All that metal you took off for weight saving has just been replaced with wire!!!!!!!!!!!

Ironically I still haven't got to the lightening phase of this project yet (other than the glass hood) - but for all the weight of an 80s motor and accessories vs. a 2000s motor and accessories (other than the turbo) this has to be a zero sum endeavor thus far.

Mike, lanolin hand cleaner is great for cleaning up the insulation. There's not much worse than electrical tape goo stuck to your fingers.

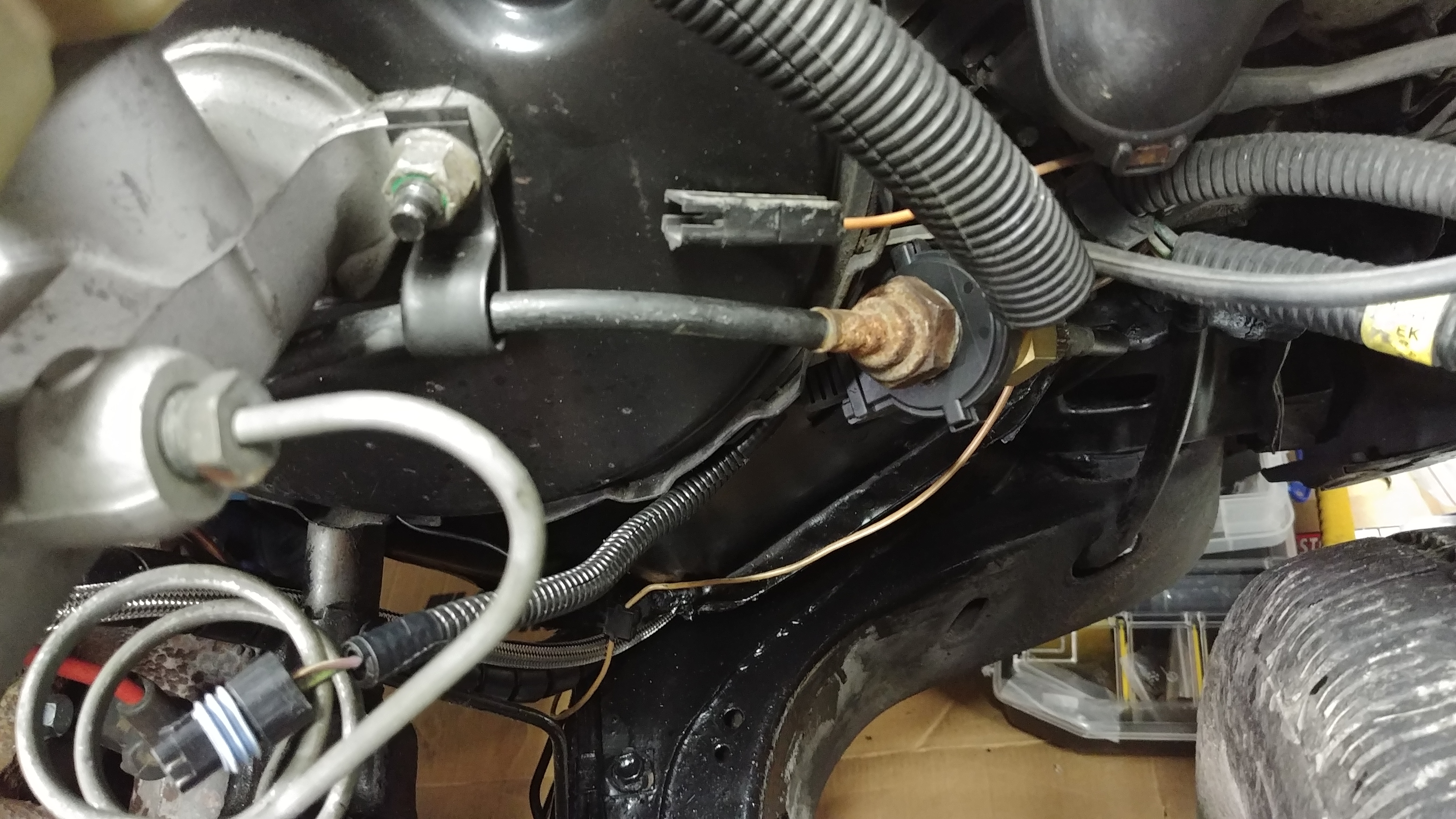

I used a combination of WD-40, a brass wire brush on the aluminum, and stiff nylon brush and an old toothbrush on the wiring - and lots of brake cleaner and compressed air. I wiped my hands down a lot while fishing wires back through the harness.

Oh man. This reminds me of wiring my brother's car. Not as fun a bolting on headers or an accessory drive. You're into the engine harness a lot deeper than I got. I'm glad you are showing this part of the build, even if truthfully, I don't enjoy seeing it. It's part of it. It always irks me when the TV shows gloss over the wiring or just build a simple vehicle that doesn't have anything more than lights.

No, the fun isn't immediately there - but the satisfaction of having it done properly will be. Even if no one will ever truly appreciate it or what it took to achieve. My motivation is usually pretty low for these portions of projects - which is why I paused everything else until I got a grip on this. I suppose the saving grace with this job is how much simpler the approach is versus the wagon - and therefore is going a lot quicker. Having some experience under my belt obviously helps, but this is achievable by anyone with a smidgen of self-discipline and the ability to read and follow instructions.