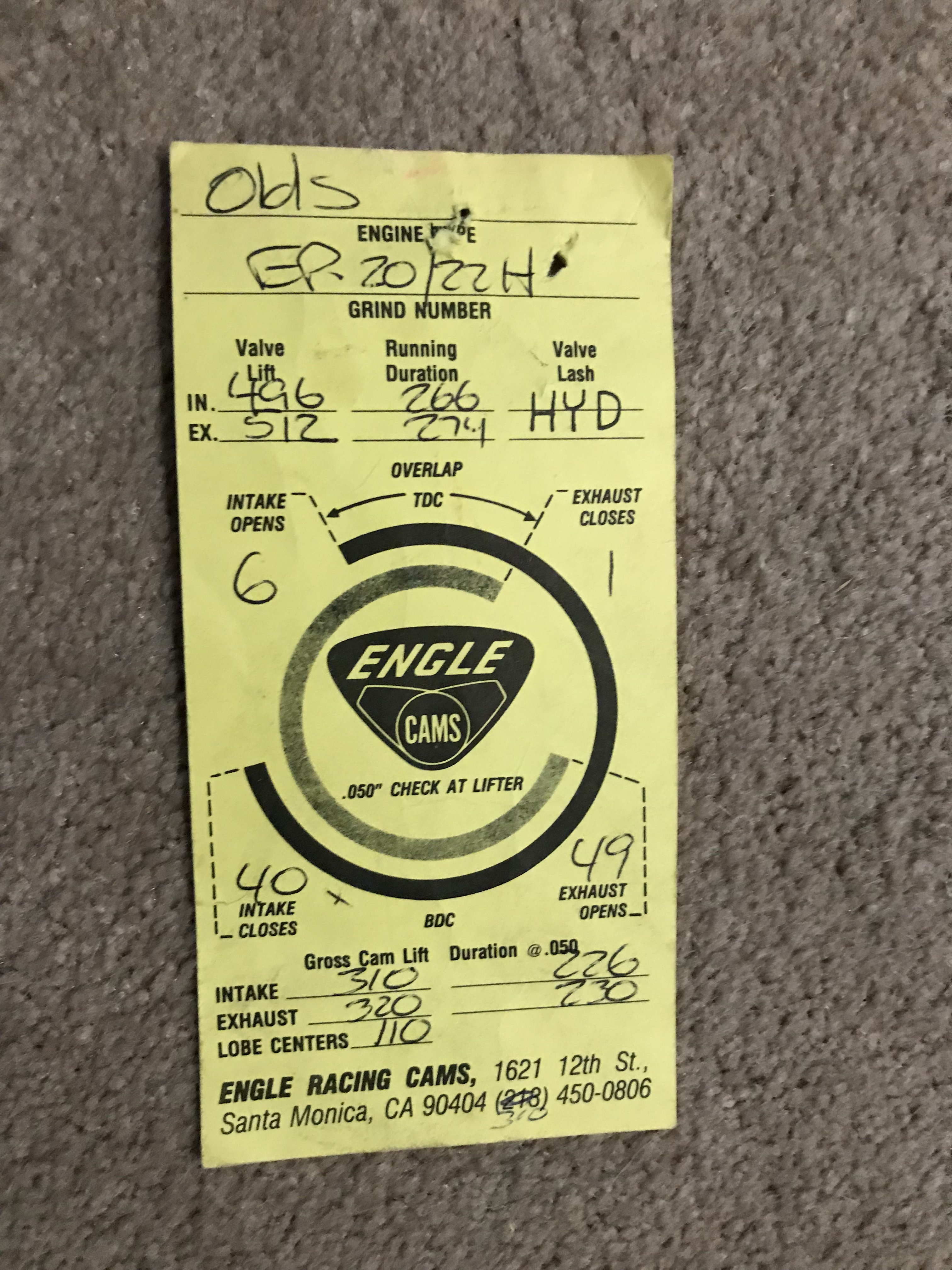

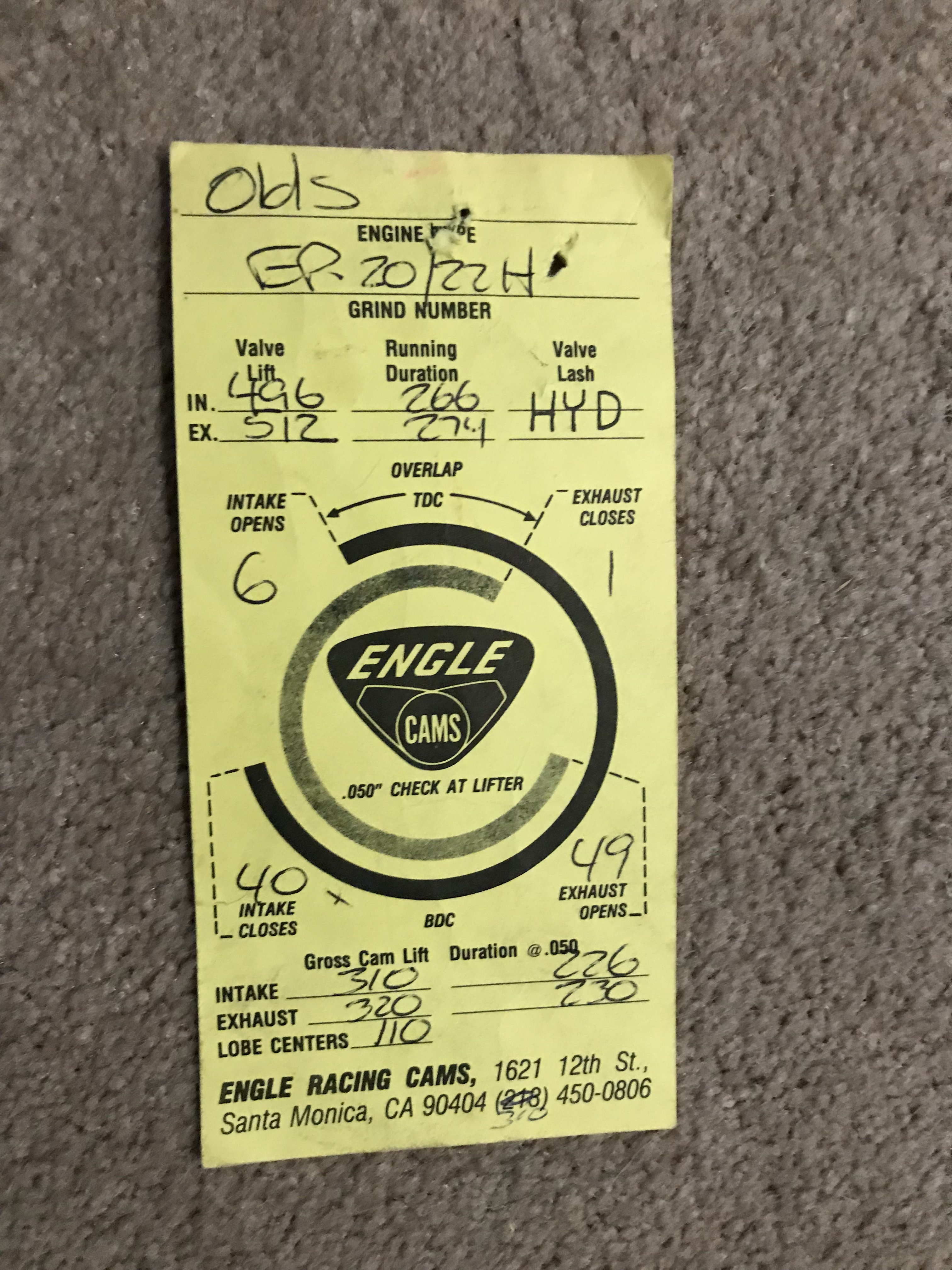

Anyway, I just found my cam card. I went straight to Engle since they did Mondello's grinds anyway and went with their 2720H and I had the right original cam specs 226/230 .496/.512. Pretty mellow by big block standards but "eventually" you will all get to hear it and experience remotely at least its performance.

Just correcting the record . . .

Anyway, I just found my cam card. I went straight to Engle since they did Mondello's grinds anyway and went with their 2720H and I had the right original cam specs 226/230 .496/.512. Pretty mellow by big block standards but "eventually" you will all get to hear it and experience remotely at least its performance.

Just correcting the record . . .

Last edited: