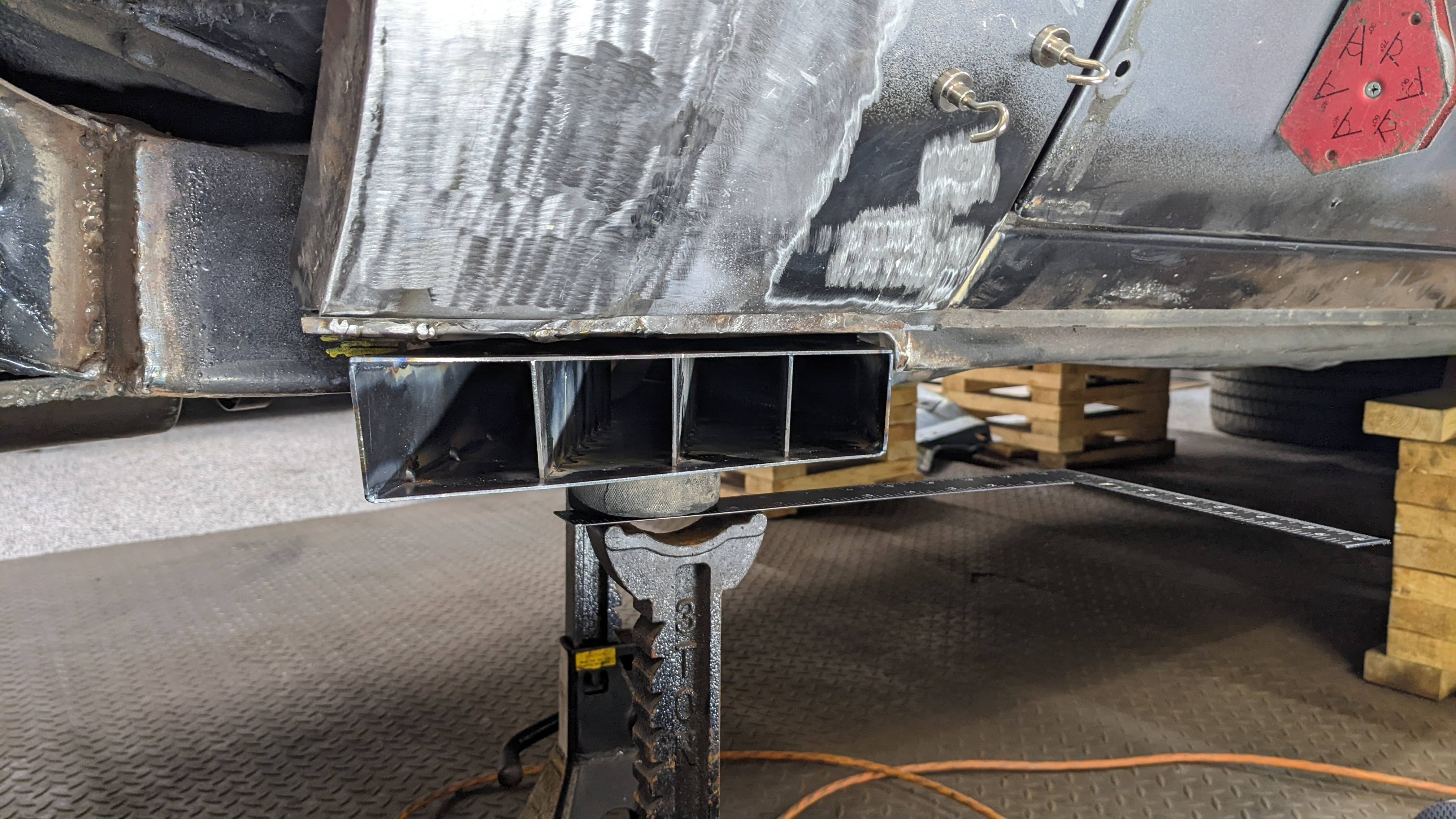

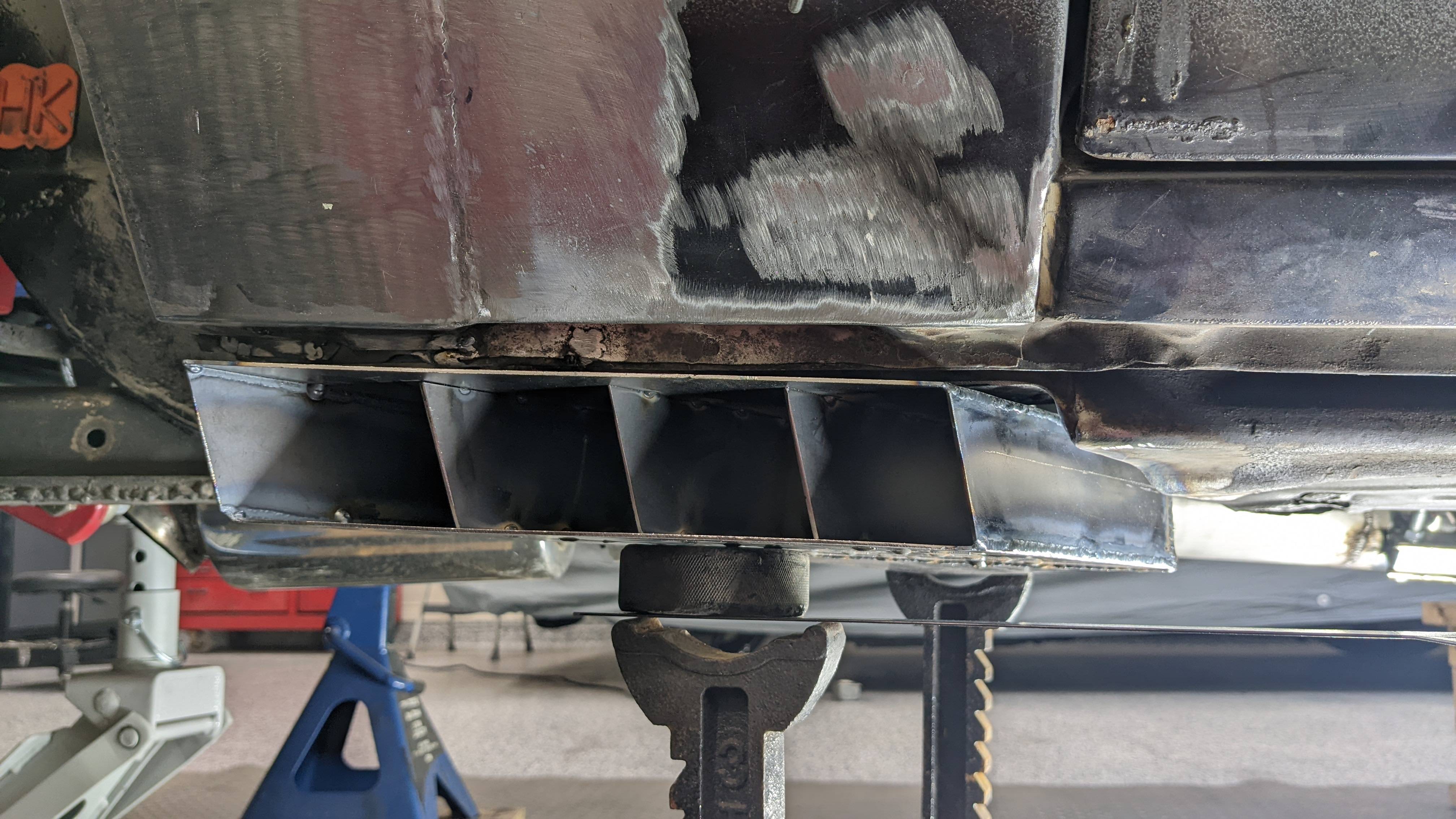

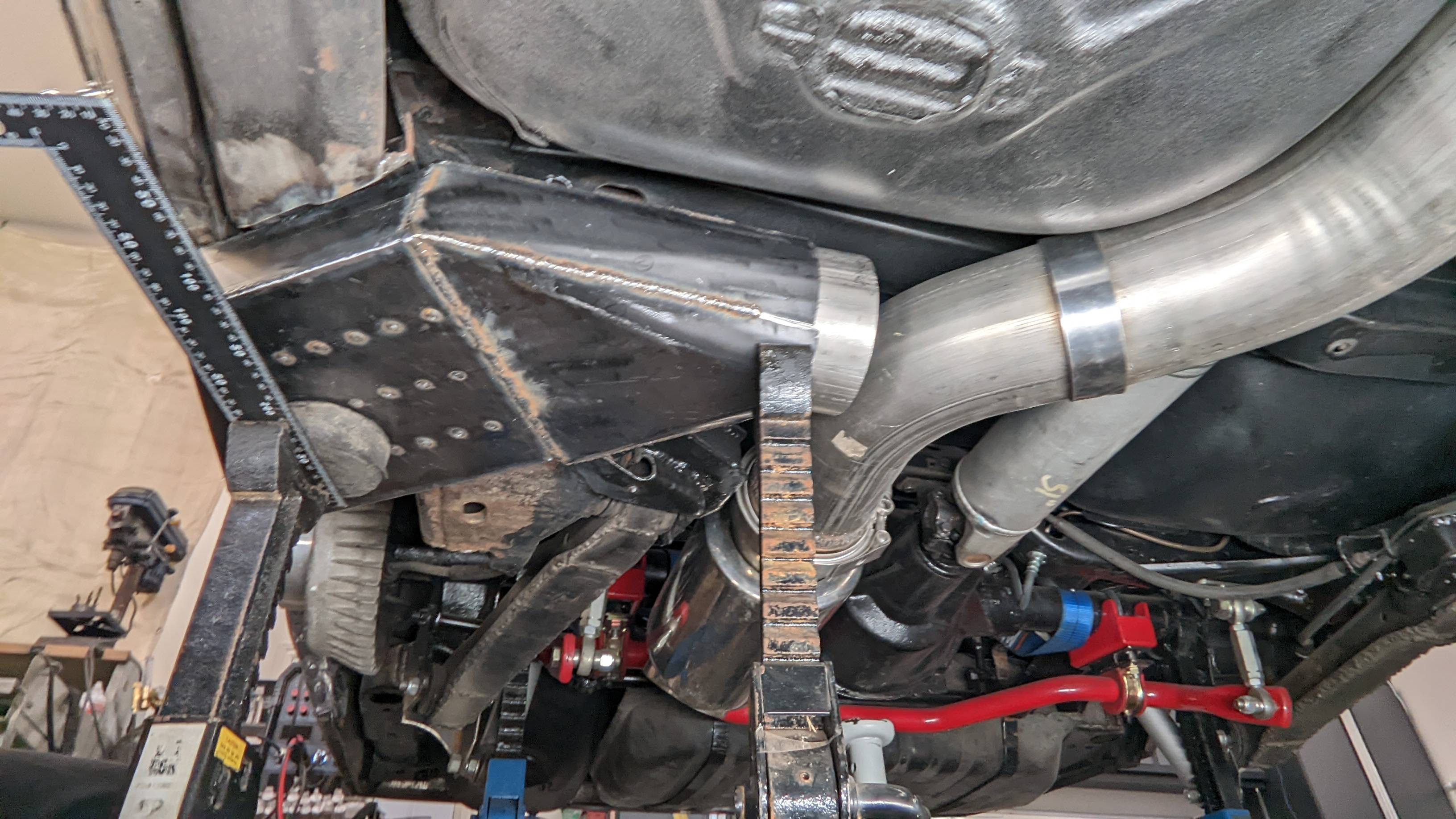

Boomtube goes here. Ground clearance is a big concern, as is fitment to the body. Hanging it under the factory frame would be... unsightly (and lazy). Now it will be tight to the pinch weld under the rocker and quarter panel.

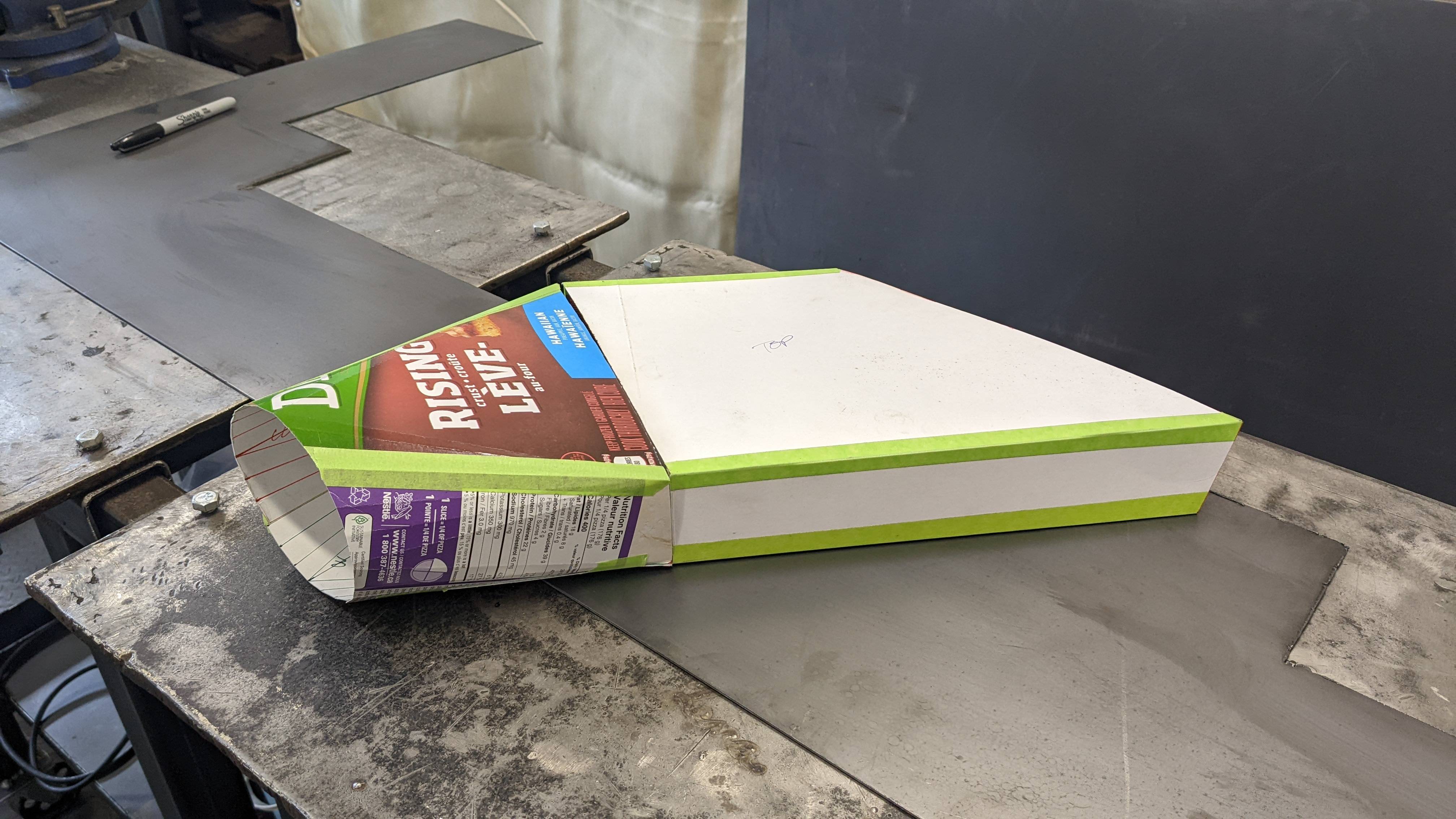

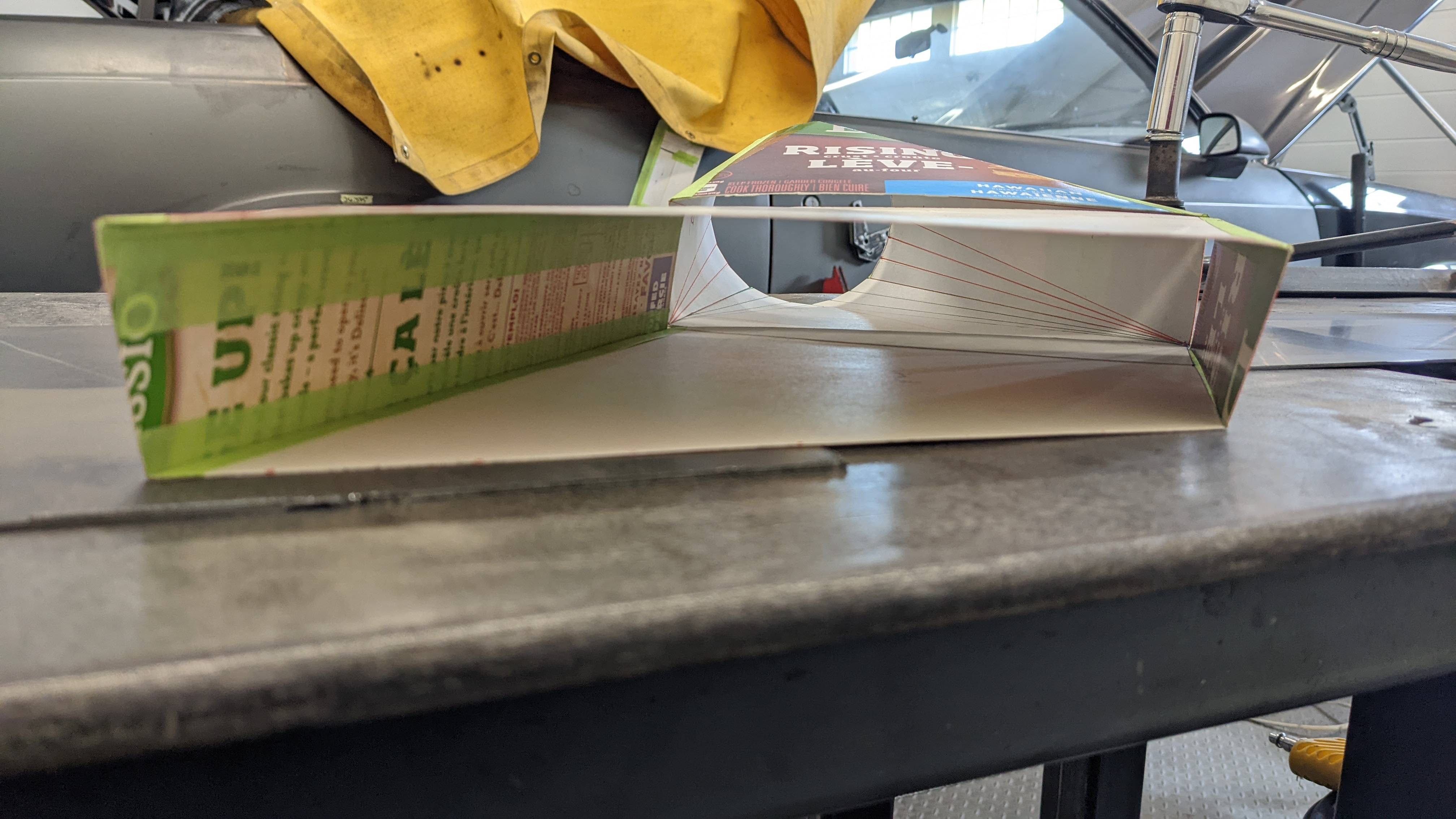

Needed a couple of reference marks to get the cut lines where I wanted them. The goal was to have the sectioned area square with the pinch weld... so that was my guide.

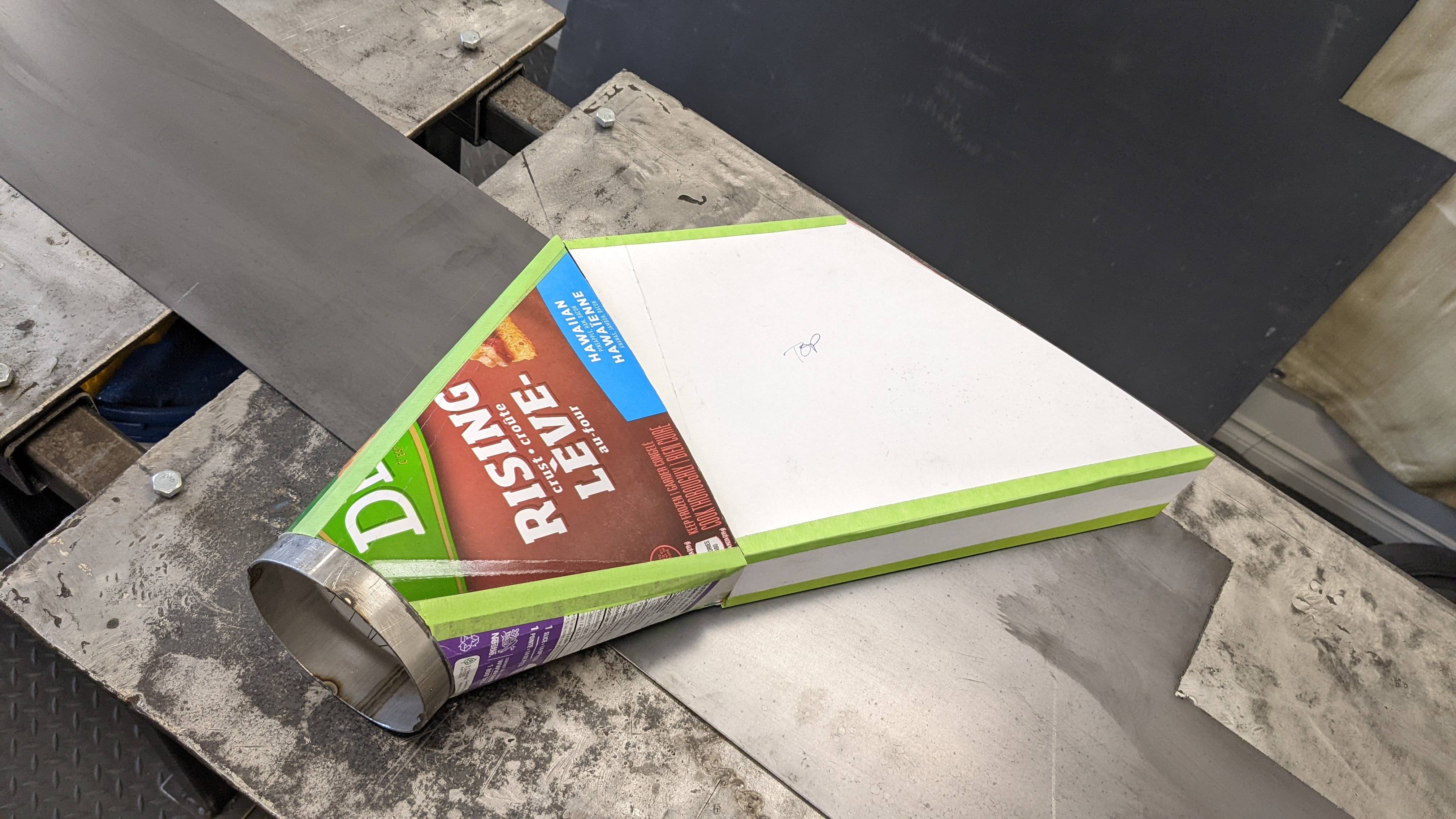

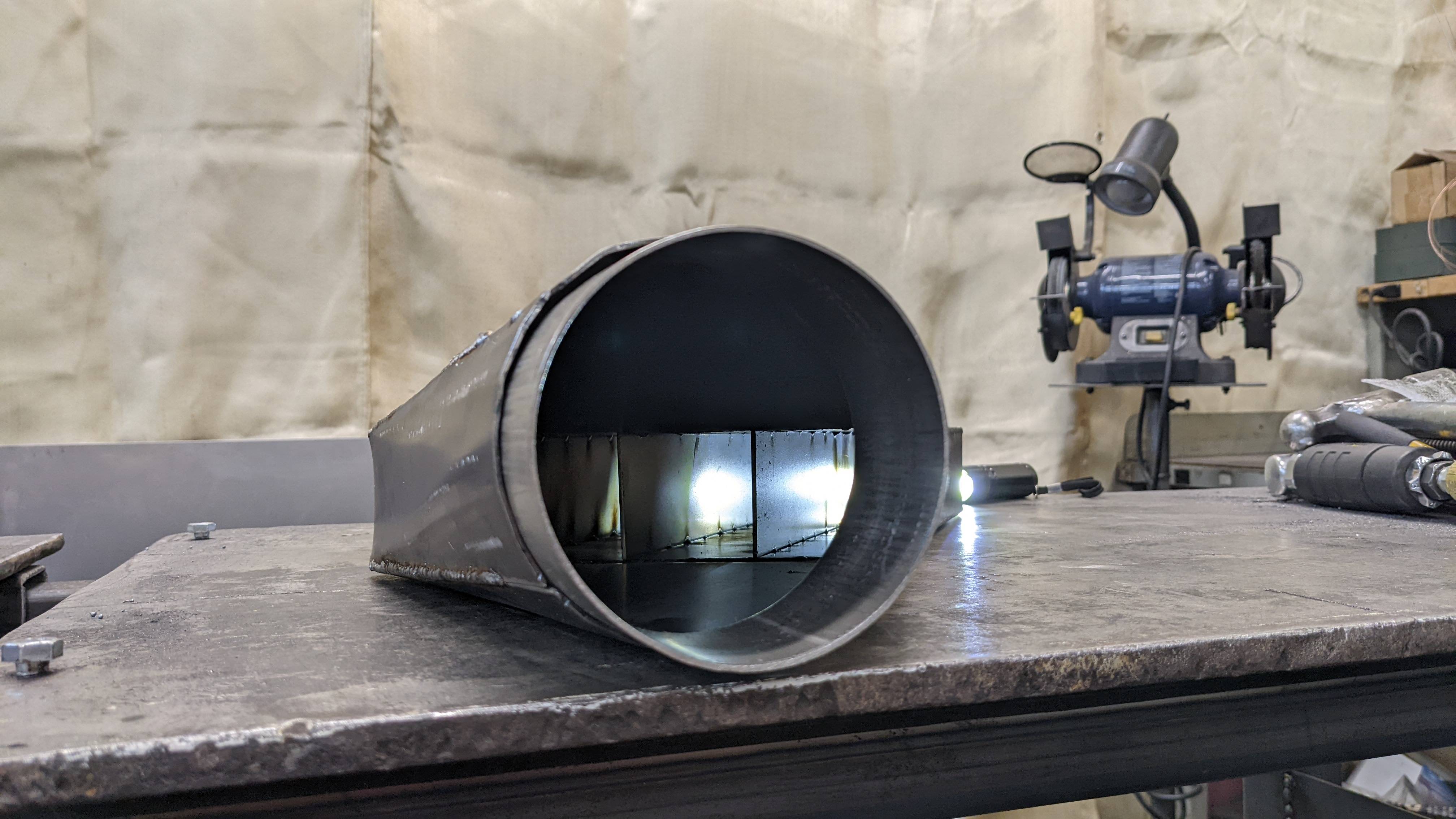

The cuts will be angled toward the rear tire, the boom tube will be square to the wheel lip. I made templates to validate this. The cut will be 8.5" wide to go around the 8x2 tip.

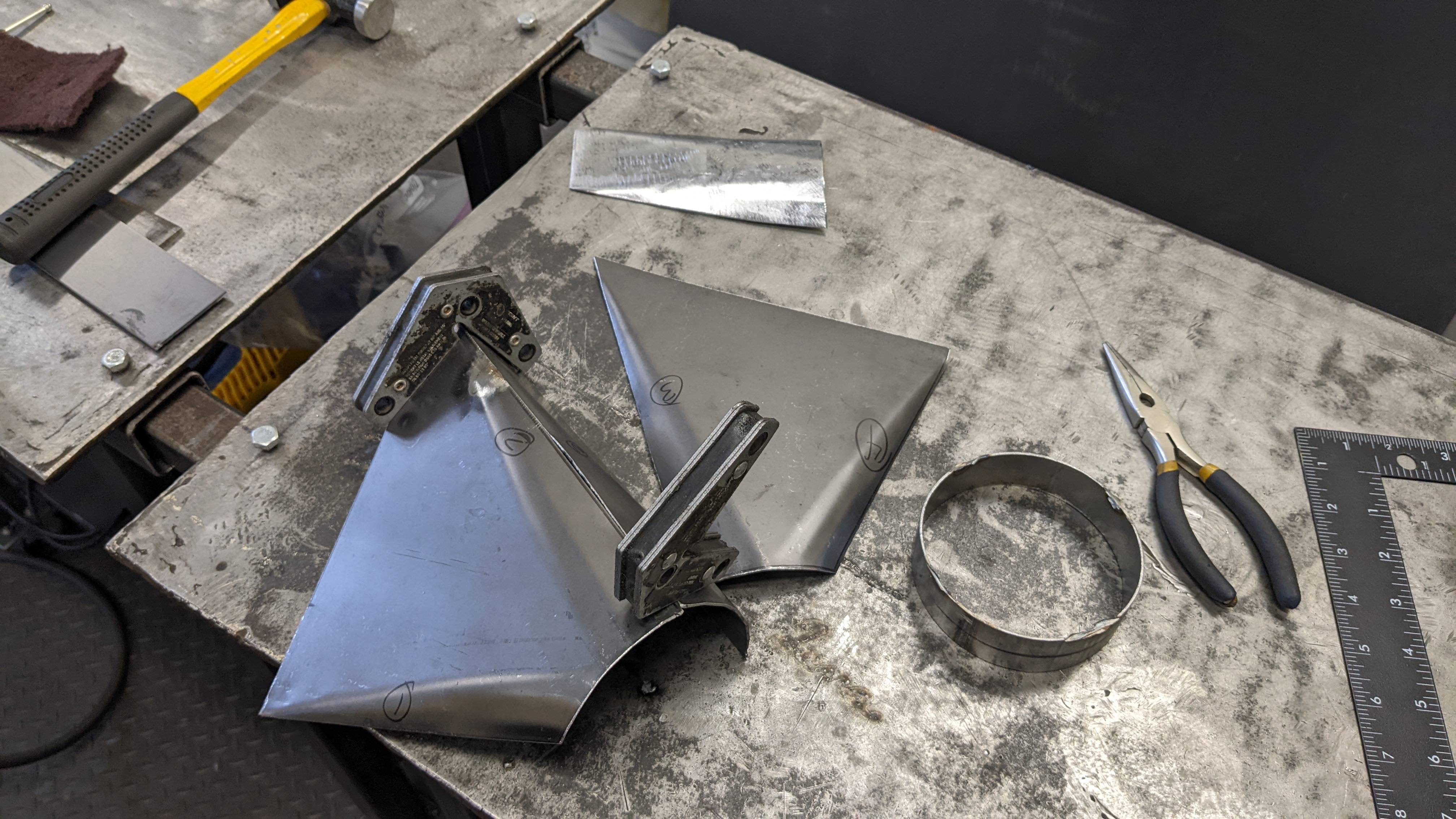

More on this chunk in a moment.

Cleaned out the oils and waxes that would otherwise run down into the welds. Been there done that.

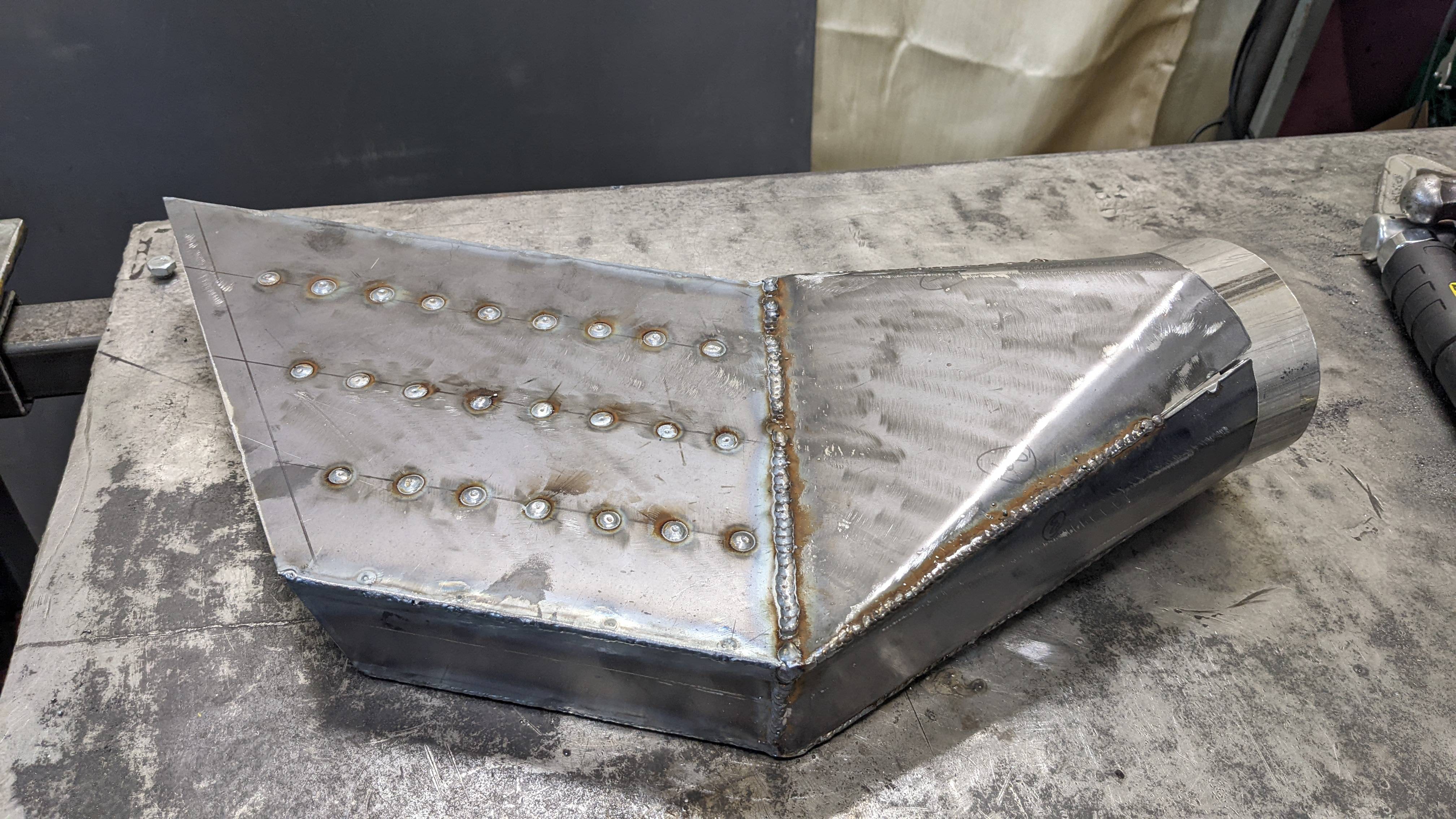

I am not sure if it is because of inflation or being a cheap Scottish descendant - but I decided to work with the stock section rather than making a whole new part. It would be welded front and back before re-installation.

Welder goes bzzzzt... bzzzzt... bzzzzt...

Grinder goes... bzzzt? whirl? whatever. It sucks.

I am going to soften and smooth the welds in the corners (and any other unsightly areas) with the TIG later on. Maybe.

Now I just have to connect A to B. Easy enough.

Time to craft another bespoke part to fill the void.