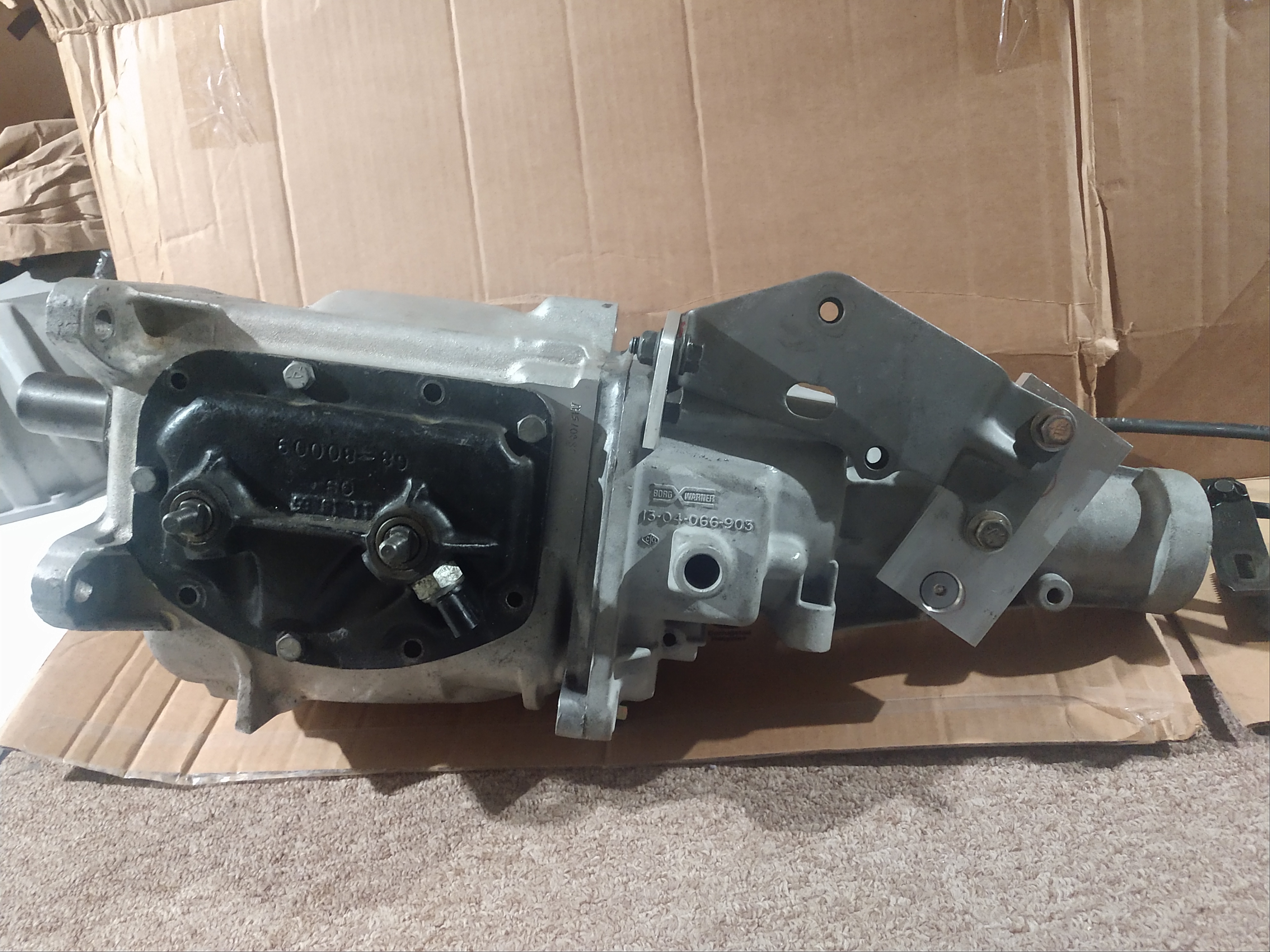

I finally have my car driving and can say that the swap was a complete success. I now have a very factory looking Super T10 swap into my 78 4 speed Malibu.

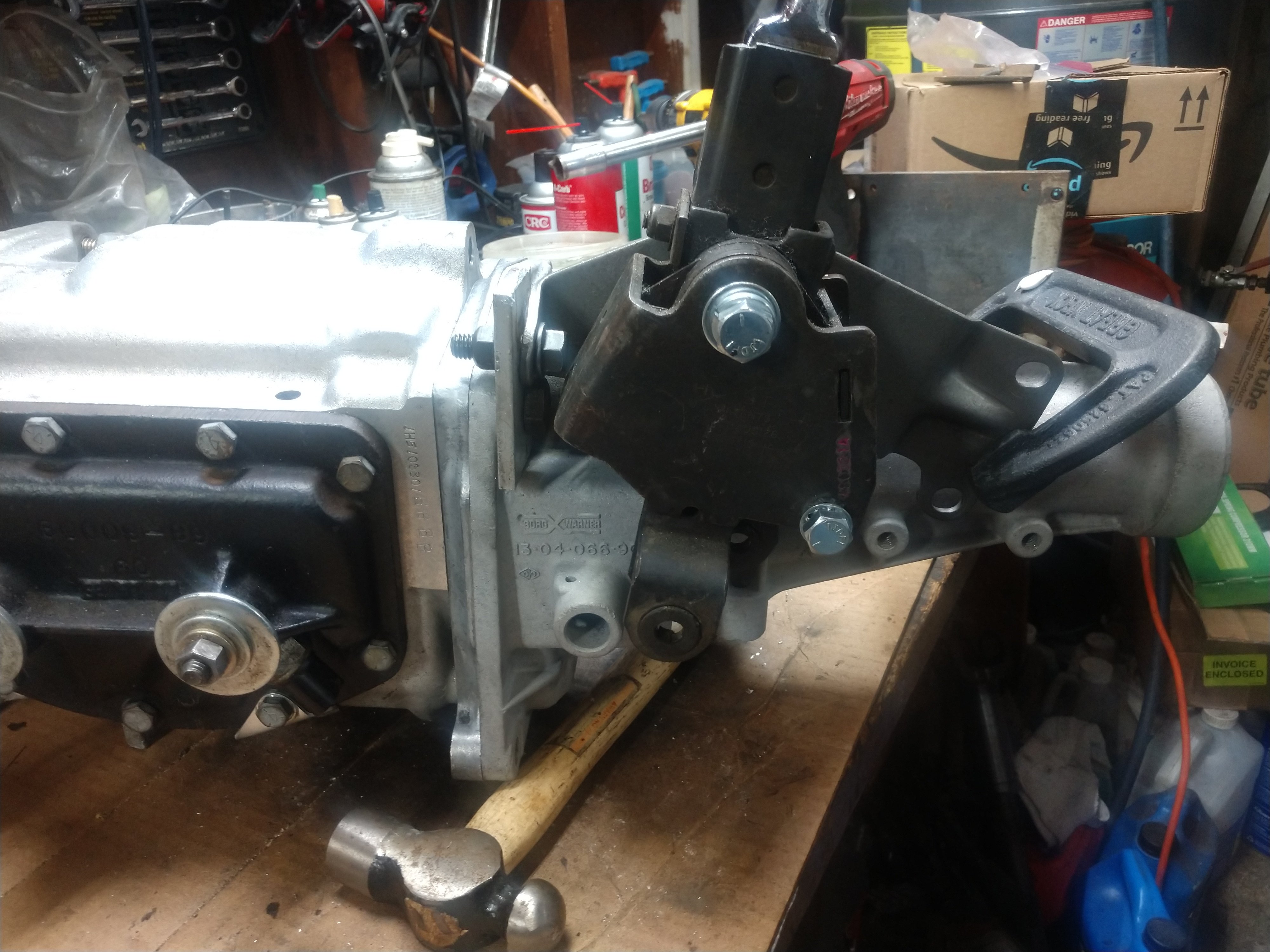

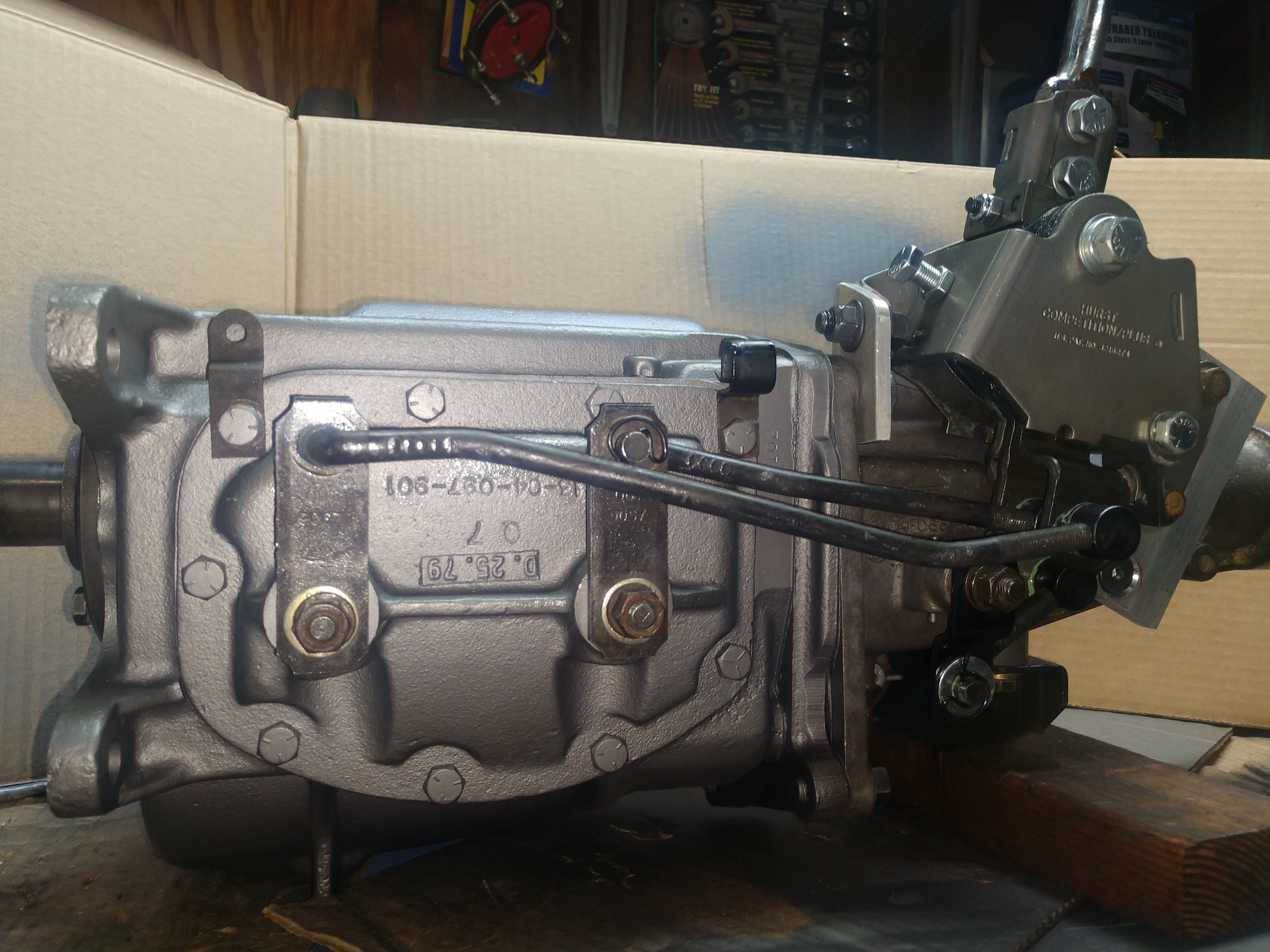

I decided when I swapped out the original 305 that I would also replace the Saginaw 4 speed before I broke it. In its place is a home built nodular iron 2.88 first gear Super T10.

I went to the trouble because I wanted it to look stock which meant stock looking shifter in the stock location and I did not want to loose my original console.

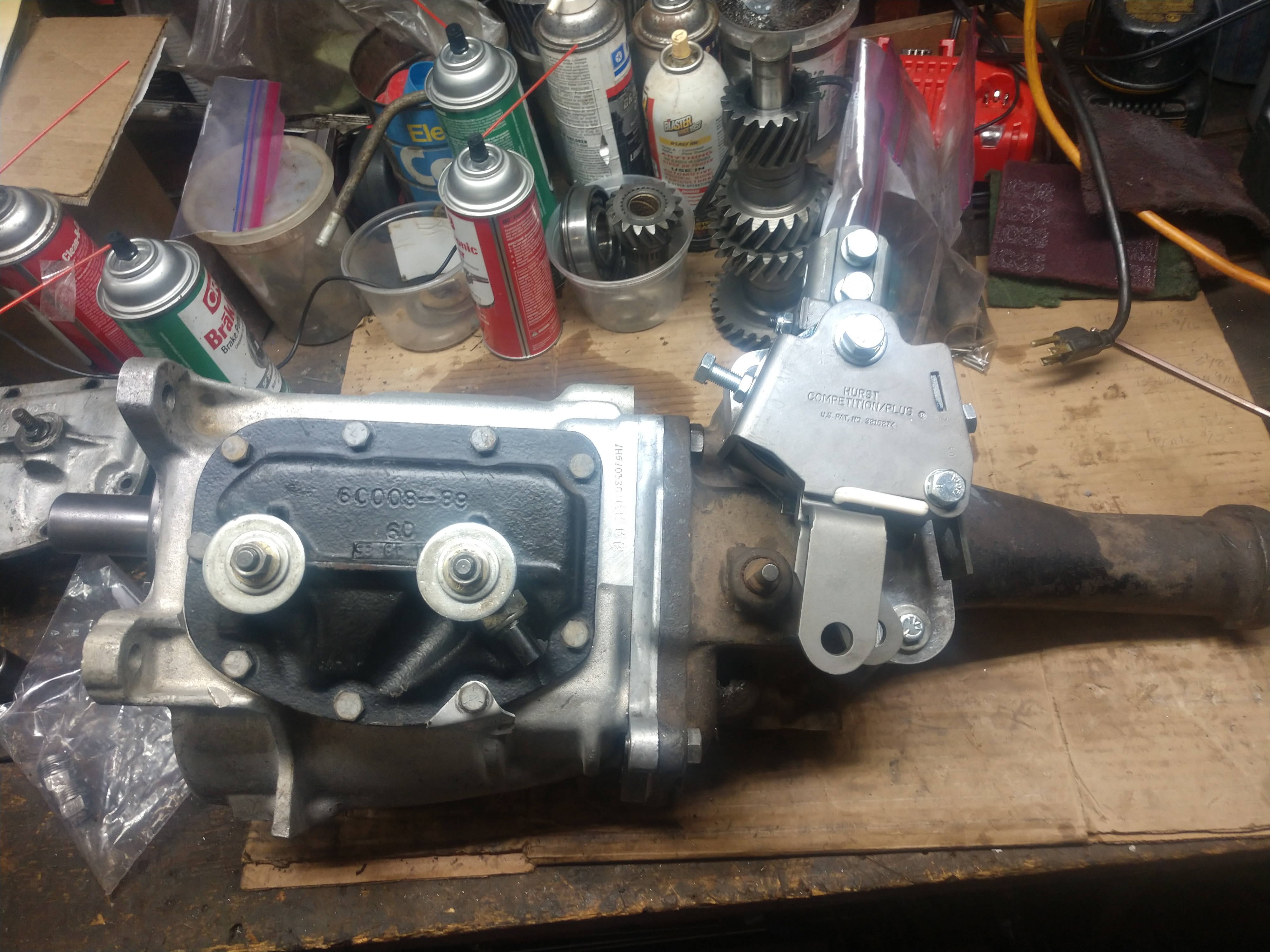

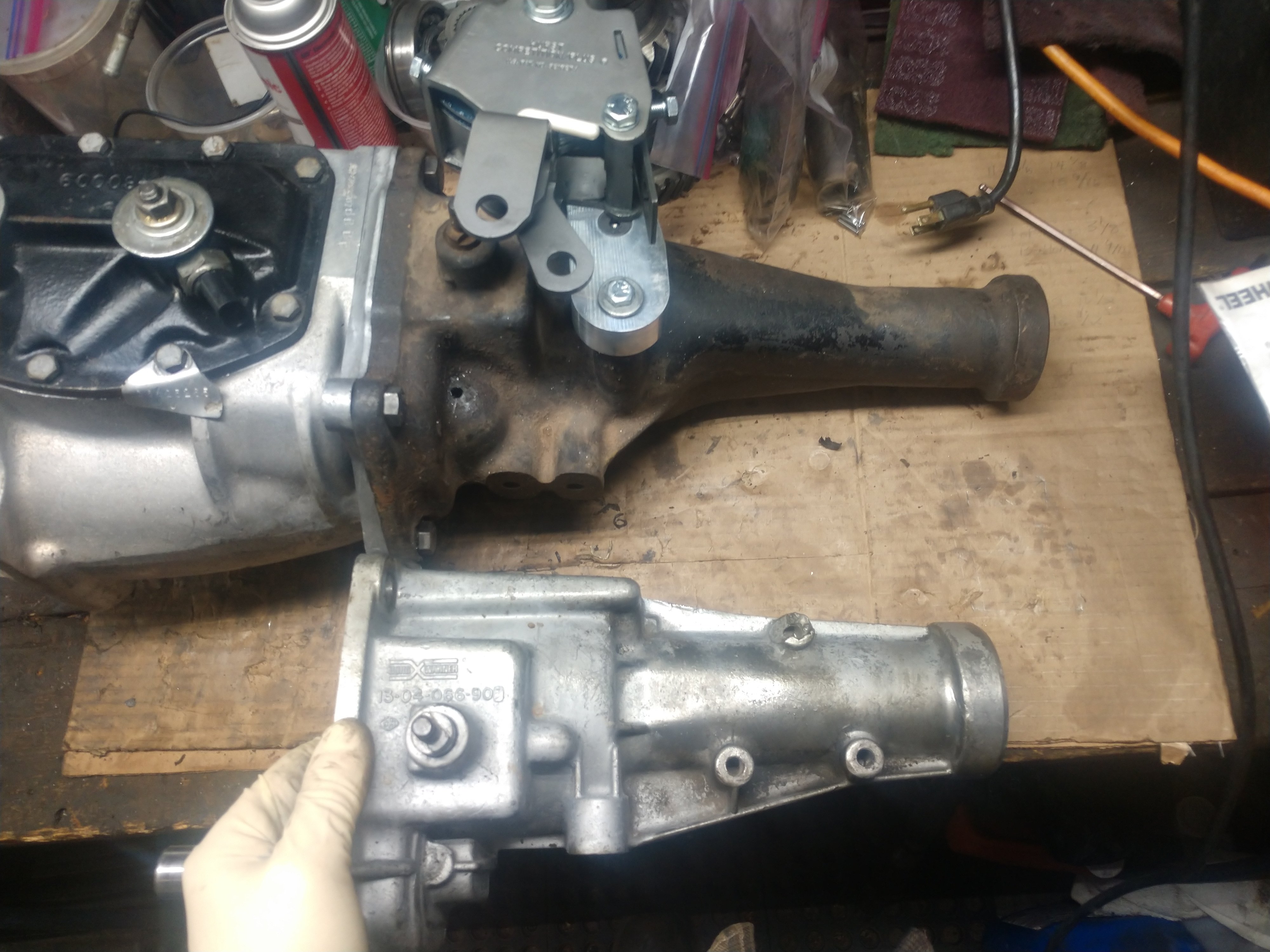

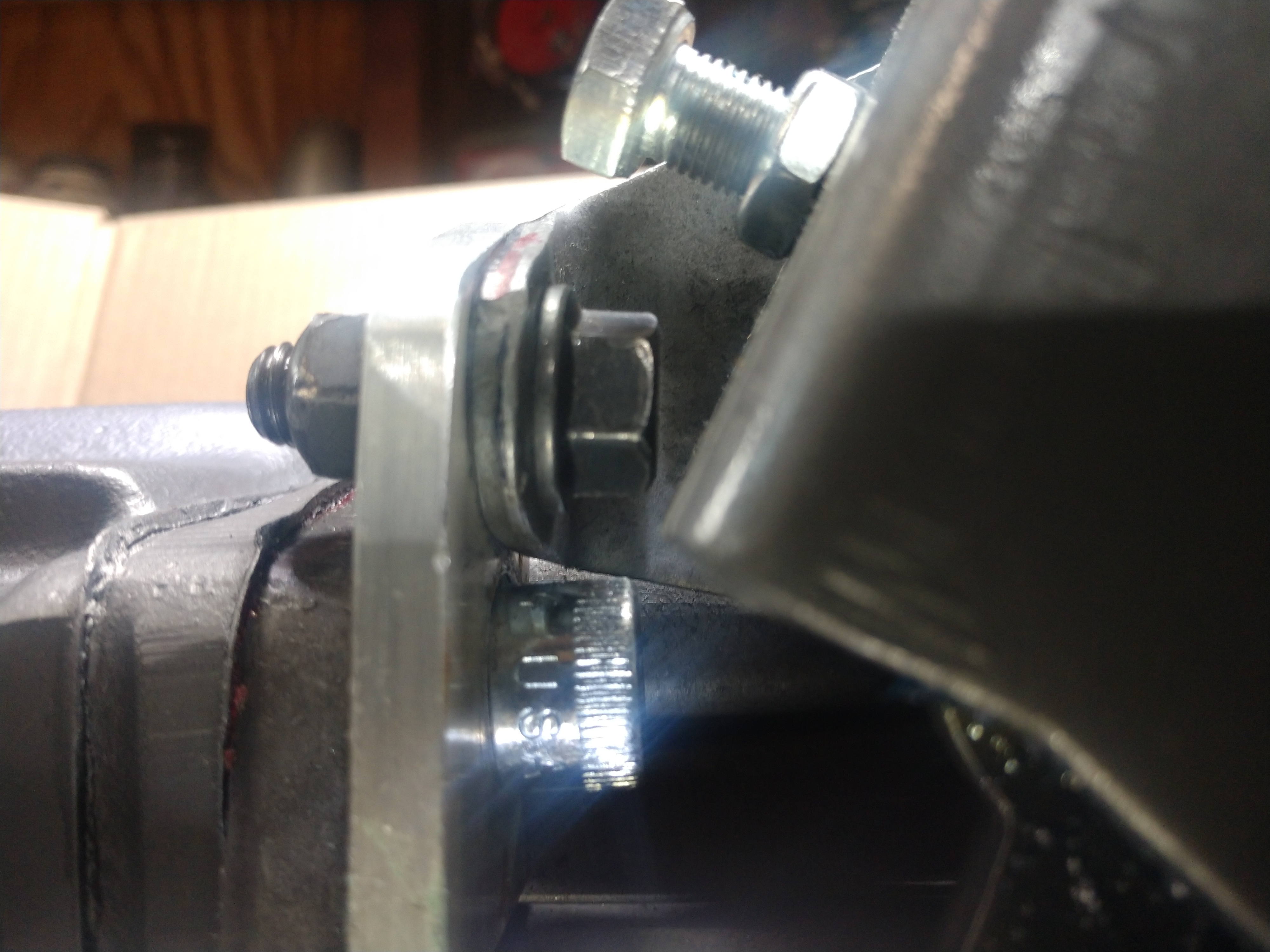

The original 78-81 A body 3 and 4 speeds had a shifter location that was not in the typical location as most floor shifted GM 3 and 4 speed cars used. The shifter is mounted to the front of the tail because of the location of the seats in relation to the transmission. The Saginaw transmissions make this possible as reverse is located inside the main case where the T10 and Muncie have it located inside the tail.

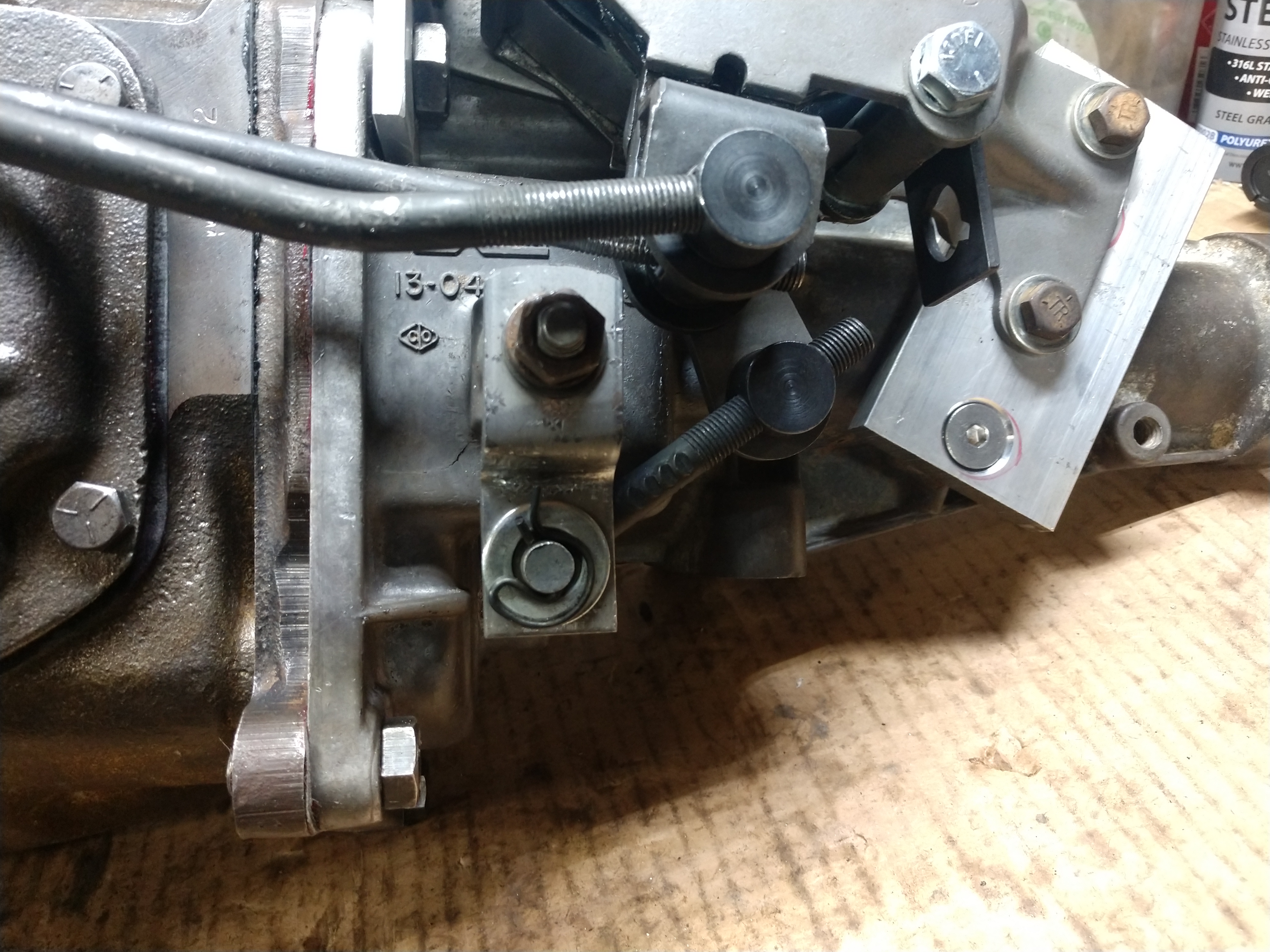

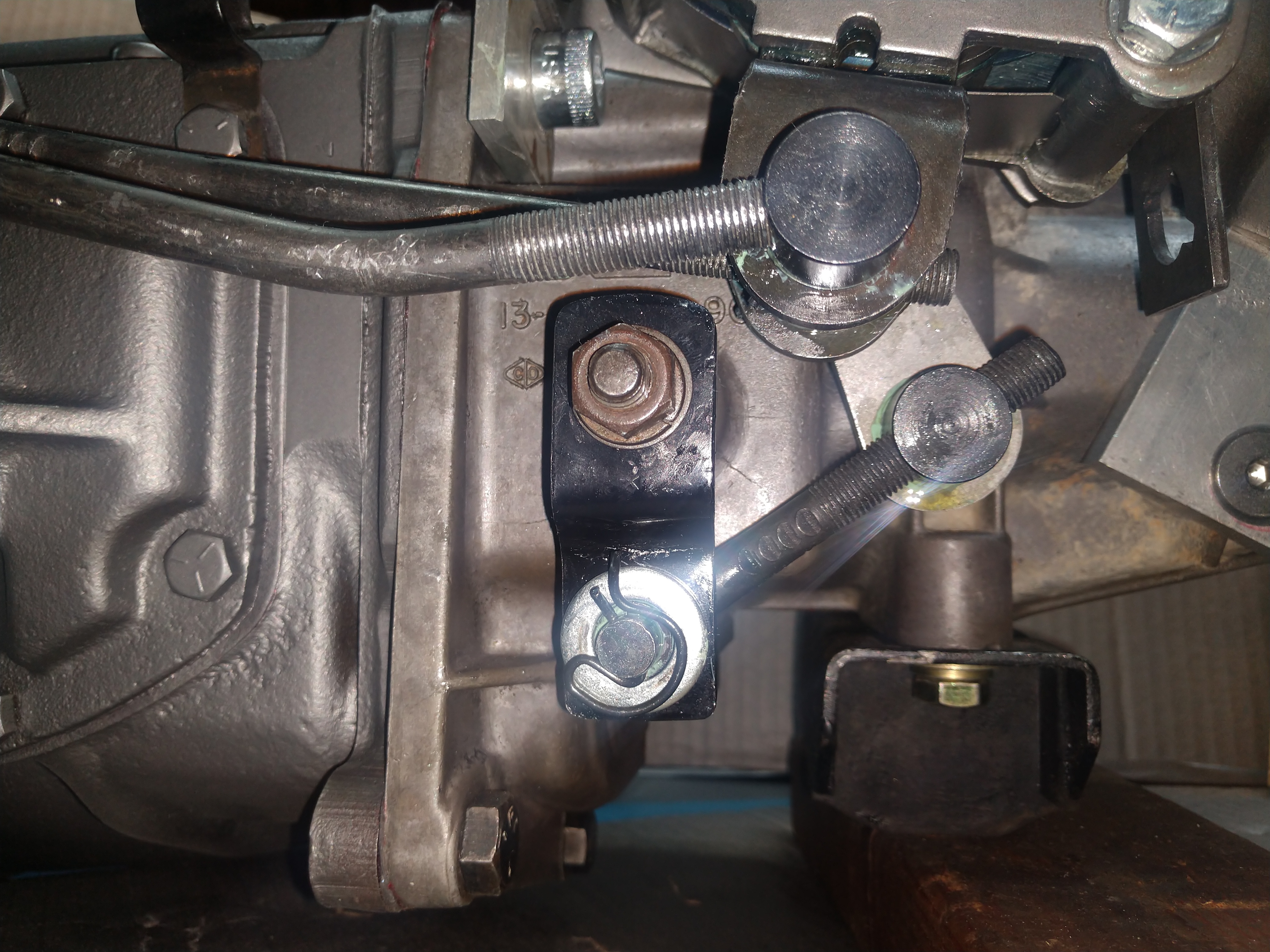

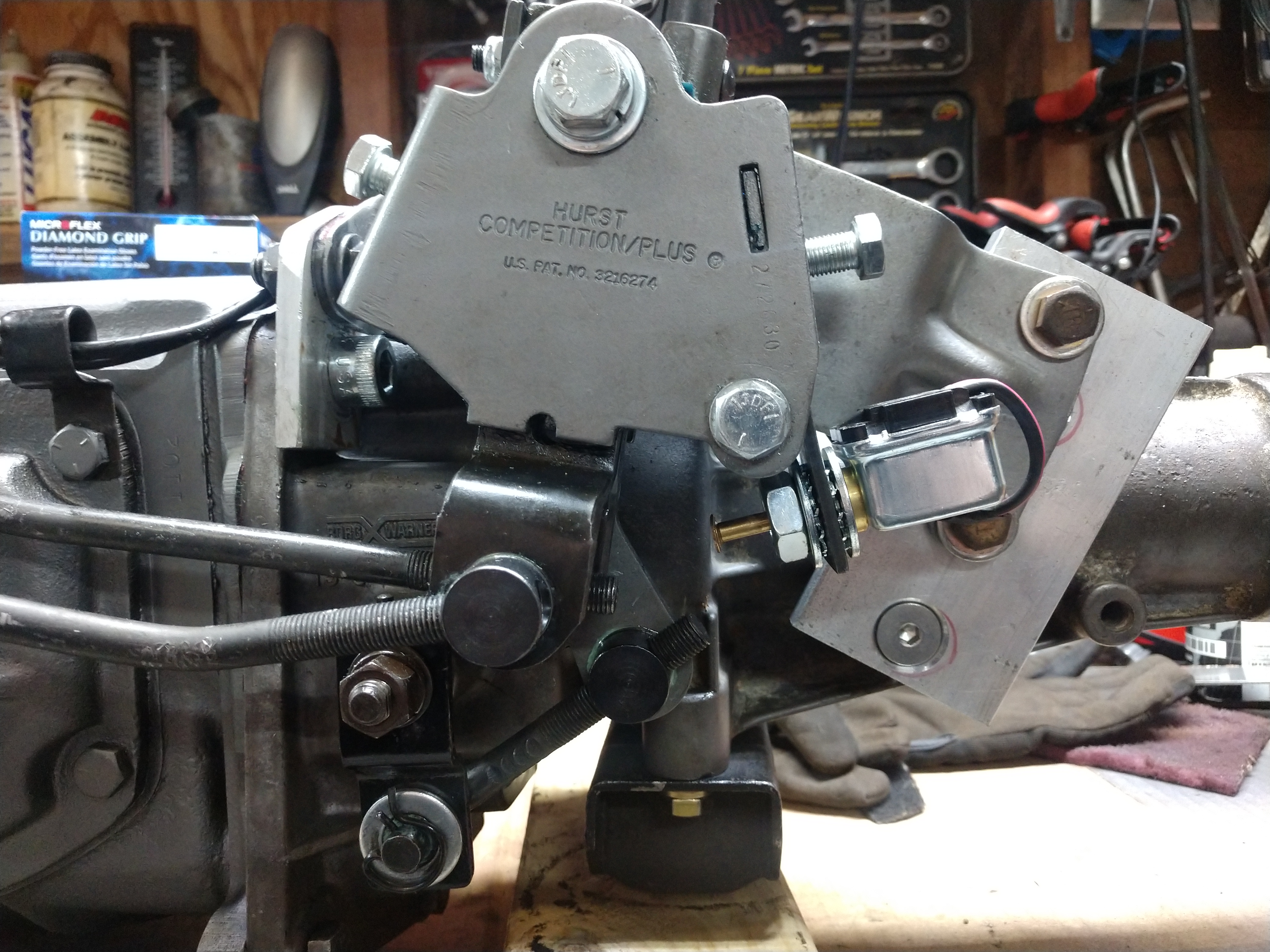

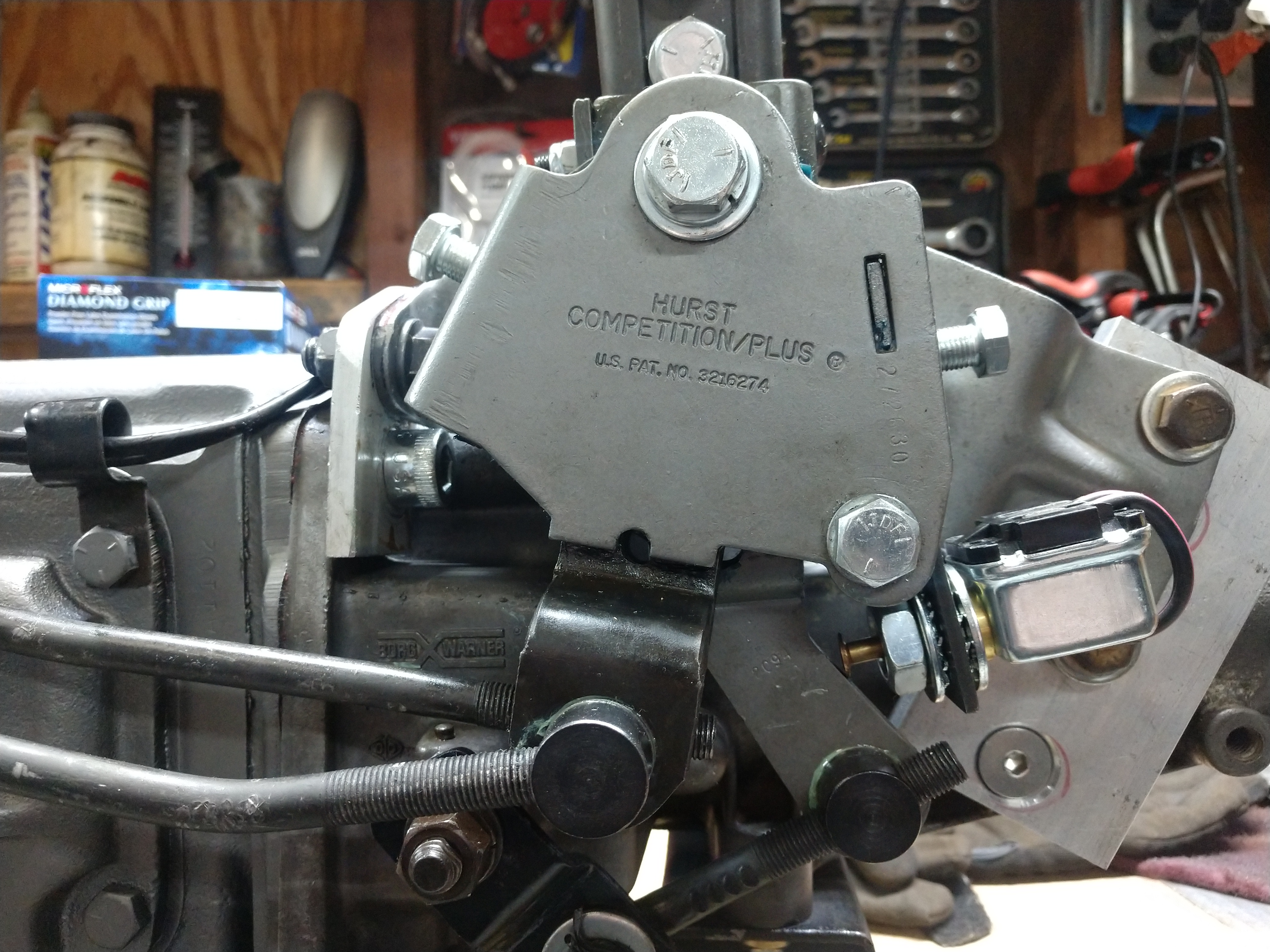

I started researching what strong transmissions would permit mounting the shifter on the front of the tail. I stumbled onto the early Ford Falcon which used a T10 transmission. I purchased a Falcon Hurst Competition plus shifter and complete mounting and linkage kit. I also was able to snag a Falcon specific tail housing to experiment with. First I will post what the Saginaw 4 speed looks like with the stock shifter.

I decided when I swapped out the original 305 that I would also replace the Saginaw 4 speed before I broke it. In its place is a home built nodular iron 2.88 first gear Super T10.

I went to the trouble because I wanted it to look stock which meant stock looking shifter in the stock location and I did not want to loose my original console.

The original 78-81 A body 3 and 4 speeds had a shifter location that was not in the typical location as most floor shifted GM 3 and 4 speed cars used. The shifter is mounted to the front of the tail because of the location of the seats in relation to the transmission. The Saginaw transmissions make this possible as reverse is located inside the main case where the T10 and Muncie have it located inside the tail.

I started researching what strong transmissions would permit mounting the shifter on the front of the tail. I stumbled onto the early Ford Falcon which used a T10 transmission. I purchased a Falcon Hurst Competition plus shifter and complete mounting and linkage kit. I also was able to snag a Falcon specific tail housing to experiment with. First I will post what the Saginaw 4 speed looks like with the stock shifter.

Attachments

Last edited: