So I'm way behind on this thread but we've been working on it and I do have some good pictures. I doubt I'll get the thread totally caught up tonight, but I'm going to move the thread forward. Here goes:

When I left off, we had the new flywheel, new clutch assembly and the bellhousing installed in the car. The next task before we tried to stab the transmission was to transfer the shifter from the T-10 to the Toploader. There was more to this than it sounds like. First of all, I don't know what GearVendors had in mind when they manufactured the adapter plate they sent us to bolt the Hurst Competition Plus shifter to their Toploader tailhousing. The bolt hole for the lower right (when facing the shifter from the driver's side) mounting point didn't line up. To get it to line up, the shifter would have to be rotated clockwise, with the top mounting bolt as the pivot, considerably. The shape of the tailhousing would not allow this and we didn't want the stick rocked back like that. Here is a picture of the stick mocked up on the transmission, but only bolted on at the top. This will help illustrate what I'm trying to explain...

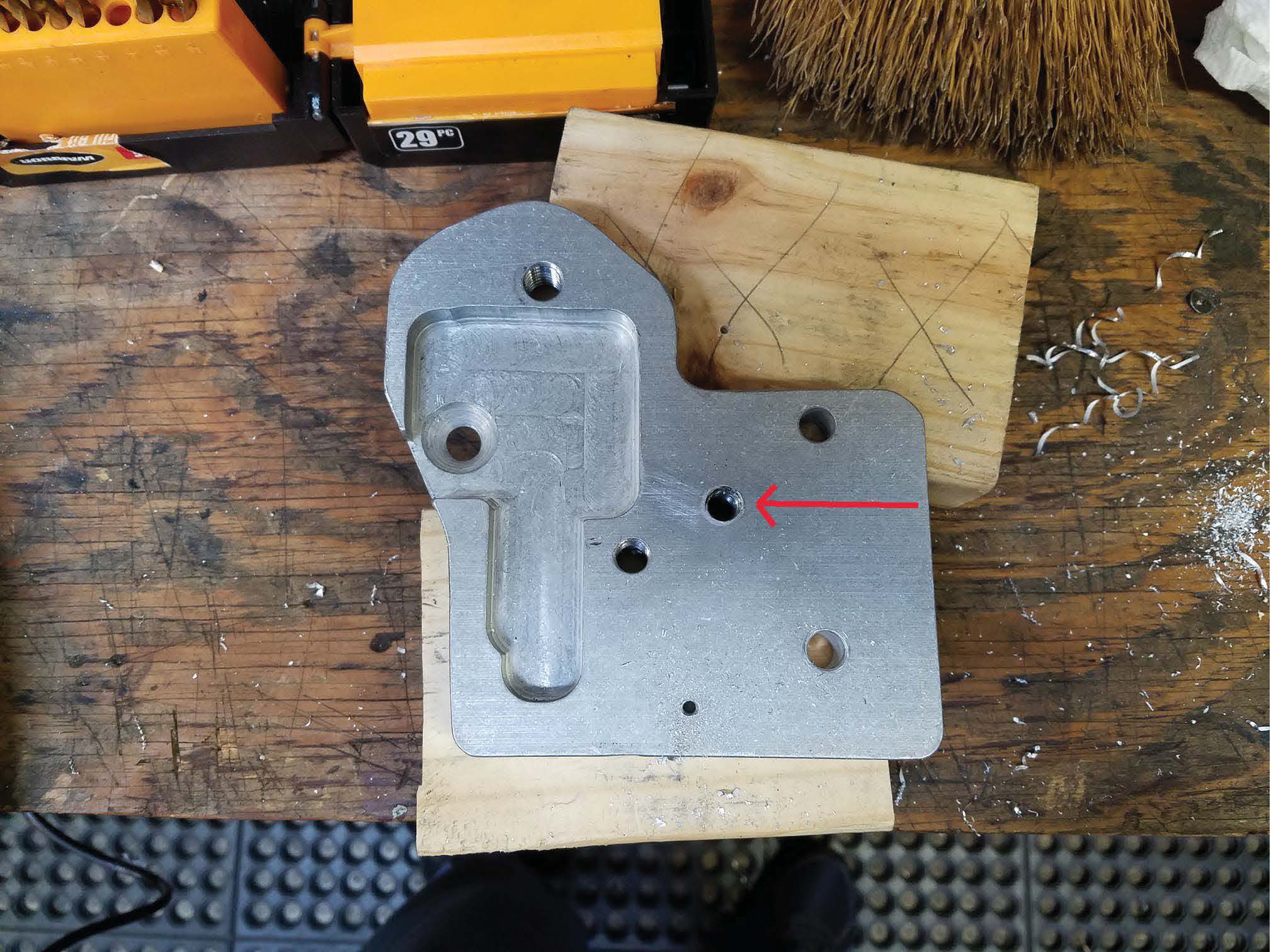

Now take a look at their adapter plate. The bolt hole with the arrow pointing to it is the hole I had to drill and tap threads into. The hole that is a little lower and to the left is the hole they provided. There was no way to use their two holes to mount the shifter flush to the tailhousing like it is supposed to be....

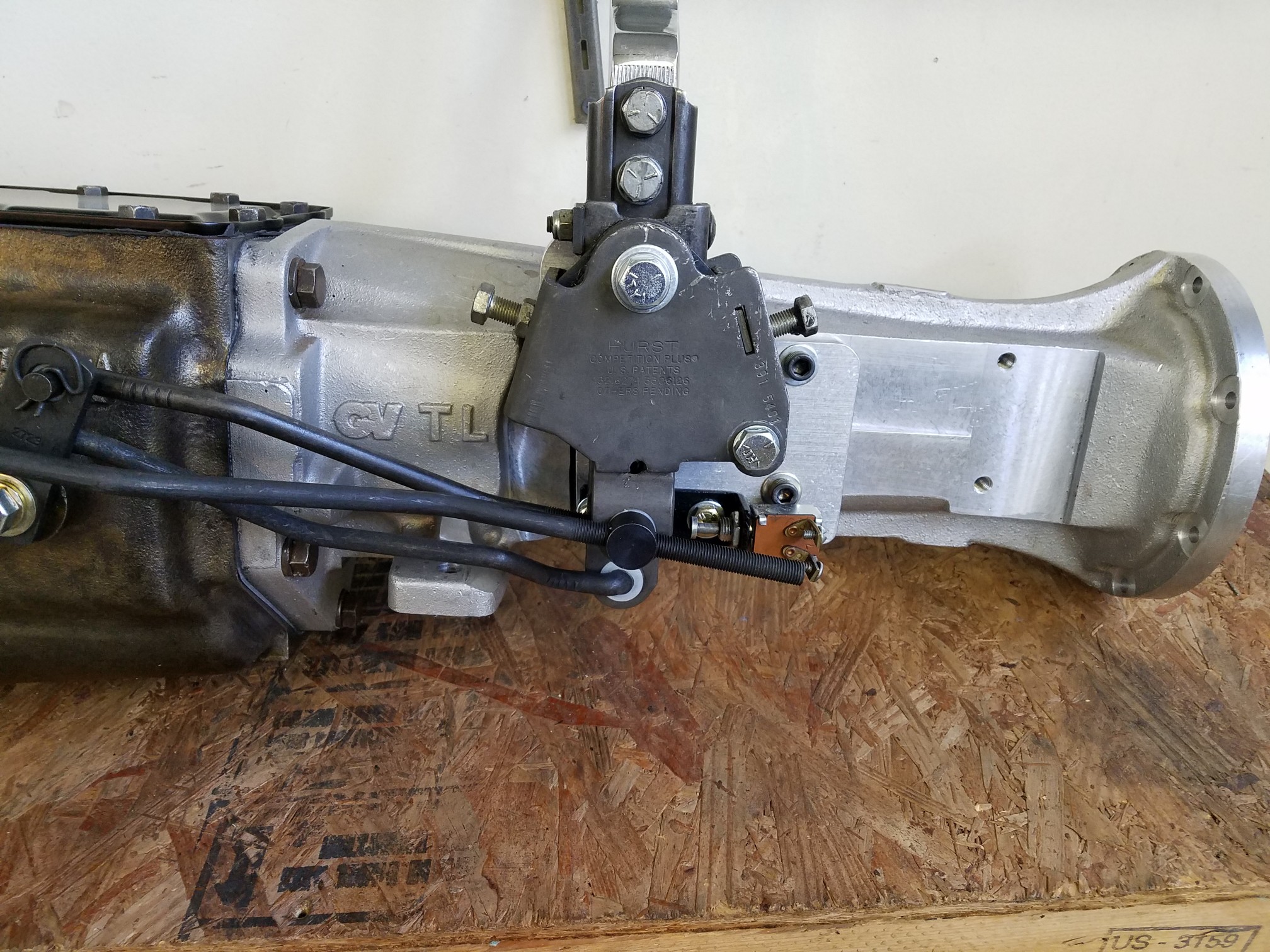

In the first picture above, you can see that I have all of the linkage installed and adjusted. While the shifter is the same one that was on the T-10, the linkage is all new as the rods are all different for the Toploader than those for the T-10. In the picture above of the adapter plate, you can see a small hole I've drilled in it towards the bottom center of it. That is one of two new holes I had to drill in it and tap for our reverse light switch bracket.

Here is a look at the shifter installed with both bolts, the reverse light switch and bracket installed, all the linkage adjusted, and the stops adjusted....

And here is a shot a little closer in....

Believe it or not, I spent an entire Saturday fitting and adjusting the shifter to the Toploader and GearVendors tailhousing. Still, at the end of the day that issue had been overcome.

The way I remember it, I went back over there on Sunday and we made the first attempt to stab the Toploader. It went in pretty easy. We then tried to jack it up and get the crossmember installed and found that the flange at the end of the tailhousing where the GearVendors unit mounts to it was hard against the transmission tunnel. That flange falls right behind a floor pan brace. We had to trim a flange off of that brace and had to hammer it and the tunnel some for clearance. This is the best picture I have. The unit is stabbed on in this picture and the crossmember is installed. You can see primer above that flange where we did some hammering and can see that we have clearance to the flange in this shot. You can also see that the GearVendors unit itself is hard against the tunnel....

In this shot, you can see the unit against the tunnel a little better....

We probably had the GearVendors unit, the Toploader and the crossmember in and out dozen times that Sunday. At the end of the day we were close but not quite there on clearance. The next weekend I went over and we did the final massaging of the tunnel and then pulled everything out again so we could clean up the floor pan and paint the beat up areas. It wasn't anything fancy, just a little primer and gloss black paint from a rattle can.

The next hurdle to overcome was modifying the transmission mount and the crossmember. The GearVendors tailhousing is technically for a Mustang. Consequently the distance between the bolt holes on the transmission mounting flange is smaller than that of the Galaxie. At first I thought, no sweat. We'll just get a Mustang transmission mount. Unfortunately the Mustang uses a totally different type of mounting system than the Galaxie. The Galaxie uses a metal strap that is inside the crossmember and captures a rubber mount between the transmission and the crossmember. Here is a look....

In the picture above, we've already cut the metal U shaped strap in half, cut away the extra length, and welded it back together....

We've also cut the rubber mount in half and cut away some of the material in each half to narrow it and make it fit. We've also trimmed the openings in the crossmember to make the narrowed mount and U shaped strap fit...

Here's a look at the modified setup...

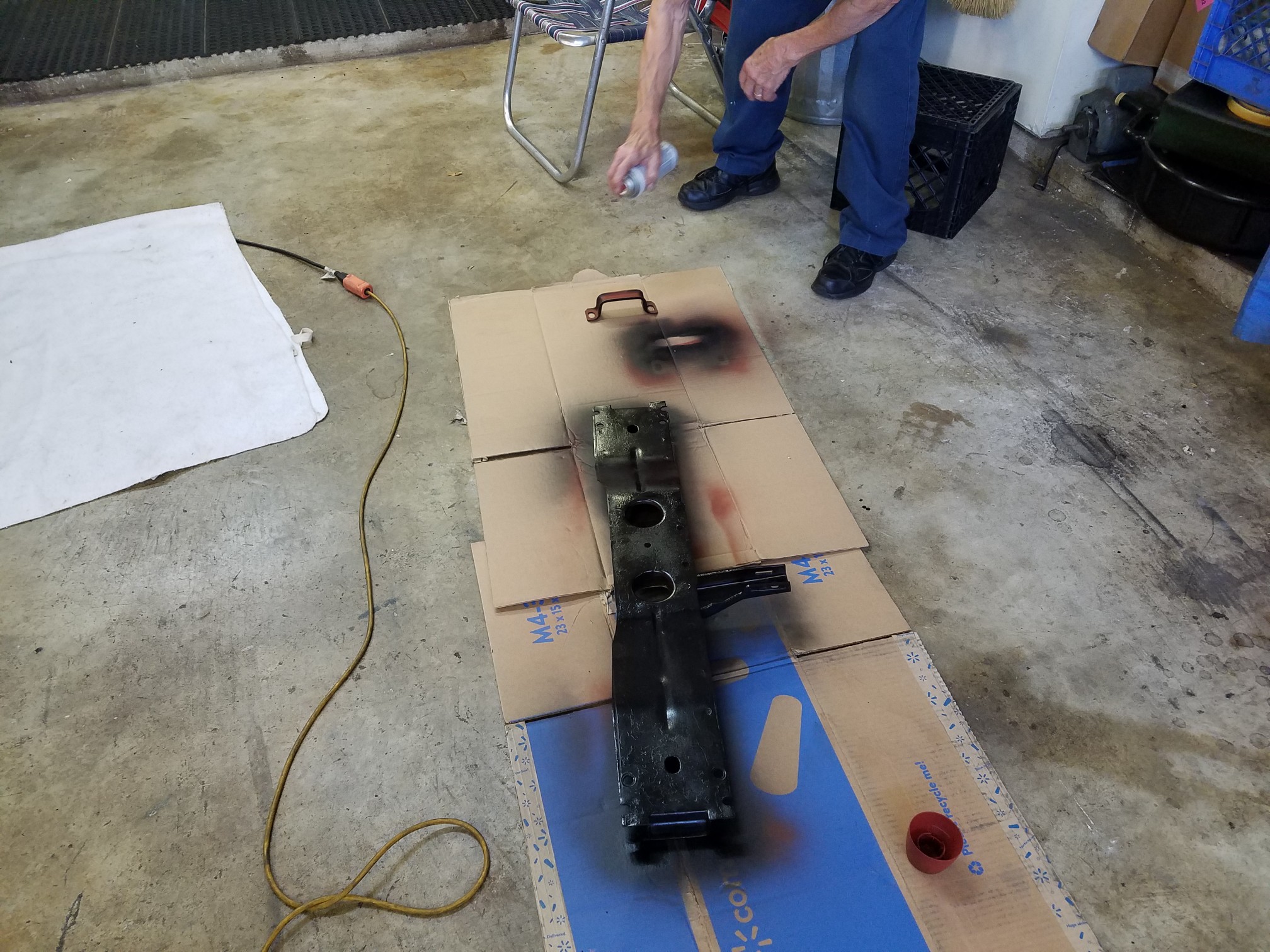

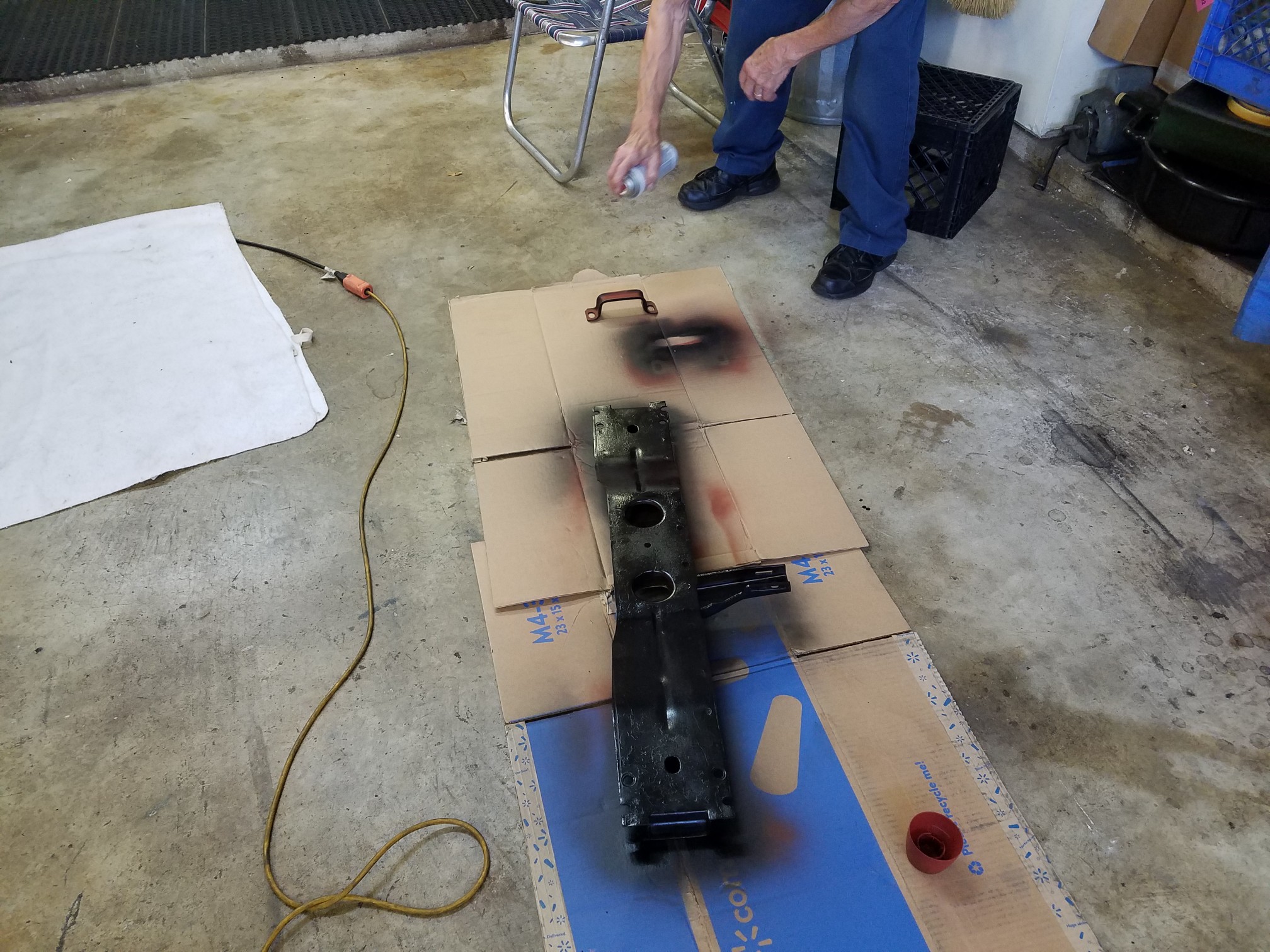

One the slicing and dicing was complete, it was time for a new coat of paint. Dad had painted the crossmember many years ago when the frame was out of the car and the rest of the frame was cleaned and painted. It was pretty dirty though from some nagging leaks, most of which have been resolved at this point. Dad cleaned the crossmember up with mineral spirits and it took most of the paint off but left the primer. Here it is getting a new coat...

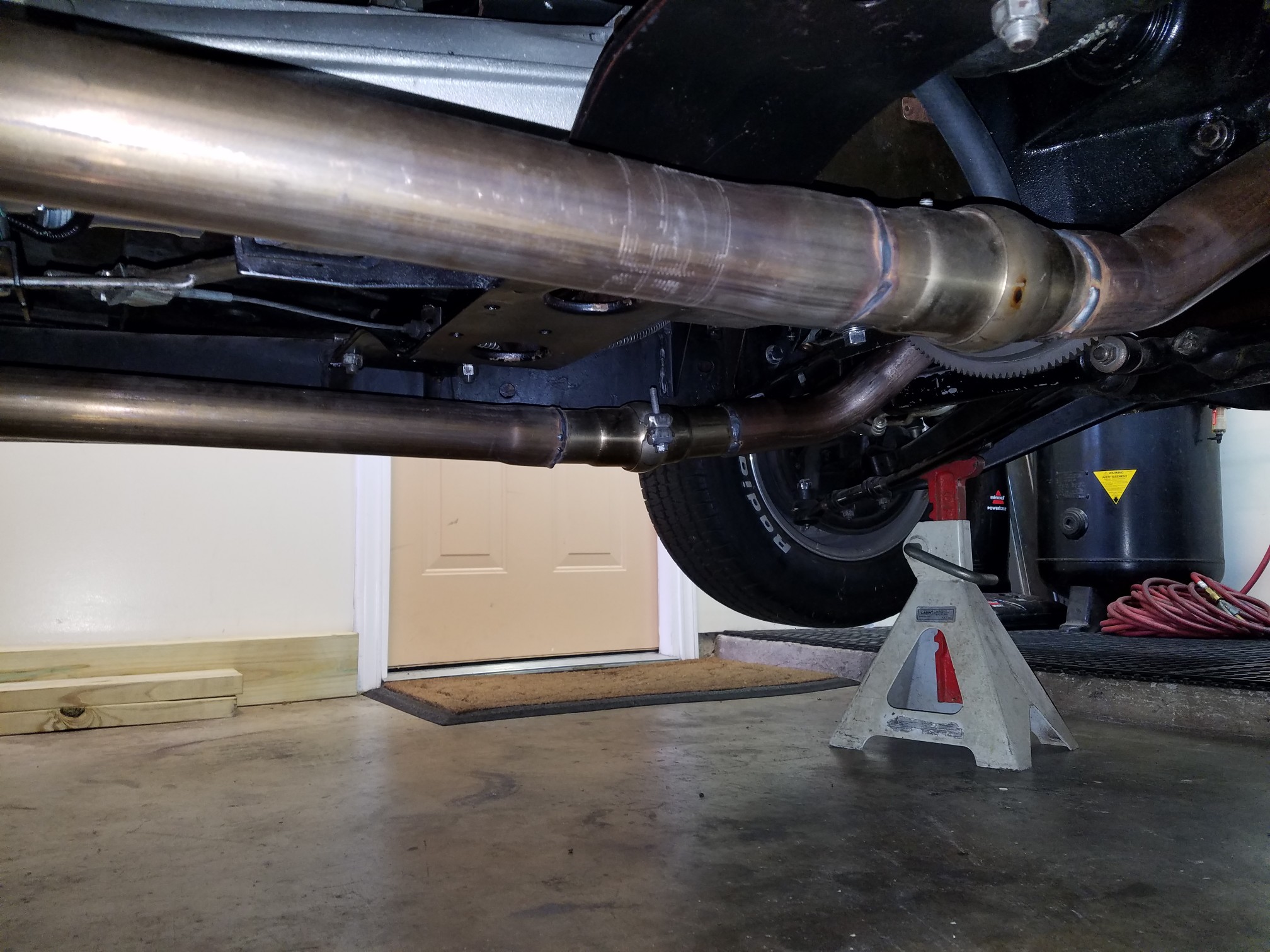

Next everything went back in. It wasn't without difficulty. The bolt holes in the Galaxie tailhousing for the transmission mount are fine thread. The bolt holes in the GearVendors housing were coarse. I didn't catch it (I didn't even think of it) so you can imaging the unwanted consequences. Fixing both bolt holes with a Helicoil ate us alive for the better part of day. I'm guessing another day was spent on getting the speedometer drive squared away. I had to pull the drive out of the GearVendors unit and replace the driven gear since we've changed rear tire size on the car since the GearVendors kit was ordered five years ago. There was also some time spent running the wiring for the speed sensor and the shift solenoid through the tunnel. I also had to make a small bracket to guide the emergency brake linkage and to keep it from rubbing on the bottom of the GearVendors unit. Still, here is the unit in, with the transmission bolted down to the crossmember and with everything hooked up...

A look from the other side. You can see the new wiring coming through a new grommet in the side of the tunnel...

At that point we measured for the driveshaft and ordered it. You may notice in the pictures above that we have the passenger side exhaust reinstalled but the driver's side is still off. Another difference between the GearVendors tailhousing and the Galaxie tailhousing is the distance between the transmission output shaft and the mount flange for the transmission mount. The distance is smaller on the GearVendors tailhousing by roughly 7/8". In other words, when the transmission is bolted to the crossmember, the end of the output shaft is lower with respect to the floorboard than it was with the Galaxie tailhousing. An unfortunate consequence of this is that the driver's side exhaust downpipe is now hard against the slave cylinder for the power steering. We were never that worried about being able to modify the pipe to correct that but we wanted to wait until we had the driveshaft bolted in the car and had checked the driveline angles before we did it. We didn't want to modify the pipe only to find that the driveline angles were unacceptable and we were going to have to jack the transmission up and put a spacer (like 7/8" thick) between it and the mount. If that were the case, the pipe wouldn't need modified but tunnel surgery to make room for the GearVendors unit would be necessary.

We got the new driveshaft on Tuesday and I went over to Dad's with it Tuesday night. We installed the shaft and checked the driveline angles. I'm pleased to report they both checked fine. We have 3-1/2° in the front and 4-1/2° in the back. I didn't snap any pics of the driveshaft installed in the car but I'll get some this weekend. The next hurdle to overcome is modifying the driver's side exhaust downpipe to clear the power steering slave cylinder. To that end I ordered a 2 pound spool of 0.023" stainless steel MIG wire. I also ordered a 2-1/2" mandrel bent J-bend in 409 stainless steel as a practice piece and possibly as material. Last night, on the way home from work, I picked up one of these...

For those unfamiliar, that is Tri-Mix, which is the gas you need for MIG welding stainless steel. So, at this point I have everything I need except for the talent to weld stainless exhaust. I hope to formulate a plan to modify the downpipe on Dad's car and get some practice in this weekend. I sprang for the materials to be able to do this work myself since there will be some fabrication needed when the exhaust goes on my car and the Y-pipe on my truck needs some modification to fit properly. I'm sick of hearing it bang on the transmission crossmember. My buddy who helped me with some welding pointers and suggestions when I modified the crossmember for my car will likely come over and help me again. He's pretty excited that I geared up to weld stainless. We'll see how it goes. That's it for now gents. There is other progress to report that was made while we were waiting for the new driveshaft from Denny's but I'll put that in another update. I need to get some more pictures anyway. I should get those this weekend and get another update up next week. Until then, thanks for following along.

Best,

Jared