what type of cutter do you use? I don't want to hack anything up if i can avoid it.I just cut the nuts/bolts off the Olds mounts and spent my time bolting in the SBC frame mounts.

Olds 350 to Chevy 350 Swap

- Thread starter zipties

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Angle air grinder with a cut off wheelwhat type of cutter do you use? I don't want to hack anything up if i can avoid it.

feeling good even though technically behind schedule. gretched a cutter from a buddy and made some sparks in the engine bay.

very easy work although i did score the olds mounts a bit due to the little flares/bulges hugging the bolt head.

smoothed them a bit, then cleaned them up and hit them with some hammertone. someone wanted these so i wasn't going to just decimate them with a saw.

this is the last thing that needed to come 'out' of the car - now im gonna do some cleaning in the engine bay and make the final preparations for install.

very easy work although i did score the olds mounts a bit due to the little flares/bulges hugging the bolt head.

smoothed them a bit, then cleaned them up and hit them with some hammertone. someone wanted these so i wasn't going to just decimate them with a saw.

this is the last thing that needed to come 'out' of the car - now im gonna do some cleaning in the engine bay and make the final preparations for install.

Look for anything A or B body up to 89 for AC, Alt, PS and etc. Pull everything up front. That will be your multi belt system, & AC on Drivers Side, use the AC lines from A Body Caprice or similar, PS will work better.

You can use front setup from 89 or after should be serpentine belt setup, but pulley from PS will hit or be too close to steering box. AC will be on Passenger side. You will have to keep air pump or serpentine setup won't work. There is no bypass pulley for air pump.

You can use front setup from 89 or after should be serpentine belt setup, but pulley from PS will hit or be too close to steering box. AC will be on Passenger side. You will have to keep air pump or serpentine setup won't work. There is no bypass pulley for air pump.

i have a belt setup from a circa 84ish block that i was planning on using. no A/C so no worries, I am going to keep the heat for now though.Look for anything A or B body up to 89 for AC, Alt, PS and etc. Pull everything up front. That will be your multi belt system, & AC on Drivers Side, use the AC lines from A Body Caprice or similar, PS will work better.

You can use front setup from 89 or after should be serpentine belt setup, but pulley from PS will hit or be too close to steering box. AC will be on Passenger side. You will have to keep air pump or serpentine setup won't work. There is no bypass pulley for air pump.

got everything knolled out in the workshop. flexplate is one i grabbed from a early 90s OBS 350. Found the 84 vbelt setup which is in good shape, looks like i lost the little shim/washer for the PS pump so I'll have to do some measuring when it's alltogether.

Tomorrow I hope to at least have the brick in the car. trying to make the most of the long weekend..

Tomorrow I hope to at least have the brick in the car. trying to make the most of the long weekend..

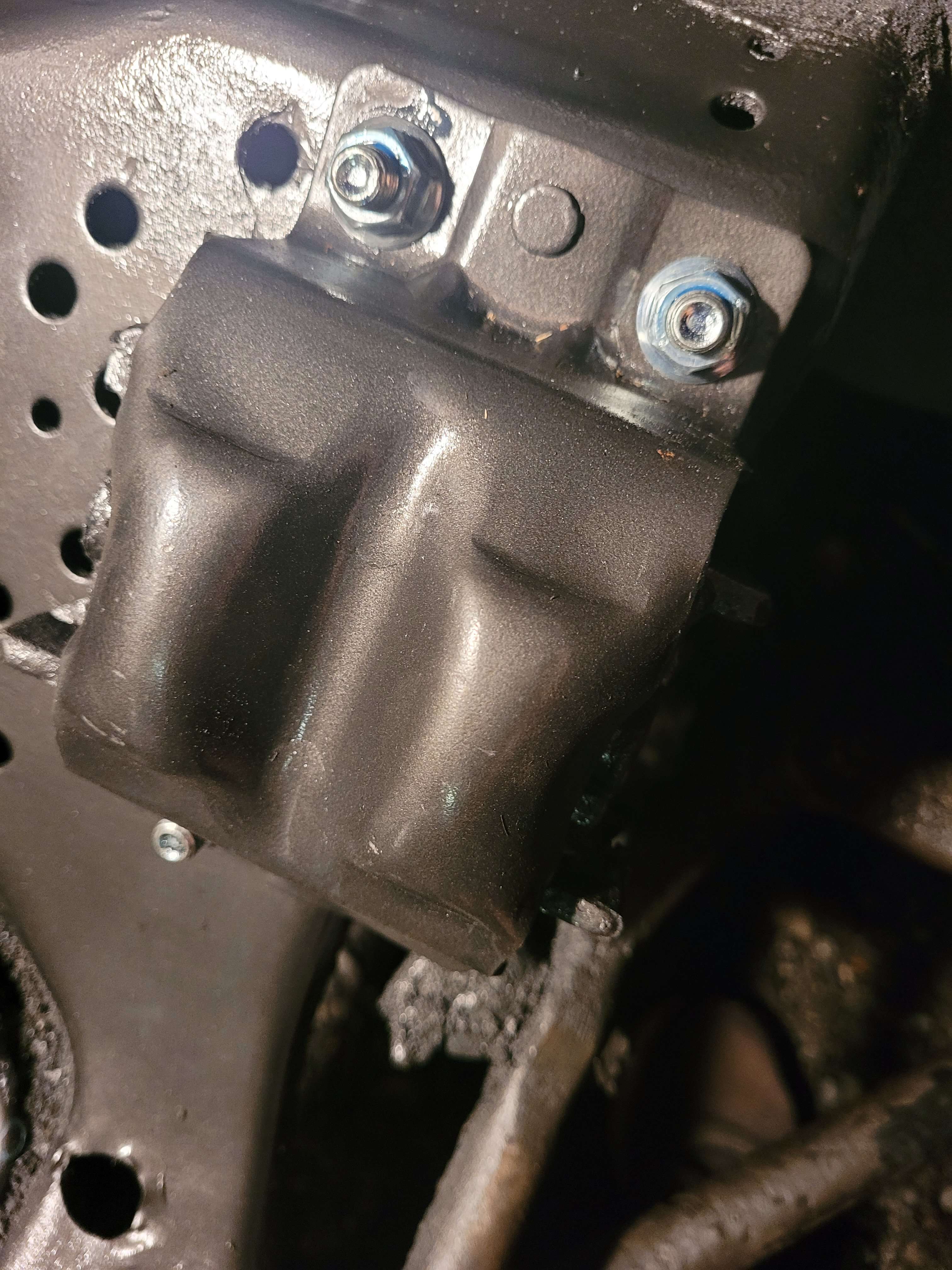

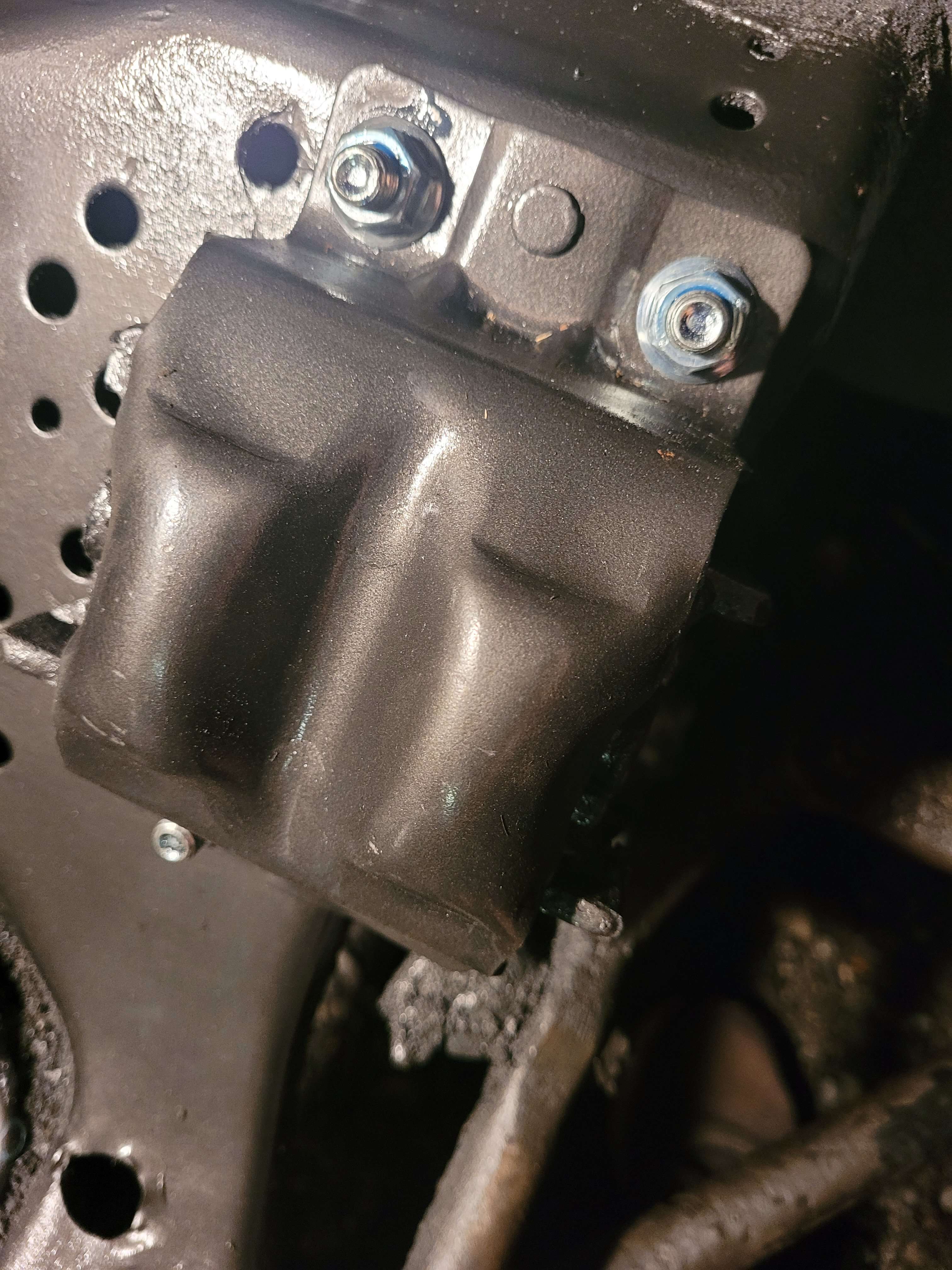

just some pics from the clamshell install that may help someone out. nothing fancy.

this was done with the motor out (obviously) but nothing else removed from the front end. Not in the mood to wrangle the suspension yet. I cleaned the mounting holes and grabbed the bolts - I used M10 flange bolts. Top two bolts were like 1 1/4, bottom was 1 3/4 - only reason being they didnt't have enough of the smaller bolts lol.

Just used a length of twine and twisted it around the thread of the bolt, tight. snake it through the oblong hole on the front of the crossmember and pull the bolt through. i used a little pick to help guide the bolt in. once its through, get the nut on it and take the twine off, rinse and repeat.

once the bolts are in place, i put the clamshells on by just holding the bolt and sliding the mount on, then putting the nut back on. Flange nuts make it turbo easy because they keep from spinning around due to friction. Getting them tight enough can still be tricky, i used used a long wrench to hold the top bolts, and a basic socked with an extension through the lower A arm window for the bottom.

here they are, i don't exactly like having bolts in 'upside down' so i put some loctite on prior to cinching them down. don't think they're moving though. really easy stuff but it can be hard finding thorough info on custom jobs sometimes, so i try to make sure i document stuff both for my future reference and incase someone comes along looking for answers.

nevermind the grime around the rest of the bay, I only cleaned and painted the base of the cradle so it didn't rust out. Gonna clean and paint the rest of the bay soon.

looking around for a non-AC heater box to swap in. IDK if they make replacement units buy they're probably big money. would be ideal to trade the box in this with someone looking for A/C

this was done with the motor out (obviously) but nothing else removed from the front end. Not in the mood to wrangle the suspension yet. I cleaned the mounting holes and grabbed the bolts - I used M10 flange bolts. Top two bolts were like 1 1/4, bottom was 1 3/4 - only reason being they didnt't have enough of the smaller bolts lol.

Just used a length of twine and twisted it around the thread of the bolt, tight. snake it through the oblong hole on the front of the crossmember and pull the bolt through. i used a little pick to help guide the bolt in. once its through, get the nut on it and take the twine off, rinse and repeat.

once the bolts are in place, i put the clamshells on by just holding the bolt and sliding the mount on, then putting the nut back on. Flange nuts make it turbo easy because they keep from spinning around due to friction. Getting them tight enough can still be tricky, i used used a long wrench to hold the top bolts, and a basic socked with an extension through the lower A arm window for the bottom.

here they are, i don't exactly like having bolts in 'upside down' so i put some loctite on prior to cinching them down. don't think they're moving though. really easy stuff but it can be hard finding thorough info on custom jobs sometimes, so i try to make sure i document stuff both for my future reference and incase someone comes along looking for answers.

nevermind the grime around the rest of the bay, I only cleaned and painted the base of the cradle so it didn't rust out. Gonna clean and paint the rest of the bay soon.

looking around for a non-AC heater box to swap in. IDK if they make replacement units buy they're probably big money. would be ideal to trade the box in this with someone looking for A/C

Looks fine. If you have any concerns, once nuts are torqued, you can just tack with mig.

I never did understand why GM did their motor mounts the way they did. It would have been so easy to spin weld in the nuts or just thread the holes, and doing so would have been faster in production as well.

You might find AC delete box in the 70's vintage, after 81/82 era it's going to be difficult. Once GM went with C3 (CCC/EST), AC came standard most cases. The ECM needed the AC clutch to engage to help shut down engine and prevent run-on.

I never did understand why GM did their motor mounts the way they did. It would have been so easy to spin weld in the nuts or just thread the holes, and doing so would have been faster in production as well.

You might find AC delete box in the 70's vintage, after 81/82 era it's going to be difficult. Once GM went with C3 (CCC/EST), AC came standard most cases. The ECM needed the AC clutch to engage to help shut down engine and prevent run-on.

rainy day, cant get much done outside so looking inward. shuffling stuff around when I decided to do a quick mockup:

these are gonna be more at home on a 383 but still looks fun. Pretty sure i have a cheesy set of BOWTIE center bolt valve covers that will match too.

thinking about setting up for paint but i can't justify wasting it on this block rn.

i did slap a basically new set of UMI mounts on it though.

getting kinda anxious about using the BOP plate. i know i just have to shim the bolts between the plate and converter, it just seems like a bit of an asspain. considering pulling the thing into this bay for the actual install.

also, check this dude out pretending to be my hood ornament:

these are gonna be more at home on a 383 but still looks fun. Pretty sure i have a cheesy set of BOWTIE center bolt valve covers that will match too.

thinking about setting up for paint but i can't justify wasting it on this block rn.

i did slap a basically new set of UMI mounts on it though.

getting kinda anxious about using the BOP plate. i know i just have to shim the bolts between the plate and converter, it just seems like a bit of an asspain. considering pulling the thing into this bay for the actual install.

also, check this dude out pretending to be my hood ornament:

- Status

- Not open for further replies.

Similar threads

- Replies

- 12

- Views

- 508

BUILD THREAD

350 Olds engine

- Replies

- 4

- Views

- 359

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.