Engine Miss.. rounded lobes?

- Thread starter MrSony

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Fuel system seems fine to me as well. Seems to get good fuel pressure at all RPM, accel. pump works, two nice streams of fuel into the primaries. The carb is all new rebuilt from Everyday Performance (I fixed that this morning actually, the one I dicked up by dropping it), and it runs really well other than the miss. It happens most at idle when the engine is cold, and almost goes away as it warms up. Almost non existent at speed, but when at a stop in gear bubbububububububbbbbbububububbbbbubububbbbububbbb and the motor shakes something fierce. Tomorrow I'll try and get a video of the motor running and doing the Harlem Shake.

get a air/fuel mixture gauge so you won't need to guess

hmmm... after looking up that cam from the link you posted, non-adjustable valve-train comes to mind. pardon my suggestion of an improperly set valve.the cam's base circle may not be wiped at all, so ticking noise may not be present. if no access to IR heat checker, your next best bet is as simple as a "t'd" vacuum line to a vacuum gauge. uneven breathing through the intake tract will show its ugly head that way. i can't make a face like your sound description, but if the vacuum gauge needle bounces at roughly the same intervals as your popping noises, you'll know then for sure if valvetrain is the culprit. fuel, air and spark recipe hasn't changed in a long time. bouncing needle is the result of several conditions. an improperly set valve may be the easiest cure... don't throw the baby out with the bath water! check easy things first. good luck.

now having said that...how many miles are on those heads/guides? is there any chance of varnish deposits further up the valve's stem causing a valve to hang up? much like an older lifter needs coaxing in order to remove it from its bore?

how consistent is that misfiring(appearing) condition? i just put together an ignition system where the ignition box could trigger a timing light with a spark plug leaning against a grounded engine part, but could not get the same result from that very same plug wire on the spark plug that was in the hole. i blamed that on a faulty ignition box, then i ripped the boot off another plug wire... then i went for my clamp-on meter to check the brand new plug wires and infinite ohms!!! checked on the previously ran accel wires and they were bad too WTF?!?!... so then my google friend tells me that my clamp -on meter specs say that my "O.L."(Outside of Limit) value read from those THREE plug wires was likely okay, since my meter can only verify resistance up to 400 ohms. what a chump eh? don't throw the baby out with the bath water. something simple is being allowed to occur... you haven't tried the right test yet.

as soon as i turned the starter over for mine, the timing light blinked a few times... then started flashing for every revolution. i'd have never thought plug wires needed run-in time, but it sure appears that way.

keep digging! i hope it's a simple remedy for ya...just remember to breathe normally through all this k

Last edited:

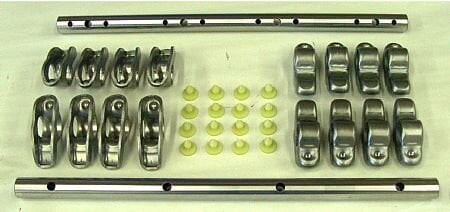

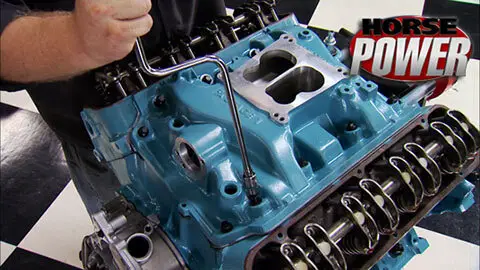

How could a valve be improperly set? There is no way to set them. I had the heads gone through; mildly surfaced to even up any irregularities, three angle valve job, two valves replaced, and all the valve guides checked for wear and replaced where necessary. I installed a different stem seal than the old fashioned umbrella type that that particular shop used, and I did the thing where you take a rubber mallet and bop the tip of the valve to seat the keepers and what not. All valves moved freely. 1st picture is of factory replacement rocker arms and shaft, along with the plastic nylon buttons. I inspected my old shafts and rockers for any wear, or cracks. Everything checked out fine. Second picture is of a 350 Buick HorsepowerTV built a while back with the rockers on the engine. There is no way to adjust them.hmmm... after looking up that cam from the link you posted, non-adjustable valve-train comes to mind. pardon my suggestion of an improperly set valve.

EDIT: The mild surfacing was more of a grazing, just to clean up the surface. I did not need to purchase new, shorter pushrods to compensate. Intake bolted on normally.

Attachments

Starting with the obvious questions, cuz no one seems to have asked;

What exactly are you seeing that makes you think it's missing?

At what rpm are you idling where you are getting this much shake with that cam?

Do you have a new harmonic balancer on there? What kind of flexplate or flywheel are you using?

Do you have a vacuum gauge and oil pressure gauge and what are you seeing at idle and at the rpm you suspect a misfire?

What exactly are you seeing that makes you think it's missing?

At what rpm are you idling where you are getting this much shake with that cam?

Do you have a new harmonic balancer on there? What kind of flexplate or flywheel are you using?

Do you have a vacuum gauge and oil pressure gauge and what are you seeing at idle and at the rpm you suspect a misfire?

I think you should solve your carb problem you posted in another thread you just started and check for a vaccum leak, then see if you still have a miss....

Starting with the obvious questions, cuz no one seems to have asked;

What exactly are you seeing that makes you think it's missing?

At what rpm are you idling where you are getting this much shake with that cam?

Do you have a new harmonic balancer on there? What kind of flexplate or flywheel are you using?

Do you have a vacuum gauge and oil pressure gauge and what are you seeing at idle and at the rpm you suspect a misfire?

1. The engine is physically shaking and sounds like its missing, or firing twice on two or more cylinders.

2. Idle mostly. 800rpm in park when hot, 600 in gear when hot, goes away above 1500 or so RPM. It shakes the whole car, it's not just a little wiggle. It shakes like a motor that's idling at like 500rpm or about to die, but other than the shaking and the probable missing it runs near perfect at all rpm.

3. Yes, I have a stock flexplate and new harmonic balancer from TA Performance. yes, I know that's not really a good ide. One would think the shaking would be just as prevalent at high rpm as it is at idle if it's a balance problem.

4. No vacuum gauge, but I have a mechanical oil pressure gauge. When cold, it reads 50psi at idle, 20 hot at idle. At rpms above 2500, it stays pegged at 50-60. I also have an adjustable oil pressure regulator.

I've checked for vacuum leaks. I can't find any around the intake, or carb or carb mounting pad on the intake. If i had a vacuum leak, I think it would idle way higher than the 800rpm it does.I think you should solve your carb problem you posted in another thread you just started and check for a vaccum leak, then see if you still have a miss....

I've checked for vacuum leaks. I can't find any around the intake, or carb or carb mounting pad on the intake. If i had a vacuum leak, I think it would idle way higher than the 800rpm it does.

How did you check for vaccum leaks?, I use carb cleaner....

Same here. I emptied like two cans. I even used the straw and sprayed at the primary throttle shafts, nothing. No rise in RPM. Sprayed around the base of the carb, around the carb where the airhorn connects to the main body, at all the vacuum fittings, all around the intake, nothing.How did you check for vaccum leaks?, I use carb cleaner....

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 152

- Replies

- 0

- Views

- 175

- Replies

- 0

- Views

- 90

- Replies

- 23

- Views

- 623

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.