I spent some more time on the car yesterday. Up first, the hood. I had to take it back off so I could cut off a few of the support ribs on the underside, thus making clearance for my 14" drop base air cleaner.

I didn't begin with a fully-charged battery, so it didn't surprise me when I had to stop at the ~80% mark for a recharge.

After some more juice, the last little bit came off with no difficulty. I then ground off the edges a bit, hit the appropriate spots with some touch-up paint, and I was good to go.

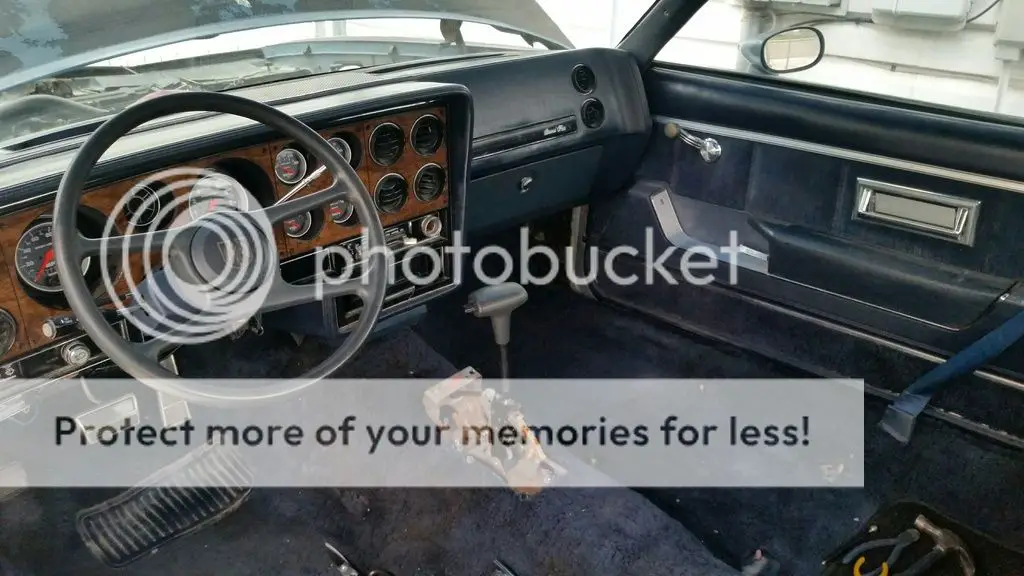

Next goal: install the junkyard floor shifter. I had already cut a rectangular hole in the carpet and made some marks on the tunnel, so it was just a matter of drilling holes and bolting the thing in place. I had been putting the off because my friend Mike had offered to use his nutsert tool so we could complete this process entirely from above... but since he wasn't here, I crawled under to take a closer look. Hmm, maybe I'll have enough clearance for standard bolts and nuts. So I grabbed my drill and went to town. After the holes were made, I was able to use a magnet to help hold two of the bolts in place after I pushed them in from below, then I got back inside and installed the washers and nuts. Nice.

The forward holes would not be so easy. Due to such small clearance between the trans and the tunnel, the bolt was too long to be inserted into the hole from below (thanks in part to the large round washers I was using on the underside of the car for additional rigidity). I found a different bolt which was slightly shorter--just enough to fit in the hole--but now it was too short for me to get a nut onto it by myself. I went next door and got a neighbor kid to sit inside the car and help me get this one together. For the last hole, even my slightly shorter bolt was too long to be inserted into its hole... so for now I had the kid help me tighten down the three bolts which were in place and I called it good enough. On my next run to Ace, I'll see if I can find an even shorter bolt for that last hole.

But, hey--I've got a (mostly) period-correct Pontiac floor shifter in my car!

The cable that came with it (from an early '90s W-body Grand Prix sedan) was plenty long, so much so that I didn't even need to drill another hole in the tunnel. Instead, the cable goes under the dash, through the firewall, around the master cylinder, then back down under the car. I have it attached to the trans, but I need to 'customize' the bracket so the cable is rigidly held in the right spot... and I decided to do that another day.

Finally, I opened my fancy TCI EZ-TCU controller. The harness on this thing is much larger than I expected, though I guess that is due to all the capabilities it offers. I read through the instructions to see which features I don't need (or at least don't need to install right now), then I carefully bound up and zip tied the unneeded wires to minimize the bulk and excess wiring. I started to install the harness as they recommend, meaning I fished the transmission wires down from the engine bay and routed them to the trans. This let me see how much excess wire length there was, which in turn lets me decide where to mount the TCU. The driver's inner fenderwell is the spot I chose. However, this isn't a flat piece of steel... so I'll need some standoff feet to properly bolt the thing in place. Gee--looks like I'll be making that next Ace run soon enough.

At this point it was getting dark and starting to rain, so that's where I stopped for the night.