MONTE CARLO "COPO" Monte Carlo SS - Turbosaurus Build (Swinging Dick Racing's c*ck got bent... she bounced a little too high & hard, & came down awkwardly)

- Thread starter motorheadmike

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

my ears are a' bleeding..👍

That's a passenger problem.

A passenger issue until……….the ride is too long lol.

That’s not too low imo.

‘Bagged’ ? Is that synonymous with tanked!

That’s not too low imo.

‘Bagged’ ? Is that synonymous with tanked!

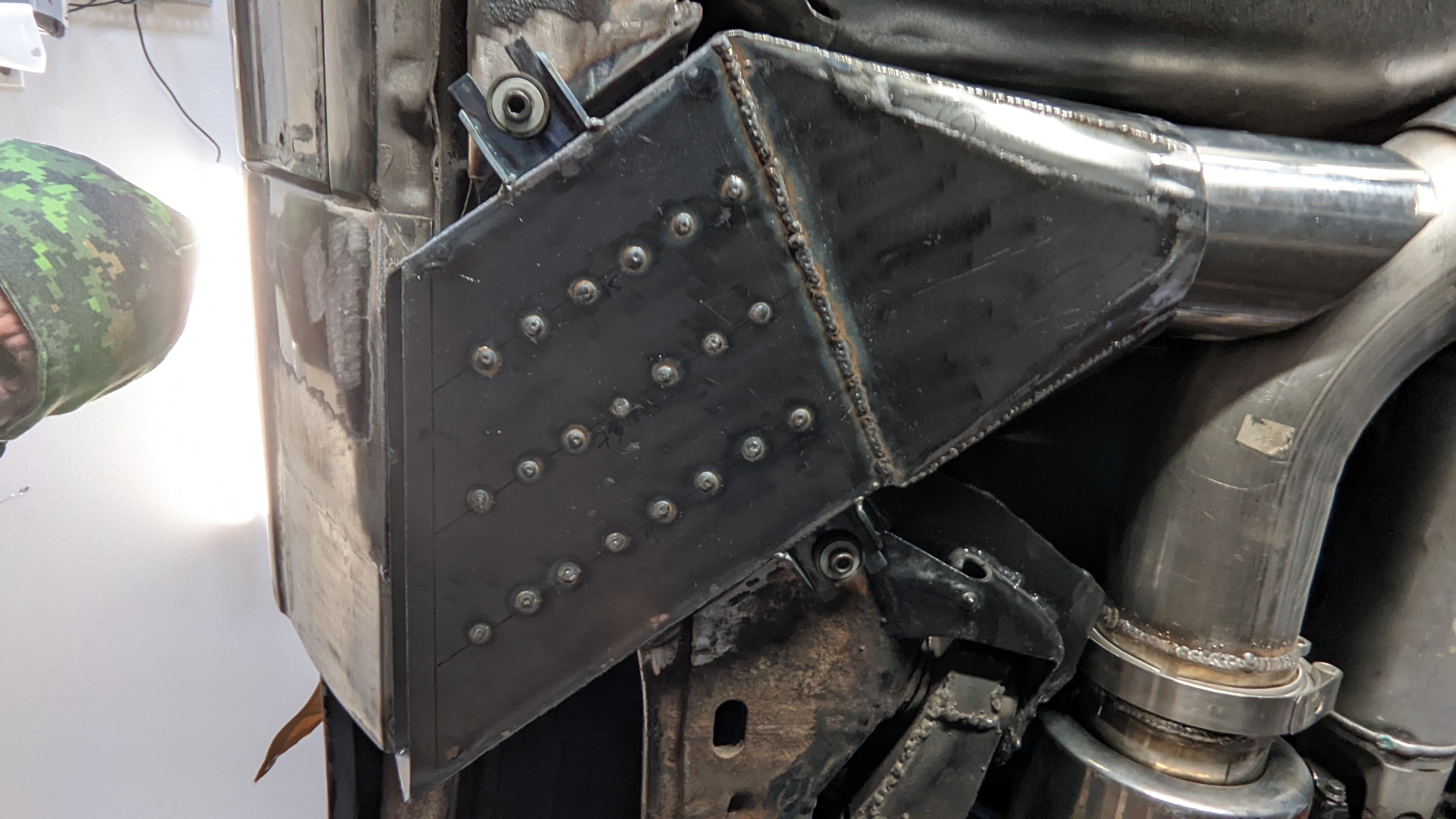

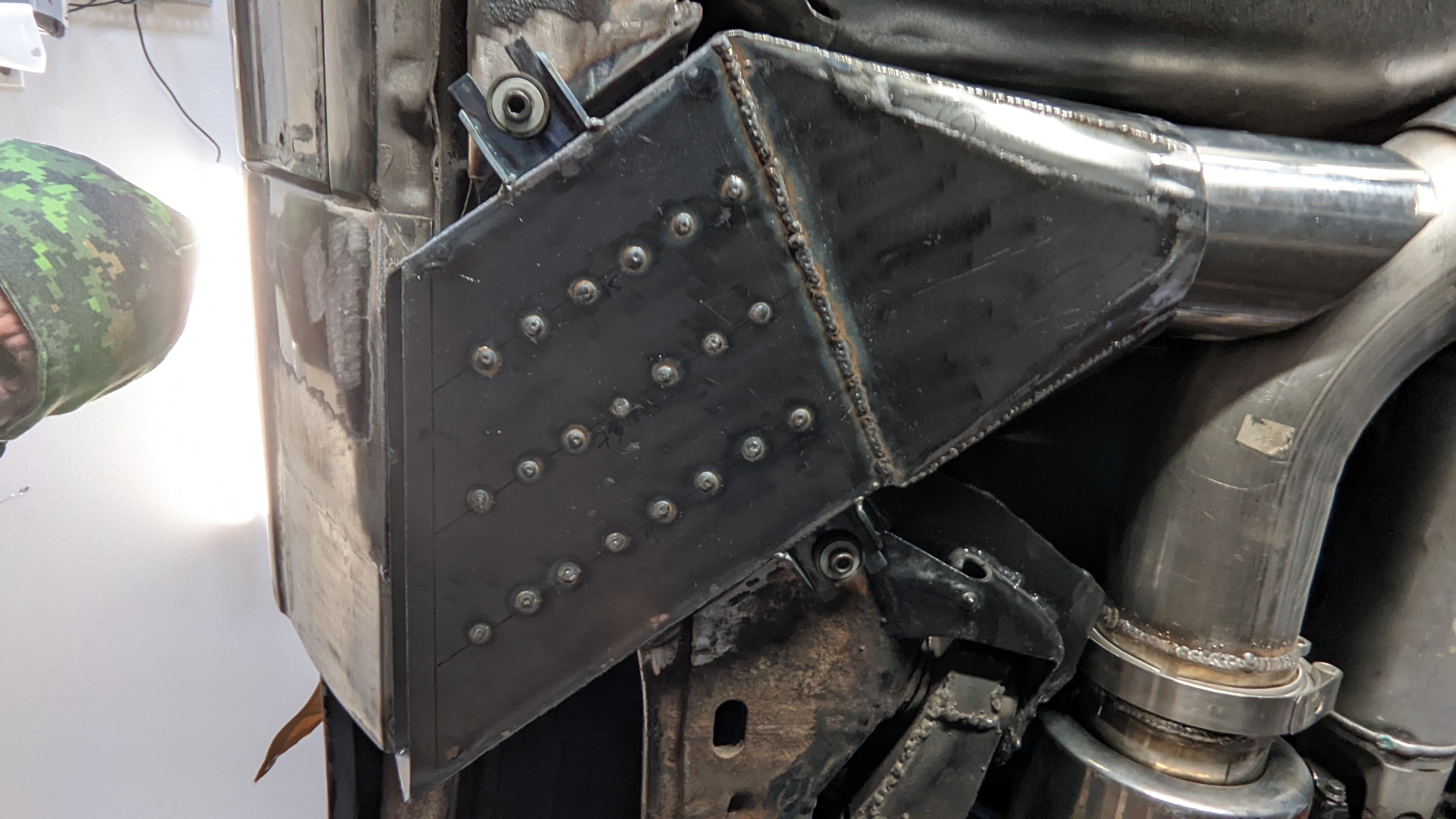

Made a couple of mounting brackets and fit some isolators. Once lined up and tacked on I drilled a couple of holes and installed some riv-nuts into the frame, and then fusion welded their flanges in place with a few tacks. Next step was choosing a section of pipe and coping it to fit the bend in the pipe. Senior Plasma made this a much faster process working with the stainless (sh*t is hard on blades).

I will be using a slip fit to allow for more adjustment. Then some finish welding on the boom tube and cutting of the existing system. My plan is to keep the existing connection to the muffler for a cutout/loud valve, I am just going to cap it for now. Too many ideas and not enough money...

I will be using a slip fit to allow for more adjustment. Then some finish welding on the boom tube and cutting of the existing system. My plan is to keep the existing connection to the muffler for a cutout/loud valve, I am just going to cap it for now. Too many ideas and not enough money...

Last edited:

Gorgeous day for plasma cutting and welding!

Finally got to this stage.

It still needs some refinement, a touch of welding, and some paint. But, it is "done". I capped the end of the muffler and left it in place for the time being... it might be doing something, it might not. Overall it isn't that obnoxious at idle. Off idle is a different story...

Primed the pump twice and it fired right up. Kudos to my tuna!

Finally got to this stage.

It still needs some refinement, a touch of welding, and some paint. But, it is "done". I capped the end of the muffler and left it in place for the time being... it might be doing something, it might not. Overall it isn't that obnoxious at idle. Off idle is a different story...

Primed the pump twice and it fired right up. Kudos to my tuna!

Last edited:

Gorgeous day for plasma cutting and welding!

View attachment 194634

View attachment 194635

Finally got to this stage.

View attachment 194636

It still needs some refinement, a touch of welding, and some paint. But, it is "done". I capped the end of the muffler and left it in place for the time being... it might be doing something, it might not. Overall it isn't that obnoxious at idle. Off idle is a different story...

Primed the pump twice and it fired right up. Kudos to my tuna!

Like my Camaro, it sounds like a loud pickup truck. 🤣

Like my Camaro, it sounds like a loud pickup truck. 🤣

Stupid factory cams.

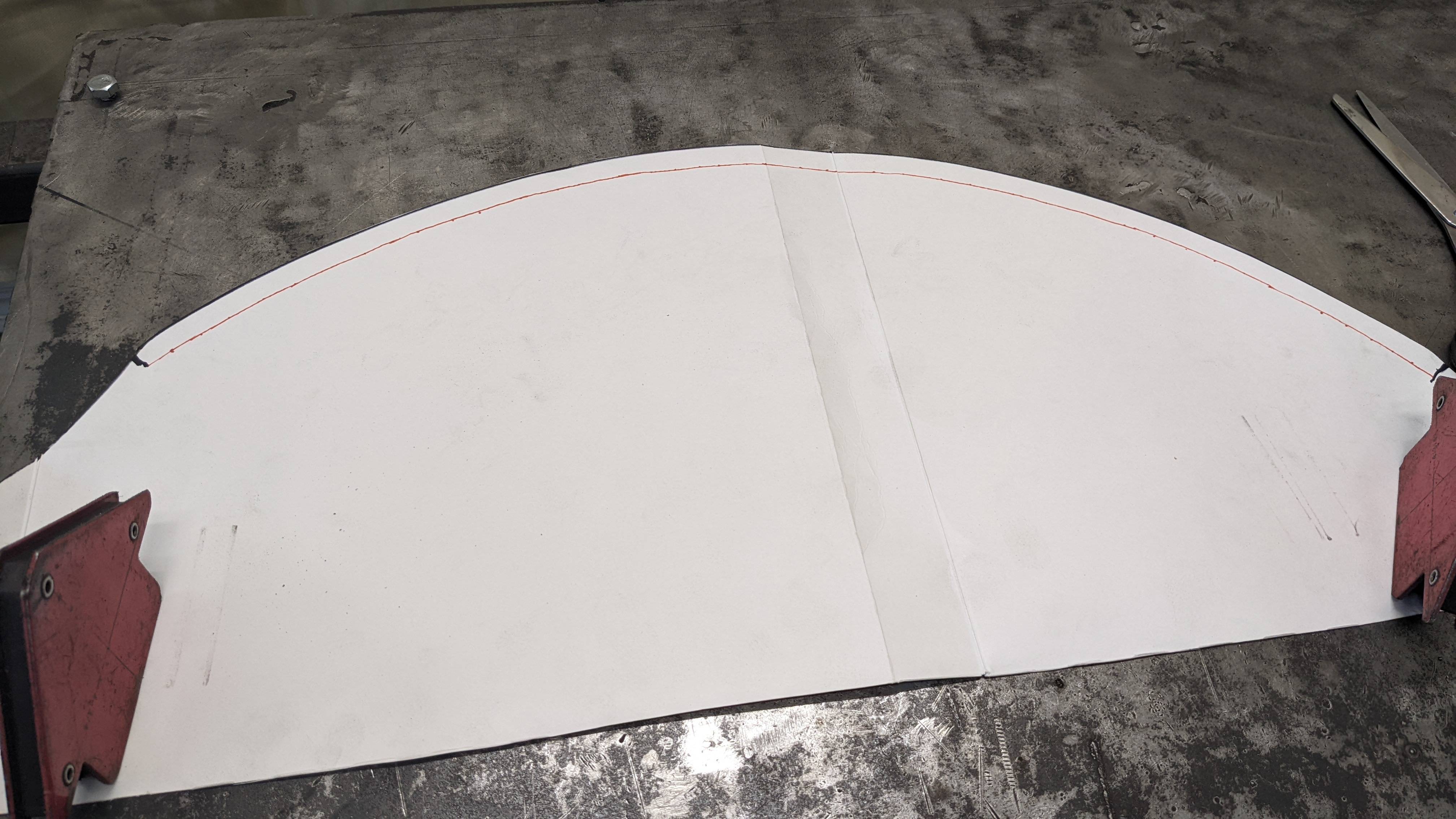

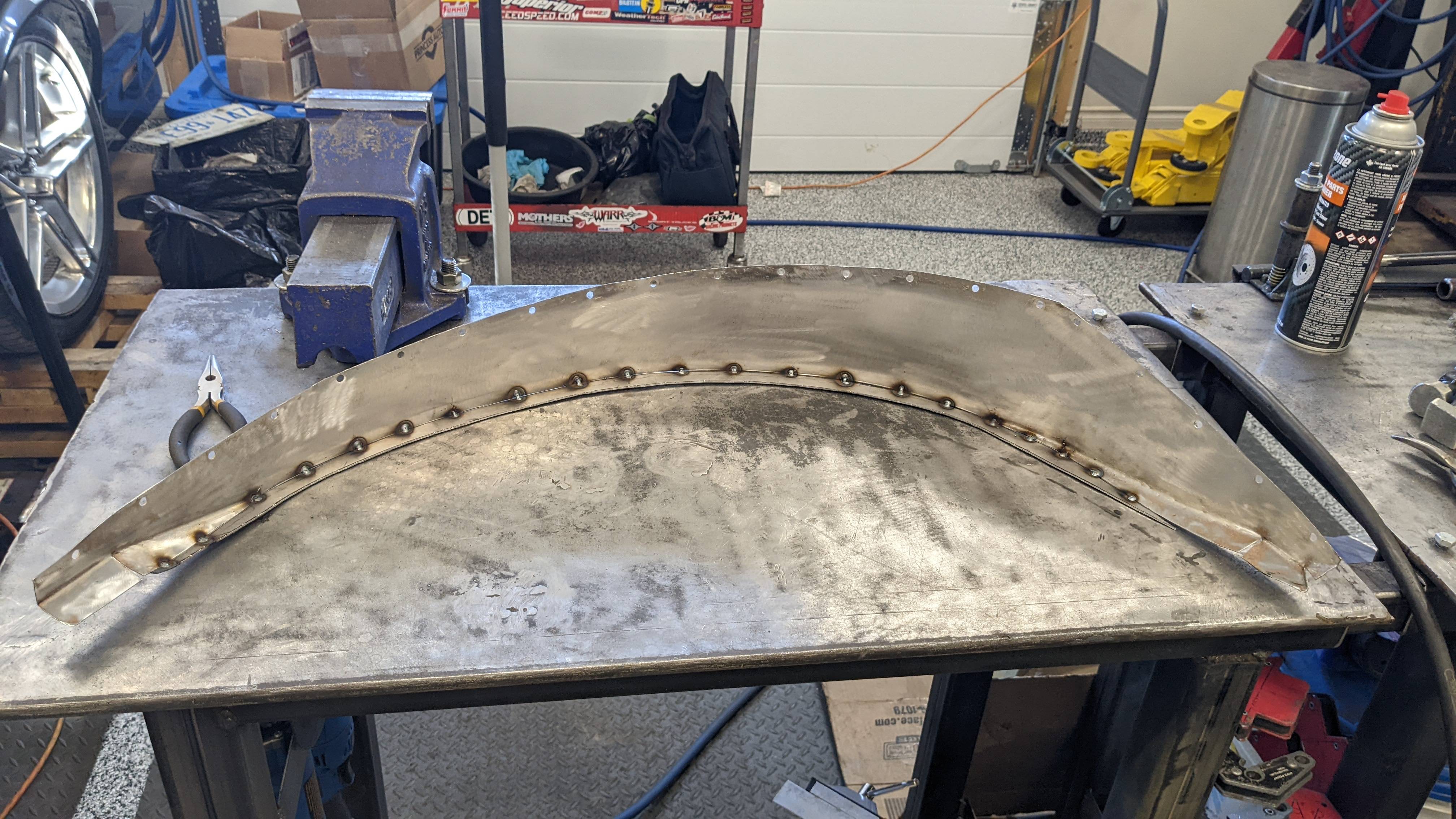

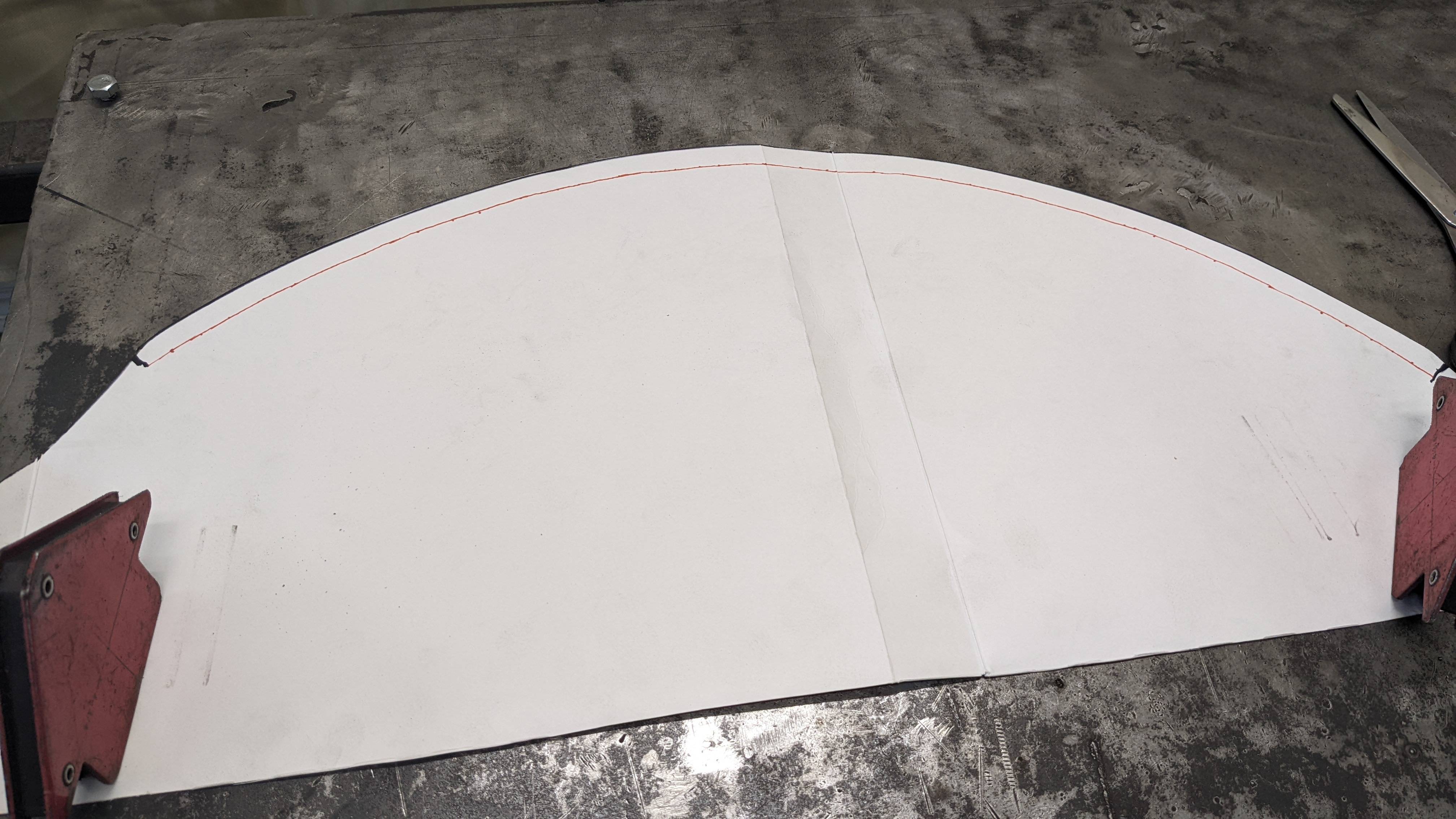

After taking a day off I decided to lean into solving a problem I created over a year ago... and then compounded by driving on in raw steel. It all starts with a pizza box and a dream.

Trimmed and added a 1/2" to make a template for a flange.

Magnets and a bit of tape, and traced to the sheet metal.

Nothing beats 90lbs of dead weight to keep the sheet from vibrating. I dressed the edge before cutting it off the sheet as this is critical to fitting into the tub properly, and it would be a lot more cumbersome to do once it is loose.

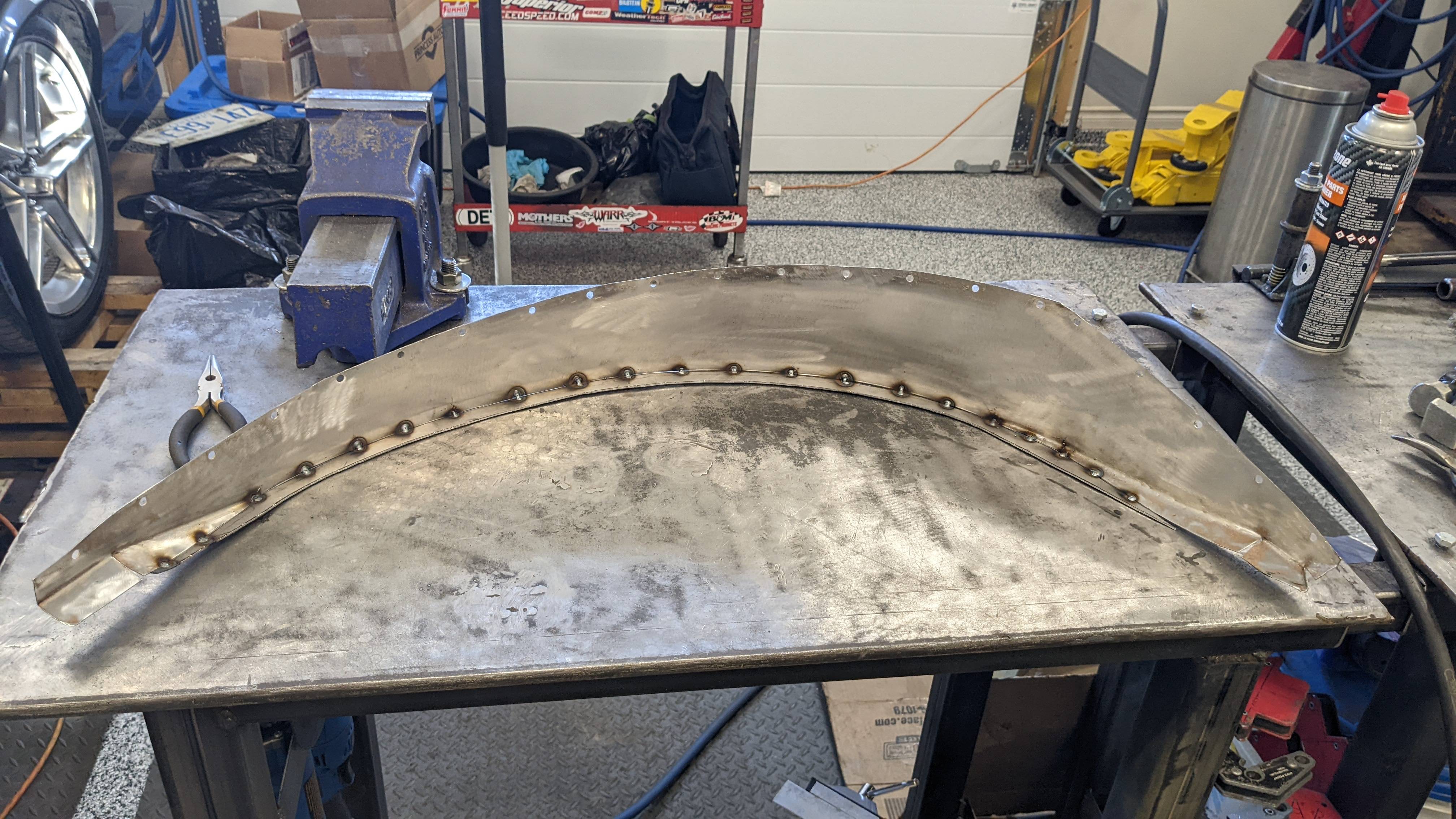

Tack. tack. tack.

Tack tack tack tack tack... tack tack tack tack tack... tack tack tack tack tack...

A bunch of hammer and dolly work to shape the flange to the contour of the quarter panel. I have a sudden urge for Ruffles.

Fits pretty good. I am going to back fill this seam with a bunch of seam sealer.

Trimmed and added a 1/2" to make a template for a flange.

Magnets and a bit of tape, and traced to the sheet metal.

Nothing beats 90lbs of dead weight to keep the sheet from vibrating. I dressed the edge before cutting it off the sheet as this is critical to fitting into the tub properly, and it would be a lot more cumbersome to do once it is loose.

Tack. tack. tack.

Tack tack tack tack tack... tack tack tack tack tack... tack tack tack tack tack...

A bunch of hammer and dolly work to shape the flange to the contour of the quarter panel. I have a sudden urge for Ruffles.

Fits pretty good. I am going to back fill this seam with a bunch of seam sealer.

Last edited:

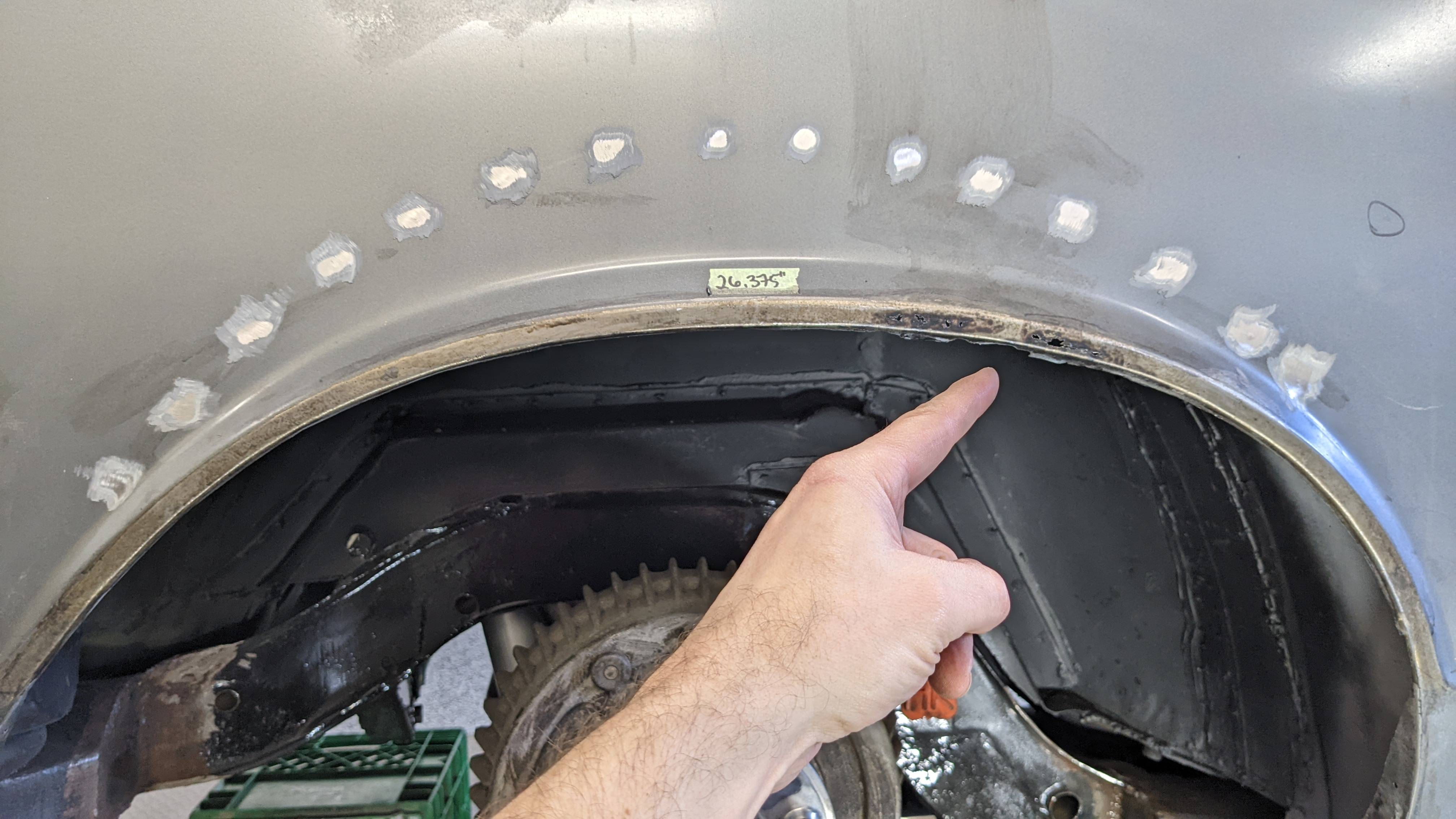

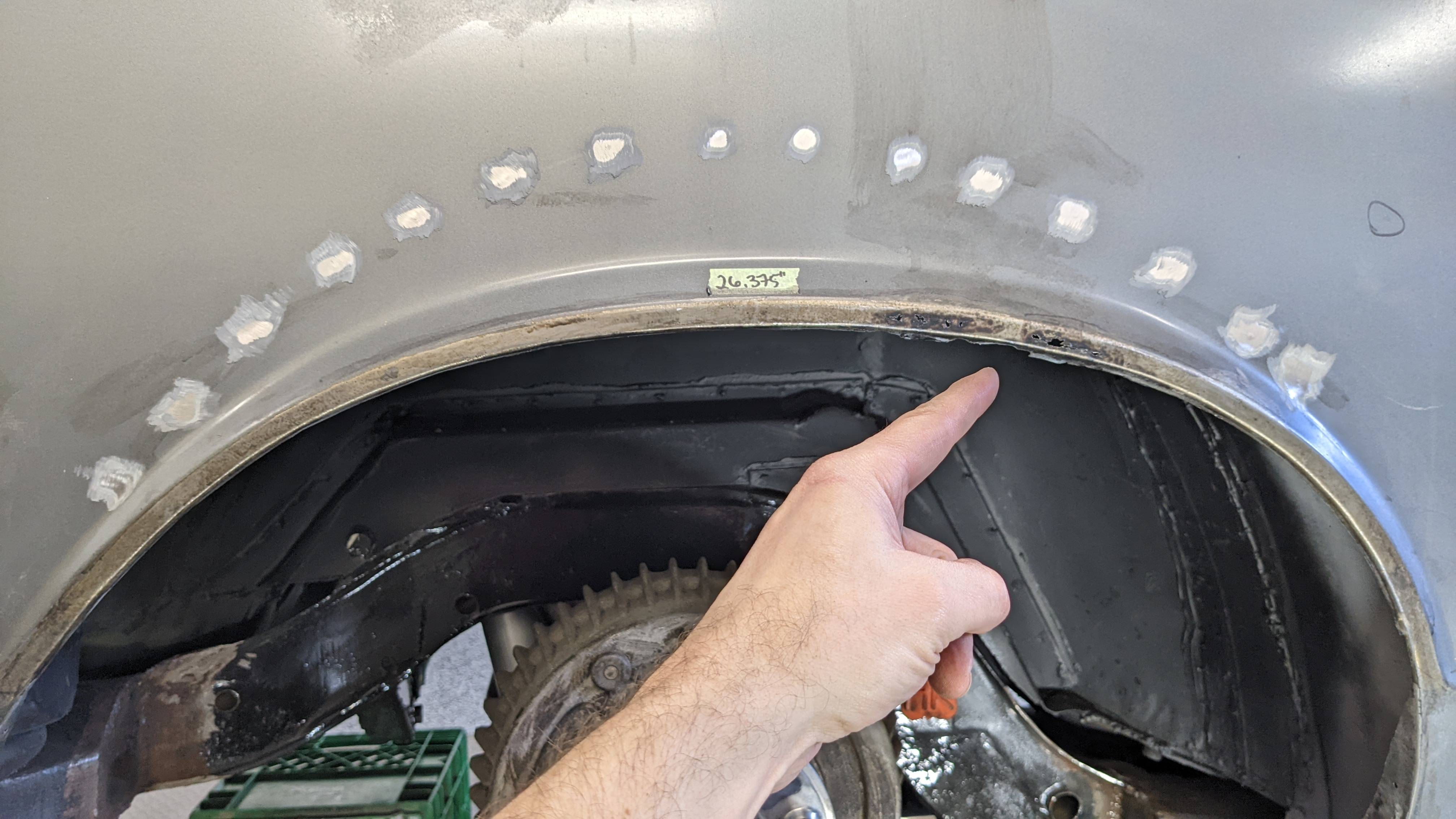

And here you can see the final decision burned through that awesome factory paint. Yup. I welded it to the outer quarter skin. Why? To cut down the noise and put some strength and stability back into the area. It still sounds like a steel drum on either side of the welded arch... but, much much better than factory. It will improve more with the seam sealer and undercoating in place.

Checking the damage... LOL.

The weld through primer was giving me fits on this side. I cleaned up the spot weld areas before burning in the other side.

The idea is to avoid this:

I have a few other tricks up my sleeve that I should be able to get underway tomorrow.

Next up was fixing this unsightly mess poking through. This was probably the most stressful repair to date just because of where it is located on the car. Jacking it up would make me a sad panda.

I didn't take picture of the first section of the repair because I was so focused on the process. But, as you can see I broke it down into two parts to minimize the potential to mess up the body lines.

Nothing special, just a lot of time spent working on fitment.

I struggled with blow through the first one until I welded the backside. On the second one I got the outside tacks partially done, and immediately tacked the inside before finishing the outside.

Perfect? No. Rusty? No. A little hammer and dolly work trued it up real quick.

I will probably be back at this tomorrow. I need to run a 1/8" rod around the inside of the lip (or what is left of it) before the final dressing of the wheel tubs, primer, seam sealer, and top coat. Oh joy.

Checking the damage... LOL.

The weld through primer was giving me fits on this side. I cleaned up the spot weld areas before burning in the other side.

The idea is to avoid this:

I have a few other tricks up my sleeve that I should be able to get underway tomorrow.

Next up was fixing this unsightly mess poking through. This was probably the most stressful repair to date just because of where it is located on the car. Jacking it up would make me a sad panda.

I didn't take picture of the first section of the repair because I was so focused on the process. But, as you can see I broke it down into two parts to minimize the potential to mess up the body lines.

Nothing special, just a lot of time spent working on fitment.

I struggled with blow through the first one until I welded the backside. On the second one I got the outside tacks partially done, and immediately tacked the inside before finishing the outside.

Perfect? No. Rusty? No. A little hammer and dolly work trued it up real quick.

I will probably be back at this tomorrow. I need to run a 1/8" rod around the inside of the lip (or what is left of it) before the final dressing of the wheel tubs, primer, seam sealer, and top coat. Oh joy.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 137

- Replies

- 14

- Views

- 394

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.