A few Saturdays back, Sean got the Camaro out and Dad had the Galaxie out as usual for the ride to breakfast. I got to ride in both the same morning. It was a good day. I got some good pictures.....

Dad had cleaned up and detailed the wheels the week before and it really shows in those pictures.

After breakfast, we did some measuring of the operating angles of the universal joints...

So we have about a 0.5° operating angle at the back and about a 4° operating angle at the front. We were considering putting in 2° leaf spring shims to bring the pinion closer to parallel with the output shaft but that would increase the operating angle at the front joint to somewhere close to 6°. To remind everyone, the powerteam was dropped substantially at the transmission mount to fit the GearVendors Overdrive unit in the tunnel without substantial tunnel mods. The car doesn't vibrate at any speed but we were looking at the driveline angles because the clutch has a tendency to chatter/shudder in reverse. To optimize the driveline angles, the powerteam really needs to come back up at the transmission mount but that would require removing most of the interior and performing surgery on the tunnel. It can be done but will be a huge project.

A year or two back Dad got some Traction Master traction bars from his wife for Christmas.....

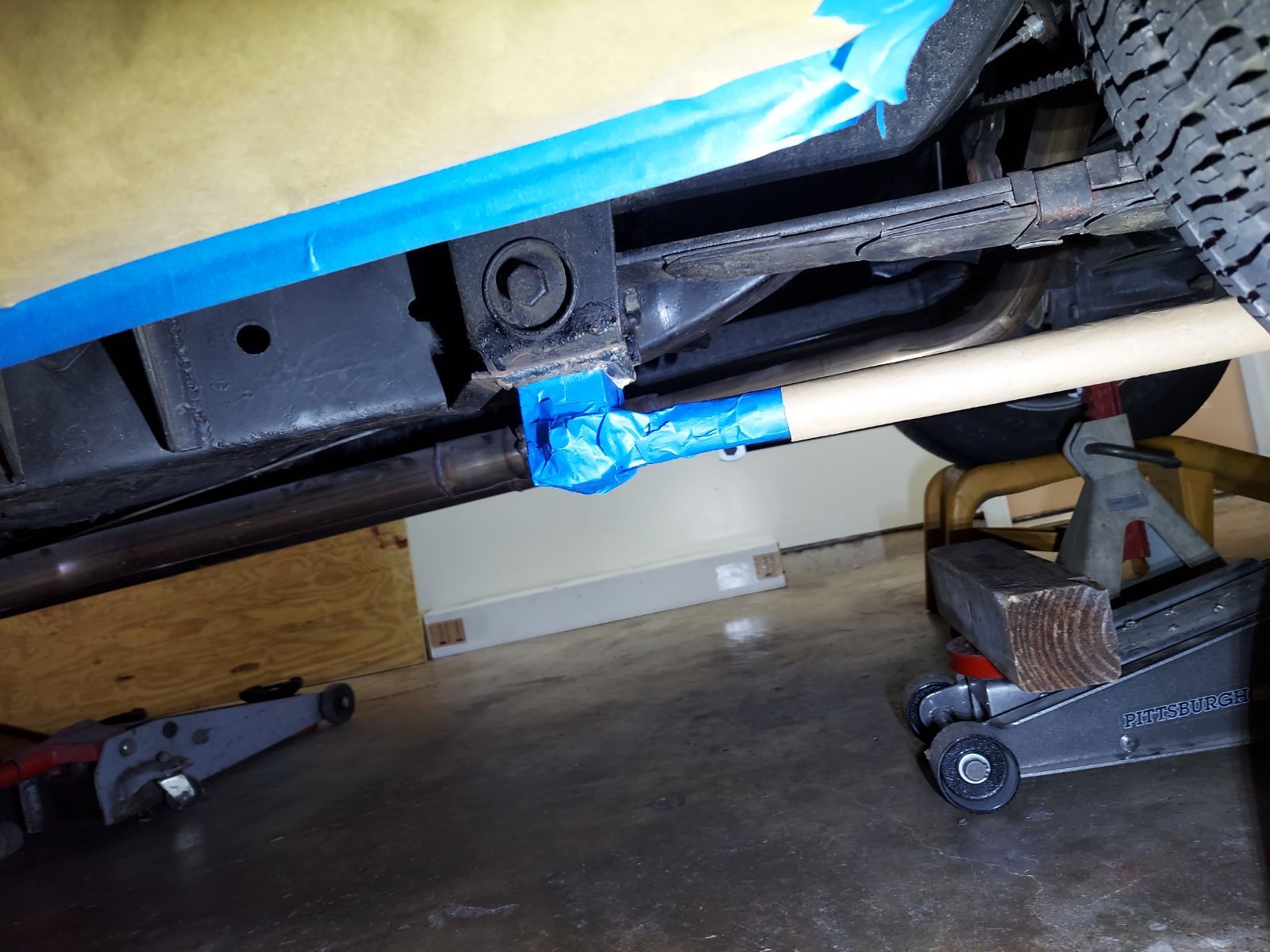

We decided to move forward with installing these and see if they helped with the clutch in reverse or not. Last weekend I went to Dad's and we got the car back up on ramps and installed the bars at the rear. We cleaned up the welding surfaces at the front mounts and got them clamped up....

initially, the plan was for me to do the welding at the front but that was going to take some time as I was going to want to get some material to practice on and I was going to need to practice. Also, our 110V welder was marginal for this job since the steel on the car is 5/16" and the steel on the traction bar brackets is 11/32". I figured we could chamfer and pre-heat and get by but in the interest of just getting it done, we got a professional welder out there today. It worked out great. The guy is a life long friend of a friend of mine. He's a car guy and is a welder by trade. He welds pipeline casing for a living. He showed up with his truck with his welding rig on it at Dad's and knocked it out. He stick welded it. I assure you, it's not about to fall off......

Dad is going to clean up the area and touch up the paint and then he'll get the car down on off the ramps. Then we'll see how the car is with the bars and take it from there. I guess that's it for now friends.